* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Copper-Catalyzed Oxidation of Benzoin to Benzil 738

Marcus theory wikipedia , lookup

Physical organic chemistry wikipedia , lookup

Acid–base reaction wikipedia , lookup

Rate equation wikipedia , lookup

Woodward–Hoffmann rules wikipedia , lookup

Chemical equilibrium wikipedia , lookup

Ene reaction wikipedia , lookup

Chemical thermodynamics wikipedia , lookup

Industrial catalysts wikipedia , lookup

Electrochemistry wikipedia , lookup

George S. Hammond wikipedia , lookup

Enzyme catalysis wikipedia , lookup

Photoredox catalysis wikipedia , lookup

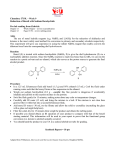

SYNT m o d u l a r · l a b o r a t o r y · p r o g r a m · i n · publisher: H. A. Neidig c h e m i s t r y 738 organic editor: Joe Jeffers Copper-Catalyzed Oxidation of Benzoin to Benzil prepared by Carl T. Wigal, Lebanon Valley College PURPOSE OF THE EXPERIMENT Oxidize benzoin to benzil using ammonium nitrate and copper(II) ion as a catalyst, monitoring the reaction by thin-layer chromatography. Characterize the product using melting point measurement and infrared spectroscopy. EXPERIMENTAL OPTIONS Semi-Microscale Oxidation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Microscale Oxidation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 BACKGROUND REQUIRED You should be familiar with making micropipets, vacuum filtration, recrystallization, melting point measurement, thin-layer chromatography (TLC), and infrared spectroscopy (IR). BACKGROUND INFORMATION An important category of chemical reactions involves the transfer of electrons from one molecule to another. These reactions, called oxidation– reduction or redox reactions, are used to synthesize a large variety of compounds. Redox reactions also control energy flow in biological systems. In a redox reaction, one atom or molecule loses electrons while another gains electrons. In organic reactions, the gain or loss of electrons is not always clear. Consequently, organic chemists define redox in terms of the loss or gain of carbon–hydrogen bonds. An organic oxidation is defined as the loss of carbon–hydrogen bonds, while an organic reduction is defined as a gain of carbon–hydrogen bonds. In an organic oxidation, a bond involving a more electronegative element, usually oxygen, replaces the carbon–hydrogen bond. The various oxidation states of a carbon atom are shown in Equation 1. The symbol [O] indicates an unspecified oxidizing agent. H H C H [O] H H C OH H H methane methanol O [O] H C O [O] H formaldehyde H C O [O] OH formic acid HO C CO2 OH + H2O (Eq. 1) carbonic acid Benzoin can be oxidized to the diketone benzil using a Cu2+ salt and ammonium nitrate. Only catalytic amounts of copper(II) acetate are necessary because the Cu2+ is continuously recycled. The pattern is shown in Figure 1 on the next page. Copyright 2000 by Chemical Education Resources, Inc., P.O. Box 357, 220 South Railroad, Palmyra, Pennsylvania 17078 No part of this laboratory program may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage and retrieval system, without permission in writing from the publisher. Printed in the United States of America 03 02 01 00 — 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 2 SYNT 738/Copper-Catalyzed Oxidation of Benzoin to Benzil Figure 1 Recycling of copper ion in the benzoin oxidation benzoin benzil 2 Cu2+ 2 Cu+ N2 + 3 H2O NH4NO3 + 2 H+ The oxidation mechanism is shown in Figure 2. In the first redox cycle, benzoin donates an electron to Cu2+, forming Cu+ and benzoin radical cation A. The benzoin radical cation loses a proton to acetate ion (AcO–), forming acetic acid (AcOH) and a resonance stabilized radical, depicted by structures B and C. Another redox cycle between Cu2+ and the radical takes place, forming a second Cu+ ion and cation D, which loses a proton to another acetate ion to form benzil. Cu2+ H Cu+ H H O O O O O O C C C C C C + A H AcO benzoin AcOH AcO – – B H AcOH H H O O O O O O C C C C C C D C benzil Figure 2 + Cu+ Cu2+ Mechanism for the copper-catalyzed oxidation of benzoin The Cu+ ions formed in these redox cycles are reoxidized to Cu2+ by ammonium nitrate, which is present in excess. This reaction, shown in Equation 2, forms ammonium nitrite (NH4NO2), which decomposes to nitrogen and water under the reaction conditions. 2 Cu+ + 2 H+ + NH4NO3 → 2 Cu2+ + H2O + NH4NO2 → 2 Cu2+ + N2↑ + 3 H2O (Eq. 2) In this experiment, you will oxidize benzoin to benzil using the copper-catalyzed oxidation procedure described above. You will monitor the reaction using TLC. You will characterize the product using melting point and IR spectroscopy. 2000 by Chemical Education Resources 3 Semi-Microscale Oxidation Semi-Microscale Oxidation Equipment 100-mL beaker 250-mL beaker* 250-mL beaker, with aluminum foil or plastic wrap cover† Büchner funnel, with adapter Bunsen burner 50-mL Erlenmeyer flask 125-mL filter flask, with vacuum tubing filter paper forceps glass stirring rod 10-mL graduated cylinder 50-mL graduated cylinder magnetic stir bar 4–5 melting point capillary tubes microspatula 3 open-ended capillary tubes Pasteur pipet, with latex bulb pencil reflux assembly condenser, with tubing 25-mL round-bottom flask ruler sand bath‡ stirring hot plate§ support stand thermometer, –10 to 260 °C 3 TLC plates, silica gel, 2.5 × 7.5-cm, with fluorescent indicator 2.0-mL transfer pipet 2 utility clamps watch glass *for ice-water bath † or 4-oz screw-cap jar with lid for TLC developing chamber ‡ crystallizing dish or electric flask heater filled with sand § or electric flask heater and magnetic stirrer Reagents and Properties substance acetic acid, glacial ammonium nitrate quantity molar mass (g/mol) 6.0 mL 60.05 1.0 g benzil* benzoin 2.0 g copper(II) acetate solution 1.5 mL dichloromethane 6 mL ethanol, 95% bp (°C) 118 mp (°C) d (g/mL) 1.049 80.04 210.23 94–95 212.25 135–137 40 <16 mL potassium bromide 0.100 g *product Preview • Assemble the reflux apparatus • Add the benzoin, ammonium nitrate, acetic acid, and copper(II) acetate solution • Reflux the reaction mixture for up to 60 min • Monitor the reaction using TLC • Allow the reaction mixture to cool to room temperature • Pour reaction mixture into ice-water solution • Use vacuum filtration to isolate the crude product 2000 by Chemical Education Resources 4 SYNT 738/Copper-Catalyzed Oxidation of Benzoin to Benzil • Recrystallize the product • Use vacuum filtration to isolate the purified product • Dry and weigh the product • Characterize the product using melting point and IR PROCEDURE 1. Setting Up the Apparatus Caution: Wear departmentally approved safety goggles at all times while in the chemistry laboratory. Always use caution in the laboratory. Many chemicals are potentially harmful. Prevent contact with your eyes, skin, and clothing. Avoid ingesting any of the reagents. Depending upon your glassware, assemble a reflux apparatus similar to that shown in Figure 3. Figure 3 Reflux apparatus with round-bottom flask Caution: Glacial acetic acid is corrosive. Use a fume hood. Ammonium nitrate (NH4NO3) is oxidizing and irritating. Copper(II) acetate [Cu(OAc)2] solution is corrosive and irritating. The solid materials are not soluble in acetic acid at room temperature. The solids dissolve as the pot is heated for refluxing. NOTE 1: 2. Refluxing the Reaction Mixture 3. Setting Up the Chromatography System Remove the 25-mL round-bottom flask from the apparatus. Place a magnetic stir bar in the round-bottom flask. Transfer 6.0 mL of glacial acetic acid, 1.0 g of NH4NO3, and 2.0 g of benzoin to the flask. Add 1.5 mL of the Cu(OAc)2 solution. [NOTE 1] Reattach the flask to the reflux apparatus. Start the flow of water through the condenser. Heat the reaction mixture to boiling and reflux, while stirring, for up to 60 min. Caution: Do not use a Bunsen burner near the flammable 95% ethanol. Using open-ended capillary tubing and a Bunsen burner, prepare 3–5 micropipets for TLC spotting. Obtain three 2.5 × 7.5-cm silica gel TLC plates. At the top, label the three plates “30 min”, “45 min”, and “60 min”, respectively. Using a ruler as a straightedge, draw a very faint pencil line across each plate 1 cm from the bottom. Do not cut through the silica gel with your marks. Make three small vertical lines that intersect the horizontal line at 6, 12, and 18 mm from the left side of the plate. 2000 by Chemical Education Resources Semi-Microscale Oxidation 5 Using a pencil, label the plate from left to right below the vertical lines with “Bzo”, “Rxn”, and “Bzl”. Caution: Benzil is irritating. Obtain standard samples of benzoin and benzil from your laboratory instructor. Using a micropipet, spot benzoin at the position labeled Bzo on each plate. Discard the micropipet. Using a new micropipet, spot benzil at the position marked Bzl on each plate. Discard the micropipet. Caution: Dichloromethane is toxic and irritating. Prepare a developing chamber by adding 6 mL of dichloromethane to a 250-mL beaker. Add filter paper to the chamber to act as a wick. Cover the chamber with aluminum foil or plastic wrap and set it aside in a fume hood. 4. Monitoring the Reaction After 30 min, remove the heat from the flask. Allow the reaction mixture to cool for 2 min. Work quickly to minimize the time the reflux is interrupted. Remove the condenser from the reflux apparatus. Use a micropipet to spot the reaction mixture on the 30 min TLC plate at the position marked Rxn. Replace the condenser and restart the reflux. Wait until the reaction mixture is boiling to continue timing the reaction. In the meantime, place the TLC plate in the developing chamber. Cover the chamber with the foil or plastic wrap. Develop the plate until the eluent is within 1 cm of the top of the plate. Remove the plate from the chamber. Immediately mark the eluent front with a pencil. Keep the plate in the fume hood for 1 min to allow the dichloromethane to evaporate. Caution: Ultraviolet radiation can cause severe damage to the eyes. Wear UV protective goggles. Do not look directly into the UV lamp. View the plate under UV light to visualize the spots. Use a pencil to circle each spot. Note the relative amounts of benzoin and benzil from the reaction spot. After 45 min of reaction time, obtain a second sample for TLC analysis. Analyze as before, using the 45 min plate. If the reaction is complete, as indicated by the absence of benzoin in the sample, stop the reflux. Cool the reaction for 10 min. Go to Part 5. If benzoin remains in the reaction mixture, continue the reflux. After 60 min of reaction time, stop the reaction. Obtain a third sample for TLC analysis. Analyze as before, using the 60 min plate. Note whether or not the reaction is complete. In either case, go to Part 5. 5. Collecting, Washing, and Drying the Crystals 2000 by Chemical Education Resources Place 40 mL of an ice-water mixture in a 100-mL beaker. Use forceps to remove the stir bar. Pour the reaction mixture into the 100-mL beaker containing the ice-water mixture. Stir the mixture vigorously with a glass stirring rod to induce crystallization and to break up any lumps of solid material that may form. 6 SYNT 738/Copper-Catalyzed Oxidation of Benzoin to Benzil Assemble a vacuum filtration apparatus using a Büchner funnel. Turn on the water to the aspirator. Moisten the filter paper with a few drops of distilled or deionized water. Vacuum filter the crystalline solid. Wash the crystals with 20 mL of distilled water. Allow the crystals to dry in the Büchner funnel by pulling air through the funnel for 10 min. Weigh your dried product and record its mass. 6. Recrystallizing Benzil NOTE 2: Crystallize benzil slowly so that large crystals form. Rapid crystallization of the supersaturated solution forms very fine crystals that are difficult to dry. 7. Characterizing the Product Caution: 95% Ethanol is flammable and toxic. Do not use near an open flame. Place your crude product in a 50-mL Erlenmeyer flask. Add 8.0 mL of 95% ethanol for every gram of crude product placed in the flask. Use the hot plate to heat the mixture gently until the ethanol boils. If the product does not completely dissolve, gradually add more ethanol dropwise until all of the solid dissolves in the boiling solvent. [NOTE 2] Allow the solution to cool to room temperature. If necessary, scratch the bottom of the flask to induce crystallization. Prepare an ice-water bath using a 250-mL beaker. Place the flask containing the solution in the ice-water bath for 5 min to complete the crystallization. Filter the crystals using vacuum filtration. Allow your product to air dry in the filter funnel for 10 min. Transfer the product from the filter paper to a watch glass to finish drying. Weigh the product and record the mass. Measure the melting point of your dry product. Caution: Potassium bromide is irritating and hygroscopic. Prepare a KBr pellet of your product. Obtain the IR spectrum as directed by your laboratory instructor. 8. Cleaning Up Use the labeled collection containers provided by your laboratory instructor. Clean your glassware with soap or detergent. Caution: Wash your hands thoroughly with soap or detergent before leaving the laboratory. Microscale Oxidation Equipment 50-mL beaker 100-mL beaker* 250-mL beaker, with aluminum foil or plastic wrap cover† Bunsen burner reflux glassware, conical vial assembly‡ condenser, with tubing 5.0-mL conical vial reflux glassware, elastomeric connector assembly‡ condenser, with tubing elastomeric connector 5.0-mL round-bottom flask 10-mL Erlenmeyer flask§ 25-mL filter flask, with vacuum tubing filter paper 2000 by Chemical Education Resources 7 Microscale Oxidation forceps glass stirring rod 10-mL graduated cylinder Hirsch funnel, with adapter magnetic spin vane or stir bar 4–5 melting point capillary tubes microspatula 3 open-ended capillary tubes 2 Pasteur pipets, with latex bulb pencil ruler sand bath** stirring hot plate†† support stand thermometer, –10 to 260 °C 3 TLC plates, silica gel, 2.5 × 7.5-cm, with fluorescent indicator 1.0-mL transfer pipet‡‡ 2.0-mL transfer pipet 2 utility clamps watch glass *for ice-water bath † or 4-oz screw-cap jar with lid for TLC developing chamber ‡ use the reflux assembly indicated by your laboratory instructor or 13 × 100-mm test tube § **crystallizing dish or electric flask heater filled with sand †† or electric flask heater and magnetic stirrer ‡‡ or 1.000-mL micropipet Reagents and Properties substance quantity molar mass (g/mol) bp (°C) acetic acid, glacial 1.5 mL 60.05 118 ammonium nitrate 0.250 g 80.04 benzil* benzoin 0.500 g copper(II) acetate solution 0.5 mL dichloromethane 6 mL ethanol, 95% mp (°C) d (g/mL) 1.049 210.23 94–95 212.25 135–137 40 <4.0 mL potassium bromide 0.100 g *product Preview • Assemble the reflux apparatus • Add the benzoin, ammonium nitrate, acetic acid, and copper(II) acetate solution • Reflux the reaction mixture for up to 60 min • Monitor the reaction using TLC • Allow the reaction mixture to cool to room temperature • Pour reaction mixture into ice-water solution • Use vacuum filtration to isolate the crude product • Recrystallize the product • Use vacuum filtration to isolate the purified product • Dry and weigh the product • Characterize the product using melting point and IR 2000 by Chemical Education Resources 8 SYNT 738/Copper-Catalyzed Oxidation of Benzoin to Benzil PROCEDURE 1. Setting Up the Apparatus Caution: Wear departmentally approved safety goggles at all times while in the chemistry laboratory. Always use caution in the laboratory. Many chemicals are potentially harmful. Prevent contact with your eyes, skin, and clothing. Avoid ingesting any of the reagents. Depending upon your glassware, assemble a reflux apparatus similar to that shown in Figure 4(a) or 4(b). Figure 4 Microscale reflux apparatus with (a) conical vial or (b) round-bottom flask and elastomeric connectors Caution: Glacial acetic acid is corrosive. Use a fume hood. Ammonium nitrate (NH4NO3) is oxidizing and irritating. Copper(II) acetate [Cu(OAc)2] solution is corrosive and irritating. The solid materials are not soluble in acetic acid at room temperature. The solids dissolve as the pot is heated for refluxing. NOTE 1: 2. Refluxing the Reaction Mixture 3. Setting Up the Chromatography System Remove the 5.0-mL conical vial (round-bottom flask) from the apparatus. Place a magnetic spin vane or stir bar in the vial (flask). Transfer 1.5 mL of glacial acetic acid, 0.250 g of NH4NO3, and 0.500 g of benzoin to the vial (flask). Add 0.5 mL of the Cu(OAc)2 solution. [NOTE 1] Reattach the conical vial (flask) to the reflux apparatus. Start the flow of water through the condenser. Heat the reaction mixture to boiling and reflux, while stirring, for 60 min. Caution: Do not use a Bunsen burner near the flammable 95% ethanol. Using open-ended capillary tubing and a Bunsen burner, prepare 3–5 micropipets for TLC spotting. Obtain three 2.5 × 7.5-cm silica gel TLC plates. At the top, label the three plates “30 min”, “45 min”, and “60 min”, respectively. Using a ruler as a straightedge, draw a very faint pencil line across each plate 1 cm from the bottom. Do not cut through the silica gel with your marks. Make three small vertical lines that intersect the horizontal line at 6, 12, and 18 mm from the left side of the plate. Using a pencil, label the plate from left to right below the vertical lines with “Bzo”, “Rxn”, and “Bzl”. 2000 by Chemical Education Resources Microscale Oxidation Caution: 9 Benzil is irritating. Obtain standard samples of benzoin and benzil from your laboratory instructor. Using a micropipet, spot benzoin at the position labeled Bzo on each plate. Discard the micropipet. Using a new micropipet, spot benzil at the position marked Bzl on each plate. Discard the micropipet. Caution: Dichloromethane is toxic and irritating. Prepare a developing chamber by adding 6 mL of dichloromethane to a 250-mL beaker. Add filter paper to the chamber to act as a wick. Cover the chamber with aluminum foil or plastic wrap and set it aside in a fume hood. 4. Monitoring the Reaction After 30 min, remove the heat from the vial (flask). Allow the reaction mixture to cool for 2 min. Work quickly to minimize the time the reflux is interrupted. Remove the condenser from the reflux apparatus. Use a micropipet to spot the reaction mixture on the 30 min TLC plate at the position marked Rxn. Replace the condenser and restart the reflux. Wait until the reaction mixture is boiling to continue timing the reaction. In the meantime, place the TLC plate in the developing chamber. Cover the chamber with the foil or plastic wrap. Develop the plate until the eluent is within 1 cm of the top of the plate. Remove the plate from the chamber. Immediately mark the eluent front with a pencil. Keep the plate in the fume hood for 1 min to allow the dichloromethane to evaporate. Caution: Ultraviolet radiation can cause severe damage to the eyes. Wear UV protective goggles. Do not look directly into the UV lamp. View the plate under UV light to visualize the spots. Use a pencil to circle each spot. Note the relative amounts of benzoin and benzil from the reaction spot. After 45 min of reaction time, obtain a second sample for TLC analysis. Analyze as before, using the 45 min plate. If the reaction is complete, as indicated by the absence of benzoin in the sample, stop the reflux. Cool the reaction for 10 min. Go to Part 5. If benzoin remains in the reaction mixture, continue the reflux. After 60 min of reaction time, stop the reaction. Obtain a third sample for TLC analysis. Analyze as before, using the 60 min plate. Note whether or not the reaction is complete. In either case, go to Part 5. 5. Collecting, Washing, and Drying the Crystals 2000 by Chemical Education Resources Place 10 mL of an ice-water mixture in a 50-mL beaker. Use forceps to remove the stir bar from the reaction vial (flask). Pour the reaction mixture into the 50-mL beaker containing the ice-water mixture. Stir the mixture vigorously with a glass stirring rod to induce crystallization and to break up any lumps of solid material that may form. Assemble a vacuum filtration apparatus using a Hirsch funnel. Turn on the water to the aspirator and moisten the filter paper with a few drops of distilled or deionized water. Vacuum filter the crystalline solid. Wash the crystals with 5 mL of distilled water. 10 SYNT 738/Copper-Catalyzed Oxidation of Benzoin to Benzil Allow the crystals to dry in the Hirsch funnel by pulling air through the funnel for 10 min. Weigh your dried product and record its mass. 6. Recrystallizing Benzil NOTE 2: Crystallize benzil slowly so that large crystals form. Rapid crystallization of the supersaturated solution forms very fine crystals that are difficult to dry. 7. Characterizing the Product Caution: 95% Ethanol is flammable and toxic. Do not use near an open flame. Place your crude product in a 10-mL Erlenmeyer flask or a 13 × 100-mm test tube. Add 0.8 mL of 95% ethanol for every 0.100 g of crude product placed in the flask. Use a hot plate to heat the mixture gently until the ethanol boils. If the product does not completely dissolve, gradually add more ethanol dropwise until all of the solid dissolves in the boiling solvent. [NOTE 2] Allow the solution to cool to room temperature. If necessary, scratch the bottom of the flask (tube) to induce crystallization. Prepare an ice-water bath using a 100-mL beaker. Place the flask (tube) containing the solution in the ice-water bath for 5 min to complete the crystallization. Filter the crystals using vacuum filtration. Allow your product to air dry in the filter funnel for 10 min. Transfer the product from the filter paper to a watch glass to finish drying. Weigh the product and record the mass. Measure the melting point of your dry product. Caution: Potassium bromide is irritating and hygroscopic. Prepare a KBr pellet of your product. Obtain the IR spectrum as directed by your laboratory instructor. 8. Cleaning Up Use the labeled collection containers provided by your laboratory instructor. Clean your glassware with soap or detergent. Caution: Wash your hands thoroughly with soap or detergent before leaving the laboratory. Post-Laboratory Questions 1. Calculate the percent yield for your product, before and after recrystallization, using Equation 3. actual yield, g percent yield, % = (100%) theoretical yield, g (Eq. 3) 2. Calculate the percent recovery from the recrystallization, using Equation 4. mass after recrystallization, g percent (Eq. 4) = (100%) recovery, % mass before recrystallization, g 3. Use your TLC data to explain whether or not the oxidation reaction went to completion. 4. Describe the major differences and similarities between the IR spectra of benzoin and benzil. Compare your product IR spectrum with spectra for benzoin and benzil. 5. Benzoin can also undergo reduction with reagents like NaBH4. Propose a structure for the product obtained from the reduction of benzoin. Discuss the stereochemical aspects of this material. 2000 by Chemical Education Resources Pre-Laboratory Assignment NAME SECTION DATE SYNT 738/Copper-Catalyzed Oxidation of Benzoin to Benzil Pre-Laboratory Assignment 1. What safety precautions must be taken when using glacial acetic acid? 2. Calculate the theoretical yield for the oxidation of benzoin using an excess of ammonium nitrate and catalytic copper(II) acetate. Show your calculations here and in your laboratory notebook. 2000 by Chemical Education Resources 11 12 SYNT 738/Copper-Catalyzed Oxidation of Benzoin to Benzil 3. Classify the following partial reactions as oxidations or reductions. (a) O O C C OH H (b) Zn Zn+ (c) (d) NH4NO3 NH4NO2 ISBN 0-87540-738-2 2000 by Chemical Education Resources