* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Flow-through electroporation based on constant voltage

Survey

Document related concepts

Transcript

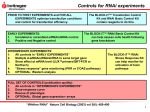

Contents lists available at ScienceDirect Journal of Controlled Release j o u r n a l h o m e p a g e : w w w. e l s ev i e r. c o m / l o c a t e / j c o n r e l Flow-through electroporation based on constant voltage for large-volume transfection of cells Tao Geng a, Yihong Zhan a, Hsiang-Yu Wang b, Scott R. Witting c, Kenneth G. Cornetta c, Chang Lu a,d,e,⁎ a Department of Agricultural and Biological Engineering, Purdue University, West Lafayette, IN 47907, USA Department of Chemical Engineering, National Cheng Kung University, Tainan City 701, Taiwan Department of Medical and Molecular Genetics, Indiana University, Indianapolis, IN 46202, USA d Weldon School of Biomedical Engineering, Purdue University, West Lafayette, IN 47907, USA e School of Chemical Engineering, Purdue University, West Lafayette, IN 47907, USA b c a r t i c l e i n f o Article history: Received 2 December 2009 Accepted 5 January 2010 Available online 29 January 2010 Keywords: Transfection Electroporation Disposable device Constant voltage Large volume a b s t r a c t Genetic modification of cells is a critical step involved in many cell therapy and gene therapy protocols. In these applications, cell samples of large volume (108–109 cells) are often processed for transfection. This poses new challenges for current transfection methods and practices. Here we present a novel flow-through electroporation method for delivery of genes into cells at high flow rates (up to ∼ 20 mL/min) based on disposable microfluidic chips, a syringe pump, and a low-cost direct current (DC) power supply that provides a constant voltage. By eliminating pulse generators used in conventional electroporation, we dramatically lowered the cost of the apparatus and improved the stability and consistency of the electroporation field for long-time operation. We tested the delivery of pEFGP-C1 plasmids encoding enhanced green fluorescent protein into Chinese hamster ovary (CHO-K1) cells in the devices of various dimensions and geometries. Cells were mixed with plasmids and then flowed through a fluidic channel continuously while a constant voltage was established across the device. Together with the applied voltage, the geometry and dimensions of the fluidic channel determined the electrical parameters of the electroporation. With the optimal design, ∼ 75% of the viable CHO cells were transfected after the procedure. We also generalize the guidelines for scaling up these flow-through electroporation devices. We envision that this technique will serve as a generic and low-cost tool for a variety of clinical applications requiring large volume of transfected cells. © 2010 Elsevier B.V. All rights reserved. 1. Introduction Advances in cell biology have been generating knowledge on genes, proteins and their involvement in cell development, differentiation and malignancy. Enabled by such knowledge, genetically modified cells with enhanced functions have emerged as promising materials in cell-based therapies such as cancer immunotherapy [1,2], stem cell therapy [3,4] and tissue regeneration [5]. Genetic engineering of cells provides an approach for rational design of biomaterials that can be implanted into patients. Gene transfer using viral vectors is generally considered the most efficient transfection method [6]. However, several limitations have been hindering its use. Among others, the complex cloning strategies and host inflammatory and immune responses have been most challenging [7]. Chemicals such as calcium phosphate, liposome, cationic polymers and peptides have been used for transfection, yet results can be variable and heavily influenced by the time of transfection, the type of construct and the cell type [8–11]. Furthermore, there have been reports suggesting that ⁎ Corresponding author. Present address: Department of Chemical Engineering, Virginia Tech, Blacksburg, VA 24061, USA. E-mail address: [email protected] (C. Lu). 0168-3659/$ – see front matter © 2010 Elsevier B.V. All rights reserved. doi:10.1016/j.jconrel.2010.01.030 delivery reagents may contribute to alternations in gene expression and other phenotypic changes [12]. Chemical transfection is not efficient with most primary cells due to the fact that most primary cells divide very slowly if at all. Finally, all the above transfection methods suffer from low efficacy and poor reproducibility when scaled up. Clinical trials in the context of cell therapies routinely require transfected cell samples at the order of ∼ 109 cells per trial. For example, autologous stem cell transplantation (“bone marrow transplantation”) is a commonly performed procedure and has been explored for a variety of gene therapy applications. Stem cell dosing in these application use CD34+ enriched progenitor cells given at a target dose of 5 × 106 cells per kg recipient weight. Allowing a purity of 50% of the enriched cells, and an estimated adult weight of 100 kg, an average transplant requires 109 cells. Transfection technologies for processing large volumes of cells at this scale have been seriously lacking. Electroporation is the most widely-used physical method for delivering genes into cells [13–15]. Electroporation creates pores in the cell membrane that permit gene entry by applying an external electric field. Electroporation occurs when the transmembrane potential exceeds a critical threshold value (∼ 0.25–1 V). The transmembrane potential (ΔψE) is determined by ΔψE = 0.75 g(λ)aE GENE DELIVERY Journal of Controlled Release 144 (2010) 91–100 GENE DELIVERY 92 T. Geng et al. / Journal of Controlled Release 144 (2010) 91–100 cosθ, where g(λ) is a complex function of the membrane and buffer conductivities, a is the diameter of the cell, E is the field strength and θ is the angle between the normal to the membrane surface and the field direction [16]. Compared to viral, chemical, and liposome-based gene transfection methods, electroporation offers several important advantages: high transfection efficiency for primary cells, reduced safety concerns, simple operation, and little cell-type dependency [17–19]. Electroporation (or electrofusion) has been investigated at both macro [20–22] or micro scales [23–39]. All available electroporation-based transfection methods require the use of specialized pulse generators to produce short electrical pulses at high voltage [20,21,24,27]. These pulse generators significantly increase the equipment cost and the logistic burden. Moreover, most commercial electroporators work in batch mode and each batch is restricted to a small volume of sample (∼ 1 mL or ∼ 106 cells). Electroporation techniques based on simple and low-cost equipment for large-volume transfection have not been demonstrated yet. In this work, we demonstrate high-efficacy (up to ∼ 75% transfection efficiency) and high-throughput (up to ∼ 20 mL/min) transfection of Chinese hamster ovary (CHO) cells based on flowthrough electroporation under constant voltage in fluidic channels with alternating wide and narrow sections that are fabricated on lowcost chips. These results represent a dramatic improvement on our early demonstration of flow-through electroporation with a transfection efficiency <20% and a throughput <0.1 mL/min [40]. The current performance of our devices puts the technology into the useful range for clinical therapies requiring large volume of transfected cells. We discuss the design of these flow-through electroporation devices for large-volume cell transfection and the general guidelines for scaling up flow-through electroporation devices. These disposable chip devices, together with affordable and common instruments including a syringe pump and a DC power supply, provide a compelling solution to large-volume transfection of cells at low cost. Such technology will pave the way for future testing and implementation of cell therapy procedures. the observation of transfection. It was amplified in E. coli and purified using the QIAfilter Plasmid Giga Kit (Qiagen, Valencia, CA) according to the manufacturers instructions. The plasmid DNA was then dissolved in Tris-EDTA buffer and stored at −20 °C until use. The DNA concentration was determined by UV absorbance at 260 nm. The OD 260/280 nm ratios were always between 1.8 and 2.0. 2.3. Cell culture CHO-K1 cells (ATCC, Rockville, MD) were used for gene transfection. Cells were maintained in Dulbecco's modified Eagle's medium (DMEM, Mediatech, Herndon, VA) supplemented with 10% fetal bovine serum (Sigma, St. Louis, MO), 2 mM L-glutamine (Sigma), 100 U/mL penicillin and 100 mg/mL streptomycin (Sigma) at 37 °C in a humidified incubator containing 5% CO2. Cells were subcultured every 2 days at a ratio of 1:10. 2.4. Flow-through electroporation The inlet end of the device was connected to a syringe pump (PHD infusion pump, Harvard Apparatus, Holliston, MA) through plastic tubing. Two platinum wire electrodes were inserted into the inlet and outlet reservoirs through the PDMS layer and connected to a constant voltage power supply, as depicted in Fig. 1. The channel was flushed with electroporation buffer solution (8 mM Na2HPO4, 2 mM KH2PO4, 1 mM MgSO4·7H2O and 250 mM sucrose, pH 7.4) for 5 min to condition the channel and remove impurities. The electroporation 2. Materials and methods 2.1. Chip fabrication The devices were fabricated using standard soft lithography technique described in our previous studies [40,41]. Briefly, photomasks were first created based on the microscale patterns designed by computer-aided design software (FreeHand MX, Macromedia, San Francisco, CA) and printed on high-resolution (5080 dpi) transparencies. Masters were made of negative photoresist SU-8 2025 (for channels ≤ 80 μm in the depth) and SU-8 2150 (for channels ≥240 μm in the depth) (MicroChem Corp., Newton, MA) spun on 3 inch silicon wafers (University Wafer, South Boston, MA). A layer (∼5 mm thick) of polydimethylsiloxane (PDMS, General Electric Silicones RTV 615, MG chemicals, Toronto, Canada) prepolymer mixture with a mass ratio of A:B = 10:1 was poured onto the master and baked at 80 °C for 1 h. The cured PDMS replica was then peeled off and punched to produce inlet and outlet. Glass slides were cleaned in a basic solution (H2O: 27% NH4OH: 30% H2O2 = 5: 1: 1, volumetric ratio) at 75 °C for 3 h and then rinsed with DI water and blown dry. After PDMS and a pre-cleaned glass slide were oxidized in a plasma cleaner (Harrick Plasma, Ithaca, NY), the PDMS was immediately brought into contact against the slide to form closed channels. Finally, the whole device was baked at 80 °C for another 30 min to ensure strong bonding between PDMS and glass. 2.2. Plasmid preparation The pEGFP-C1 plasmid (4.7 Kb, Clontech, Palo Alto, CA) encoding enhanced green fluorescent protein (EGFP) was chosen to facilitate Fig. 1. The flow-through electroporation device and its setup. A flow-through electroporation chip with 5 narrow/electroporation sections is shown here. A mixture of cells and plasmids in the electroporation buffer is introduced into the channel through plastic tubing. A power supply connected to platinum electrodes provides a constant voltage. The fluidic channel in the chip has wide sections (of a width of W1 and a total length of L1) and narrow sections (of a width of W2 and a total length of L2). The inset images show phase contrast (left panel) and fluorescent (right panel) images of cells transfected by pEGFP-C1 using our device. The images were taken at 48 h after electroporation in a device with 5 narrow sections. The drawing is not to scale. buffer was prepared with ultrapure (18 MΩ) water and filtered through 0.2 μm filters prior to use. The harvested cells were washed in the electroporation buffer by centrifuging at 300 g for 5 min, resuspended in the electroporation buffer containing 40 μg/mL of pEGFP-C1 plasmids at a density of 2 × 106 cells/mL, and incubated on ice. The cell/plasmid mixture was subsequently flowed through the device for electroporation while the voltage across the channel was on. The throughput for processing cells (the number of cells per unit time) can be calculated using W2 × H2 × L2 × 2 × 106/T2 (H2 is the depth of the narrow sections). During electroporation, the sample was collected from the outlet and transferred to a 96, 24 or 6 well plate containing fresh DMEM medium. The cells were then cultured at 37 °C in a humidified incubator containing 5% CO2. 2.5. Transfection and viability assays Cells were examined at 48 h after transfection to evaluate the expression of EGFP and cell viability. The samples were centrifuged at 300 g to settle the floating cells to the bottom of the wells. Medium was aspirated, and cells were gently rinsed with PBS. Afterward, cells were stained with 1 μg/mL of propidium iodide (PI, Invitrogen, Carlsbad, CA) in PBS for cell viability assay. After the samples were incubated in the dark for 20 min at room temperature, both phase contrast and fluorescent images of cells were captured at 10 different locations in each sample using an inverted fluorescence microscope (IX-71, Olympus, Melville, NY) equipped with a 20× dry objective and a CCD camera (ORCA-285, Hamamatsu, Bridgewater, NJ). A population of 1500–2000 cells was enumerated in each sample to determine the transfection efficiency (the percentage of cells expressing EGFP among the viable cells), cell viability (the percentage of viable cells among the total cells) and transfection yield (the percentage of cells expressing EGFP among the total cells). Every data point was based on three experimental trials. The transfection efficiency, cell viability and transfection yield were calculated by the following equations: Transfection Efficiencyð%Þ = ðG = V Þ × 100% Cell Viabilityð%Þ = ðV = T Þ × 100% Transfection Yieldð%Þ = ðG = T Þ × 100% where G = the number of cells expressing EGFP; V = the number of viable cells (cells without PI staining); T = the total number of cells observed. 3. Results and discussion A typical flow-through electroporation device and its setup are illustrated in Fig. 1. The fluidic channel has a number of alternating wide and narrow sections. The electrical field strength in each section is inversely proportional to the width of the section (the depth of the entire channel is uniform) (E2/E1 = W1/W2) when a constant DC voltage is established across the channel [41]. With appropriate combination of the overall voltage and the channel geometry, only the field intensity in the narrow section(s) E2 is higher than the threshold for electroporation. Cells experience pulse-like electrical field variation(s) while flowing through the channel. The number of the narrow sections determines the number of times that cells are exposed to the electroporation field. The devices can be scaled up to handle highvolume cell samples by increasing the cross-sectional areas of different sections of a channel equally. In a transfection procedure based on flow-through electroporation, the power supply and the syringe pump form the capital equipment and the disposable fluidic chips are the consumable. The cost of the capital equipment in this setup can be easily lower than US$1000 and the unit manufacturing cost of the disposable chip is lower than US$1. The use of a constant voltage in our method is particularly suitable for flow-through and 93 continuous production of transfected cells. Such simple requirement eliminates the need for high frequency and consecutive pulses with consistent parameters. 3.1. Effects of the low field in the wide sections on transfection One important advantage of our flow-through electroporation technique is that the sequence of the electric field variations (equivalent to the pulse pattern in electropulsation) can be conveniently adjusted by altering the geometry of the channel. The combination of high-intensity and low-intensity pulses has been found to produce the optimal transfection efficiency [42–46]. It was suggested that after the high intensity pulses create pores in the membrane and have DNA molecules bound to the cell surface, low intensity pulses can electrophoretically transport DNA molecules deep into the cells. In this study, we systematically investigated the effects of the low field in the wide sections on transfection by varying the residence time and field intensity in wide sections. Using smallscale devices with 5 narrow sections (with a cross section for the narrow sections at 53 µm × 70 µm), we varied the total residence time in the 6 wide sections from 0.18 to 3.22 s by changing the lengths of the wide sections and the field intensity in the wide sections from 1/11 to 1/5 of that in the narrow sections by altering the ratio in the width (narrow/wide). In these experiments, we used the same flow rate and narrow section dimensions to keep the total residence time in the narrow sections at 2 ms (0.4 ms in each). Fig. 2a shows that the transfection efficiency increased substantially with higher field strength in the narrow sections and longer residence time in the wide sections. When the total residence time in the wide sections (T1) were 0.82, 1.62 and 3.22 s, the transfection efficiency was substantially higher than that of shorter residence times (0.18 and 0.42 s). The difference made by longer residence times was not significant when the residence time was beyond 0.82 s. In the best case, we were able to achieve a transfection efficiency of ∼ 48% and this essentially doubled the transfection efficiency presented in our previous report [40] when we used similar residence times in the narrow sections but very short residence times in the wide sections (10–20 ms). As shown in Fig. 2b, when the residence time in the wide sections was shorter than 0.42 s, more than 90% of cells remained viable at all field intensities. Greatly reduced cell viability was observed with longer residence times in the wide sections (≥0.82 s). The cell viability reached ∼62% at the longest wide section with a residence time of 3.22 s when the field intensity was 800 V/cm in the narrow sections and 72 V/cm in the wide sections. The transfection yield was the product of transfection efficiency and cell viability. In Fig. 2c, the transfection yield generally increased with the field intensity and the wide section residence time with the exceptions at the high field intensities (700 and 800 V/cm) and long residence times (3.22 s), due to the high loss in the viability. In comparison to other in vitro works that applied combined high voltage and low voltage pulses [45,46], the optimal low field duration demonstrated in this study (∼several seconds) was roughly 1–2 orders of magnitude longer. This indicates that the low field may be applied for a substantially longer period than in most current protocols in order to improve the transfection efficiency with acceptable tradeoff in the cell viability. We also examined the impact of field intensity in wide sections on the transfection. Devices with different width ratios (W2:W1) of 1:5, 1:8 and 1:11 were used. These geometries determined that the ratios in the field intensity (E2:E1) were 5:1, 8:1 and 11:1 correspondingly. The field intensities in the narrow sections (E2) were identical in these devices. We also adjusted the total length of the wide sections so that the total residence time in the wide sections was set at 1.62 s in all these devices. In Fig. 2d, the transfection efficiency increased with higher field intensity in wide sections when the field intensity (in the narrow sections) was low (E2 ≤ 500 V/cm). The transfection efficiency in the device with an 1:5 ratio was substantially higher than that in GENE DELIVERY T. Geng et al. / Journal of Controlled Release 144 (2010) 91–100 GENE DELIVERY 94 T. Geng et al. / Journal of Controlled Release 144 (2010) 91–100 Fig. 2. The effects of residence time (T1) and field intensity (E1) in the wide sections in small-scale devices with 5 narrow sections. All the devices used in this experiment have the same dimensions for the narrow sections (L2 = 1 mm, separated into 5 equal segments of 200 μm each; W2 = 53 μm). The channel depth is uniformly 70 µm. (a, b, and c) The effects of residence time T1 on the transfection efficiency, cell viability and transfection yield. The residence time T1 was varied from 0.18 to 3.22 s by altering L1 from 3 to 41 mm (separated into 6 wide sections) while W1 (587 μm) was kept constant. (d, e, and f) The effects of field intensity E1 on the transfection efficiency, cell viability and transfection yield. E1/E2 (= W2/W1) was varied by altering W1 from 265 to 587 μm. In order to keep T1 constant at 1.62 s, L1 was varied from 45 to 21 mm accordingly. devices with 1:8 and 1:11 ratios in this range. However, the higher intensities in the wide sections led to drop in the transfection efficiency when the field intensity (E2 in the narrow sections) increased to > 600 V/cm. This is consistent with our previous observation of decreases in gene expression due to excessive heating [40]. Fig. 2e shows that cell viability decreased dramatically with increasing field strength in the wide sections. For example, with a 1.62 s residence time and 100–160 V/cm field intensity in the wide sections, the cell viability was only 35%. Fig. 2f shows that the device with 1:11 ratio presented an optimal overall yield due to its high viability and transfection efficiency at 800 V/cm. 3.2. Scaling up of the devices with a single narrow section In clinical cell therapies involving genetically modified cells, ∼109 cells are needed for each trial. A successful scale-up of the flowthrough electroporation device will be critical for validating the technique for these clinical procedures. Since the physics of our flow- through electroporation technique does not depend on the actual size of the device, the device can be scaled up to any dimensions as desired in principle. In this study, we examined the effects of device size on the transfection results. We first tested devices of different sizes (1×, 20×, 80×, and 320×) with only one narrow section (electroporation section). While keeping the lengths of different sections (1 narrow section of 1 mm; 2 wide sections of 5 mm each) and the width ratio (W2:W1 = 1:10) identical for all the devices, we had various cross-sectional areas for 95 the devices. Devices with scaled-up cross-sectional areas generated the same residence time under larger flow rates, compared to smaller devices. For example, with a residence time of 6.6 ms in the narrow section, a 320× device allowed a flow rate of 4.4 mL/min through the device. We found that longer residence time in the narrow section (T2) was required for larger devices to generate similar transfection efficiency as smaller devices. As shown in Fig. 3a, T2 of 1.1 ms generated reasonable transfection efficiency in 1× devices (∼31%, at E2 = 900 V/cm). However, no noticeable transfection was observed Fig. 3. The scale-up of devices with a single narrow section. All the devices used in this experiment have the same lengths for the narrow section (L2 = 1 mm) and the wide sections (L1 = 10 mm, separated into 2 wide sections) as well as the same width ratio W2:W1 = 1:10. The device size was varied by changing the cross-sectional area of the channel. The dimensions of different devices: 1×: depth = 30 μm, W1 = 500 μm, W2 = 50 μm; 20×: depth = 80 μm, W1 = 3750 μm, W2 = 375 μm; 80×: depth = 240 μm, W1 = 5000 μm, W2 = 500 μm; and 320×: depth = 550 μm, W1 = 8730 μm, W2 = 873 μm. (a, b, and c) The performance of the devices of different sizes varied with the field intensity (E2) and residence time (T2) in the narrow section. The different residence times were realized by adjusting the flow rate. (d, e, and f) The performance of the devices of different sizes varied with the residence time in the narrow section (T2) under the identical field intensity in the narrow sections E2 (800 V/cm). GENE DELIVERY T. Geng et al. / Journal of Controlled Release 144 (2010) 91–100 GENE DELIVERY 96 T. Geng et al. / Journal of Controlled Release 144 (2010) 91–100 using 20–320× devices when the same residence time was used and substantially longer T2 (≥4.4 ms) was needed to achieve half of this transfection efficiency or less in these larger devices. Interestingly, although the transfection efficiency was lower, cells suffered from less death at the high field intensities in larger devices (20, 80 and 320×) than in 1× devices, despite that longer residence times were used in these larger devices (Fig. 3b). The overall transfection yield was still substantially superior in 1x devices to those in 20, 80, and 320× devices due to the high transfection efficiency achieved in 1× devices (Fig. 3c). Although the reasons are not clear, the data suggest that in devices with one narrow section, the scale-up of the device decreased the electroporation effectiveness and the transfection efficiency. Fig. 3d–e show the results obtained when the electroporation field intensity E2 was constant at 800 V/cm. The data confirmed that larger devices required longer residence times in order to have reasonable transfection efficiency. The transfection efficiency in 1× devices was substantially higher than those in larger devices. Such decrease in the efficiency may be related to the changes in the flow pattern and the associated cell motion when the device is scaled up. In principle cell rotation in the flow should improve DNA uptake due to the larger surface area exposed to the electric field. It has been shown that changing orientation of the electric field introduces substantial improvement to the transfection efficiency [47]. It is possible that cell rotation becomes less likely when the device becomes larger. On the other hand, the larger devices offered less cell death even with longer residence time in the devices (Fig. 3e). Again, the transfection yield in the 1× devices was superior to those produced in scaled-up devices due to the much higher transfection efficiency. 3.3. Scaling up of the devices with multiple narrow sections We also conducted the scale-up of flow-through electroporation devices with multiple narrow sections. These devices process cells with multiple exposures to the electroporation field that are equivalent to multiple pulses applied in electropulsation. The multiple exposures to the electroporation field in the narrow sections improve transfection efficiency [40]. This is especially important for larger devices, which suffers from insufficient electroporation when a device with a single narrow section was used as described above. Devices of four sizes (corresponding to different cross-sectional areas) were tested (20×, 80×, 160×, and 240×). The devices all had 5 narrow sections (200 μm long each) and 6 wide sections (88 mm in the total length), as well as W2:W1 of 1:10. All experiments were conducted with E2 of 800 V/cm in narrow sections (E1 = 80 V/cm in wide sections). We varied the total residence time in the narrow sections T2 between 1.1 and 5.5 ms. Fig. 4a shows the transfection efficiency with varying total residence time T2. In 80× and 160× devices, the transfection efficiency increased with the residence time monotonically. However, the transfection efficiency peaked at 3.3 ms for 240× devices and 4.4 ms for 20× devices. The mechanisms for the two curves to have peaks may be different. We have observed in this study (Figs. 2 and 3) and previous work [40] that excessively long duration in the electroporation field may decrease the transfection efficiency, possibly due to compromise of gene expression due to Joule heating. It needs to be noted that the transfection efficiency here is the percentage of transfected cells among viable cells and therefore not directly affected by the cell death rate. This is likely the reason why the transfection efficiency had a peak at a medium residence time for 20× devices. On the other hand, the decrease in the transfection efficiency for 240× devices at longer residence times is possibly due to the decrease in the electroporation efficiency with scaling up, similar to the observation in Fig. 3. A transfection efficiency of ∼ 47% was achieved in 160× device in the best case. Unlike the devices with a single narrow section (Fig. 3), the devices with multiple narrow sections did not show decrease in the transfection efficiency with an increase in the device size up to 160×. The multi-pulse-like scheme in Fig. 4. The scale-up of devices with 5 narrow sections. All the devices used in this experiment have the same lengths for the narrow sections (L2 = 1 mm, separated into 5 equal segments of 200 μm each) and the wide sections (L1 = 88 mm, separated into 6 segments) as well as the same width ratio W2:W1 = 1:10. The device size was varied by changing the cross-sectional area of the channel. The dimensions of different devices: 20×: depth = 80 μm, W 1 = 3750 μm, W 2 = 375 μm; 80×: depth = 240 μm, W1 = 5000 μm, W2 = 500 μm; 160×: depth = 480 μm, W1 = 5000 μm, W2 = 500 μm; and 240×: depth = 412 μm, W1 = 8730 μm, W2 = 873 μm. The transfection efficiency (a), cell viability (b), and transfection yield (c) of the devices of different sizes varied with the total residence time in the narrow sections (T2) under the identical field intensity in the narrow sections (E2 = 800 V/cm). these devices likely improves the electroporation efficiency. Consistent with what is shown in Fig. 3e, Fig. 4b shows that the cell viability was higher in larger devices. With the longest residence time of 5.5 ms, we could achieve 94% viability in 240× device, while only 44% 97 of cells were viable in 20× device under the same electroporation parameters. Fig. 4c shows that the overall transfection yield was the best with 160× devices at 5.5 ms residence time. 240× devices performed better than 160× devices with residence times shorter than 4.4 ms. The effect from Joule heating in these devices can be estimated based on the applied voltage, the generated current, and the flow rate. The current increased from 0.27 to 2.1 mA when the device size scaled up from 20× to 240×. However, with higher flow rates in the larger devices, the estimated temperature increase (due to Joule heating) decreases from 9.2 K in 20× to 6.0 K in 240×. Less temperature increase in the larger devices may contribute to the higher cell viability. It needs to be noted that the temperature during operation in all these devices is lower than 37 °C based on this estimation. Compared to the devices with single narrow section, the transfection in devices with multiple narrow sections was substantially improved. The results in multi-narrow-section scaled-up devices (with an optimal transfection efficiency of ∼ 47%) were comparable to those obtained in small-scale devices (with an optimal transfection efficiency of ∼ 48%). These scaled up devices can process cell samples with a speed of up to tens of milliliters per min. The high transfection efficiency of the multi-narrow-section devices was also likely to be linked to the increased cell rotation at the multiple width reduction/expansion points. 3.4. Optimization of the large-scale devices Fig. 4 shows that simple scale-up by increasing the cross-sectional area of the device with 5 narrow sections may generate similar to better transfection results. However, the data also indicate that there is a systematic change in performance when the device size increases. This suggests the necessity of optimizing electroporation parameters (residence times, field intensities, and the combination of narrow/ wide sections) at each specific scale. We further optimized the large-scale devices for improved transfection results. The effects of the wide section dimensions and the number of alternating segments in the devices were examined. All experiments were conducted with the field strength of 800 V/cm in the narrow sections. The residence times in the devices were varied by adjusting the flow rates controlled by the syringe pump. In general, we used substantially longer wide sections to create residence times in the range of 4.4–19.4 s in these experiments (compared to 1.0–4.8 s in the above described large-scale devices) and this practice improved the transfection efficiency to the range of 60–75% (compared to ∼47% in the above). As we found with small-scale devices, the low field in the wide sections had considerable effects on the device performance. We first investigated the effects of the width of the wide sections. When E2 and the dimensions of the narrow sections are fixed, designs with larger wide sections render the field intensity in these sections lower. In this experiment, two devices had the same dimensions for the 5 narrow sections (200 μm long and 500 μm wide for each) and the same total lengths for the wide sections (88 mm), while the widths of wide sections were different (5000 μm and 7500 μm). Fig. 5 shows that the device with the smaller (5000 μm) wide sections yielded higher transfection efficiency and lower viability than the one with larger wide section width (7500 μm) when the residence time T2 was between 3.3 ms and 5.5 ms. The field intensity in the 5000 μm wide sections (∼ 80 V/cm) was substantially higher than that in the 7500 μm wide section (∼ 53 V/cm). Despite that cells spent a longer residence time T1 (by a factor of 1.5) in the 7500 µm wide section than in the 5000 μm wide section, the higher field intensity in the 5000 μm wide sections appears to be determining for more intensive electroporation and higher transfection efficacy with the residence time T2 between 3.3 ms and 5.5 ms. With longer T2 (≥5.5 ms), however, the devices with 7500 μm wide sections show a tendency to outperform Fig. 5. The effects of the field intensity in the wide sections on the performance of largescale devices with 5 narrow sections. Both devices used in this experiment have the same depth (480 μm), the same dimensions for the narrow sections (L2 = 1 mm, separated into 5 equal segments of 200 μm each; W2 = 500 μm) and the same length for the wide sections (L1 = 88 mm, separated into 6 segments). The transfection efficiency (a), cell viability (b), and transfection yield (c) varied with the total residence time in the narrow sections (T2) and the different field intensities in the wide sections (E1 = 80 or 53 V/cm) under the identical field intensity in the narrow sections (E2 = 800 V/cm). the devices with 5000 μm wide sections in terms of both transfection efficiency and cell viability. We also optimized the total length of the wide sections. While keeping the dimensions of the 5 narrow sections (200 μm long and 500 μm wide for each) and the width of wide sections (7500 μm) constant, we had different total lengths for the wide sections (88, 128, and 168 mm). We varied the total residence time in narrow sections T2 between 3.3 and 7.7 ms by adjusting the flow rate. Cells GENE DELIVERY T. Geng et al. / Journal of Controlled Release 144 (2010) 91–100 GENE DELIVERY 98 T. Geng et al. / Journal of Controlled Release 144 (2010) 91–100 experienced longer residence time in the wide sections when the total length increased. Fig. 6a demonstrates that the longer residence time in the wide sections dramatically enhanced the transfection efficiency when the total wide section length increased from 88 mm to 128 mm. However, further increase from 128 mm to 168 mm did not introduce Fig. 6. The effects of the residence time in the wide sections on the performance of large-scale devices with 5 narrow sections. All the devices used in this experiment have the same depth of 480 μm, the same dimensions for the narrow sections (L2 = 1 mm, separated into 5 equal segments of 200 μm each; W2 = 500 μm), and the same width for the wide sections (W1 = 7500 μm). The transfection efficiency (a), cell viability (b), and transfection yield (c) varied with the total residence time in the narrow sections (T2) and the different lengths of the wide sections (L1 = 88, 128, 168 mm) under the identical field intensities in the wide sections (E1 = 53 V/cm) and in the narrow sections (E2 = 800 V/cm). substantial change. This suggests that the residence time in the wide sections T1 may reach an optimum given a certain set of electric conditions. Transfection efficiency as high as 75% was achieved with a T2 of 7.7 ms and a T1 of 14.8–19.4 s. As a tradeoff, Fig. 6b shows that longer wide sections decreased the cell viability. In general, devices with multiple narrow sections yield better performance than the ones with single narrow sections. Here we also Fig. 7. The effects of the number of the narrow sections on the performance of largescale devices. All the devices used in this experiment have the same depth of 480 μm, the same total lengths for the wide sections (L1 = 128 mm) and the narrow sections (L2 = 1 mm), and the same widths for the wide sections (W1 = 7500 μm) and the narrow sections (W2 = 500 μm). The transfection efficiency (a), cell viability (b), and transfection yield (c) varied with the total residence time in the narrow sections (T2) under the identical field intensities in the wide sections (E1 = 53 V/cm) and in the narrow sections (E2 = 800 V/cm). investigated how the number of the narrow/wide sections affected the transfection when the total residence times were identical. In this experiment, the widths and the total lengths of the wide and narrow sections were kept constant (wide sections: 7500 μm wide, 128 mm long; narrow sections: 500 μm wide, 1 mm long). We divided the narrow channel into 4, 5, or 7 segments (the wide channel was separated into 5, 6, or 8 segments respectively). Fig. 7a demonstrates that the transfection efficiency became higher when the number of narrow sections increased from 4 to 5. Further increase to 7 narrow sections did not improve the transfection efficiency. Interestingly a higher number of narrow sections also improved the cell viability, as shown in Fig. 7b. This suggests that separating the electroporation period into multiple shorter durations may enable cells to reseal more readily after the treatment and maintain their viability. The overall transfection yield was the best with the devices with 7 narrow sections, given its superior performance in both transfection efficiency and cell viability (Fig. 7c). In this part, we further improved the transfection efficiency up to 75% in large-scale devices by optimizing the device design. We show that both the residence time and the field intensity in wide sections have significant effects on the transfection. Having more segments for the narrow channel also improves both transfection efficiency and cell viability. This transfection efficiency compares favorably with the results achieved using electroporation based on applying pulses to CHO cells (typically < 50%) [46–48]. 4. Conclusions In this work, we demonstrated delivery of genes into mammalian cells by flow-through electroporation under high flow rates (up to ∼ 20 mL/min) and with high efficiency (up to ∼ 75% transfection for CHO cells). By establishing a constant DC voltage across the device, cells experienced pulse-like electrical field variations while flowing in the fluidic channel with alternating sections of large and small crosssectional areas. These devices could be scaled up to increase the volume of the cell sample processed in a unit time without compromising the transfection efficiency and cell viability. Compared to the conventional cuvette-based electroporators that work essentially in batch mode, our method offers continuous production of transfected cell samples. By applying low-cost and common lab equipment such as syringe pumps, DC power supplies, and disposable chips (unit manufacturing cost <1 US dollar), this approach will have potential for highly efficient and economical genetic modification of cells in large volume. This transfection efficiency compares favorably with the results achieved using electroporation based on applying pulses to CHO cells (typically < 50%). In our study, we found that longer duration in the wide sections (T1) on the order of seconds was critical for improving transfection efficiency while E1 in the wide sections was significantly lower than the electroporation threshold (i.e. < 100 V/cm). In general, the optimal residence time in the narrow section (T2) is in the range of 1–10 ms and the accompanying total residence time in the wide sections (T1) needs to be in the range of 4–19 s for the best transfection results. For devices with one narrow section, scaling up of the device by increasing the cross-sectional area of the channel requires longer residence times in order to have comparable transfection efficiency in larger devices. In contrast, devices with multiple narrow sections do not show loss in the transfection efficiency or yield while scaled up. A high number of narrow sections also seem to improve both the transfection efficiency and the cell viability. Finally, the optimal electroporation parameters (the field intensity, the residence time, and the combination of narrow/wide sections) appear to have dependence on the device size. When the device size is drastically changed, the optimization of these parameters may need to be repeated. 99 Acknowledgements This work was supported by Wallace H. Coulter Foundation Early Career Award to CL and KGC and NSF CBET-0747105 to CL. References [1] J.N. Blattman, P.D. Greenberg, Cancer immunotherapy: a treatment for the masses, Science 305 (2004) 200–205. [2] M.H. Kershaw, M.W. Teng, M.J. Smyth, P.K. Darcy, Supernatural T cells: genetic modification of T cells for cancer therapy, Nat. Rev. Immunol. 5 (2005) 928–940. [3] A. Aiuti, S. Slavin, M. Aker, F. Ficara, S. Deola, A. Mortellaro, S. Morecki, G. Andolfi, A. Tabucchi, F. Carlucci, E. Marinello, F. Cattaneo, S. Vai, P. Servida, R. Miniero, M.G. Roncarolo, C. Bordignon, Correction of ADA-SCID by stem cell gene therapy combined with nonmyeloablative conditioning, Science 296 (2002) 2410–2413. [4] S. Kumar, D. Chanda, S. Ponnazhagan, Therapeutic potential of genetically modified mesenchymal stem cells, Gene Ther. 15 (2008) 711–715. [5] C.A. Gersbach, J.E. Phillips, A.J. Garcia, Genetic engineering for skeletal regenerative medicine, Annu. Rev. Biomed. Eng. 9 (2007) 87–119. [6] R.D. Cone, R.C. Mulligan, High-efficiency gene transfer into mammalian cells: generation of helper-free recombinant retrovirus with broad mammalian host range, Proc. Natl. Acad. Sci. U.S.A. 81 (1984) 6349–6353. [7] Q. Liu, D.A. Muruve, Molecular basis of the inflammatory response to adenovirus vectors, Gene Ther. 10 (2003) 935–940. [8] P.L. Felgner, T.R. Gadek, M. Holm, R. Roman, H.W. Chan, M. Wenz, J.P. Northrop, G.M. Ringold, M. Danielsen, Lipofection: a highly efficient, lipid-mediated DNAtransfection procedure, Proc. Natl. Acad. Sci. U.S.A. 84 (1987) 7413–7417. [9] M. Wigler, S. Silverstein, L.S. Lee, A. Pellicer, Y. Cheng, R. Axel, Transfer of purified herpes virus thymidine kinase gene to cultured mouse cells, Cell 11 (1977) 223–232. [10] O. Boussif, F. Lezoualc'h, M.A. Zanta, M.D. Mergny, D. Scherman, B. Demeneix, J.P. Behr, A versatile vector for gene and oligonucleotide transfer into cells in culture and in vivo: polyethylenimine, Proc. Natl. Acad. Sci. U.S.A. 92 (1995) 7297–7301. [11] W. Li, F. Nicol, F.C. Szoka Jr., GALA: a designed synthetic pH-responsive amphipathic peptide with applications in drug and gene delivery, Adv. Drug Deliv. Rev. 56 (2004) 967–985. [12] Y. Fedorov, A. King, E. Anderson, J. Karpilow, D. Ilsley, W. Marshall, A. Khvorova, Different delivery methods-different expression profiles, Nat. Methods 2 (2005) 241. [13] E. Neumann, M. Schaefer-Ridder, Y. Wang, P.H. Hofschneider, Gene transfer into mouse lyoma cells by electroporation in high electric fields, EMBO J. 1 (1982) 841–845. [14] M.P. Rols, C. Delteil, M. Golzio, P. Dumond, S. Cros, J. Teissie, In vivo electrically mediated protein and gene transfer in murine melanoma, Nat. Biotechnol. 16 (1998) 168–171. [15] H. Aihara, J. Miyazaki, Gene transfer into muscle by electroporation in vivo, Nat. Biotechnol. 16 (1998) 867–870. [16] J.C. Weaver, Y.A. Chizmadzhev, Theory of electroporation: a review, Bioelectroch. Bioener. 41 (1996) 135–160. [17] A. Hamm, N. Krott, I. Breibach, R. Blindt, A.K. Bosserhoff, Efficient transfection method for primary cells, Tissue Eng. 8 (2002) 235–245. [18] P. Lenz, S.M. Bacot, M.R. Frazier-Jessen, G.M. Feldman, Nucleoporation of dendritic cells: efficient gene transfer by electroporation into human monocyte-derived dendritic cells, FEBS Lett. 538 (2003) 149–154. [19] F. Andre, L.M. Mir, DNA electrotransfer: its principles and an updated review of its therapeutic applications, Gene Ther. 11 (2004) S33–S42. [20] M.P. Rols, D. Coulet, J. Teissie, Highly efficient transfection of mammalian cells by electric field pulses. Application to large volumes of cell culture by using a flow system, Eur. J. Biochem. 206 (1992) 115–121. [21] T.C. Bakker Schut, Y.M. Kraan, W. Barlag, L. de Leij, B.G. de Grooth, J. Greve, Selective electrofusion of conjugated cells in flow, Biophys. J. 65 (1993) 568–572. [22] L.H. Li, R. Shivakumar, S. Feller, C. Allen, J.M. Weiss, S. Dzekunov, V. Singh, J. Holaday, J. Fratantoni, L.N. Liu, Highly efficient, large volume flow electroporation, Technol. Cancer Res. Treat. 1 (2002) 341–350. [23] S.-W. Lee, Y.-C. Tai, A micro cell lysis device, Sens. Actuators A 73 (1999) 74–79. [24] Y.-C. Lin, M.-Y. Huang, Electroporation microchips for in vitro gene transfection, J. Micromech. Microeng. 11 (2001) 542. [25] Y.-C. Lin, C.-M. Jen, M.-Y. Huang, C.-Y. Wu, X.-Z. Lin, Electroporation microchips for continuous gene transfection, Sens. Actuators B 79 (2001) 137–143. [26] Y. Huang, B. Rubinsky, Microfabricated electroporation chip for single cell membrane permeabilization, Sens. Actuators A 89 (2001) 242–249. [27] Y. Huang, B. Rubinsky, Flow-through micro-electroporation chip for high efficiency single-cell genetic manipulation, Sens. Actuators A 104 (2003) 205–212. [28] Y.C. Lin, M. Li, C.C. Wu, Simulation and experimental demonstration of the electric field assisted electroporation microchip for in vitro gene delivery enhancement, Lab Chip 4 (2004) 104–108. [29] N.R. Munce, J. Li, P.R. Herman, L. Lilge, Microfabricated system for parallel singlecell capillary electrophoresis, Anal. Chem. 76 (2004) 4983–4989. [30] H. Lu, M.A. Schmidt, K.F. Jensen, A microfluidic electroporation device for cell lysis, Lab Chip 5 (2005) 23–29. [31] M. Khine, A. Lau, C. Ionescu-Zanetti, J. Seo, L.P. Lee, A single cell electroporation chip, Lab Chip 5 (2005) 38–43. [32] Z. Fei, S. Wang, Y. Xie, B.E. Henslee, C.G. Koh, L.J. Lee, Gene transfection of mammalian cells using membrane sandwich electroporation, Anal. Chem. 79 (2007) 5719–5722. GENE DELIVERY T. Geng et al. / Journal of Controlled Release 144 (2010) 91–100 GENE DELIVERY 100 T. Geng et al. / Journal of Controlled Release 144 (2010) 91–100 [33] S.K. Kim, J.Y. Kim, K.P. Kim, T.D. Chung, Continuous low-voltage dc electroporation on a microfluidic chip with polyelectrolytic salt bridges, Anal. Chem. 79 (2007) 7761–7766. [34] M. Khine, C. Ionescu-Zanetti, A. Blatz, L.P. Wang, L.P. Lee, Single-cell electroporation arrays with real-time monitoring and feedback control, Lab Chip 7 (2007) 457–462. [35] A. Valero, J.N. Post, J.W. van Nieuwkasteele, P.M. Ter Braak, W. Kruijer, A. van den Berg, Gene transfer and protein dynamics in stem cells using single cell electroporation in a microfluidic device, Lab Chip 8 (2008) 62–67. [36] A.M. Skelley, O. Kirak, H. Suh, R. Jaenisch, J. Voldman, Microfluidic control of cell pairing and fusion, Nat. Methods 6 (2009) 147–152. [37] J.K. Valley, S. Neale, H.Y. Hsu, A.T. Ohta, A. Jamshidi, M.C. Wu, Parallel single-cell light-induced electroporation and dielectrophoretic manipulation, Lab Chip 9 (2009) 1714–1720. [38] S. Wang, X. Zhang, W. Wang, L.J. Lee, Semicontinuous flow electroporation chip for high-throughput transfection on mammalian cells, Anal. Chem. 81 (2009) 4414–4421. [39] R. Ziv, Y. Steinhardt, G. Pelled, D. Gazit, B. Rubinsky, Micro-electroporation of mesenchymal stem cells with alternating electrical current pulses, Biomed. Microdevices 11 (2009) 95–101. [40] H.Y. Wang, C. Lu, Microfluidic electroporation for delivery of small molecules and genes into cells using a common DC power supply, Biotechnol. Bioeng. 100 (2008) 579–586. [41] H.Y. Wang, C. Lu, Electroporation of mammalian cells in a microfluidic channel with geometric variation, Anal. Chem. 78 (2006) 5158–5164. [42] M.F. Bureau, J. Gehl, V. Deleuze, L.M. Mir, D. Scherman, Importance of association between permeabilization and electrophoretic forces for intramuscular DNA electrotransfer, Biochim. Biophys. Acta 1474 (2000) 353–359. [43] S. Satkauskas, M.F. Bureau, M. Puc, A. Mahfoudi, D. Scherman, D. Miklavcic, L.M. Mir, Mechanisms of in vivo DNA electrotransfer: respective contributions of cell electropermeabilization and DNA electrophoresis, Mol. Ther. 5 (2002) 133–140. [44] S. Satkauskas, F. Andre, M.F. Bureau, D. Scherman, D. Miklavcic, L.M. Mir, Electrophoretic component of electric pulses determines the efficacy of in vivo DNA electrotransfer, Hum. Gene Ther. 16 (2005) 1194–1201. [45] S.I. Sukharev, V.A. Klenchin, S.M. Serov, L.V. Chernomordik, A. Chizmadzhev Yu, Electroporation and electrophoretic DNA transfer into cells. The effect of DNA interaction with electropores, Biophys. J. 63 (1992) 1320–1327. [46] M. Kanduser, D. Miklavcic, M. Pavlin, Mechanisms involved in gene electrotransfer using high- and low-voltage pulses—an in vitro study, Bioelectrochemistry 74 (2009) 265–271. [47] M. Rebersek, C. Faurie, M. Kanduser, S. Corovic, J. Teissie, M.P. Rols, D. Miklavcic, Electroporator with automatic change of electric field direction improves gene electrotransfer in-vitro, Biomed. Eng. Online 6 (2007) 25. [48] H. Wolf, M.P. Rols, E. Boldt, E. Neumann, J. Teissie, Control by pulse parameters of electric field-mediated gene transfer in mammalian cells, Biophys. J. 66 (1994) 524–531.