* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download enzyme

Lipid signaling wikipedia , lookup

Magnesium in biology wikipedia , lookup

Multi-state modeling of biomolecules wikipedia , lookup

Photosynthetic reaction centre wikipedia , lookup

Citric acid cycle wikipedia , lookup

Western blot wikipedia , lookup

Metabolic network modelling wikipedia , lookup

Nicotinamide adenine dinucleotide wikipedia , lookup

Ultrasensitivity wikipedia , lookup

Proteolysis wikipedia , lookup

Restriction enzyme wikipedia , lookup

Deoxyribozyme wikipedia , lookup

Oxidative phosphorylation wikipedia , lookup

NADH:ubiquinone oxidoreductase (H+-translocating) wikipedia , lookup

Biochemistry wikipedia , lookup

Catalytic triad wikipedia , lookup

Metalloprotein wikipedia , lookup

Biosynthesis wikipedia , lookup

Amino acid synthesis wikipedia , lookup

Evolution of metal ions in biological systems wikipedia , lookup

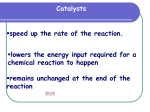

Enzymes in food industry Basics Dr Otmar Höglinger Dr. 1 Classification and Numbering of Enzyms • • • • • • Enzymes are divided into six main classes according to the type of reaction catalyzed. y They are assigned code numbers, prefixed by E.C., which contain four elements separated by points and have the following meaning: 1. the number first indicates to which of the six classes the enzyme belongs, 2. the second indicates the subclass 3. the third number indicates the sub-subclass, and 4 the ffourth is the serial number off the enzyme in the sub4. subclass 2 The six classes are distinguished in the following manner • • • • • • 1. Oxidoreductases This class encompasses all enzymes that catalyze redox reactions reactions. The recommended name is dehydrogenase whenever possible, but reductase can also be used. Oxidase is used only when O2 is the acceptor for reduction. The systematic name is formed according to d donor: acceptor t oxidoreductase. id d t 2. Transferases Transferases catalyze the transfer of a specific group, such as methyl, th l acyl, l amino, i glycosyl, l l or phosphate, h h t ffrom one substance b t tto another. The recommended name is normally acceptor grouptransferase or donor grouptransferase. The systematic name is formed according to donor: acceptor grouptransferase grouptransferase. 3. Hydrolases Hydrolases catalyze the hydrolytic cleavage of C-O, C-N, C-C, and some other bonds bonds. The recommended name often consists simply of the Substrate name with the suffix -ase. The systematic name always includes hydrolase. 3 The six classes are distinguished in the following manner • • 4. Lyases Lyases catalyze the cleavage of C-C, C-O, C-N, and other bonds by elimination. The recommended name is,, for example, p , decarboxylase, aldolase, dehydratase (e-limination of CO2, aldehyde, and water, respectively). The systematic name is formed according to Substrate group-lyase. • • 5. Isomerases Isomerases catalyze geometric or structural rearrangements within a molecule. l l Th The diff differentt ttypes off iisomerism i llead d tto th the names racemase, epimerase, isomerase, tautomerase, mutase, or cyloisomerase. • • 6. Ligases Ligases catalyze the joining of two molecules, coupled with the hydrolysis of a pyrophosphate bond in ATP or another nucleoside triphosphate. 4 Catalytic Activity of Enzymes • The theory of enzyme-catalyzed reactions proposed by Michaelis Menten is based on the assumption p that the enzyme y ( E ) and the substrate (S) form a complex (ES) by a reversible reaction. • The complex is then converted into the product (P) with the reaction rate k2, when practically no product is present. • Under commonly used conditions off enzyme activity measurement, cES can be considered to be sufficiently constant during the observed reaction period 5 Catalytic Activity of Enzymes • By using a term for the total concentration of enzyme • O obtains One bt i • Or • By introducing the Michaelis constant KM • The reaction rate as a function of cES 6 Reaction rate as a function of substrate concentration • The maximum reaction rate V, which is reached, when all of the enzyme is satureted whit substrate (cES = CEt) • The Michalis-Menten equation is • In the case of frequently occuring two-substrate reaction, a similar derivation leads to the formula: 7 Reaction rate as a function of substrate concentration 8 Factors Governing Catalytic Activity-Temperature • The temperature dependence of enzyme-catalyzed reactions exhibits an optimum because the thermodynamic increase of reaction rate is followed by a steep drop caused by thermal denaturation of the enzyme. The optimum is generally between 40-60°C. Some temperature insensitive enzymes may exhibit an optimum at almost 100°C. 100 C. 9 Pressure • • Yields of enzymatic processes can also be influenced by changing the pressure. Ad Advantage t can be b taken t k off the th stability t bilit off many enzymes ttowards d hi high h pressure in order to carry out reactions in supercritical fluids. • For example, cholesterol oxidase catalyzes the oxidation of cholesterol to 4cholesten-3-one at 123 bar and 31°C in supercritical CO2,giving a 100% conversion in one hour. • This procedure has several advantages: cholesterol is 50 times soluble in p CO2 as in water;; the solvent is inert,, nontoxic,, and supercritical nonflammable, and the enzyme, being insoluble, is easily recovered. 10 Aqueous versus organic media • • In commun with other reactions, enzymatic processes are also influenced by y the nature of solvent. The nature of the solvent can dramatically effect the substrate specifity, activity, stability, and regio- and stereoselectivity of an enzymatic transformation transformation. • The use of enzymes in organic media offers several advatages: – Enzymes are generally more thermally stable in nonaqueous media (PPL is inactivated virtuelly instantaneously at 100°C 100 C while in hydrocarbons it has a half-life of tens of hours at this temperature) – Water lubricates enzyme molecules, rendering them conformationally flexible. flexible Dehydration causes enzyms to adopt a more rigid structure. They remain properly folded in organic media even at high temperatures and resistant to denaturation. 11 Aqueous versus organic media • Another advantage of using enzymes in nonaqueous media is that it allows reactions ti to t be b carried i d outt which hi h are nott feasible f ibl iin water t d due tto thermodynamically unfavorable equilibria (eg esterifications or peptide formation) • Performing enzymatic transformations in organic solvents renders them more compatible with organic synthesis, this is important because the majority off compounds off interest to organic chemists are insoluble in water. 12 Value of pH • • • • All enzymes have an optimum pH range for activity. The optimum depends not only on pH but also on ionic strength and type of buffer buffer. It max be influenced by temperature, substrate, and coenzyme concentration. F mostt enzymes, the For th pH H optimum ti lilies iin th the range 5 tto 7 7. Extreme values of 1,5 and 10,5 have been found for pepsin and for alkine phosphatase. 13 Activation • In addition to substrates and coenzymes many enzymes require nonprotein or, in some cases, protein compounds to be fully active • The activating ion may be involved directly in the reaction by complexing p g the coenzyme y or cosubstrate ((eg g Fe ions bound to flavin or the ATP-Mg complex). • In other cases, cases the ion is part of the enzyme and either acts as a stabilizer for the active conformation (eg Zn ions in alkine phosphatase) or participates directly at the active sit (eg Mn ions in isocitrate dehydrogenase) 14 Inhibition-Irreversible Inhibition • An irreversible inhibitor frequently forms a stable compound with the enzyme y byy covalent bonding g with an aminoacid residue at the active side. • For example, diisopropyl fluorophosphat (DIFP) reacts with the serine residue at the active site of acetylcholinesterase y to form an inactive diisopropylphosporyl enzyme. • Alkylating y g reagents, g , such as iodoacetamid,, inactivate enzymes y with mercapto groups at their acive sites by modifying cysteine. 15 Reversible Inhibition • Reversible inhibition in contrast, is characterized by an equilibrium between enzyme und inhibitor. Several main groups of reversible inhibitory mechanisms can be differentiated differentiated. • Competitive Inhibition: The inhibitor competes with the substrate or coenzyme for the binding site on the active center by forming an enzyme inhibitor complex EI. Inhibition can be made ineffective by excess substrate, as is the case for inhibition of succinate dehydrogenase by malonate. • Noncompetitive Inhibition: The inhibitor decreases the catalytic activity of an enzyme without influencing the binding relationship between substrate and enzyme. This means that inhibitor and substrate can bind simultaneously to an enzyme y molecule to form ES,EI, or ESI complexes. p Noncompetitive p inhibition is dependent solely on the inhibitor concentration and is not overcome by high substrate concentration. An example is the blocking of an essential cysteine residue by such heavy metals as copper or mercury. • 16 Inhibition • Uncompetitive Inhibition: The inhibitor reacts only with the intermediary enzyme-substrate b t t complex. l A An example l iis th the reaktion kti off azide id with ith th the oxidized form of cytochrome oxidase. • Competitive inhibition: • Noncompetitive inhibition: • Uncompetive inhibition: 17 Inhibiton • Substrate Inhibition: High concentration of substrate may decrease the catalytic acivity of an enzyme. Examples are the action of ATP on phosphofructokinase or of urea on urease. • product inhibition: In manyy multienzyme y systems, y , the end product p of End p the reaction sequence may act as a specific inhibitor of an enzyme at or near the beginning of the sequence. This type of inhibition is also called feedback inhibition or retroinhibition. 18 Lineweaver Burk graphs of reversibly inhibited enzyme reactions • • • • A) Competitive C titi iinhibition hibiti B) Noncompetitive inhibition C)) Uncompetitive p inhibition ----- Uninhibited reaction 19 Inhibition • Competitive inhibition • Noncompetitive inhibition • Uncompetitive inhibition 20 Allostery • Cosubstrates with central role in the metabolism, such as acetyl-CoA, ATP, or AMP, may also influence the rate or reaction sequences by allosteric regulation regulation. • For example, phosphofructokinase, the first enzyme in the energy-supplying Embden Meyerhof Meyerhof-Parnass Parnass pathway, pathway is inhibited by a high concentration of ATP. • The binding of the effector modifies the conformation of the subunit and ist active center, which then affects modifies the conformation of the subunit and ist active center, which then affects the conformation and hence the catalytic y activityy or the entire molecule. • Allosteric enzymes ussually do not show the classical Michaelis-Menten kinetic relationship of cs,V and KM. 21 Biogenic Regulation of Acitvity • In principle, enzyme activity also be controlled by regulating the amount of enzyme in the cell. cell This can be accomplished by regulating the biosynthesis of induvidual enzymes or of several functionally related enzymes by induction or repression, or by specific attack of proteolytic enzymes. 22 Biogenic regulation of activity Activity of an allosteric enzyme as a function of substrate concentration in absence and p presence of an allosteric activator or inhibitor. 23 Quality Evaluation of Enzym preparation-Quality Criteria • The quality of enzyme preparations is characterized by activity, purity, stability, formulation, and packing. • Specific Activity: – One of the most important p q quality y criteria of an enzyme y preparation p p is ist specific p activity, i.e. the catalytic activity related to ist protein content. Specific acivity is ussually expressed as units per milligram or, for less purified products, units per gram. • Protein Determination: – Ultraviolet Absorption: Because of their content of aromatic amino acids, proteins exhibit an absorption maximum at 270-280 nm – Biuret Method: The reaction of peptide bonds with copper ions in alkaline solution yields a purple complex which can be determined photometrically. – Lowry Method: The Lowry method combines the biuret reaction of proteins with reduction of the Folin Folin-Ciocalteu Ciocalteu phenol reagent by tyrosin and tryptophan tryptophan. 24 Advantages and Limitations • • • • • • • • Advantages: Very efficient catalysis Milf conditions No organic g solvent needed Wide range of acitvity High substrate selectivity, chemoselecitvity, regioselectivity, and steroselectivity t l ti it Often fewer steps Inexpensive source of complex chiral ligands 25 Advantages and Limitations • • • • • • Limitations A il bilit and Availability d price i Operational stability and lack of flexibility Substrate and/or product inhibition Not all types of reaction accessible Cofactor regeneration sometimes needed 26 Whole Cells Versus Isolated Enzymes in Organic Synthesis Wh l cellll Whole I l t d enzyme Isolated Advantages Cheap Cofactors present Simpler equipment Simpler work up Less contamination from other enzymes Disadvantages High dilution Complex work up Side reactions caused by other enzymes present Expensive Addition of cofactors necessary where required 27 Immobilization-Carrier Binding • Enzyme proteins have amino acid residues containing chemically reactive groups, ionic i i groups, and/or d/ hydrophobic h d h bi groups, as wellll as h hydrophobic d h bi domains. • These amino acid residue and the hydrophobic domains can participate in the immobilization of enzymes through covalent linkage, ionic binding, or physical adsorption. • Covalent Binding: Amino acid residues that are not involved in the active g site of the enzymes y to be immobilized can be used site or substrate-binding for covalent binding with supports. • These are the εε-amino amino group of lysine lysine, the mercapto group of cysteine cysteine, the β-carboxyl group of aspartic acid, the γ-carboxylgroup of glutamatic acid, the phenolic hydroxyl group of tyrosine, or the hydroxyl groups of serine and threonine. 35 Examples of immobilized enzymes used in major commercial processes 36 Prinziples of enzyme immobilization 37 • • • • • • • • • • • • • 1) Si Sie kkennen d das N Nomenklatursysteme kl t t fü für E Enzyme und d kö können es anwenden. d 2) Sie kennen die Klassifizierung von Enzymen, können die einzelnen Enzymklassen beschreiben 3) Sie können die Michaelis-Menten Gleichung ableiten, sie verstehen die Anwendung dieser g können die dazugehörigen g g Diagramme g zeichnen Gleichung, 4) Kennen die Faktoren die die Enzymaktivität beeinflussen und können diese an Beispielen beschreiben. 5) Kennen die Regulationsmechanismen von Enzymen, wissen welche Inhibitorentypen es gibt und diese auch Inhaltlich beschreiben beschreiben. Sie können die einzelnen Typen auch grafisch darstellen darstellen. 6) Sie kennen auch allosterische Hemmtypen und biogene Mechanismen der Enzymregulation. 7) Wie erfolgt die Bestimmung von Proteinen, was versteht man unter spezifischer Aktivität 8)) Welche vor- und Nachteile bringt g der Einsatz von Enzymen. y 9) Welche Vor- und Nachteile bringen ganze Zellen vs. Enzymen 10) Wie können Träger für Enzyme unterteilt werden 11) Welche prinzipiellen Möglichkeiten der Immobilisierung gibt es 12) Sie können einzelne Methoden beschreiben wie Adsorbtion, Entrappment, Microverkapseln, kovalente Bindungen 13) Welche vor- und Nachteile hat die Immobilisierung 38 Advantages/Disadvantages • • • • • Enzymes iimmobilized E bili d b by covalent l t bi binding di h have th the ffollowing ll i advantages: (1) because of the tight binding, they do not leak or detach from supports during utilization (2) immobilized enzymes can easily come into contact with substrates because the enzymes are localized on the surface of supports (3) an increase in heat stability is often observed because of the strong interaction between enzyme molecules and supports • Disadvantages: (1) active structures of enzyme molecules are liable to be destroyed by partial modification (2) strong interaction between enzyme molecules and supports often hi d hinders th the ffree movementt off enzyme molecules, l l resulting lti iin d decreased d enzyme activity. (3) optimal conditions of immobilization are difficult to find • • (4) this method is not suitable for immobilization of cells (5) supports, in general, are not renewable • 39 Functional groups in proteins relevant for immobilization 40 Properties of matrices relevant for enzyme immobilization 41 Carriers • The different types of carriers used may be classified according either to the basic material,, origin g or source,, or to their structure. • • • Inorganic Organic from natural sources; and Organic synthetic materials • Inorganic carriers exhibit high pressure stability, but mayundergo g materials from natural sources in abrasion in stired vessels;; organic most cases offer favorable compatibility with proteins; organic synthetic carriers in general exhibit high chemical stability. 42 Synthetic polymers • Ion exchange materials have proven to be an economic and technically y appropriate pp p solution, as awide range g of carriers is currently available offering good capacity for enzyme immobilization, as well as proporties that have relevant to industrial scale processing. 43 Glucose isomerase • High fructose corn syrup is currently produced at a scale ofabout 10 million tons per year, year using about 1500 tons of immobilized enzyme enzyme. • Glucose isomerase is used for the isomerization reaction. • Scheme of procedures for immobilization of glucose isomerase, Novo process, process crosslinking of cells 44 Glucose isomerase • Scheme of procedures for immobilization of glucose isomerase, Novo process, crosslinking of cells 45 Glucose isomerase • • Genencor, prinziple of isolation of crystalline enzyme Adsorption onto a composite ion ion-exchange exchange matrix formed by extrusion with 50% polystyrene, 20% TIO2, 30% DEAE cellulose 46 Entrapment • • • • • • Entrapped biocatalysts are classified according to the following different types: 1) Lattice type: biocatalysts entrapped in gel matrices prepared from polysacharides, proteins, or synthetic polymers 2) Micorcapsule type: biocatalysts entrapped in microcapsules of semipermeable synthetic polymers 3) Liposome type: biocatalysts entrapped within liquid membranes prepared from phospholipids 4) Hollow fiber type: biocatalysts separeted from the environment b h by hollow ll fib fibres 5) Membrane type: biocatalysts separeted from the spent reaction solution by y ultrafiltration membranes 47 Polyacrylamide Gel • In a typical procedure, acrylamide and N,N`-methylenebisacrylamide are mixed with biocatalysts and polymerized in the presence of an initiator initiator. 48 Alginate Gel • Several natural polysaccharides, such as alginate, agar and carrageenan • Carrageenan Gel 49 Methods of immobilization of microorganisms 50 Immobilization in alginate (Syring method, jet cutter method) 51 Applications of technical enzymes 52 Industrial applications of enzymes 53 Applications of technical enzymes 54 Optimierung einer rekombinanten mikrobiellen Transglutaminase • Die mikrobielle Di ik bi ll T Transglutaminase l t i aus St Streptomyces t mobaransis b i wird i d bi bisher h überwiegend in der Lebensmitteltechnologie angewendet, da durch Vernetzung von Proteinen die Textureigenschaften zB Wurstprodukten zu verbessern. erbessern • Transglutaminasen sind Enzyme,die einen Acyl-Transfer zwischen den γCarboxyamid-Gruppe eines proteingebundenen Glutamins und primären Aminen katalysieren. • Neuere Technologien beschäftigen sich mit dem Einsatz der mikrobiellen Transglutaminase bei der Herstellung von bioabbaubaren Polymeren, wie beispielsweise p Filme und Folien aus Proteinen wie Zein und Casein. 55 Optimierung einer rekombinanten mikrobiellen Transglutaminase • Für Anwendungen Fü A d i d in der L Lebensmittelindustrie b itt li d t i wäre ä es vorteilhaft, t ilh ft eine i Enzymvariante zur Verfügung zu haben, die bei niedrigen Temperaturen eine hohe Aktivität aufweist, sich aber bei höheren Temperaturen schnell inakti ieren lässt inaktivieren lässt. 56 Random Mutagenese des MTG Gens • Die Random Mutagenese wurde mit dem GeneMorphII EZClone Domain Mutagenisis Kit durchgeführt. Die Plasmide die die Mutationen enthielten wurden, wurden schließlich in E.coli Zellen transformiert. 57 Screening auf thermostabile Varianten • Die Klonbibliothek wurde auf Varianten untersucht, die eine erhöhte Restaktivität nach Vorinkubation bei höheren Temperaturen aufwiesen aufwiesen. • Dazu wurde der aktivierte Rohenzymextrakt in 96 well bei 55°C im W Wasserbad b d vorinkubiert. i k bi t N Nach h 30 min i wurde d auff 20°C abgekühlt. b kühlt • Anschließend wurde die Aktivität der Varianten mittels kalorimetrischen Hydroxamattests gemessen. 58 Mutanten 59 Inaktivierungsverhalten ausgewählter thermostabiler Varianten 60