* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download New Advances in Catalytic Systems for Conversion of CH4 and CO2

Citric acid cycle wikipedia , lookup

Enantioselective synthesis wikipedia , lookup

Nuclear chemistry wikipedia , lookup

Electrolysis of water wikipedia , lookup

Nucleophilic acyl substitution wikipedia , lookup

Inorganic chemistry wikipedia , lookup

Biochemistry wikipedia , lookup

Acid–base reaction wikipedia , lookup

Cracking (chemistry) wikipedia , lookup

Chemical equilibrium wikipedia , lookup

Asymmetric induction wikipedia , lookup

Marcus theory wikipedia , lookup

Rate equation wikipedia , lookup

Multi-state modeling of biomolecules wikipedia , lookup

Electrochemistry wikipedia , lookup

Water splitting wikipedia , lookup

Chemical thermodynamics wikipedia , lookup

Ring-closing metathesis wikipedia , lookup

Physical organic chemistry wikipedia , lookup

Chemical reaction wikipedia , lookup

Metalloprotein wikipedia , lookup

Artificial photosynthesis wikipedia , lookup

Photosynthetic reaction centre wikipedia , lookup

Deoxyribozyme wikipedia , lookup

Process chemistry wikipedia , lookup

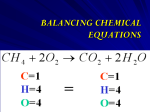

Stoichiometry wikipedia , lookup

George S. Hammond wikipedia , lookup

Evolution of metal ions in biological systems wikipedia , lookup

Catalytic reforming wikipedia , lookup

Bioorthogonal chemistry wikipedia , lookup

Click chemistry wikipedia , lookup

Photoredox catalysis wikipedia , lookup

Strychnine total synthesis wikipedia , lookup

Transition state theory wikipedia , lookup

Hydroformylation wikipedia , lookup

Hydrogen-bond catalysis wikipedia , lookup

Supramolecular catalysis wikipedia , lookup

Journal of Natural Gas Chemistry 11(2002)109–116 New Advances in Catalytic Systems for Conversion of CH4 and CO2 Gengliang Chen∗ Research Institute of Natural Gas Technology, Southwest Oil and Gas Field Company, Petro-China [Manuscript received June 25, 2002; revised September 30, 2002] Abstract: One of the main goals for developing the C1 chemical industry is the direct conversion of methane and carbon dioxide to useful products. To realize this goal, researches on new catalytic systems are being globally focused. The exploration has been evolved from traditional heterogeneous catalysis into homogeneous catalysis. Coordinate complexes, biochemical and bionics, and photo- and electrochemical catalysis have been extensively studied in recent years. Tests in laboratories have verified for the direct conversion of CH4 to CH3 OH that single-pass converstion of CH4 can reach over 70% in both Hg(II) salt and Pt(II) complex systems. The main problem of these systems is the obstacles involving reaction kinetics, so they must be solved before moving to pilot tests. Other catalytic systems discussed in the present article include explorations in the early stage. Among them, features of photo and enzymatic catalyst systems, such as mild reaction conditions, better selectivity and environmentally friendliness have been explored, and these researches are significant both in theory and in practical application. Key words: methane, carbon dioxide, methanol, acetic acid, homogeneous catalysis, photocatalysis, bionics catalysis, enzymatic catalysis 1. Introduction The C1 chemical industry has made remarkable progress in the 20th century and become an important branch of the petrochemical industry. The main achievements in this area can be summarized into three phases: (1) the syngas manufacturing processes for natural gas; (2) liquid phase carbonylation technology of CH3 OH and related homogeneous catalysis systems; (3) indirect conversion of C1 raw materials to C2 H4 , C2 H5 OH, CH3 COOH and liquid fuels via syngas. As a whole, the basis of the above achievements is the syngas manufacturing technology. Since the 1970’s, the syngas manufacturing technology has also been developed with a greater pace, but it is still considered as a high investment as well as high energy consuming process. On the other hand, studies on new processes for the direct conversion of CH4 to CH3 OH or C2 H4 , such as oxidative coupling of ∗ Corresponding author. CH4 to C2 H4 and the selective oxidation of CH4 to CH3 OH/HCHO, etc., have only made some progress in thermodynamics and kinetics, but the speed of engineering development is very slow during the past 20 years. Since the C-H bonds in CH4 is known to be the least reactive ones, and the desired oxidation products are much more active than the raw material, they are consumed before recovery, making products separation and by-products recovery very difficult. Furthermore, the greenhouse effect on global environment is going from bad to worse due to the extra discharge of CO2 , so that direct conversion of CO2 to useful products becomes another major exploration. Consequently, one of the main goals for developing C1 chemical industry is the direct conversion of CH4 and CO2 to useful products in the new era. For the realization of the goal mentioned above, researches on new catalytic systems are internationally focused at present. The exploration has 110 Gengliang Chen et al./ Journal of Natural Gas Chemistry Vol. 11 No. 3–4 2002 been evolved from traditional heterogeneous catalysis into homogeneous catalysis, and coordinate complex, biochemical and bionics, photo and electrochemical catalysis have been studied extensively (Table 1). Meantime, results from theoretical calculations of catalytic reactions by methods of quantum chemistry can Table 1. Direct conversion of CH4 and CO2 2. Homogeneous catalysis systems of transition metal salts and their coordinate complexes The studies for the activation of the C-H bonds in CH4 with the titled new catalytic systems have made great progress in C1 chemical industry since the 1980’s. At first, Pd(II) was selected as the catalyst. Kao et al. [1] suggested a homogeneous system using Pd(II) as the catalyst and H2 O2 as initiator in a CF3 COOH (TFA) medium for oxidizing CH4 to CH3 OH in 1991. Under 80 and 5.5 MPa of CH4 pressure, the single-pass yield might reach over 60% in one hour . The main problem for this reaction is that further oxidation of CH3 OH cannot be controlled (Equation (1)). CH4 + H2 O2 −→ CH3 OH + H2 be matched to those from laboratory tests in certain extent, because of the great progress in surface chemistry and related techniques of analysis and measurement, which may be beneficial to the design and verification of special catalytic systems. Some of these systems will be discussed as follows. (1) Periana et al. [2] suggested other homogeneous catalyst systems using Hg(II) salts as the catalyst and SO3 as the oxidant in a concentrated H2 SO4 medium in 1993. The reaction of CH4 to CH3 OH undergoing directly in concentrated H2 SO4 at 180 is catalyzed by Hg(OSO3 H)2 , and CH3 OSO3 H (methyl sulfate) is formed. The CH3 OSO3 H is further hydrolyzed to produce CH3 OH and the by-product SO2 is re-oxidized for circulation. Tests of this reaction on a 1 L scale unit showed that CH4 conversion of 50%, selectivity of 85% (to methanol) and single-pass yield of >42% were obtained [2]. The overall reaction equations can be expressed as Equations (2) and (3). Recently, Gang et al. [3] have reported that the single-pass yield of this reaction can reach as high as 70% under similar conditions. CH4 + 2H2 SO4 −→ CH3 OSO3 H + 2H2 O + SO2 (2) CH3 OSO3 H + H2 O → CH3 OH + H2 SO4 (3) Nowadays most of the researchers consider the activation of the C-H bonds in methane is a radical reaction, but there are quite different mechanisms involved in the above process of oxidizing CH4 to CH3 OH. Pariana et al. proposed that the catalytic cycle can be mainly separated into 3 steps. First, a C-H bond is attacked electrophilically by the Hg(OSO3 H)2 and the intermediate CH3 HgOSO3 H is formed in this activation step. Then, CH3 HgOSO3 H reacts with concentrated H2 SO4 to produce CH3 OSO3 H and Hg2 (OSO3 H)2 in the functionalization step. Finally the Hg2 (OSO3 H)2 is re-oxidized by concentrated H2 SO4 , and Hg(OSO3 H)2 with the original catalytic activity is regenerated in the re-oxidation step. The proposed reaction mechanism is shown in Figure 1. 111 Journal of Natural Gas Chemistry Vol. 11 No. 3–4 2002 Many transition metal coordinate complexes are studied due to the poisonous effects of the conventional mercury catalysts. In 1998, Periana et al. reported a catalysis system of activating the C-H bond in concentrated H2 SO4 , with a Pt-complex at 180 and the single-pass yield of CH4 to CH3 OH reached over 70%, leading to a new breakthrough in this research area [4]. be the re-oxidation of the catalyst (Equation (5)). Kinetic analyses on the oxidation of the solution of methyl bisulfate show that the rate constant for the oxidation of methane is at least 100 times greater than that for methyl bisulfate. (bpym)Pt(II)Cl2 + 3H2 SO4 −→ (bpym)Pt(IV)Cl2 (HSO4 )2 + SO2 + H2 O (5) Figure 1. Proposed reaction mechanism for the Hg(II) salt catalysis system. Earlier, they used simple Pt-amine complexes as the catalysts, such as soluble cis- or transPt(NH3 )2 Cl2 . But under the reaction conditions, the irreversible protonation of the NH3 ligands in these complexes will occur, resulting in the formation of insoluble PtCl2 (Equation (4)), and the half-life of the catalysts is only about 15 min in the concentrated H2 SO4 medium at 180 . Pt(NH3 )2 Cl2 + 2H2 SO4 −→ (PtCl2 )n ↓ +2NH4 HSO4 (4) Further investigations on N-based ligands led to the discovery that pyrimidine with high affinity to Pt is an ideal catalyst system. As shown in Figure 2, the complex dichloro-(2,2-bipyrimiyl)Pt(II) [(bpym)PtCl2 ] is still stable in 20% oleum at 200 for 50 h. The reaction of methane (3.4 MPa, 115 mmol) with 80 ml of 102% H2 SO4 containing a 50 mM concentration of (bpym)PtCl2 at 220 for 2.5 h resulted in ∼90% methane conversion and the formation of a ∼1M solution of methyl bisulfate at 81% selectivity. The overall reaction equations are similar to Equations (2) and (3). As shown in Figure 2, the oxidation reaction also includes 3 steps. Since the reaction rates of both the activation and functionalizition are much faster than that of re-oxidation, the rate-limiting step would Figure 2. Proposed catalytic cycle (bpym)PtCl2 complex. for the Now another new catalytic reaction of interest is the direct carbonylation of CH4 to CH3 COOH (Equation (6)). Further investigation according to Equation (1) in a TFA medium at 100 revealed that CuSO4 /K2 S2 O8 or Pd(II)/H2 O2 systems can catalyze the reaction of CH4 with CO (or CO2 ) to produce CH3 COOH (or CH3 COOH and CH3 OH). Even though the single-pass yield of this reaction is still very low, it dose develop a new route for converting C1 raw materials to C2 products directly [5]. Although there are arguments about the mechanism of Equation (6), most of the researchers consider that it is a radical reaction (see Figure 3). 112 Gengliang Chen et al./ Journal of Natural Gas Chemistry Vol. 11 No. 3–4 2002 CH4 + CO −→ CH3 COOH (6) Figure 3. Proposed mechanism for Equation (6). 3. Transition metals and their coordinate complexes via photocatalysis In 1997, Bromberg et al. observed with timeresolved ultra-fast IR spectroscopy that the complex CpRhCO was formed from Rh-complex CpRh(CO)2 [Cp = C5 H5 ] under room-temperature and photocatalysis[6], which exhibits high activity when reacting with CH4 . But the yield of CpRhCO is so low that it can not be identified. The mechanism of this reaction is shown in Figure 4(A). Under the same conditions, a yield of about 30% for the activated product is given in the catalysis system of Tp*Rh(CO)2 [Tp*=HB-Pz3*; Pz3 *=3,5-dimethylpyrazolyl]. The mechanism of this reaction is shown in Figure 4(B). As shown in Figure 4, one CO group will be lost from the Rh-complex Tp*Rh(CO)2 under the catalytic action of UV irradiation to form a coordinatively unsaturated (16-electron) complex of Tp*Rh(CO)RH. In the starting material Tp*Rh(CO)2 , three pyrazolyl arms are coordinated to the Rh center, forming an η 3 complex (Figure 4(C)). During the process of photocatalysis, one pyrazolyl arm may be detached from the Rh center and the detached complex would be η 2 (Figure 4(D)). The η 2 complex may further lose a pyrazol ligand under room-temperature and the action of photocatalysis, then a complex with only 2 pyrazol ligands, Bp*Rh(CO)2 [Bp*=H2B-Pz2*], is formed, as shown in Figure 4(D). Figure 4. C-H bond activation catalyzed by Rh-complexes. By monitoring the C-H bond activation reaction of alkanes catalyzed by Rh-complexes in a solution at room-temperature, it can be shown that the final breaking of the C-H bond will occur in 230 ns after the action of photocatalysis in cyclohexane. Before the bond can be broken, the Tp*Rh(CO)2 complex must dissipate its initial excess vibrational energy and then breaks one of the Rh-bonds. Immediately following the rate-limiting C-H bond-activation step, the Rh-N bond will rearrange to stabilize the final product. These steps before and after activation provide the structural and electronic environment around the metallic center that allows the reaction to occur. The coordinate complexes of Rh(II) and Ru(II) are ideal photosensitive materials. They can absorb light energy to form excited-states, which may be used for capturing and storing of light energy by electrontransfer reactions, thus leading to the opening of an Journal of Natural Gas Chemistry Vol. 11 No. 3–4 2002 important way for the utilization of solar energy in the future. In 1997, Sutin et al. [7] reported that by using Ru(II)(bpy)3 [bpy = bipyrimidine] as a photosensitizer and Rh(II)(bpy)3 as a catalyst, H2 O can be split into hydrogen and oxygen, and CO2 can be reduced to CH3 OH or CO by photolysis reactions. Triethanolamine or triethylamine is used as an electron donor in this catalytic system. The tests show that transition metal complexes can absorb a significant part of energy of the solar spectrum, and have long-lived excited states. The energy released from the excited-states is used for the splitting of H2 O, and the hydrogen released can reduce CO2 to CH3 OH selectively. Despite that the thermodynamics and kinetics of photoreactions remain unclear in many systems, the value of these systems is of significance for the C1 chemical industry. For this reason, a wide range of investigations for photo-induced reactions has been undertaken in some famous laboratories, such as the Brookhaven National Laboratory, the Lawrence Berkeley National Laboratory, etc. In 1996, Margl et al. [8] also reported that the Rhphosphine complex can catalyze the carbonylation of CH4 with CO directly to produce acetic acid, and the processes of CO migration and insertion were studied in detail by the dynamical density functional theory. Results show that direct carbonylation of CH4 is a complicated reaction that includes 13 steps, but the two rate-limiting steps are CO migration and insertion . 113 soluble non-heme iron enzyme and contains a hydroxlase(MMOH), a reductase(MMOR) and a protein component(MMOB). MMOH is the core component for catalytic oxidation and appears to be basically a kind of spiral structure. It includes three subunits called α-, β-, and γ- chains and a dinuclear iron cluster located on the α-chain. In the cluster, two iron atoms share a common hydroxy binding and each is coordinated by a single histidine and a single nonbinding glutamate. The function of the MMOB is for forming a stable complex with MMOH, so it will obviously affect the activity of MMOH. Kinetic studies indicate that the complex with a stoichiometric ratio of 2 MMOB/MMOH has the optimum reaction rate in catalytic oxidation. The functions of MMOR are in the transferring of electrons to MMOH for its reduction and in the forming of a special complex with the β-chain of MMOH. 4. Enzymatic and bionics catalysis In nature, there are some kinds of bacteria which have the ability to oxidize methane from the metabolism of anaerobic bacteria or other natural sources to satisfy their own needs for energy and carbon. These bacteria have very complicated molecular structure and are an integral part for the functioning of the enzyme. A part of a three-component enzyme called Methane Monooxygenase(MMO) can selectively oxidize CH4 to CH3 OH according to Equation (7). CH4 + NADH(enzyme) + O2 −→ CH3 OH + NAD+ + H2 O (7) Purified MMO was successfully isolated from nature and its crystal structure and the functions of the different components in catalytic oxidation were studied by Elango et al. [9] in 1997. MMO is a Figure 5. The structural changes of dinuclear iron atom in MMOH. In the catalytic oxidation process, the functions of MMOH are similar to those of cytochrome P-450, which can activate the O2 molecule, resulting in the coordination of an inactive C-H bond of CH4 [10]. At the beginning of the catalytic cycle, Fe (III) of the dinuclear iron cluster in MMOH is reduced to Fe (II) by a synergism of both MMOR and MMOB, leading to the forming of an active center and an intermediate (P). After the O2 molecule is broken up, water and FeO active species (Q) with the ability to cleave the C-H bond catalytically are formed at the same time. The C-H bond in CH4 is activated by the active species Q, and CH3 OH is produced at last. The two iron atoms 114 Gengliang Chen et al./ Journal of Natural Gas Chemistry Vol. 11 No. 3–4 2002 in the cluster are re-oxidized to the original state of Fe (III), whereas the CH3 OH is detached from the active center. The species Q has a dinuclear iron cluster [Fe2 (IV) O2 ] with a kind of diamond core structure and plays a key role in selective oxidation[11]. Based on a radical mechanism, the structural changes of the cluster in MMOH are shown in Figure 5. According to knowledge gained from the research of natural enzymes, chemically mimic MMO has been widely investigated since 1990’s. Although many different kinds of mimic enzymes have the ability to activate the C-H bond in methane to a certain extent, a rule manifests that the more similar a structure it has, the higher oxidative activity it exhibits. Therefore, small molecular models of the mimic enzyme with dinuclear iron cluster has been focused in recent years. At present, a mimic enzyme with good activity has been synthesized by Lee and his co-workers[12]. They described this synthetic model compound as that which has at its active center two Fe (III) atoms connected to each other by two hydroxy bridging groups and a carboxylate bridge. In the meantime, the bulky terphenyl-based carboxylate ligands are utilized to simulate more generally the steric effects of the protein component in the natural enzyme. Recently the concept of bionics catalysis has also been used for the reduction of CO2 to CH3 COOH selectively [13]. On the earth, the origin of life requires the formation of C-C bonds under primordial conditions which consisted mostly of an unproductive mixture of CO2 , N2 and H2 O, with only traces of molecular hydrogen. An alternate theory considers that life has a chemoautotrophic origin. According to this postulation, the earliest bacteria fed on CO2 and their metabolism were initiated by the reductive formation of methyl mercaptan(CH3 SH) and its subsequent carbonylation to activated thioacetic acid (CH3 -CO-SH), akin to the reductive acetyl-coenzyme A (CoA) pathway. The key enzyme in this pathway, acetyl-CoA synthane, contains an [Ni-Fe] reaction center and can catalyze reactions for the synthesis of acetic acid. The net reaction (Equation (8)) may be summarized as follows: CH3 SH + CO + H2 O −→ CH3 COOH + H2 S (8) As mentioned above, there is a genus of acetogenic bacteria in nature, and they can convert CO into acetic acid. This process requires a number of enzymes and co-factors that contains transition met- als of Fe, Ni, Mo and Co. The first step is the oxidation of hydrogen to supply the reducing equivalents to drive the process, then this reaction is catalyzed by hydrogenase. The [Ni-Fe] hydrogenase is an example of such kind of enzymes, and it has an interesting bimetallic cluster at its active site. The structure of the cluster is solved by Volbeda et al.(see Figure 6), which will be taken as the basis of bionics catalysis for Equation (8). Moreover, the sulfur-rich coordinate environment observed for the [Ni-Fe] hydrogenase is a common element amongst the enzymes involved in CO2 metabolism. Figure 6. Bimetallic cluster at the [Ni-Fe] hydrogenase active site. Not only the MMO and the like exist in the carbon cycle of nature, but also the enzymes with the ability for the reduction of CO2 to CH4 . So, it is possible to reduce CO2 to CH3 OH if the conditions are suitable. In view of this consideration, Obert et al. reported an enzymatic coupled sequential reduction of CO2 to CH3 OH by using a series of reductions catalyzed by three different enzymes in 1999 [14]. Overall, the process involves an initial reduction of CO2 to formate catalyzed by formate dehydrogenase (FDH), followed by reduction of formate to HCHO by formaldehyde dehydrogenase (FADH), and finally formaldehyde is reduced to CH3 OH by alcohol dehydrogenase (ADH). In this process, reduced nicotinamide adenine dinucleotide (NADH) is used as a terminal electron donor for each dehydrogenasecatalyzed reduction. The overall process is shown in Equation (9). CO2 −→ HCOOR −→ HCHO −→ CH3 OH (9) Two reaction systems were studied by Obert et al. One was in the solution phase by using an enzyme stock solution and the other was sol-gel encapsulated samples prepared by using the biocompatible synthesis method. The results from these two systems are shown in Table 2. The results listed above show primary possibilities of producing CH3 OH using CO2 as a raw material by enzymatic catalysis. However, methanol production by the use of enzymes is not economical or time saving unless a reasonable way to regenerate the 115 Journal of Natural Gas Chemistry Vol. 11 No. 3–4 2002 NADH can be found, or a way for providing electrons to the chemically mimic enzymes, and discerning the Table 2. NAD (µmol) optimal conditions for large enzymatic production of methanol. Relative Comparison of Methanol Production in Solution and in Sol-Gel Solution MeOH (µmol) MeOH/ NADH Sol-gel yielda (%) MeOH (µmol) MeOH/ NADH yielda (%) 50 1.3 ± 0.7 0.02 7.8 15.2 ± 0.4 0.30 91.2 100 7.0 ± 0.9 0.07 21.0 26.6 ± 0.6 0.26 79.8 150 10.2 ± 0.6 0.07 20.4 28.5 ± 0.7 0.19 57.0 200 11.2 ± 0.9 0.05 16.8 29.2 ± 0.6 0.15 43.8 a yield = moles of MeOH/0.33 (moles of NADH). 5. The reaction of CO2 with CH4 to produce acetic acid The direct carboxylation of methane is a reaction with potentially tremendous values not only for C1 chemical industry, but also for environmental protection. It may provide a brand new way to reduce the discharging of CO2 by way of reacting CO2 with CH4 to produce acetic acid directly. Since 1998, a research project for the reaction of CO2 with CH4 to produce acetic acid has been underway in the University of North Carolina, which is sponsored by the U.S. Environment Protection Agency [15]. The results from diffuse reflectance infrared fourier transfer spectroscopy (DRIFTS) show that the peaks of acetic acid occur in the spectrum for the reaction of equal moles of CH4 and CO2 on a heterogeneous catalysis system of 5% Pt/charcoal. This implied that the synthesis reaction of acetic acid in the system can be given as in Equation (10). CH4 (g) + CO2 (g) ←→ CH3 COOH(g) (10) Using the minimum free energy method, thermodynamic analysis on Equation (10) for a mixture of 5% CH4 and 95% CO2 indicates that the equilibrium yield of acetic acid will increase with higher temperature and pressure. But the CH4 conversion is only 1.6 ppm at 1000 K and 15 MPa, which means that a serious thermodynamic limitation does exist in the reaction at industrial conditions for the Equation (10). Recently researches have been focused on the utilizing of second reactions which are favorable thermodynamically and kinetically in the system. The produced acetic acid can then be removed continuously from the system by the second reaction, resulting in the shifting of the equilibrium to the direction of producing acetic acid. The second reaction listed in Equation (11) is an example for producing methyl ac- etate. Results from calculation indicate that the CH4 conversion can be raised to 200 ppm when both of Equation (10) and Equation (11) exist in the reaction system simultaneously. However, the low conversion in CH4 implies that a big limitation still exists. CH4 (g) + CO2 (g) + CH3 OH(g) ←→ CH3 COOCH3 (g) + H2 O(g) (11) Then, production of ethylene acetate according to Equation (12) is studied as a second reaction. Results from calculation for a stoichiometric mixture of CH4 , CO2 and C2 H2 indicate that the CH4 conversion according to Equation (12) increases with lower temperatures and higher pressures. The CH4 conversion can reach 0.983 at 300 K and 15 MPa and 0.971 at 300 K and 0.5 MPa, respectively. Very high conversion of CH4 can be reached only if there is a liquid phase in the system. In the gas phase reaction, the CH4 conversion will rapidly decrease, so it is only 0.0025 at 305 K and 0.5 MPa. CH4 (g) + CO2 (g) + C2 H2 (g) ←→ CH3 COOC2 H3 (g) (12) Presently the development of related catalysis systems for the reactions mentioned above is underway actively and the mechanism of the reactions in the catalytic cycle is also proposed. 6. Conclusion (1) For the sake of changing the situation of syngas processes associated with C1 chemical industry and reducing extra discharges of CO2 , studies for converting CH4 and CO2 directly into useful products become “hot spots”of exploration globally. (2) For the realization of the above goals, the main direction of exploration is placed on different kinds of 116 Gengliang Chen et al./ Journal of Natural Gas Chemistry Vol. 11 No. 3–4 2002 new catalytic systems. As a whole, researches have already shifted from the traditionally heterogeneous systems into homogeneous systems. Among them, more attention is paid to the transition metal salts and their coordinate complexes, photocatalysis, and enzymatic and bionics catalysis. (3) Tests in laboratory have verified that single pass yield of methanol from direct oxidation of methane can reach over 70% in both Hg(II) salt and Pt(II) complex systems. Although the reaction medium and the oxidant have strong corrosiveness, the process may be fulfilled under industrial conditions at present. The serious problem is the obstacle in reaction kinetics, so it must be solved before coming to pilot tests. (4) The other catalytic systems discussed in this article are still in the early stage of exploration. Among them, the features of photo and enzyme catalytic systems are mild reaction conditions, better selectivity and environmentally friendly, so they are potentially valuable both theoretically and practically. (5) It must be pointed out that the engineering of homogeneous systems has made some progress since the process of liquid phase carbonylation of methanol was put into production. New advances on supercritical fluid reactions, fluorous biphasic catalysis and ultrafiltration for catalyst recovering, etc., may provide necessary technical means to realize the goals mentioned above in the future. References [1] Kao L C, Hutson A C, Ayusman S et al. J Am Chem Soc, 1991, 113: 700 [2] Periana R A, Taube D J, Evitt E R et al. Science, 1993, 259: 340 [3] Gang X, Birch H, Zhu Y M et al. J Catal, 2000, 196(2): 287 [4] Periana R A, Taube D J, Evitt E R et al. Science, 1998, 280: 560 [5] Lin M, Sen A. Nature, 1994, 368: 613 [6] Bromgerg S E, Yang H, Asplund M C et al. Science, 1997, 278: 269 [7] Sutin N, Brunschwig B S, Creutz C et al. Comments Inorg Chem, 1997, 19: 67 [8] Margl P, Ziegler T, Blöchl P E et al. J Am Chem Soc, 1996, 118: 5412 [9] Elango N, Radhakrishnan R, Froland W A et al. Protein Science, 1997, 6: 556 [10] Que Jr L, Watanaba Y. Science, 2001, 292: 651 [11] Shu L, Nesheim J C, Kauffman K et al. Science, 1997, 275: 515 [12] Lee D, Lippard S J. J Am Chem Soc, 2001, 123: 4611 [13] Marr A C, Spencer D J E, Schroder M. Coord Chem Rev, 2001, 219: 1055 [14] Obert R, Dave B C. J Am Chem Soc, 1999, 121: 12192 [15] Wilcox E, Gogate M R, Spivey J J, Roberts G. Stud Surf Sci Catal, 2001, 136: 42