* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Development of Multi-Component Reactions using Catalytically Generated Allyl Metal Reagents

Cracking (chemistry) wikipedia , lookup

Woodward–Hoffmann rules wikipedia , lookup

Marcus theory wikipedia , lookup

Physical organic chemistry wikipedia , lookup

Fischer–Tropsch process wikipedia , lookup

George S. Hammond wikipedia , lookup

Kinetic resolution wikipedia , lookup

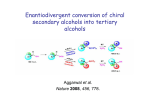

Enantioselective synthesis wikipedia , lookup

Elias James Corey wikipedia , lookup

Vinylcyclopropane rearrangement wikipedia , lookup

Aldol reaction wikipedia , lookup

Asymmetric induction wikipedia , lookup

Diels–Alder reaction wikipedia , lookup

Hofmann–Löffler reaction wikipedia , lookup

Discodermolide wikipedia , lookup

Ring-closing metathesis wikipedia , lookup

Wolff–Kishner reduction wikipedia , lookup

Baylis–Hillman reaction wikipedia , lookup

Ene reaction wikipedia , lookup

Hydroformylation wikipedia , lookup

Petasis reaction wikipedia , lookup