* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download (1125) Catalytic Dehydration Reactions for Green Synthesis of

Physical organic chemistry wikipedia , lookup

Liquid–liquid extraction wikipedia , lookup

Fluid catalytic cracking wikipedia , lookup

Chemical reaction wikipedia , lookup

Peptide synthesis wikipedia , lookup

Process chemistry wikipedia , lookup

Photoredox catalysis wikipedia , lookup

Citric acid cycle wikipedia , lookup

Stoichiometry wikipedia , lookup

Hydrogen-bond catalysis wikipedia , lookup

Kinetic resolution wikipedia , lookup

Fatty acid synthesis wikipedia , lookup

Click chemistry wikipedia , lookup

Ring-closing metathesis wikipedia , lookup

Catalytic reforming wikipedia , lookup

Biochemistry wikipedia , lookup

Butyric acid wikipedia , lookup

Bioorthogonal chemistry wikipedia , lookup

Biosynthesis wikipedia , lookup

Acid dissociation constant wikipedia , lookup

Supramolecular catalysis wikipedia , lookup

Acid strength wikipedia , lookup

Hydroformylation wikipedia , lookup

Acid–base reaction wikipedia , lookup

Strychnine total synthesis wikipedia , lookup

Lewis acid catalysis wikipedia , lookup

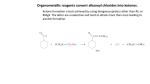

Proceedings of International Symposium on EcoTopia Science 2007, ISETS07 (2007) Catalytic Dehydration Reactions for Green Synthesis of Bioactive Natural Products Akira Sakakura1 1. EcoTopia Science Institute, Nagoya University, Nagoya, Japan Abstract: More environmentally benign alternatives to current chemical processes, especially large-scale fundamental reactions, are in strong demand for many reactions. We have developed catalytic dehydration processes based on acid–base combination chemistry. Bulky diarylammonium pentafluorobenzenesulfonates are mild and extremely active ester condensation catalysts. In the presence of the catalysts, ester condensation of carboxylic acids with an equimolar amount of alcohols is performed in heptane by heating at 80 °C. Even though the ester condensation is performed under heating conditions without the removal of water, the reaction proceeds well without any deceleration due to the generated water. Furthermore, the steric bulkiness of the N-aryl groups and the S-pentafluorophenyl group in the catalyst suppresses the dehydrative elimination of secondary alcohols to produce alkenes. In addition, the immobilization of bulky diarylammonium pentafluorobenzenesulfonate on a polymer support provides an efficient atom-economical esterification catalyst that can be easily recovered and reused. Phosphoric acid monoesters are selectively synthesized by the catalytic dehydrative condensation of an equimolar mixture of phosphoric acid and alcohols. The reaction is catalyzed by a mixture of perrhenic acid (1 mol%) and dibutylamine (20 mol%) under azeotropic reflux conditions with the removal of water in NMP–o-xylene (1:1 v/v). To the best of our knowledge, this is the first successful example for the direct catalytic condensation of an equimolar mixture of phosphoric acid and alcohols for the selective synthesis of phosphoric acid monoesters. Keywords: Catalysis, Dehydration Condensation, Ester, Phosphoric Acid Monoester 1. BULKY DIARYLAMMONIUM PENTAFLUOROBENZENESULFONATES AS EFFECTIVE CATALYSTS FOR ESTER CONDENSATION REACTION The ester condensation reaction is among the most fundamental organic transformations, and more environmentally benign alternative synthetic approaches to the ones currently used are in strong demand by the chemical industry [1]. With regard to green chemistry, in particular with respect to atom economy and E-factor, several catalytic methods for the ester condensation reaction between equimolar amounts of carboxylic acids and alcohols have been developed [2–6]. Conventionally in fact esterifications are conducted with an excess of carboxylic acids or alcohols against its reaction counterpart in the presence of an acid catalyst, or with a stoichiometric dehydrating reagent or an activated carboxylic acid derivative in the presence of a stoichiometric amount of base. The use of excess amounts of substrates is a wasteful practice in itself. Furthermore, the use of stoichiometric dehydrating reagents or activated carboxylic acid derivatives leads to the formation of significant amounts of undesired by-products. Purifying the crude products from (excess) substrates or from reaction by-products is a rather demanding task. It is therefore easy to see why the direct catalytic condensation between equimolar amounts of carboxylic acids and alcohols that does not require the presence of dehydrating agents is, at least in principle, such an attractive synthetic goal. Among these ‘green’ catalytic condensations, metal-free organocatalytic methods are particularly desirable, especially for industrial processes. In 2000, Tanabe and coworkers reported that diphenylammonium triflate ([Ph2NH2]+[OTf]–, 1.0–10 mol%) efficiently catalyzed the ester condensation reaction at 80 °C without need for the removal of water [2]. Unfortunately however, since [Ph2NH2]+[OTf]– is the salt of a superacid (TfOH) and a weak base (Ph2NH), it is a strong Brønsted acid, and as such difficult to use in the reaction of sterically demanding and acid-sensitive alcohols. In the course of our continuing study on environmentally benign dehydration catalysts, we have developed N,N-dimesitylammonium pentafluorobenzenesulfonate 1 and N-(2,6-diphenylphenyl)-N-mesitylammonium pentafluorobenzenensulfonate 2 as mild and selective ester condensation catalysts (Figure 1) [7–10]. C6F5SO3H [pKa(CD3 CO2D) = 11.1, H0 = –3.98] is a weaker acid than trifluoromethansulfonic acid [TfOH, pKa(CD3 CO2D) = –0.74, H0 = –14.00], concentrated H2SO4 Ph NH2 1 NH2 [O3SC6F5] 2 Fig 1. Bulky diarylammonium pentafluorobenzenesulfonates. Corresponding author: A. Sakakura, [email protected] 772 [O3SC6F5] Ph Proceedings of International Symposium on EcoTopia Science 2007, ISETS07 (2007) OH Ph(CH2)3CO2 catalyst (5 mol%) Ph(CH2)3CO2H + + heptane (bp. 98 °C) reflux 3 conv. (%) 100 80 conv. (%) 100 A 4 catalyst: + [Ph2NH2] [OTf]– 40 0 conv. (%) 100 2 4 6 time (h) 60 8 10 0 0 catalyst: 1 40 5 20 2 4 6 time (h) 8 4 60 catalyst: [Mes2NH2]+[OTf]– 40 C 80 4 3 5 20 5 B 80 3 60 0 4 3 20 0 10 5 0 2 4 6 time (h) 8 10 Fig 2. Ester condensation of 4-phenylbutyric acid with cyclododecanol (3). The proportions of 3 (red circle), 4 (green square) and 5 (blue triangle) in the reaction mixture over time are shown. Table 1. Esterification reaction of carboxylic acids with equimolar amounts of alcohols catalyzed by 1.a R1CO2H + HOR2 1:1 molar ratio 1 2 1 (1 mol%) entry 1 product (R CO2R ) Ph(CH2)3CO2-n-C8H17 2 c-C6H 11CO2-n-C8H17 5 98 10 3 t-C4H9CO2-n-C8H17 6 93 11c 4 5 Ph Ph time (h) yield (%) 1 99 CO2-n-C8H17 5 CO2-n-C8H17 24 R1CO2R2 heptane, 80 °C 1 96 12 96 2 product (R CO2R ) Ph(CH2)3CO2Bn entry 9 time (h) yield (%) 2 95 Ph(CH2)3CO2 Ph(CH2)3CO2 MeO CO2 99 24 85 (0)b 4 95 (0)b 24 97 (0)b 24 73 24 99 72 92 C5H11-n C5H11-n C5H11-n C5H11-n Ph(CH2)3CO2 13 3 Ph(CH2)3CO2 6 7 PhCO2-n-C8H17 MeO CO2-n-C8H17 24 91 14d 1 99 15d 3 99 16 MeO MeO CO2 CO2 OMe OMe 8 Ph CO2-n-C8H17 MeO CO2 a Unless otherwise noted, a solution of carboxylic acids (2 mmol) and alcohols (2 mmol) in heptane (4 mL) was heated at 80 °C in the presence of 1 (1 mol%). b Yield of alkenes is shown in parentheses. c 2 (1 mol%) was used. d 1 (10 mol%) was used. [pKa(CD3 CO2D) = 7.5, H0 = –11.93] and p-toluenesulfonic acid [pKa(CD3CO2D) = 8.5, H0 = –4.5]. This means that 1 and 2 are milder acids than the corre- sponding ammonium triflates, sulfates, and tosylates. Nevertheless, 1 and 2 have much higher catalytic activities than Tanabe’s catalyst ([Ph2NH2]+[OTf]–) (Figure 2), 773 Proceedings of International Symposium on EcoTopia Science 2007, ISETS07 (2007) Table 2. Esterification reaction under solvent-free conditions at room temperature.a R1CO2H + HOR2 1 (1 mol%) (1.1 equiv) no solvent, rt entry 1 2 3b 1 2 product (R CO2R ) Ph(CH2)3CO2Me time (h) 24 yield (%) 95 CO2Me 8 24 72 68 CO2Me 11 24 91 82 48 90 CO2-n-C8H17 48 69 CO2-n-C8H17 24 48 74 71 42 69 MeO O 4 5b R1CO2R2 O 6 7b 8 9b CO2Me MeO O OMe 10 Ph CO2-n-C8H17 ing esters (entries 4–6). 2-Alkoxycarboxylic acids were very reactive substrates probably due to favorable chelation between the substrates and 1 (entries 7, 8, 12 and 14–16). 1 could be used for acid-sensitive alcohols such as benzyl alcohol, allylic alcohols, and secondary alcohols (entries 9–13). In particular, esterification with sterically demanding alcohol 6-undecanol gave the desired esters in good yield without the production of alkenes (entries 11 and 12). Although Lewis acidic metal salts such as Hf(IV) and Zr(IV) were not adapted to 1,2-diols due to tight chelation with metal ions [12], these diols were also esterified in high yield by 1 (entry 13). Less-reactive aryl alcohols and 1-adamantanol were also esterified in high yields (entries 14–16). Surprisingly, ester condensation reactions with more-reactive primary alcohols proceeded even at room temperature (22°C) without solvents (Table 2). Most carboxylic acids were esterified with 1.1 equivalents of methanol in good yield in the presence of 1 mol% of 1 (entries 1–6). 1-Octanol was also reactive, although the reactivity was lower than methanol (entries 7–10). As far as we know, this is the first example of an ultimate green esterification process. One major problem associated with the use of soluble catalysts lies in recovery of the catalyst from the reaction a Unless otherwise noted, a solution of carboxylic acids (2 mmol) and alcohols (2.2 mmol) was reacted at room temperature in the presence of 1 (1 mol%). b 2 (1 mol%) was used. Br (2.71 mmol Br/g) + NH2 due to the hydrophobic environment created around the ammonium protons in the catalyst [11]. Even though the ester condensation was performed under heating without the removal of water, the reaction proceeded well without any deceleration due to the generated water. When the ester condensation of 4-phenylbutyric acid with cyclododecanol (3) was conducted in the presence of Tanabe’s catalyst (5 mol%) in heptane under reflux conditions (bath temperature 115 °C), a significant amount of the undesired cyclododecene (5) was produced along with cyclododecyl 4-phenylbutyrate (4) (Figure 2, graph A). The use of dimesitylammonium triflate ([Mes2NH2]+[OTf]–) showed higher catalytic activity than [Ph2NH2]+[OTf]– and reduced the production of 5 (Figure 2, graph B). Furthermore, the ester condensation catalyzed by 1 (5 mol%) proceeded more rapidly and the production of 5 decreased (Figure 2, graph C). The use of less-polar solvents such as heptane is important. The catalytic activities of 1 and 2 increased in such less-polar solvents, to give esters in good yields. To explore the generality and scope of the selective esterification catalyzed by 1 (1 mol%) at 80 °C, the condensation was examined with an equimolar mixture of various structurally diverse carboxylic acids and alcohols (Table 1). 2-Unsubstituted carboxylic acids, 2-monosubstituted carboxylic acids, and sterically demanding 2,2-disubstituted carboxylic acids were smoothly condensed to produce the corresponding esters (entries 1–3). α,β-Unsaturated carboxylic acids and benzoic acids were also transformed into the correspond- Pd(dba)2 (20 mol%) BINAP (45 mol%) t-BuONa (36 equiv) NH toluene 120 °C, 3 days (75%) 6 (1.76 mmol N/g) C6F5SO3H (3 equiv) NH2 toluene, rt (97%) [O3SC6F5] 7 Ph(CH2)3CO2H 7 (5 mol%) + Ph(CH2)3CO2-n-C8H17 heptane 80 °C,1 h HOC8H17 run 1 2 3 4 5 6 7 8 9 10 conv. (%) 99 99 99 99 99 99 99 99 98 99 Fig 3. Preparation of polymer-supported catalyst 7 and its recovery and reuse for the ester condensation. 774 Proceedings of International Symposium on EcoTopia Science 2007, ISETS07 (2007) medium. A simple solution is to immobilize the catalyst on a polymeric matrix. Figure 3 describes the preparation of immobilized catalyst 7. 4-(N-Mesitylamino)polystyrene resin (6) was prepared by palladium-catalyzed cross-coupling of 4-bromopolystyrene resin cross-linked with 2% divinyl benzene (2.71 mmol Br/g, 200–400 mesh) with 2,4,6-trimethylaniline in 75% yield. 7 was then readily prepared in 97% yield by treating 6 with C6F5SO3H. In contrast, an immobilized catalyst could not be prepared from 6 and TfOH since the resin decomposed with superacidic TfOH. 7 was recovered by filtration and reused more than ten times as the catalyst for the direct ester condensation reaction of 4-phenylbutyric acid with octanol, and no loss of activity was observed for the recovered catalyst. Table 3. Catalytic activities of metal oxides for the direct condensation of phosphoric acid with an equimolar amount of stearyl alcohol.a n-C18H37OH + catalyst (10 mol%) NMP–PhCl (1:1 v/v) azeotropic reflux 1:1 molar ratio 10 h n-C18H37OPO3H2 H3PO4 entry 1 catalyst HOReO3 yield (%) entry 97 6 catalyst ReO2 yield (%) 8 2 TMSOReO3 94 7 MoO3 8 3b Re2O7 81 8 WO3 12 4 MeReO3 12 9b V2 O5 17 5 35 10 no catalyst 7 ReO3 A solution of phosphoric acid (2 mmol) and alcohols (2 mmol) in NMP–PhCl (1:1 v/v) was heated in the presence of a metal oxide (10 mol%) under azeotropic reflux conditions for 10 h. b The amount (10 mol%) of the metal oxide was based on the metal atom. 2. SELECTIVE SYNTHESIS OF PHOSPHORIC ACID MONOESTERS BY THE DEHYDRATIVE CONDENSATION OF PHOSPHORIC ACID Phosphoric acid monoesters are some of the most important substances in materials chemistry, medicinal chemistry, and so on. Many phosphoric acid monoesters have been synthesized on an industrial scale and are used as necessities in our daily life [13, 14]. From the perspective of green chemistry, the direct catalytic condensation of phosphoric acid with equimolar amounts of alcohols is attractive for the synthesis of phosphoric acid monoesters, especially for the industrial scale synthesis, since the reaction produces only water as a byproduct. Although various methods for the direct catalytic condensation of carboxylic acids with equimolar amounts of alcohols have been reported [1–9], there is no successful method for synthesizing phosphoric acid monoesters by the direct catalytic condensation of phosphoric acid with equimolar amounts of alcohols [15, 16]. The esterification of phosphoric acid is much more difficult than that of carboxylic acids due to the stronger acidity of phosphoric acid. Previously, we reported that a catalytic amount of nucleophilic bases such as N-butylimidazole promoted the dehydrative condensation of phosphoric acid and alcohols [17]. However, this condensation is not a true catalytic process, since the reaction requires one equivalent of tributylamine (n-Bu3N). Here we report our recent development of the catalytic condensations between phosphoric acid and alcohols for the selective synthesis of phosphoric acid monoesters. In our previous work, a 1:1 (v/v) mixture of N,N-dimethylformamide (DMF) and nitroethane (EtNO2) was used as a solvent [17]. Since phosphoric acid can not be dissolved in that solvent, 100 mol% of n-Bu3N is required to dissolve phosphoric acid and promote the reaction. We considered that Lewis acidic metal oxides might catalyze the condensation in N-methyl-2-pyrrolidone (NMP)–o-xylene (1:1 v/v) or NMP–chrolobenznene (PhCl) (1:1 v/v) in the absence of any auxiliary base, since phosphoric acid is dissolved well in NMP–o-xylene (1:1 v/v) and NMP–PhCl (1:1 v/v) even without an auxiliary base. Some metal oxides have been shown to be versatile green catalysts for dehydration reactions [18–21]. Therefore, we first investigated the catalytic activities of various metal oxides (10 mol%) that promoted the dehydrative condensation of phosphoric a acid with an equimolar amount of stearyl alcohol. By screening of reactivities of several metal oxides, we found that some rhenium(VII) oxo compounds such as perrhenic acid (HOReO3), trimethylsilyl perrhenate (TMSOReO3) and rhenium(VII) oxide (Re2O7) efficiently promoted the dehydrative condensation of phosphoric acid (1.0 equiv) with stearyl alcohol in NMP–PhCl (1:1 v/v), to selectively give the corresponding phosphoric acid monoester (Table 3, entries 1–3) [22]. In contrast, the reactivities of methyltrioxorhenium (MTO, CH3ReO3), rhenium(VI) oxide (ReO3) and rhenium(IV) oxide (ReO2) were very low (entries 4–6). The other metal oxides such as molybdenum(VI) oxide (MoO3), tungsten(VI) oxide (WO3) and vanadium(V) oxide (V2O5) were almost inert (entries 7–9). Under the reaction conditions described above, rhenium(VII) oxo comounds gradually decomposed to dark insoluble species (probably oligomeric low-valent rhenium oxides) to be inactivated. Actually, when the reaction was conducted in the presence of smaller amount (1 mol%) of perrhenic acid at azeotropic reflux in NMP–o-xylene (1:1 v/v) for 12 h, stearyl phosphate was obtained in very low yield (16%, Figure 4, red circles). The same reactivity was observed even in the absence of perrhenic acid showed (black squares). Therefore, we examined additives that could stabilize perrhenic acid under the present reaction conditions, and found that 10–20 mol% of several organic amines could stabilize perrhenic acid to promote the condensation efficiently. Especially, sterically less hindered secondary and tertiary amines, such as dibutylamine (Bu2NH) and dimethyloctylamine, gave excellent results. In the presence of 20 mol% of Bu2NH, the reaction catalyzed by 1 mol% of perrhenic acid gave stearyl phosphate in excellent yield (98%, green squares). The reaction mixture was a clear dark blown solution when the reaction was conducted in the presence of Bu2NH. When the reaction was conducted with Bu2NH (20 mol%) in the absence of perrhenic acid, stearyl phosphate was obtained in only 39% 775 Proceedings of International Symposium on EcoTopia Science 2007, ISETS07 (2007) n-C18H37OH + HOReO3, Bu2NH NMP–o-xylene H3PO4 (1:1 v/v) 1:1 molar ratio azeotropic reflux Table 5. Dehydrative condensation of phosphoric acid with alcohols catalyzed by HOReO3 and n-Bu2NH.a n-C18H37OPO3H2 ROH + H3PO4 (1.1 equiv) yield (%) 100 HOReO3 (1 mol%) n-Bu2NH (20 mol%) ROPO3H2 NMP–o-xylene (1:1 v/v) azeotropic reflux, 12 h 80 entry 1 product (ROPO3H2) n-C18H37OPO3H2 yield (%) 98 2 (Z)-n-C8H17CH=CH(CH2)8OPO3H2 100 60 3b (Z)-n-C8H17CH=CH(CH2)8OPO3H2 96 4 (E)-n-C8H17CH=CH(CH2)8OPO3H2 100 5 n-C12H25(OCH2CH2)2OPO3H2 100 40 6 20 n-C9H19 (OCH2CH2)2OPO3H2 0 0 2 4 6 8 time (h) 10 100 H 12 H 7 Fig 4. Yield versus time for the dehydrative condensation of phosphoric acid with an equimolar amount of stearyl alcohol. Green squares, HOReO3 (1 mol%) and Bu2NH (20 mol%); blue triangles, Bu2NH (20 mol%); red circles, HOReO3 (1 mol%); black squares, without HOReO3 and Bu2NH. H H2O3PO 95 (0)c H H a Reaction of phosphoric acid (2.2 mmol) with alcohols (2 mmol) was conducted in the presence of HOReO3 aq. (1 mol%) and n-Bu2NH (20 mol%) in NMP–o-xylene (1:1 v/v, 10 mL) at azeotropic reflux for 12 h. b The reaction of H3PO4 (110 mmol) with oleyl alcohol (100 mmol) was conducted in the presence of HOReO3 aq. (0.5 mol%) and n-Bu2NH (20 mol%). c The reaction was conducted in the presence of HOReO3 aq. (10 mol%) without n-Bu2NH. yield (blue triangles). Therefore, Bu2NH primarily contributed to the stabilization of perrhenic acid. It is very interesting that a mixture of perrhenic acid (1 mol%) and Bu2NH (20 mol%) showed good catalytic activity, although Lewis acidic metal oxides were generally inactivated by bases. To explore the generality and scope of the dehydrative condensation catalyzed by the mixture of perrhenic acid and n-Bu2NH, the reactions of phosphoric acid (1.1 equiv) with various alcohols were examined (Table 5). The activity of this catalyst was much higher than that of 8, and various phosphoric acid monoesters were synthesized in almost quantitative yields. Unsaturated primary alcohols such as (Z)-oleyl alcohol and its (E)-isomer could be easily converted to the corresponding phosphoric acid monoesters in excellent yields (100%, entries 2 and 4). The geometries of the C–C double bonds in oleyl alcohol and its (E)-isomer were maintained during the reaction. The present protocol could be easily applied to a large-scale process, and the condensation of phosphoric acid (1.1 equiv) with oleyl alcohol (100 mmol) catalyzed by HOReO3 (0.5 mol%) and n-Bu2NH (20 mol%) gave oleyl phosphate in 96% yield (entry 3). Ethylene glycol dodecyl ether and ethylene glycol p-nonylphenyl ether (Igepal® CO-210) also showed high reactivities (100%, entries 5 and 6). Phosphoric acid monoesters of ethylene glycol dodecyl ether and ethylene glycol p-nonylphenyl ether are useful surfactants as ingredients in detergents. A secondary alcohol such as β-cholestanol was also converted to the corresponding phosphoric acid monoester in 95% yield (entry 7), while the product was completely decomposed when the reac- tion was conducted in the absence of n-Bu2NH because of the high acidity of the reaction media. n-Bu2NH contributed to the stabilization of the acid-sensitive substrate as well as perrhenic acid. 3. CONCLUSION We developed the direct catalytic dehydrative condensation of carboxylic acid and phosphoric acid with an equimolar amount of alcohols, to selectively give carboxylic acid esters and phosphoric acid monoesters in excellent yields. The present methods would provide the environmentally and industrially ideal synthesis of the condensation products. ACKNOWLEDGEMENT The author thanks Professor Kazuaki Ishihara, Graduate School of Engineering, Nagoya University, for his helpful discussion. All experiments in this manuscript were operated by Miss Shoko Nakagawa (ester condensation reaction) and Mr. Mikimoto Katsukawa (synthesis of phosphoric acid monoesters). The author is also grateful to these two students at Graduate School of Engineering, Nagoya University. REFERENCES 1. J. Otera, Esterification, Wiley, Weinheim (2003). 2. K. Wakasugi, T. Misaki, K Yamada and Y. Tanabe, Tetra- 776 Proceedings of International Symposium on EcoTopia Science 2007, ISETS07 (2007) hedron Lett. 41 (2000), pp. 5249–5252. 3. T. Funatomi, K. Wakasugi, T. Misaki and Y. Tanabe, Green Chem. 8 (2006), pp. 1022–1027. 4. K. Ishihara, S. Ohara and H. Yamamoto, Science 390 (2000), pp. 1140–1142. 5. K. Manabe, X.-M. Sun and S. Kobayashi, J. Am. Chem. Soc. 123 (2001), pp. 10101–10102. 6. J. Xiang, S. Toyoshima, A. Orita and J. Otera, Angew. Chem. Int. Ed. 40 (2001), pp. 3670–3672. 7. K. Ishihara, S. Nakagawa and A. Sakakura, J. Am. Chem. Soc. 127 (2005), pp. 4168–4169. 8. A. Sakakura, S. Nakagawa and K. Ishihara, Tetrahedron 62 (2006), pp. 422–433. 9. A. Sakakura, S. Nakagawa and K. Ishihara, Nature Protocols 2 (2007), pp. 1746–1751. 10. K. Ishihara, A. Sakakura and M. Hatano, Synlett, (2007), pp. 686–703 (account). 11. A. Sakakura, H. Watanabe, S. Nakagawa and K. Ishihara, Chem. Asian J. 2 (2007), pp. 477–483. 12. K. Ishihara, M. Nakayama, S. Ohara and H. Yamamoto, Tetrahedron 58 (2002), 8179–8188. 13. T. F. Tadros, Applied Surfactants: Principles and Applica- tions, Wiley, Weinheim, (2005). 14. A. D. F. Toy and E. N. Walsh, Phosphorus Chemistry in Everyday Living, American Chemical Society, Washington, DC, ed. 2, (1987). 15. Y. Hayakawa, In Comprehensive Organic Synthesis, Vol. 6 (Eds.: B. M. Trost, I. Fleming, E. Winterfeldt), Pergamon, Oxford, (1991), pp. 601–630. 16. C. B. Reese, Org. Biomol. Chem. 3 (2005), pp. 3851–3868. 17. A. Sakakura, M. Katsukawa and K. Ishihara, Org. Lett., 7 (2005), pp. 1999–2002. 18. K. Ishihara, Y. Furuya and H. Yamamoto, Angew. Chem. Int. Ed. 41 (2002), pp. 2983–2986. 19. A. Sakakura, R. Kondo and K. Ishihara, Org. Lett. 7 (2005), pp. 1971–1974. 20. A. Sakakura, S. Umemura, R. Kondo and K. Ishihara, Adv. Synth. Catal. 349 (2007), pp. 551–555. 21. A. Sakakura, R. Kondo, S. Umemura and K. Ishihara, Adv. Synth. Catal. 349 (2007), pp. 1641–1646. 22. A. Sakakura, M. Katsukawa and K. Ishihara, Angew. Chem. Int. Ed. 46 (2007), pp. 1423–1426. 777