* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Three-dimensional microfabricated bioreactor and

Cell membrane wikipedia , lookup

Biochemical switches in the cell cycle wikipedia , lookup

Endomembrane system wikipedia , lookup

Cell encapsulation wikipedia , lookup

Extracellular matrix wikipedia , lookup

Tissue engineering wikipedia , lookup

Cellular differentiation wikipedia , lookup

Cell growth wikipedia , lookup

Cell culture wikipedia , lookup

Cytokinesis wikipedia , lookup

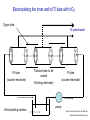

Three-dimensional microfabricated bioreactor and closed-loop control system Alex Makowski Michael Hwang Jenny Lu Dr. John Wikswo Ultimate Project Goals Computer modulated growth of tissue structures within microfluidic devices. Possible uses include drug testing and dose determination, bypassing several stages of FDA trials. Problem Statement- Design progress is blocked on three distinct fronts: Sensors are required to provide computer with necessary information. Bioreactor design limits the quantity and quality of cell morphology within the device. Previously used cells (primary human fibroblasts) do not easily form tissue-like structures. Subsequent Requirements: Choose or design an appropriate sensor for pH measurements (most needed to determine cell metabolism and health). Choose a cell line that will exhibit some kind of morphological change under successful conditions. Redesign the bioreactor to incorporate new cell line and maximize efficiency of pH sensors. Previous cell lines used… Primary human fibroblast and endothelial cells High cost Lower passages Difficult to exhibit 3D morphology Need morphology as control Why use MCF10A cell line? Human breast epithelial cell line (MCF10A) Have in stock Less expensive Forms acinar morphology Illustration courtesy of Weaver Lab Cell Culture Model of Epithelial Acini Confocal Imaging of Acini from 3-D matrigel cultures Illustration courtesy of Cassio Lynm, JAMA Simplified Experimental Setup Electrical connection for tubular Ti electrode Copper plate Copper wire Titanium tube Slide Courtesy of Sayed A. M. Marzouk United Arab Emirates University Electroplating the inner wall of Ti tube with IrO2 Tygon tube To potentiostat Pt tube (counter electrode) Electroplating solution Titanium tube to be coated Pt tube (counter electrode) (Working electrode) pump Slide Courtesy of Sayed A. M. Marzouk United Arab Emirates University Improvements over pH Optical fiber-type sensor • Improved response time (6 s vs. 2-3 min.) – Important for frequent measurements – Allows faster recalibration • No stagnant volume – T-junction for fiber creates a volume around sensor with little or no convective flow – Lack of convection diffusionlimited analyte transport even longer response time