* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Zinc Alkyls in Organic Synthesis

Woodward–Hoffmann rules wikipedia , lookup

Marcus theory wikipedia , lookup

George S. Hammond wikipedia , lookup

Asymmetric hydrogenation wikipedia , lookup

Kinetic resolution wikipedia , lookup

Hofmann–Löffler reaction wikipedia , lookup

Diels–Alder reaction wikipedia , lookup

Elias James Corey wikipedia , lookup

Ene reaction wikipedia , lookup

Physical organic chemistry wikipedia , lookup

Wolff–Kishner reduction wikipedia , lookup

Ring-closing metathesis wikipedia , lookup

Baylis–Hillman reaction wikipedia , lookup

Hydroformylation wikipedia , lookup

Petasis reaction wikipedia , lookup

Stille reaction wikipedia , lookup

Enantioselective synthesis wikipedia , lookup

Asymmetric induction wikipedia , lookup

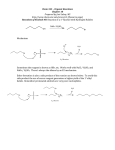

Zinc Alkyls in Organic Synthesis Zinc alkyls, including diethylzinc (DEZ), were first synthesized by Frankland in the 1800’s.[1] It was not until the 1970’s that chemists found a series of their special utility. Work to that period was reviewed by Furukawa and Kawabata.[2] In recent years, interest in zinc alkyls increased significantly as synthetic organic chemists found the exceptional efficiency with which these reagents perform certain asymmetric organic transformations. That zinc alkyls, especially DEZ, have made a substantial inroad into synthetic chemistry is evidence by their use in commercial manufacture of leading active pharmaceutical ingredients (API). Akzo Nobel Functional Chemicals B.V. has pioneered the large-scale manufacturing process for zinc alkyls and has been producing commercially in our Deer Park, Texas plant since the 1960’s. We are now the world’s largest manufacturer of zinc alkyls. Table 1 lists major commercial and developmental dialkylzinc compounds from AkzoNobel. In this technical bulletin, we describe the applications of diethylzinc (DEZ) and other dialkylzinc compounds in organic synthesis. A separate technical bulletin details the properties of zinc alkyls.[3] Table 1. Properties of AkzoNobel Zinc Alkyls Zinc Alkyl NPL*), % (solvent) Acronym CAS no. Molecular formula Formula weight Boiling point, °C at mm Hg Dimethylzinc DMZ 544-97-8 (CH3)2Zn 95.45 44 at 760 13 (toluene), Developmental 21 (THF) Diethylzinc DEZ 557-20-0 (C2H5)2Zn 123.50 118 at 760 23(hexane), 22 (toluene) Commercial DNPZ 628-91-1 (n-C3H7)2Zn 151.55 48 at 10 31 (heptane) Research Di-n-propylzinc Diisopropylzinc DIPZ 625-81-0 (i-C3H7)2Zn 151.55 96 at 40 Di-n-butylzinc DNBZ 1119-90-0 (n-C4H9)2Zn 179.60 45 at 2 Availability Research 29 (heptane) Research Diisobutylzinc DIBZ 1854-19-9 (i-C4H9)2Zn 179.60 34 at 3 Research Di-sec-butylzinc DSBZ 7446-94-8 (sec-C4H9)2Zn 179.60 56 at 4 Research Di-t-butylzinc DTBZ 16636-96-7 (t-C4H9)2Zn 179.60 34 at 12 Research Diphenylzinc DPHZ 1078-58-6 (C6H5)2Zn 219.6 280 at 760 Research Dicyclohexylzinc DCHZ 15658-08-9 (C6H11)2Zn 231.69 64 at 0.0001 Research ) * NPL (Non-Pyrophoric Limit) determined by paper-char test.[3] OMS 06.389.02/August 2008 Page 1 of 10 With more than 60 commercial and developmental alkyls of aluminum, magnesium, boron and zinc, Akzo Nobel Functional Chemicals B.V. is a world leader in manufacturing and distributing metal alkyls. Our infrastructure includes manufacturing plants in Deer Park, Texas and Rotterdam, the Netherlands and blending/transfilling facilities in Tianjin (China), Mahad (India), and Paulinia (Brazil). While majority of our products go to the polyolefin industry, many of them have found increasing applications in the pharmaceutical industry, owing to their unique properties and versatile functions in organic synthesis. In addition, the improved know-how in safe handling of these previously perceived ‘dangerous’ materials has ensured pure and consistent metal alkyls to be readily available in commercial quantities. Today, several metal alkyls of Akzo Nobel Functional Chemicals B.V. are used by world’s leading pharmaceutical companies to make active pharmaceutical ingredients (APIs). We invite you to visit www.akzonobel.com/polymer to learn more. Diethylzinc (DEZ) in Organic Synthesis Of the many zinc alkyls that have been synthesized, diethylzinc (DEZ), is the most commonly used. It has found applications in a variety of organic transformations, including those of asymmetric nature. Like most zinc alkyls, DEZ is an easily handled low viscosity liquid that is conveniently miscible in most hydrocarbon solvents. This section is devoted to applications of DEZ, organized by classes of transformations. It is believed that some of the examples below are the actual chemistry used in the synthesis of major API’s. Cyclopropanation The most well-known application of DEZ in organic synthesis is arguably the Simmons-Smith cyclopropanation. The pioneering work of Simmons and Smith used zinc dust in combination with diiodomethane (CH2I2) to convert alkenes to cyclopropanes.[4] In that methodology, CH2I2 is first reacted with Zn to form the active reagent ICH2ZnI, which coordinates with the olefin to form a cyclic bond. Later, Furukawa and Kawabata found that replacing the zinc dust with a more convenient DEZ renders the reaction much more rapid.[2] They suggested that the reaction of DEZ and CH2I2 forms the active reagent ICH2ZnCH2CH3 and byproduct CH3CH2I. Their work also provided evidence that cyclopropanation in the presence of DEZ and CH2I2 proceeds stereo specifically, i.e. cis-alkenes give rise to syn-cyclopropanes and trans-alkenes yield anti-cyclopropanes. R1 R2 R1 R2 H H DEZ, CH2I2 H H OMS 06.389.02/August 2008 Page 2 of 10 Those workers further demonstrated a potentially useful variation using substituted diiodomethane in place of diiodomethane. With DEZ, the technique provided cyclopropanation with concomitant addition of a third substituent.[5] Tri-substituted cyclopropanes were therefore synthesized. The authors suggested that the nature of substituents on the starting alkene determines the relative position of the third substituent. The workers also noted that the reaction proceeds by electrophilic addition, preferentially giving the thermodynamically less stable yet synthetically more interesting syn-isomer. Alkenes containing hydroxyl groups, however, yielded primarily the anti-isomer. In addition to linear alkenes, these workers successfully cyclopropanated a wide range of substrates, including cycloalkene, norbornene, cycloalkenyl ether and furan. R1 DEZ, R3CHI2 H R2 R1 R2 H H H R3 H R3 = CH3, Ar, CH2X In the study of epothilone synthesis, Danishefsky found DEZ to be effective in cyclopropanation within a complex chemical environment.[6] In this case, the alkene substrate was part of a cyclic vinyl ether. The conversion was performed in diethylether solvent at 25°C and gave a yield of 93%. H CH3 CH3 O O DEZ, CH2I 2 ether, 25 C PhH2CO PhH2CO OH CH3 OH CH3 CH3 CH3 Similarly, Bristol-Myers Squibb scientists demonstrated that cyclopropanation could be accomplished on a substituted pyrroline.[7] The methodology involved forming the DEZ/CH2I2 reagent in methylene chloride/dimethylether solvent and was applied in the synthesis of cyclopropyl-fused pyrrolidine derivatives. O 1. DEZ/toluene 2. CH2I2 N O N CH2Cl2, DME -30 C O O CONH2 CONH2 Merck chemists showed that CH2I2 may be replaced by similar analogues. They accomplished cyclopropanation of a terminal olefin using DEZ in toluene, but with 1,2-dichloroethane and chloroiodomethane.[8] Advantages of these reagents with the more conventional reagent, DEZ and CH2I2, were not discussed. OH 1. DEZ/toluene 2. 1,2-dichloroethane 3. CH2ClI 0 C, 3 hrs OH OMS 06.389.02/August 2008 Page 3 of 10 Asymmetric Additions to Aldehydes and Ketones DEZ is also useful in catalytic asymmetric addition to aldehydes or ketones forming chiral secondary or tertiary alcohols. These reactions typically involve an amine or a sulfonamide ligand in combination with tetraisopropyl titanate (TIPT). The added substituent comes from zinc alkyls such as DEZ or dimethylzinc (DMZ). For conversion of ketones to optically active tertiary alcohols, Walsh discovered a bis-sulfonamide diol ligand and its use along with TIPT and DEZ. The combination was shown to yield tertiary alcohols with a remarkable enantioselectivity, up to 99% enantiomeric excess (ee).[9] Diphenylzinc (DPHZ) was also shown to be effective in this type of reaction. The authors suggested that these results are superior to that from other DEZ additions which use dimethylamino isoborneol (DAIB) or a camphor-based hydroxysulfonamide ligand. Walsh demonstrated the effectiveness of his technique with a wide array of substituent groups on the ketone, e.g. alkyl, halogenated alkyl, phenyl, and alkoxy phenyl. Other interesting zinc alkyls, e.g. di-n-butylzinc, dicyclohexylzinc, were not evaluated. R32Zn (1.6 eq.) Ti(O-iPr)4 (1.2 eq.) bis-sulfoneamide diol ligand O R1 R2 HO R3 hexane/toluene, RT, 16-48 hrs. R1 R2 up to 99% ee Walsh’s catalytic enantioselective method was also applied to asymmetric addition to cyclic -unsaturated ketones.[10] Various substituted cyclic enones were examined with both DEZ and DMZ. Yield of the tertiary alcohol were reported to be in the 20-84% range with enantioselectivity in the 95-99% range for most substrates. O R1 OH Ti(OiPr)4 ZnR2 Ligand R R1 hexane/toluene RT n n In that work, introducing oxygen during the reaction led to tandem addition and epoxidation of the olefin to form epoxy alcohols. This addition procedure also yielded high enantioselectivity (97-99%), with epoxy alcohols being formed as single diastereomers. O R1 n Ti(OiPr)4 ZnR2 Ligand hexane/toluene RT OH R R1 O2 0 C to RT O n OMS 06.389.02/August 2008 Page 4 of 10 For asymmetric addition to aldehydes, Noyori discovered that DEZ in combination with DAIB is effective. The transformation to secondary alcohols was performed with excellent enantioselectivity.[11] In that work, DEZ was used to alkylate substituted benzaldehydes, forming chiral secondary alcohols. Liu et al. later used a aminonaphthol chiral ligand to achieve extraordinarily high yield and selectivity.[12] There, the reaction using DEZ in hexane and 15 mol% of the chiral ligand gave 97% yield with 99.8% ee. OH CHO DEZ/hexane 10 mol% ligand RT, 24 hrs R R up to 97% yield and 99.8% ee Other Addition Reactions Zinc alkyls have also found utility in synthesis of allylic amines and alcohols. These allylic species are useful intermediates in API manufacturing. A review of the literature indicates that such compounds are readily synthesized using alkenyl organozinc reagents. Those reagents are typically formed by the reaction of a suitable alkyne with Cp2ZrHCl, followed by a reaction with DMZ. The resulting compound is a methyl vinylzinc reagent. In that methodology, DMZ and DEZ are often equally effective. Wipf and co-workers showed that such a vinylzinc intermediate may be reacted with imines to obtain allylic amines.[13] When CH2I2 is used as the solvent, C-cyclopropylamines or homoallylic amines resulted depending on the order of addition. 1. Cp2ZrHCl R1 MeZn R1 2. DMZ R2 NR3 R2 CH2I2 NR3 + + CH2I2 R2 NR3 NHR3 NHR3 NHR3 R1 R2 R2 R1 R2 R1 anti(major) syn(minor) anti(major) syn(minor) Li and Walsh employed a similar reagent along with the above mentioned bis-sulfonamide diol ligand to accomplish asymmetric vinylation of ketones.[14] Here, the ligand and TIPT were first added to the organozinc reagent, followed by addition of the prochiral ketone. The reaction proceeded at room temperature, giving yield and enantioselectivity of allylic alcohols of greater than 90% for most substrates tested. OMS 06.389.02/August 2008 Page 5 of 10 Cp2ZrHCl + R3 R3 Cp2ClZr DMZ R3 R1R2CO Ti(O-iPr)4 (1.2 eq.) bis-sulfoneamide diol ligand R1 R3 MeZn HO R2 Walsh and co-workers also demonstrated an interesting variation to this technique. Here, (Z)-trisubstituted allylic alcohols were synthesized in a one-pot coupling reaction.[15] The synthesis involved first reacting a bromoalkyne with dialkylborane generated in situ, e.g. from triethylborane (Et3B) and borane dimethylsulfide (BH3 SMe2), followed by reactions with DEZ and aldehyde. The (Z)-tri-substituted allylic alcohol product was isolated in 73% yield. 1 Br R 1. R22BH, 0 C 2. DEZ, -78 C 3. R3CHO OH 3 R1 R R2 A slight modification of this methodology led to the formation of an epoxy alcohol.[16] Whereas the classic Sharpless asymmetric epoxidation employs TIPT, t-butylhydroperoxide (TBHP) and diethyl tartrate (DET) or isopropyl tartrate (DIPT),.[17] Walsh and co-workers used a zinc alkoxide intermediate from an alkyne, morpholino isoborneol (MIB) ligand, DEZ and aldehyde. Upon introducing oxygen in the presence of TIPT and DIPT, they obtained epoxy alcohols with high enantiomeric purity and good yield. R1 1. Cy2BH 2. (-)-MIB, 4 mol% 3. DEZ, -10 C 4. R'CHO R' OZnEt OH 5. O2 R 6. TIPT, (+)-DIPT R' 68-92% yield 77-98% ee up to 4.5:1 d.r. R O In a remarkably creative technique, DEZ formed the basis for an organozinc reagent used in a ketone alkynylation reaction. The reagent facilitated an asymmetric addition with exceptional yield and selectivity.[18] DEZ, or equally effectively DMZ, was reacted with a chiral auxiliary (1R,2S)-N-pyrrolodinylnorephedrine, giving a chiral zinc alkoxide. Transmetallation of this zinc alkoxide with a suitable Grignard, in this case a cyclopropyl alkynyl-MgCl, provided the desired organozinc reagent. The reagent was reacted with the ketoaniline substrate to prompt the desired alkynylation. OMS 06.389.02/August 2008 Page 6 of 10 OH Ph 1. CF3 CHOH Zn Ph OEt Zn MgCl 2. DEZ N N N H3C OEt O O Ph [1] H3C H3C Cl Cl CF3 O 1 M Citric Acid [1] + 15 hrs OH CF3 95.3% yield 99.2% ee NH2 NH2 Using the same reagent as in Simmons-Smith cyclopropanation, DEZ/CH2I2, Macdonald accomplished C-alkylation of phenol. Whereas typical reagents would alkylate at the oxygen site, this reaction yielded ortho-methylation.[19] This synthetic method, relevant to accessing phenolic natural products, was successfully applied to a series of phenol compounds. OH OH CH3 DEZ, CH2I2 Toluene Reflux The combination of DEZ and CH2I2 was shown by Zercher and co-workers to be useful in another noteworthy application. In this procedure, the reagent was used to extend the chain length of -keto esters by one carbon atom, forming -keto esters.[20] The authors proposed that a cyclopropyl intermediate may be involved. Depending on the subsequent reactant used, a variety of -keto esters could be obtained. Immediate quenching yielded simple chain extension, whereas further reaction with I 2 and 1,8-diazobicyclo[5.4.0].undec-7-ene (DBU) inserted an olefin function. Alternatively, reaction with an aldehyde inserted an alcohol side chain. O OR 1. I2 2. DBU Et R' O Zn O R' O OR O C O O O DEZ CH2I2 NH4 Cl OR R' R' OR O H R"CHO R" OH O OR R' O OMS 06.389.02/August 2008 Page 7 of 10 Work-Up The work-up procedure of reactions involving DEZ is similar to those of other reactions employing organometallic reagents. It includes quenching with aqueous salt solution, extraction with an organic solvent, drying of the organic fraction, concentration in vacuo, and purification. Other variations may be similarly effective depending on the chemistry under consideration. See the work of Walsh, Tan, Macdonald, Danishefsky, and Zercher for details. In general, the reaction mixtures can be quenched with an aqueous solution of NH4Cl (either dilute or saturated), NaHCO3, or water. In most cases, it is advisable to cool the mixture to 0°C prior to quenching. The cooling allows a better control of the highly exothermic reaction between water and DEZ. Extraction can be performed with ethers or aliphatic solvents. The organic layer is usually dried with Na2SO4 or MgSO4. After separating the dried organic layer, the solvent is removed by vacuum. At this point, the product is typically in an oil form. The concentrated product is then purified by column chromatography or HPLC. Reactions of Other Zinc Alkyls Dimethylzinc (DMZ) has been used in similar ways as DEZ in organic reactions. Because DMZ is highly volatile (bp 44°C), accurate addition of the reagent into the reaction mixture can be difficult. When the reaction mixture is not cooled to a low temperature, a portion of the DMZ added will vaporize into the headspace, rendering it unavailable for reaction. This vaporization makes stoichiometric additions tricky. When DMZ or DEZ give identical results, the less volatile DEZ may be preferred. As with DEZ, DMZ is most commonly used in alkylation-addition reactions. Reetz and Westermann showed that direct geminal alkylation of ketones may be performed using DMZ with alkyl lithium and TiCl4.[21] In that work, the side chain n-alkyl group of tetrahydrocannabinoid was replaced with a tertiaryalkyl group. The product was noted to be pharmacologically interesting. In this procedure, the alkyl lithium was first mixed with the substrate ketone. The resulting lithium alcoholate was further reacted with DMZ and TiCl4 to effect the desired alkylation. The product therefore received one alkyl group from the alkyl lithium and the other from DMZ. H3CO OCH3 H3 CO OCH3 OCH3 1. DMZ 2. TiCl4 R2Li CH2 Cl2 , - 40 C hexane, - 40 C R1 R1 H3 CO OLi R1 CH3 O R2 R2 Further to DMZ and DEZ, other dialkylzinc compounds worth noting are diphenylzinc (DPHZ) and di-tbutylzinc (DTBZ). These zinc alkyls were used in Cu-catalyzed reactions reported by Johnson.[22] OMS 06.389.02/August 2008 Page 8 of 10 In that work, DPHZ and DTBZ were used in eletrophilic amination reactions. These zinc alkyls were particularly effective in replacing the alkoxy group, resulting in tertiary amines. O N + (Ph)2Zn 91% CuCl2 (2.5 mol%) O N OBz Ph THF, 15 min + (t-Bu)2Zn O N t-Bu 99% As noted above, specially synthesized organozinc reagents are highly effective in certain transformations. Typically, organo-magnesium or -lithium reagents are transmetallated with dialkylzinc to form the desired reagent. Noyori and co-workers assembled a prostaglandin analogue by sequentially linking side chains to 2-cyclopentenone.[23] In that synthesis, equimolar amounts of cyclopentenone, vinylic lithium and DMZ were mixed, followed by addition of methyl 6-formylhexanoate. The result was a three-component coupling with 82-92% yield and 10:1 selectivity of 7S/7R. DMZ was suggested to be critical in effecting the consecutive linking with the initial step being the reaction of DMZ with vinylic lithium to form a lithium methyl/vinyl mixed zincate. HO O O O COOCH3 H + OTBMDS COOCH3 DMZ Li OTBMDS OTBMDS OTBMDS 82-92% yield, 7S/7R=10:1 Properties, Safety and Handling of Zinc Alkyls For properties, safety and handling of zinc alkyls, readers are recommended to review our separate technical bulletin that addresses the subject in detail.[3] Briefly, zinc alkyls are typically clear, colorless liquids and are miscible in all proportions with saturated aliphatic hydrocarbons. Many of the lower zinc alkyls, such as DMZ and DEZ are highly pyrophoric. Nonpyrophoric limits for selected solutions of zinc alkyls are provided in Table 1. Both neat and solutions of zinc alkyls react violently with water. Zinc alkyls should be handled under an inert atmosphere. Nitrogen (oxygen and water content typically < 5 ppm) is used at AkzoNobel. Zinc alkyls are generally light-sensitive. Samples stored in clear glass bottles often become turbid within a few days at ambient temperature. Analysis of wt% Zn is performed by standard analytical methods using the hydrolyzate of the zinc alkyl. Gas chromatography (GC) may also be used to assess the purity of zinc alkyls, by analyzing hydrocarbons produced upon hydrolysis. OMS 06.389.02/August 2008 Page 9 of 10 References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. a) E. Frankland, Liebigs Ann. Chem., 71, 171 (1848), b) E. Frankland, J. Chem. Soc., A, 2, 263 (1849) and c) E. Frankland, J. Chem. Soc., A, 3, 44 (1850). J. Furukawa and N. Kawabata, Adv. Organomet. Chem., 12, 83 (1974). Properties of Zinc Alkyls from AkzoNobel, Technical Bulletin from Akzo Nobel Functional Chemicals B.V., (2003). M. B. Smith and J. March, March’s Advanced Organic Chemistry, 5th Ed., Wiley, New York (2001), Ch.15 and references therein. J. Nishimura, N. Kawabata, and J. Furukawa, Tetrahedron, 25, 2647 (1969). P. Bertinato, E. J. Sorensen, D. Meng, and S. J. Danishefsky. J. Org. Chem., 61, 8000 (1996). W.O. Patent Application 2004/052850 A2 (Bristol-Myers Squibb, 2004). U.S. Patent 6,610,692 B1 (Merck, 2003). a) U.S. Patent 6,660,884 B2 (U. of Pennsylvania, 2003), b) S.-J. Jeon, H. Li, C. Garcia, L. K. LaRochelle and P. J. Walsh, J. Am. Chem. Soc., 70, 448 (2005), c) C. Garcia, L. K. LaRochelle and P. J. Walsh, J. Am. Chem. Soc., 124, 10970 (2002), and d) C. Garcia and P. J. Walsh, Org. Lett., 5, 3641 (2003). S. J. Jeon and P. J. Walsh, J. Am. Chem. Soc., 125, 9544 (2003). M. Kitamura, S. Suga, K. Kawai and R. Noyori, J. Am. Chem. Soc., 108, 6071 (1986). D.-X. Liu, L. C. Zhang, Q. Wang, C.-S. Da, Z.-Q. Xin, R. Wang, M. C. K. Choi and A. S. C. Chan, Org. Lett., 3, 2733 (2001). P. Wipf, C. Kendall and C. R. J. Stephenson, J. Am. Chem. Soc., 125, 761 (2003). H. Li and P. J. Walsh, J. Am. Chem. Soc., 126, 6538 (2004). Y. K. Chen, P. J. Walsh, J. Am. Chem. Soc., 126, 3702 (2004). A. E. Lurain, P. J. Carroll and P. J. Walsh, J. Org. Chem., 70, 1262 (2005). Y. Gao, R. M. Hanson, J. M. Klunder, S. Y. Ko, H. Masamune and K. B. Sharpless, J. Am. Chem. Soc., 109, 5765 (1987). L. Tan, C. Chen, R. D. Tillyer, E. J. J. Grabowski and P. J. Reider, Angew. Chem. Int. Ed., 38, 711 (1999). E. K. Lehnert, J. S. Sawyer and T. L. Macdonald, Tetrahedron Lett., 30, 5215 (1989). J. B. Brogan and C. K. Zercher, J. Org. Chem., 62, 6444 (1997). M. T. Reetz and J. Westermann, J. Org. Chem., 48, 254 (1983). A.M. Berman and J. S. Johnson, J. Am. Chem. Soc., 126, 5680 (2004). M. Suzuki, Y. Morita, H. Koyano, M. Koga and R. Noyori, Tetrahedron, 46, 4809 (1990). All information concerning this product and/or suggestions for handling and use contained herein are offered in good faith and are believed to be reliable. AkzoNobel Functional Chemicals, however, makes no warranty as to accuracy and/or sufficiency of such information and/or suggestions, as to the product's merchantability or fitness for any particular purpose, or that any suggested use will not infringe any patent. Nothing contained herein shall be construed as granting or extending any license under any patent. Buyer must determine for himself, by preliminary tests or otherwise, the suitability of this product for his purposes. The information contained herein supersedes all previously issued bulletins on the subject matter covered. The user may forward, distribute, and/or photocopy this document only if unaltered and complete, including all of its headers and footers, and should refrain from any unauthorized use. You may not copy this document to a website. AkzoNobel Functional Chemicals Amersfoort, The Netherlands T +31 33 467 6767 F +31 33 467 6151 E [email protected] AkzoNobel Functional Chemicals Chicago, U.S.A. T +1 312 544 7000 T +1 800 828 7929 (Toll free US only) F +1 312 544 7188 E [email protected] Akzo Nobel (Asia) Co., Ltd. Shanghai, PR China T +86 21 2220 5000 F +86 21 2220 5558 E [email protected] www.akzonobel.com/polymer 2006-2008 AkzoNobel Functional Chemicals OMS 06.389.02/August 2008 Page 10 of 10