* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Protein-Engineered Biocatalysts in Industry

Survey

Document related concepts

Metalloprotein wikipedia , lookup

Point mutation wikipedia , lookup

Photosynthetic reaction centre wikipedia , lookup

Oxidative phosphorylation wikipedia , lookup

Real-time polymerase chain reaction wikipedia , lookup

Western blot wikipedia , lookup

Catalytic triad wikipedia , lookup

Enzyme inhibitor wikipedia , lookup

Proteolysis wikipedia , lookup

Peptide synthesis wikipedia , lookup

Oligonucleotide synthesis wikipedia , lookup

Evolution of metal ions in biological systems wikipedia , lookup

Biochemistry wikipedia , lookup

Deoxyribozyme wikipedia , lookup

Biosynthesis wikipedia , lookup

De novo protein synthesis theory of memory formation wikipedia , lookup

Transcript

Protein-Engineered Biocatalysts in Industry

F

F

F

O

F

O

N

N

F

NH 2

N

O

N

N

N

F

CF3

N

N

CF3

Stefan McCarver

Group Meeting

June 18 th, 2015

Protein-Engineered Biocatalysts in Industry

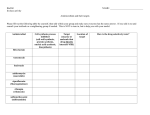

Diverse applications of enzymes

■ World enzyme market in 2003

Product

USD (Millions)

Detergents

789

Foods

634

Agriculture and feed

376

Textile processing

237

Pulp, paper, leather, and chemicals

222

Sanchez, S.; Demain, A. L. Org. Process Res. Dev. 2011, 15 , 224–230.

Protein-Engineered Biocatalysts in Industry

Diverse applications of enzymes

■ Enzymes can provide many advantages for chemical synthesis

O

O

HN

HN

lipase

OAc

OAc

Higher enantioselectivity and regioselectivity

Can be effective in both aqueous and organic media

Typically do not require protecting groups

N3

CHO

Me

N3

OH

aldolase

Operate under mild conditions with high efficiency

O

OPO32–

Me

OH

O

HO

OH

OH

OPO32–

Koeller, K. M.; Wong, C.-H. Nature 2001, 409, 232–240.

Protein-Engineered Biocatalysts in Industry

Utilizing natural enzymes for chemical reactions

■ Naturally occuring enzymes usually do not have desired catalytic reactivity

Naturally occuring enzyme

Ideal biocatalyst

Activity for specific substrate(s)

Activity for desired substrate(s)

Unstable under process conditions

Tolerates process conditions

How do chemists transform natural enzymes into useful biocatalysts?

Protein-Engineered Biocatalysts in Industry

Modification of enzyme catalysts

■ Proteins are modified through iterative mutation and screening

screening

mutagenesis

and

selection

Parent enzyme

Mutant proteins

■ Evolved proteins are used as parents for another iteration

■ The process is continued until desired reactivity is reached

Evolved enzyme

Bloom, J. D.; Arnold, F. H. Proc. Natl. Acad. Sci. U.S.A. 2009, 106 , 9995–10000.

Protein-Engineered Biocatalysts in Industry

Generating protein diversity

■ Methods for mutagenesis

Site-directed mutagenesis

A number of methods are known for specifically substituting individual amino acids in a protein

Requires a lot of structural information to be useful, often a crystal structure and computational modeling

Error-prone PCR

The polymerase chain reaction reaction is naturally error prone

This can be amplified by increasing Mg 2+, adding Mn 2+ and by using unequal nucleotide concentrations

Gene shuffling

DNA sequences from several similar proteins are fragmented and randomly recombined

A larger extent of fragmentation results in a greater number of single site mutations

Primrose, S. B.; Twyman, R. In Principles of Gene Manipulation and Genomics, 7 th ed.; Wiley-Blackwell, 2006; ch. 8

Protein-Engineered Biocatalysts in Industry

Generating protein diversity

■ Methods for mutagenesis

Site-directed mutagenesis

A number of methods are known for specifically substituting individual amino acids in a protein

Requires a lot of structural information to be useful, often a crystal structure and computational modeling

Error-prone PCR

The polymerase chain reaction reaction is naturally error prone

This can be amplified by replacing some Mg 2+ with Mn 2+ and by using excess of certain nucleotides

Gene shuffling

DNA sequences from several similar proteins are fragmented and randomly recombined

A larger extent of fragmentation results in a greater number of single site fragmentations

Primrose, S. B.; Twyman, R. In Principles of Gene Manipulation and Genomics, 7 th ed.; Wiley-Blackwell, 2006; ch. 8

Protein-Engineered Biocatalysts in Industry

Generating protein diversity

■ Methods for mutagenesis

Site-directed mutagenesis

A number of methods are known for specifically substituting individual amino acids in a protein

Requires a lot of structural information to be useful, often a crystal structure and computational modeling

Error-prone PCR

The polymerase chain reaction reaction is naturally error prone

This can be amplified by increasing Mg 2+, adding Mn 2+ and by using unequal nucleotide concentrations

Gene shuffling

DNA sequences from several similar proteins are fragmented and randomly recombined

A larger extent of fragmentation results in a greater number of single site mutations

Primrose, S. B.; Twyman, R. In Principles of Gene Manipulation and Genomics, 7 th ed.; Wiley-Blackwell, 2006; ch. 8

Protein-Engineered Biocatalysts in Industry

Generating protein diversity

■ Methods for mutagenesis

Site-directed mutagenesis

A number of methods are known for specifically substituting individual amino acids in a protein

Requires a lot of structural information to be useful, often a crystal structure and computational modeling

Error-prone PCR

The polymerase chain reaction reaction is naturally error prone

This can be amplified by replacing some Mg 2+ with Mn 2+ and by using excess of certain nucleotides

Gene shuffling

DNA sequences from several similar proteins are fragmented and randomly recombined

A larger extent of fragmentation results in a greater number of single site fragmentations

Primrose, S. B.; Twyman, R. In Principles of Gene Manipulation and Genomics, 7 th ed.; Wiley-Blackwell, 2006; ch. 8

Protein-Engineered Biocatalysts in Industry

Case studies

HO

OH

iPr

Ph

O

OH

NH

CO2Ca0.5

N

O

O

O

Me

Ph

O

Me

Me

Me

F

Me

Atorvastatin (Lipitor)

Simvastatin (Zocor)

F

F

NH 2

O

N

N

F

N

N

CF3

Sitagliptin (Januvia)

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

OH

iPr

Ph

OH

NH

CO2Ca0.5

N

O

Ph

F

Atorvastatin (Lipitor)

■ Lowers blood cholesterol by inhibiting the HMG-CoA reductase enzyme

■ Discovered at Parke-Davis, later acquired by Pfizer

■ Best-selling drug of all time, with over $125 billion in total sales

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Process route

O

OH

NC

Me

CO2Et

OH

OtBu

NC

LDA, THF

NaBH 4, MeOBEt 2

O

CO2tBu

THF/MeOH –90 °C

OH

OH

NC

CO2tBu

key hydroxynitrile

Me

2,2-DMP

O

Acetone, MsOH

iPr

O

Me

Me

H 2, Raney-Ni

NC

MeOH, NH 3

CO2tBu

Me

H 2N

O

CO2tBu

Me

O

O

iPr

PhHN

Ph

O

O

O

Me

Ph

heptane, toluene

THF, pivalic acid

NH

CO2tBu

N

F

O

O

deprotection

Atorvastatin

salt formation

calcium

Ph

F

Ma, S. K. et. al. Green Chem. 2012, 12 , 81–86.

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Previous routes to hydroxynitrile starting material

OH

NC

■ Estimated demand 100 mT per year

CO2Et

■ Simplified route that reduces waste is highly desirable

key hydroxynitrile

1) NaCN

2) NaOH

OH

HO

Cl

3) EtOH, H +

HBr

OH

HO

CO2Et

NaCN

OH

Br

CO2Et

OH

NC

CO2Et

from kinetic

resolution

kinetic resolution - max 50% yield

two steps involving the use of cyanide

HBr required to form bromohydrin

Ma, S. K. et. al. Green Chem. 2012, 12 , 81–86.

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Previous routes to hydroxynitrile starting material

OH

NC

■ Estimated demand 100 mT per year

CO2Et

■ Simplified route that reduces waste is highly desirable

key hydroxynitrile

1) HO –, H 2O2

HO

HBr

lactose

2) H +

O

O

EtOH

NaCN

OH

Br

CO2Et

OH

NC

CO2Et

uses chiral pool materials

HBr required to form bromohydrin

Ma, S. K. et. al. Green Chem. 2012, 12 , 81–86.

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Previous routes to hydroxynitrile starting material

OH

NC

CO2Et

key hydroxynitrile

O

O

Cl2

EtOH

■ Estimated demand 100 mT per year

■ Simplified route that reduces waste is highly desirable

asymmetric

O

Cl

CO2Et

hydrogenation

NaCN

OH

Cl

CO2Et

OH

NC

CO2Et

high pressure H 2 for asymmetric reduction

harsh cyanation conditions

Ma, S. K. et. al. Green Chem. 2012, 12 , 81–86.

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Previous routes to hydroxynitrile starting material

OH

NC

CO2Et

key hydroxynitrile

■ Estimated demand 100 mT per year

■ Simplified route that reduces waste is highly desirable

Issues to be addressed

■ Requirement of chiral pool materials or high pressure hydrogenation to access alcohol

■ Cyanation requires harsh conditions, challenging to separate product from byproducts

Ma, S. K. et. al. Green Chem. 2012, 12 , 81–86.

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Enzymatic route to hydroxynitrile starting material

OH

NC

■ Estimated demand 100 mT per year

CO2Et

■ Simplified route that reduces waste is highly desirable

key hydroxynitrile

ketone

reductase

O

Cl

CO2Et

Cl

CO2Et

O

HCN

CO2Et

OH

NC

CO2Et

Halohydrin dehalogenase

NADPH NADP

gluconate

– HCl

OH

glucose

glucose

dehydrogenase

Ma, S. K. et. al. Green Chem. 2012, 12 , 81–86.

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Ketone reductase mechanism

ketone

reductase

O

Cl

Tyr

CO2Et

OH

Cl

CO2Et

NADPH NADP

gluconate

O

His

H

H

N

N

H

N

H

glucose

glucose

Lys

dehydrogenase

H

O

R small

R large

O

Asp

H

H

O–

O

■ Proton transfer occurs from tyrosine residue

NH 2

N

■ Hydrogen bond to histidine orients substrate

O

O

■ Lysine provides electrostatic stabilization

H

■ NADPH positioned by hydrogen bond to asparagine

OH

NADPH

Kratzer, R.; Wilson, D. K.; Nidetzky, B. Life 2006, 58, 499–507.

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Enzymatic route to hydroxynitrile starting material

OH

NC

■ Estimated demand 100 mT per year

CO2Et

■ Simplified route that reduces waste is highly desirable

key hydroxynitrile

ketone

reductase

O

Cl

CO2Et

Cl

CO2Et

O

HCN

CO2Et

OH

NC

CO2Et

Halohydrin dehalogenase

NADPH NADP

gluconate

– HCl

OH

glucose

glucose

dehydrogenase

Ma, S. K. et. al. Green Chem. 2012, 12 , 81–86.

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Halohydrin dehalogenase mechanism

Arg

H 2N

H

N

Tyr

H

Cl

O–

O

halide

binding pocket

CO2Et

OH

NC

CO2Et

Halohydrin dehalogenase

H

Cl

CN –

OH

H

O

Ser

CO2Et

■ Deprotonation by tyrosine residue

Arg

H 2N

H

N

Tyr

■ Hydrogen bonding catalysis from serine

■ Binding pocket for departing halide

H

H

O

■ NADPH positioned by hydrogen bond to asparagine

O

H

Cl –

halide

binding pocket

O

Ser

CO2Et

Janssen, D. B. et. al. J. Bacteriol. 2001, 183 , 5058–5066.

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Directed evolution of KRED and GDH enzymes using DNA shuffling

ketone

reductase

O

Cl

CO2Et

Cl

CO2Et

O

HCN

CO2Et

OH

NC

CO2Et

Halohydrin dehalogenase

NADPH NADP

gluconate

– HCl

OH

glucose

glucose

dehydrogenase

Ma, S. K. et. al. Green Chem. 2012, 12 , 81–86.

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Directed evolution of KRED and GDH enzymes using DNA shuffling

ketone

reductase

O

Cl

– HCl

OH

CO2Et

Cl

CO2Et

O

HCN

CO2Et

OH

NC

CO2Et

Halohydrin dehalogenase

NADPH NADP

gluconate

glucose

glucose

dehydrogenase

Initial process (wild-type enzymes)

Final process (evolved enzymes)

Substrate (g/L)

80

160

Reaction time (h)

24

8

Enzyme loading (g/L)

9

0.9

Isolated yield (%)

85

95

> 99.5

> 99.9

Product ee (%)

Ma, S. K. et. al. Green Chem. 2012, 12 , 81–86.

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Directed evolution of HDDH enzyme using DNA shuffling

ketone

reductase

O

Cl

CO2Et

Cl

CO2Et

O

HCN

CO2Et

OH

NC

CO2Et

Halohydrin dehalogenase

NADPH NADP

gluconate

– HCl

OH

glucose

glucose

dehydrogenase

Ma, S. K. et. al. Green Chem. 2012, 12 , 81–86.

Protein-Engineered Biocatalysts in Industry

Synthesis of atorvastatin

■ Directed evolution of HDDH enzyme using DNA shuffling

ketone

reductase

O

Cl

– HCl

OH

CO2Et

Cl

CO2Et

O

HCN

CO2Et

OH

NC

CO2Et

Halohydrin dehalogenase

NADPH NADP

gluconate

glucose

glucose

dehydrogenase

Inital process (wild-type enzyme)

Final process (evolved enzyme)

Substrate (g/L)

20

140

Reaction time (h)

72

5

Enzyme loading (g/L)

30

1.2

Isolated yield (%)

67

92

> 99.5

> 99.5

Product ee (%)

Ma, S. K. et. al. Green Chem. 2012, 12 , 81–86.

Protein-Engineered Biocatalysts in Industry

Synthesis of sitagliptin

F

F

NH 2

O

N

N

F

N

N

CF3

Sitagliptin (Januvia)

■ Antidiabetic dipeptidyl peptidase-4 inhibitor

■ Developed and marketed by Merck

■ Often used as a combination therapy with other medicines

Protein-Engineered Biocatalysts in Industry

Synthesis of sitagliptin

■ First generation process route

F

F

1) [(S)-binapRuCl2]

F

F

HBr, H 2

O

CO2Me

EDC, LiOH

OH

CO2H

2) NaOH

83%

F

F

2) EDC, NMM

N

O

N

CF3

F

F

N

N

N

CF3

78% (4 steps)

H 2PO 4–

NH 3+ O

2) H 3PO 4

N

N

HN

NH

1) H 2, Pd/C

O

F

F

BnO

N

81%

F

BnO

F

2) DIAD, PPh 3

F

1) base

F

1) BnONH 2•HCl

N

N

F

N

N

CF3

Desai, A. A. Angew. Chem. Int. Ed. 2011, 50, 1974–1976.

Protein-Engineered Biocatalysts in Industry

Synthesis of sitagliptin

■ Second generation process route

O

O

F

O

F

CO2H

O

F

Me

Me

iPr 2HNEt +

O–

F

•HCl

F

O

O

N

CF3

O

83%

N

O

tBuCOCl, iPr 2NEt

F

N

HN

CF3CO2H

Me

Me

then NH 4OAc

F

F

F

NH 2

1) [{Rh(cod)Cl} 2], NH 4Cl,

O

F

N

N

2) heptane/iPrOH

CF3

one pot, 82% yield

NH 3+ O

tBu-josiphos, H 2

N

N

F

H 2PO 4–

N

N

F

N

3) H 3PO 4

N

CF3

81% yield

> 99.9% ee

Desai, A. A. Angew. Chem. Int. Ed. 2011, 50, 1974–1976.

Protein-Engineered Biocatalysts in Industry

Synthesis of sitagliptin

■ Third generation process route

F

F

transaminase

F

O

O

NH 2

pyridoxal phosphate

N

N

F

F

N

N

O

N

N

iPrNH 2

F

N

N

CF3

■ Transition metal catalyzed hydrogenation

required carbon treatment to remove Rh as

well as ee upgrade through recrystallization

■ Biocatalysis presents an opportunity to

attain excellent yield and near perfect

selectivity under mild conditions

CF3

NH 2

O

ATA-117

Me

Me

> 99.9% ee

Chem. Commun. 2009, 2127–2129.

Savile, C. K. et. al. Science 2010, 329, 305–309.

Protein-Engineered Biocatalysts in Industry

Transaminase mechanism

Lys

Me

Me

Me

NH

NH

NH 2

OH

H 2O3PO

Me

Me

Me

Ph

N

H

Ph

Me

NH

H

NH 2

OH

H 2O3PO

N

H

Me

Me

OH

H 2O3PO

Lys

Me

NH 3

N

H

Me

Me

Me

Lys

NH 2

NH

N

H

Me

Me

Me

Me

Ph

Ph

Me

N

H

NH

H 2O

Lys

NH 2

OH

N

H

Me

Lys

Me

Ph

Me

H 2O3PO

NH 2

OH

H 2O3PO

NH 2

O

NH 3

Me

Me

O

H

OH

N

H

Me

NH

Ph

NH

H 2O3PO

Lys

Me

NH 2

NH 2

OH

H 2O3PO

Me

Lys

Ph

NH 2

O

OH

H 2O3PO

N

H

NH 3

Lys

Me

Savile, C. K. et. al. Science 2010, 329, 305–309.

Protein-Engineered Biocatalysts in Industry

Synthesis of sitagliptin

■ Design of a transaminase catalyst - site saturation libraries in small and large pockets

Savile, C. K. et. al. Science 2010, 329, 305–309.

Protein-Engineered Biocatalysts in Industry

Synthesis of sitagliptin

Orange: Large pocket

Green: Catalytic

residues

Teal: Small Pocket

Savile, C. K. et. al. Science 2010, 329, 305–309.

Protein-Engineered Biocatalysts in Industry

Synthesis of sitagliptin

■ Third generation process route

F

F

transaminase

F

O

O

NH 2

pyridoxal phosphate

N

N

F

F

N

N

iPrNH 2

O

N

N

F

CF3

N

N

CF3

■ Site saturation and combinatorial libraries of binding pocket screened for activity

■ Most active mutant subjected to directed evolution for activity and stability under process conditions

Savile, C. K. et. al. Science 2010, 329, 305–309.

Protein-Engineered Biocatalysts in Industry

Synthesis of sitagliptin

■ Process optimization

NH 2

NH 2

Me

O

NH 2

O

N

N

N

N

N

N

F

N

N

O

N

N

F

N

CF3

CF3

F

CF3

N

F

F

F

Activity on model substrate

Activity on sitagliptin ketone

Optimized process

38% conversion

76% conversion

92% yield, > 99.9% ee

10 g/L enzyme

10 g/L enzyme

0.6 g/L enzyme

2 g/L substrate

2 g/L substrate

200 g/L substrate

0.5 M iPrNH 2

0.5 M iPrNH 2

1 M iPrNH 2

5% DMSO / triethanolamine

5% DMSO / triethanolamine

50% DMSO / triethanolamine

Savile, C. K. et. al. Science 2010, 329, 305–309.

Protein-Engineered Biocatalysts in Industry

Synthesis of sitagliptin

■ Process optimization

NH 2

NH 2

Me

O

NH 2

O

N

N

N

N

N

N

F

N

N

O

N

N

F

N

CF3

CF3

F

CF3

N

F

F

F

Activity on model substrate

Activity on sitagliptin ketone

Optimized process

38% conversion

76% conversion

92% yield, > 99.9% ee

10 g/L enzyme

10 g/L enzyme

0.6 g/L enzyme

2 g/L substrate

2 g/L substrate

200 g/L substrate

0.5 M iPrNH 2

0.5 M iPrNH 2

1 M iPrNH 2

5% DMSO / triethanolamine

5% DMSO / triethanolamine

50% DMSO / triethanolamine

Savile, C. K. et. al. Science 2010, 329, 305–309.

Protein-Engineered Biocatalysts in Industry

Synthesis of sitagliptin

■ Process optimization

NH 2

NH 2

Me

O

NH 2

O

N

N

N

N

N

N

F

N

N

O

N

N

F

N

CF3

CF3

F

CF3

N

F

F

F

Activity on model substrate

Activity on sitagliptin ketone

Optimized process

38% conversion

76% conversion

92% yield, > 99.9% ee

10 g/L enzyme

10 g/L enzyme

0.6 g/L enzyme

2 g/L substrate

2 g/L substrate

200 g/L substrate

0.5 M iPrNH 2

0.5 M iPrNH 2

1 M iPrNH 2

5% DMSO / triethanolamine

5% DMSO / triethanolamine

50% DMSO / triethanolamine

Savile, C. K. et. al. Science 2010, 329, 305–309.

Protein-Engineered Biocatalysts in Industry

Synthesis of sitagliptin

■ Third generation process route

F

F

transaminase

F

O

O

NH 2

pyridoxal phosphate

N

N

F

F

N

N

O

N

N

iPrNH 2

F

CF3

N

N

CF3

■ Increase in overall yield relative to second generation process: 13%

■ Waste reduction relative to second generation process: 19%

Savile, C. K. et. al. Science 2010, 329, 305–309.

Protein-Engineered Biocatalysts in Industry

Synthesis of simvastatin

HO

O

O

Me

O

O

Me

Me

Me

Me

Simvastatin (Zocor)

■ Lipid lowering medication - HMG CoA reductase inhibitor

■ Developed and marketed by Merck

■ Produced by semisynthesis from lovastatin

Protein-Engineered Biocatalysts in Industry

Synthesis of simvastatin

■ Produced by semisynthesis

HO

O

O

Me

O

HO

xxx

O

Me

Me

xxx

O

O

steps

Me

O

O

Me

Me

Me

xxx

Me

Me

Lovastatin

Simvastatin

Isolated from Aspergillus terreus

Increased inhibitory properties

Hydroxymethylglutaryl CoA reductase inhibitor

Lower undesirable side effects

Xie, X.; Watanabe, K.; Wojcicki, W. A.; Wang, C. C. C.; Tang, Y. Chem. Biol. 2006, 13 , 1161–1169.

Protein-Engineered Biocatalysts in Industry

Synthesis of simvastatin

■ Typical semisynthetic route

HO

O

O

xxx

O

O

Me

HO

O

hydrolysis

O

Me

OH

Me

xxx

O

OH

xxx

Me

Me

O

O

O

Me

xxx

Me

OH

Me

xxx

Me

TBSO

Cl

Me

Me

O

O

O

Me

Me

HO

xxx

Me

xxx

Me

O

O

O

deprotect

O

xxx

Me

xxx

xxx

Me

TBSO

O

TBSCl

xxx

Me

TBSO

O

Me

Me

Me

xxx

Me

Me

Xie, X.; Watanabe, K.; Wojcicki, W. A.; Wang, C. C. C.; Tang, Y. Chem. Biol. 2006, 13 , 1161–1169.

Protein-Engineered Biocatalysts in Industry

Synthesis of simvastatin

■ Potential synthesis utilizing biocatalysis

HO

O

O

Me

O

O

xxx

O

hydrolysis

O

Me

HO

Me

OH

xxx

Me

xxx

Me

Me

HO

O

Direct enzymatic route:

Me

S

Me

■ Higher yielding process, cost savings

■ Remove need for protecting groups

CoA

O

O

O

Me

xxx

Me

O

Me

Me

Me

xxx

Me

Xie, X.; Watanabe, K.; Wojcicki, W. A.; Wang, C. C. C.; Tang, Y. Chem. Biol. 2006, 13 , 1161–1169.

Protein-Engineered Biocatalysts in Industry

Synthesis of simvastatin

■ Selective biocatalytic acylation reaction

US Patent WO/2011/041231

Protein-Engineered Biocatalysts in Industry

Synthesis of simvastatin

■ Selective biocatalytic acylation reaction

HO

O

HO

O

Me

O

Me

Me

Me

S

Me

O

Me

Me

xxx

Directed

O

O

OH

saturation mutagenesis

O

Me

Me

CO2Me

Me

Improved thermal stability

Improved acyltransferase activity

evolution

error-prone PCR

xxx

Use of a small molecule acyl donor

Xie, X.; Watanabe, K.; Wojcicki, W. A.; Wang, C. C. C.; Tang, Y. Chem. Biol. 2006, 13 , 1161–1169.

Protein-Engineered Biocatalysts in Industry

Synthesis of simvastatin

■ Directed evolution of acyltransferase

US Patent WO/2011/041231

Protein-Engineered Biocatalysts in Industry

Synthesis of simvastatin

■ Directed evolution of acyltransferase

Improved Catalytic Activity

6"

5"

kcat (min-1)

4"

3"

2"

1"

0"

0"

1"

2"

3"

4"

5"

6"

7"

8"

9"

10"

Directed evolution round

US Patent WO/2011/041231

Protein-Engineered Biocatalysts in Industry

Synthesis of simvastatin

■ Directed evolution of acyltransferase

Improved

Improved Protein

Catalytic

Solubility

Activity

6"

250"

-1)

Solubility

kcat (min

(mg/L)

5"

200"

4"

150"

3"

100"

2"

50"

1"

0" 0"

0" 0"

1" 1"

2" 2"

3"3"

4"4"

5"5"

6"6"

7"7"

8"

8"

9"

9"

10"

Directed

Directedevolution

evolutionround

round

US Patent WO/2011/041231

Protein-Engineered Biocatalysts in Industry

Synthesis of simvastatin

■ Directed evolution of acyltransferase

Improved

Improved

ImprovedProtein

Catalytic

ProteinSolubility

Stability

Activity

6"

250"

51#

49#

5"

200"

-1)

Solubility

kcat

Tm(min

(°C)

(mg/L)

47#

4"

45#

150"

3"

43#

100"

41#

2"

39#

50"

1"

37#

0"

35#0"

0"0#0"

1"1#1"

2"2#2"

3"3#3"

4"4#4"

5"5#5"

6"

6#

6"

7"

7#

7"

8"

8#

8"

9"

9#

9"

10"

10#

Directed

Directed

Directedevolution

evolution

evolutionround

round

round

US Patent WO/2011/041231

Protein-Engineered Biocatalysts in Industry

Synthesis of simvastatin

■ Selective biocatalytic acylation reaction

HO

O

HO

xxx

O

Me

O

Me

Me

Me

O

O

OH

Me

Me

O

Me

S

O

Me

Me

CO2Me

Me

■ Reduced use of hazardous substances and solvents in synthesis

■ Catalyst from renewable feedstocks, byproducts all recycled

■ Produced in 97% yield compared to < 70% for previous processes

Xie, X.; Watanabe, K.; Wojcicki, W. A.; Wang, C. C. C.; Tang, Y. Chem. Biol. 2006, 13 , 1161–1169.

Protein-Engineered Biocatalysts in Industry

Case studies

HO

OH

iPr

Ph

O

OH

NH

CO2Ca0.5

N

O

O

O

Me

Ph

O

Me

Me

Me

F

Me

Atorvastatin (Lipitor)

Simvastatin (Zocor)

EPA Presidential Green Chemistry Award 2006

EPA Presidential Green Chemistry Award 2012

F

F

NH 2

O

N

N

F

N

N

CF3

Sitagliptin (Januvia)

EPA Presidential Green Chemistry Award 2010