* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Oregonism

Biochemical switches in the cell cycle wikipedia , lookup

Cell encapsulation wikipedia , lookup

Cellular differentiation wikipedia , lookup

Extracellular matrix wikipedia , lookup

Tissue engineering wikipedia , lookup

Cytokinesis wikipedia , lookup

Programmed cell death wikipedia , lookup

Organ-on-a-chip wikipedia , lookup

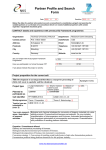

Cell culture wikipedia , lookup

Biomass Production of the Bacteria Oenococcus oeni Ashton, R., Juenke, C., Kennedy, B., and Leitschuh, J., School of CBEE Problem Statement Biomass Production Process Modeling Biomass Production Commercial biomass production of the bacteria Oenococcus Oeni (a bacteria that performs malolactic acid fermentation in wine) is currently inefficient and expensive. The growth, processing and packaging of O. oeni will be optimized in order to create a cost effective strategy for biomass production. O. oeni biomass is grown to its maximum cell density in a bioreactor. The cell broth is then concentrated by centrifugation. Prior to freeze-drying the concentrated cells are exposed to pre freeze-drying treatments such as cryoprotectants. The cells are then freeze-dried for packaging and storage. Cell density (X, g/L) changes over time at a rate proportional to the current cell density. Background X (t ) X e Adapted cell broth Cell broth Centrifuge Pre freeze-dry treatment The specific growth rate is effected by a number of factors including temperature, pH, dissolved oxygen and growth media composition. Optimization of μmax is integral to optimizing biomass production. Freeze-dryer Bioreactor Freeze-dried cells Process flow diagram for the biomass production of Oenococcus oeni. 1 μm Electron microscopy image of the bacteria Oenococcus oeni (~1 μm), which is used to reduce tartness in wine by converting malic acid from grapes to a softer tasting lactic acid [1]. Industry Production Scale-Up The Oregon market calls for 1000 lb of bacteria per year. Using growth parameters determined in a 3L bioreactor (left), nine 1000L bioreactors would be required to meet this demand. The scaled-up design (right, not to scale) takes into account freeboard space, a conical bottom of height, Hcone, and a height, Htotal, to diameter, D, ratio of 2 (a general heuristic for bacterial bioreactors). Motor Air sparger Agitator Baffle O. oeni Scale-up O. oeni performs ML fermentation in wine production, reducing tartness by converting malate (malic acid) in grapes to lactate (lactic acid) and giving the wine a “buttery” flavor and aroma [2], [3]. Htotal = 1.8 m Time, t A typical growth curve for a bacterial culture in a bioreactor. Fed batch started here. It did not significantly increase growth. Scale-up bioreactor design. Downstream Processing and Packaging The effect of lyophilization (freeze-drying) in varying sucrose solutions on cell viability is currently being investigated. Lyophilization is being considered for production scale storage and packaging. 1.5 Extended lag phase due to refrigeration of cells prior to inoculation. 1 0.5 Fed-Batch Operation (Run 4) Batch Operation (run 3) Vacuum chamber 0 References Freeze-drying cells [1] Yarris, L. (n.d.). Science Beat. Secrets of the wine cellar: the genome of a wine-making microbe . Retrieved March 2, 2010, from Berkely Lab: http://www.lbl.gov/Science-Articles/Archive/JGI-winemaking-genome.html [3] Feast NH. http://blogs.nashuatelegraph.com/livefreeordine/2009/04/ Lag phase 2 Vacuum chamber [2] African Trading Company. http://www.africantradingco.com/winebarrels.html Log (exponential) phase 2.5 Cell Density (g/L) Market and Strategy: Oregon’s Willamette Valley will be the target market. Our strategy will be to provide the following: • Superior quality and service • Culture variety including indigenous bacteria for the wine industry • Execute ML ferments with upwards of 95% confidence • Localized service • Reduced costs Lab scale bioreactor. Death phase Oenococcus oeni was grown in a 3L lab-scale bioreactor containing the rich medium Luria Broth at pH 4.0 and 25°C (optimum values determined from literature) under both batch and fed-batch conditions. Fed-batch operations did not appear to effect the maximum cell density. D = 0.9 m Mission statement: To cultivate microorganisms for the wine and beer industry in the Pacific Northwest and provide a superior product that will maximize fermentation efficiency by reducing energy and biomass costs. Stationary phase Biomass Production Results Hcone = 0.5 m Business Plan • Dr. Christine Kelly • Dr. Phil Harding • Coralie Backlund • Kelsey Yee • Andy Brickman Cell growth can be categorized into 4 stages: • Lag phase: the organism becomes used to the environment. • Exponential phase: cells grow exponentially. • Stationary phase: biomass production ceases • Death phase: cell death exceeds cell growth Goal: maximize the cell density at the stationary phase. ln(X) Concentrated cell broth Malate Lactate + CO2 Acknowledgements Mathematically this is represented as: where μ represents the specific growth rate. During exponential growth the specific growth rate reaches its maximum and remains constant at μ = μmax. max t Therefore, during exponential growth: 0 Inoculum Oenococcus oeni is an important bacterial species used for malo-lactic (ML) fermentation in the wine industry. ML fermentation is a secondary fermentation in wine in which malic acid (a naturally occurring acid in grapes) is converted to lactic acid, and occurs after the primary alcoholic fermentation performed by yeast. It improves wine quality by reducing the total acidity, thereby softening the wine. In addition, it infuses a favorable buttery aroma from an intermediate of ML fermentation called diacetyl. dX X dt 0 50 100 Time (hr) 150 The growth curves for O. oeni. Inoculum for the fed-batch run had been previously refrigerated which caused the extended lag phase. Analysis of growth curves from O. oeni yielded: max 0.07hr which correlates to the highest specific growth rate for this organism found in literature. Maximum cell densities occurred around 1.7-1.9 g/L. This appeared to be independent of substrate levels as indicated by the fed-batch operation. These values are also verified by literature as being high yields for O oeni. 1 Vacuum pump Vacuum pump attached to the Lyo-centre lyophilizer. Lyo-centre vacuum chamber and vacuum flask. 200