* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Full-Text PDF

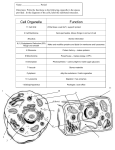

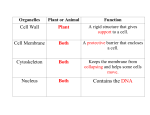

Cell nucleus wikipedia , lookup

Cytokinesis wikipedia , lookup

Protein (nutrient) wikipedia , lookup

Theories of general anaesthetic action wikipedia , lookup

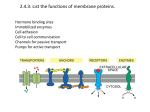

G protein–coupled receptor wikipedia , lookup

Magnesium transporter wikipedia , lookup

Protein phosphorylation wikipedia , lookup

SNARE (protein) wikipedia , lookup

Model lipid bilayer wikipedia , lookup

Signal transduction wikipedia , lookup

Cell membrane wikipedia , lookup

Protein moonlighting wikipedia , lookup

Organ-on-a-chip wikipedia , lookup

Protein–protein interaction wikipedia , lookup

Endomembrane system wikipedia , lookup

Proteolysis wikipedia , lookup