* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download NUMERICAL SIMULATION OF CORONA

Maxwell's equations wikipedia , lookup

Classical mechanics wikipedia , lookup

Newton's theorem of revolving orbits wikipedia , lookup

Speed of gravity wikipedia , lookup

Renormalization wikipedia , lookup

Magnetic monopole wikipedia , lookup

Equations of motion wikipedia , lookup

Introduction to gauge theory wikipedia , lookup

Aharonov–Bohm effect wikipedia , lookup

Work (physics) wikipedia , lookup

Fundamental interaction wikipedia , lookup

Field (physics) wikipedia , lookup

Standard Model wikipedia , lookup

Lorentz force wikipedia , lookup

Theoretical and experimental justification for the Schrödinger equation wikipedia , lookup

Relativistic quantum mechanics wikipedia , lookup

History of subatomic physics wikipedia , lookup

Electric charge wikipedia , lookup

Elementary particle wikipedia , lookup

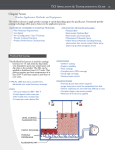

NUMERICAL SIMULATION OF CORONA-CHARGING POWDER COATING SYSTEM by Thanh Lam Department of Electrical and Cornputer Engineering Submitted in partial fulfilment of the requirements for the degree o f Master o f Engineering Sciences Faculty o f Graduate Studies The University o f Western Ontario London, Ontario August 1998 OThanh Lam, 1998 National Library Bblioth&que nationale du Canada Acquisitions and Bibliographie SeMces Acquisitions et seMces bibliographiques 395 Wenington Street OttawaON K1A ON4 395. rue Wellington Ottawa O(J K I A ON4 canada Canada The author has granted a nonexclusive licence allowing the National Lib,rary of Canada to reproduce, loan, distnbute or seil copies of ths thesis in microform, paper or electronic formats. L'auteur a accordé une licence non exclusive permettant a la Bibliothèque nationale du Canada de reproduire, prêter, distribuer ou vendre des copies de cette thèse sous la forme de microfiche/nlm, de reproduction sur papier ou sur format électronique. The author retains ovmership of the cop+ght in this thesis. Neither the thesis nor substantial extracts fiom it may be printed or otherwise reproduced without the author's permission. L'auteur conserve la propriété du droit d'auteur qui protège cette thèse. Ni la thèse ni des extraits substantiels de celle-ci ne doivent être imprimés ou autrement reproduits sans son autorisation. ABSTRACT This thesis describes a numerical algorithm to calculate the electric field. charge density and the particle trajectories in a coronacharging powder coating system. The system consists of an electrostatic powder gun, powder particles and a target plane. The algorithm employs an iterative technique where the Finite Element Method is used for cornputing the electric field strength i n conjunction with the Method of Characteristics for determining the ionic charge density and the Particle-In-Cell Method for simulating the powder particle trajectories from the gun to the target plane. The airflow between the electrostatic gun and the target plate is calculated by solving the Navier-Stokes equation for steady viscous laminar flow. The particle trajectories are modeled using the Basset, Boussineq and Oseen equation and integrated using the Euler's method. The process is ccrnputed recursively until a self-consistent solution for the electric field, particle trajectories and t h e space charge density distribution is obtairied. The algorithm is used t o simulate the powder particle trajectories for variations of particle size, corona voltage, charge t o mass ratio, mass transfer rate and the gun position relative to the target plane. The results provide a further understanding of the electric field. powder iii trajectories and the space charge density distribution in the electrostatic coating process. ACKNOWLEGEMENTS First, 1 would like t o t a k e this opportunity t o express my sincere gratitude to my chief advisor Professor Kazirnierz Adamiak for h i s invaluable guidance and s u p p o r t throughout the project. 1 would also like t o thank Professor G 5 . P Castle, Professor Terry E. Base, and Dr. Sergey Primak f o r their advise and helpful discussions o n t h e project. Finally, I want t o thank my parents, my family and al1 my friends for their support and everlasting encouragement t h r o u g h al1 these years. T A B L E OF CONTENTS CHAPTE R 1 Introduction ------------------------*------------------------------1 1 - -..*----------.----.--------------- 1- 1 Background .------. 1. 2 Objectives ----------------.-------.-------.------+-+--+.-------------.--------------.------3 *--* * .*.- *-*---.*----- CHAPTER 3 Mathematical Mode1 of Powder Coating 4 . 3 . 1 interpolation o f Space Charge Density ...4 4 4.4 Calculating t h e Powder Particle Trajectories --------------------.. ...46 4.5 Convergence of the Iterative Process ----...............----.---------------49 CHAPTER 6 Conclusions and Recommenda tions - .---- 78 6.1 78 Conclusions ---------,,.--....-.--------...-..-----.-----.---------.------------ 6.2 Recommendations --------...--....,.-------.--.----.------------------.---80 83 REFERENCES .---.----.-----------------------+-+..-.------------.--------------*--------------- 89 APPENDIX ---------.--------------.-..----.----------------------------------.---- CURRICULUM VITAE ------.--------------------.----*----*-*-**-----------.--------------.--~*------.--.-- 94 LIST OF FIGURES Figure 1 . 1 Schematic diagram of an electrostatic powder coating unit ............................ Figure 2.1 Particle charging by corona discharge............................................................. 2 9 Figure 2.2 Schernaîic representation of back-ionization in corona-charged powder layer 14 Figure 2.3 Schematic of a low voltage curona gun ....................................................... 16 Figure 3.1 Geornetry of the electrostatic powder c o a ~ unit g ....................................... 21 Figure 3.2 Charge assigrnent in Particle-In-CeiJ method .............................................. 32 Figure 3 -3 Boundary conditions for airflow mode1 ....................................................... -34 Figure 4.1 Flowchart of cornputer program ................................................................. - 3 7 Figure 4.2 Electric field at tip of wrona wire surfiice .................................................... 41 Figure 4.3 Trajectory seps for characteristic hes ......................................................... 43 Figure 4.4 Interpolation of charge density at FEM mesh nodes .................................... -46 Figure 5.1 Electric field distribution in EPC system ....................................................... 54 Figure 5.2 Axial component ofelehc field in EPC system .......................................... - 5 5 Figure 5.3 Radial component of electric field in EPC systern ........................................ -56 Figure 5.4 Contour plot of the electric field near corona wire ....................................... - 5 7 Figure 5.5 Ions demity distn'bution produced by corona discharge ............................... -59 Figure 5.6 Space charge deosity distributioa in EPC system .......................................... 60 Figure 5.7 Powder tmjectories in EPC system .............................................................. -64 Figure 5.8 Particle velocity vecton dong trajectories in EPC system (Pauthenia LVna Q/W-1- 3 mClkg) .........*.............................................*..................... -65 Figure 5.9 Particle velocity vecton with smaller charge to mass ratio (Singh minimum Q M=.0.2 rnC/kg) ............................................................................... 66 Figure 5.10 Electric field vecton dong particle trajectories in EPC system ................... 67 Figure 5.11 Electric field intensity d o n g the furthest trajectory .................................... 68 Figure 5.12 Axial component of air velocity dong axial axis ......................................... 69 Figure 5.12 Particle tnjectories as finction of applied voltage ................................... Figure 5.13 Particle trajectories as funaion of charge to mass ratio Figure 5.14 Particle trajectories as fiinction of particle radius -73 .............................. 74 ....................................... 75 Figure 5.15 Particle trajectories as fùnction of mass transfer rate .................................. 76 Figure 5.16 Particle trajectories for d e r gun-to-target separation ............................ 77 Figure A l An electrostatic powder coating unit manufactured by Wagner................... 90 Figure A2 Powder flow of a flat spray gun nonle ....................................................... 90 Figure A3 Flowchart of Finite Element subrouthe ....................................................... 91 Figure A4 Flowchart of a subroutine evaluating space charge density using MOC Figure A5 nowchart of a subrouthe evaluating the particle trajectories ....... 92 ...................... 93 LIST OF TABLES Table 2.1 Advantages and disadvantages of different types of powder in EPC ............... I I Table 5.1 Parameters of the EPC Process...................................................................... 52 NOMENCLATURE Svrnbol Descri~tion Unit ion mobility mZ/~s absolute room temperature K operating temperature K normal atmospheric pressure Pa operating pressure Pa roughness factor t i me axial position radial position permittivity permittivity of free space ( 8 . 8 5 4 8 4 2 ) relative permittivity Peek's corona onset electric field electric field axial component o f electric field radial component of electric field electric field at corona wire surface current density space charge density electric potential electric potential associated with node i shape function associated with node i charge density associated with node i characteristic matrices of triangular mesh energy function associated with one triangle energy function powder discharge time constant powder resistivity powder particle radius mass of particle powder density fluid density maximum charge carried b y a particle charge to mass ratio charge density coefficient ernitting angle space-time trajectory of ions number of trajectory segments initial incrernent step trajectory step constant force acting on particle air drag force gravity force electrostatic force particle velocity fluid velocity drag coefficient gravitational constant (9.81) diffusion coefficient equivalent charge of super particle number o f toroidal rings mass transfer rate area of triangle average radius of a triangle length of corona wire radius of corona wire length o f gun nozzle radius of gun nozzle radius of target plane gun to target distance electric potential at corona wire electric potential at target plane mean radius of particle particle eject velocity radial component of fluid velocity axial component of fluid velocity axial component of particle velocity radial component o f particle velocity kinematic viscosity stream function vorticity axial acceleration of particle radial acceleration of particle axial position of particle radial position of particle error of inner loop error of outer loop CHAPTER 1 Introduction 1.1 Background Electrostatic Powder Coating (EPC) is a process whereby electrostatic forces are applied to increase the transfer efficiency of powder particles onto a grounded workpiece. The high deposition rate and low operating costs have attracted many industrial manufacturers to apply EPC to their finishing products such as household appliances and auto body parts. The coating process generally consists of three main stages: 1 . Charge and transport the powder to the workpiece 2 . Deposit the powder to the workpiece 3 . Transport the workpiece to an oven and fuse powder t o form a continuous coating A diagram of a corona charging EPC system is shown in Figure 1 . 1 . It consists of a fluidized bed hopper, an electrostatic g u n and a workpiece connected t o ground. T h e powder is usually an epoxy resin ground to a very small mean size of 10-100 p m diameter. The powder is first fluidized in the bed hopper and then pumped to the electrostatic gun. A very thin corona wire connected to a high voltage supply is L- Free ions - Corona wire \ Q 0-- - Q-O -0 - Elecmc Fluidized bed hopper High voltage generator 8 a Control unit Figure 1.1. Schematic diagram of an electrostatic powder coating unit placed at the gun nozzle. When the applied voltage is higher than the onset voltage, a phenornenon known as corona discharge is created which produces a cloud of unipolar ions. These ions attach to the passing-by powder. The powder particles become charged and are carried to the grounded workpiece and adhered to i t by the electrostatic forces. T h e workpiece is then transported to an oven where the powder is fused t o form a continuous coating. 1.2 Objectives T h e objective of this project is t o develop a full numerical algorithm of a corona-charging EPC process. It applies the Finite Element Method and the Method of Characteristics to compute the electric field and the space charge distribution coupled with the numerical integration of the Basset, Boussinesq and Oseen's equation and the Particle-In-Cell Method to determine the trajectories of the powder particles. The mode1 is used t o study the trajectories of powder particles for various operating conditions such as different applied voltages, mass transfer rates, particle sizes, charge to mass ratios and gun-to-target separations. CHAPTER 2 Electrostatic Powder Coatiog 2.1 Introduction There are two cornmon EPC systems used in the commercial applications: the tribo charging system and the corona charging system. They differ not only in the way the particles are charged, but also in the electrical conditions o f the transport and the deposition zones. In the corona charging system. the powder particles are charged by bombardment with the ions produced in the corona discharge. A high voltage supply is required to create the corona discharge but it also generates a strong electric field which drives the powder particles towards the target. I n the tribo charging system, the powder particles are charged by frictional contact between the powder particles and the material of the gun body. The cloud of charged particles ejected from the gun forms a space charge, which in turn produces an electric field conveying the particles towards the target. Considerable research has been undertaken t o study the charging mechanism of the t w o systems. A cornparision o f the tribo versus corona charging systems was reviewed by Kleber [ 2 1 ] , Moyle and Hughes [29], and Reddy [ 3 2 ] . Many different gun designs and powder materials were investigated and tested to optimize the transfer efficiency of the coating process. 2.2 Tribo Charging Frictional or tribo charging has been k n o w n for more than 2000 years. When two insulating materials are rubbed together repetitively, the material with the higher work function will be charged negatively while the other is charged positively. For some powder materials. they can experience considerable frictional charging during transport from the bed hopper to the electrostatic gun. This charging usually depends on the temperature, density, conductivity, permittivity, duration of contact, surface treatment, and number of contact points. I n some instances, the powder acquires an amount of charge in the same order of magnitude as in the corona charging. The amount of charge acquired by the powder is very important i n the EPC as it establishes not only the intensity of the electric field which drives the particles towards the workpiece, but also the ability of the particles t o adhere to the grounded workpiece. The advantage of the tribo system is that it does not need a high voltage supply to generate the ions for charging the powder particles such as in the corona charging system. Because of this. the system produces no free ions and gives a superior powder penetration into targets that have corners and cavities. The drawback of the system is the steady decrease in t h e mean charge to mass ratio d u e to the accumulation of a powder layer on the interna1 surface of the gun barrel. This occasionally makes t h e tribo charging system unreliable and unpredictable during a long coating operation. 2.3 Corona Charging 2.3.1 Corona Discharge The most important property of the corona discharge is its ability to generate a space charge in the gas filled regions. This ionic space charge can be used for charging small solid particles, liquid droplets, or dielectric surfaces making possible numerous applications such as powder coating, paint spraying, crop spraying, electrophotography. particle separation and precipitation. The corona discharge is produced when a high voltage is applied between two electrodes with different curvatures. In the corona charging EPC system, the electrostatic powder gun consists of a very thin corona wire connected to a high voltage supply and the workpiece connected to ground as shown in Figure 1 . 1 . When a high negativel voltage is applied to the corona wire, it produces a very high electric field region near the corona wire known as the ionization region. Positive ions created by ionization from electromagnetic radiation o r ot her mechanisms are attracted t o the corona wire while electrons are repelled away by the h i g h electric field. The electrons accelerate away from the negative corona wire and gain sufficient energy to ionize any molecules with which they collide. These collisions produce an avalanche of electrons and positive ions until new electrons are formed far enough away that they are unable t o gain sufficient energy from the electric field between collisions t o ionize another atom. The electrons emerging from the ionization region are attached to air molecules t o form a space charge cloud of negative ions drifting from the corona wire towards the grounded target. These ions help suppress the electric field near the corona wire making t h e corona discharge stable and accessible for charging powder particles in the EPC process. 2.3.2 Pauthenier L i m i t When the spraying powder particles enter the space charge cloud produced by the corona discharge, the particles are charged by the negative ions impinging on the particle surfaces untii the repelling 1 For more information about positive and negative corona. set White[ll] and Hughes[ZO]. electric field produced by the particles is equal to the surrounding field a s shown in Figure 2 . 1 . The charging then ceases and the particle is said t o have acquired a saturation charge, known as the Pauthenier limit. Pauthenier predicted that the tirne variation of the charge on a spherical particle by corona charging is given by where a is the particle radius and E is the electric field intensity. From the above equation, the maximum charge that can be acquired by the particle depends on the magnitude of the electric field and t h e square of t h e particle radius. In normal coating operation, the charging tirne is very small, usually about 0.01-0.1 rns for a particle in the charging zone with a sufficiency strong electric field E [IO]. The maximum charge acquired by the powder particle is therefore equal t o For a spherical particle with density p,, t h e saturation charge to mass ratio is elearic field source of ions (a) no charge (b) saturation charge Figure 2 . 1 Particle charging by corona discharge. 2.4 Parameters of EPC System The effectiveness o f the EPC. system is measured by the transfer efficiency and the quality of the finish coating. The transfer efficiency may be defined as the ratio of the powder mass deposited on the target to the mass of the powder emitted from the gun. The primary goals are to obtain a transfer efficiency as high as possible while meeting the aesthetic requirements for the coating applications concerned. These goals can be achieved by optimizing the following factors: powder materiais. flow rate. powder charging and the adhesion ont0 the workpiece. 2.4.1 Powder Material AH materiais can be electrostatically applied in an EPC process provided they are electrical insulating and can b e produced in powder form of approximately 10 - 100 pm mean diameter. The powders used are normally made of synthetic materials with high resistivity such as polyester, epoxy. vinyls. etc ... The mean particle size and the geometric standard deviation of the size distribution of the powder particles have a dominant effect on the final coating appearance and the charging characteristics. Smaller particle sizes and deviation are found to give a more uniformly deposited powder layer and greater coating consistency while larger particle sizes usually acquire a bigger charge and are more efficiently deposited on the grounded workpiece. Singh 1361 observed that the mean charge to mass ratio ( Q M) is inversely proportional t o the particle radius for tribo charging where as the powder pigmentation and the surface chemistry have a dominant effect on the mean charge to mass ratio for corona charging. Basic data of some commercial powders and their applications obtained from Cross [ 1 5 ] are compared in Table 2 . 1 . T a b l e 2.1 Advaotages a n d d i s a d v a n t a g e s of different types of powder i n E P C . Material Acrylic Cellulose acetate Chlorinated polyethers Epoxies Fluorocarbons Nylon Polyester Polyethylene Polyurethane Vinyls Disadvan tages Advantages High durability, good hardness, excellent chemical resistance Excellent flow, good gloss and colour, excellent chernical resistance Excellent corrosion, mechanical and electrical 1 resistance, good dimensional stability Excellent adhesion, high alkali, abrasion and corrosion resistance High exterior durability and service temperature, low coefficient of friction, Excellent chemical and electrical resistance L o w coefficient of friction, high dielectric strength, chernical and abrasion resistance T hermoplastic and t hermoset avaiiable, intermediate cost Good chernical resistance and electrical insulation, excellent flexibility, low 1 water absorption, resists low temperatures, low cost High chernical resistance, Excellent hardness. good gloss and flow Poor f l o w , moderate adhesion, brittle Moderate adhesion, soft film, discolours at high temperature Poor exterior durability, h i g h cost, fair adhesion 1 1 1 / in exterior applications. , High chernical resistance, high dielectric strength, long-term durability, good Abrasion resistance, 1 intermediate cost I Chalking and yellowing high cost Poor adhesion, requires high curing temperature, high cost 1 Films beiow 100 pm ( difficult, poor adhesion, 1 high cost, low service temperature High curing temperature Poor adhesion and durability, poor exterior durability, and abrasion 1 resistance, low service temperature Poor adhesion, h i g h water resistivity,chalks and yellows in exterior use Poor adhesion, only thick films 175 pm / 2.4.2 Powder Flow The powder flowability and fluidization are also very important in the powder coating process. In order to have uniform coating, the powder must flow through the gun and be well dispersed while maintaining a uniform mass transfer rate. Even minor changes in dispersion and flow characteristics alter the film properties. Mazumder et al.[26] found that powder with a wider size distribution has a higher fluidity while powder with a surface treatment additive gives a better flowability. The flow rate usually depends on the work environment and the equipment used. A flow rate of 1-3 g/s is commonly applied in many industrial EPC processes. 2.4.3 Powder Charging The charging of powder is considered to be the most important step i n the EPC process. The amount of charge acquired by the powder particles not only determines their trajectories b u t also their adherence to the workpiece. If the charging is too low, the powder may not adhere t o t h e workpiece; if too high, i t can give rise t o poor quality coating. Singh [36] found that the deposition efficiency is a function of the mean charge to mass ratio ( Q / M )of the powder. The higher the mean charge to mass ratio, the higher the deposition rate. Therefore. it is very important that the powder particles are charged consistently with a sufficient charge during the coating process in order to maximize the efficiency. Singh e t al. [ 3 5 ] reported that a minimum charge t o mass ratio o f 2x10-' C / k g is required before the powder particles will adhere to any grounded w o r k p i e c e . A charge to mass ratio o f 5 x 1O-' C/kg is usually necessary f o r a d e q u a t e adhesion in t h e coating process. 2.4.4 Powder Adhesion When t h e c h a r g e d powder particles a r e carried near t h e grounded workpiece, they a r e a t t r a c t e d t o the workpiece by t h e Coulomb force. The powder particles build u p a layer covering the workpiece. The workpiece is then t r a n s p o r t e d t o an oven t o fuse t h e particles and form a continuous c o a t i n g . Meanwhile. t h e powder must retain its charge so it doesn't fa11 off t h e workpiece. The time constant f o r t h e discharge o f the powder is given a s where E~ i s 5 is the p o w d e r resistivity, EQ is t h e permittivity o f free space and t h e relative permittivity of the p o w d e r material. For insulating powder with resistivity exceeding 10" am,it can retain i t s charge for several minutes while conductive particles o r materials with l o w resistivity tend to l o s e their charge rapidly and fa11 off t h e workpiece. Therefore, the powder resistivity must b e selective so that the particle will retain its charge long enough to fuse and form the finishing coating. As more and more particles and ions move from the gun to the workpiece, the potential across the deposited layer increases. As the layer thickness increases, the field strength increases until it reaches a critical field strength ( - 3 x 1 0 ~ V/m) sufficient t o cause a break down in the surrounding air. The break down produces bipolar ions. which neutralize the incoming charge particles and create a non-uniform coating on the workpiece. This is known as back ionization. Back ionization often Iimits the thickness of the deposited layers and can produce a poor quality finishing by creating surface blemishes such as pinholes. moon craters, and the orange peel effect in the finishing coating. Free ions w Charged particles Uncharged Figure 2.2 Schematic representation of back-ionization in a corona-charged powder layer 2.5 Low Voltage Corona G u n As discussed earlier. the tribo system is unreliable and the corona system produces excessive free ions giving rise to the early onset of back ionization. One approach for eliminating these free ions is to modify the corona gun design as shown in Figure 2 . 2 . Instead of placing the corona wire outside the gun nozzle, the corona wire is withdrawn within the confines o f the gun notzle [ 2 9 ] . If an additional electrode. called an attractor electrode, is grounded and placed near the corona wire, the corona discharge can be generated at a much lower voltage. Corona charging is carried out in the interelectrode spacing within the g u n nozzle. Al1 the powder emanating from the g u n will pass through the corona region and will b e charged, while the free ions are attracted to the attractor electrode and very few ions are ejected from the gun nozzle. With these low voltage guns, there are some operational difficulties due t o the powder deposition on the interna1 attractor electrode and the gun nozzle. As the powder deposition increases, it decreases the charging and can also cause the onset of back ionization within the gun. Thus, these guns would require regular maintenance after a period of coating operation. Figure 2 . 3 2.6 Schematic of a low voltage corona gun Literature Review of EPC Simulation The numerical simulation of the corona charging EPC system consists of calculating the electric field, space charge and the powder particle distribution from the gun t o the target. The particle and the space charge density are dependent o n the electric field. On the other hand, t h e electric field is dependent on the particle and the space charge density. Therefore, both distributions are mutually coupled and should be solved simultaneously. In 1987, A n g and Lloyd [6] presented a computational mode1 for calculating the trajectories of charged particles in an EPC system. The equation of motion of the particle was formulated by performing a force balance of the aerodynamic and the electrostatic forces involved. The airflow from the gun nozzle was measured using a hot wire anemometer and found to be reasonably approximated by Tallien's solution for an axisyrnmetric jet [Il. Using a point-to-plane mode1 developed by Wu [42]. the electric field was calculated by solving the one-dimensional Poisson's equation assuming the charge density distribution was constant. The trajectories of the particles were calculated and compared with the experimental measurements using photographic techniques. The accuracy between the computed and the experimental results showed improvement when moving towards the centerline of the air jet. The results showed that the airflow from the spraying gun was responsible for the initial particle transport, with increasing dominance of the electrostatic forces near the grounded workpiece mainly due the field enhancement effect of the space charge. Artamonov and Vereshchagin [7] described a mathematical mode1 for calculating the electric field and the space charge density distribution of an electrostatic spraying process. The electric field and the space charge density from the gun t o the target plane were found to be interconnected and described by the Poisson and the continuity equation. The Finite Difference Method was used to solve both equations simultaneously. The calculated results showed that the particle size affects greatly the deposition efficiency. Higher efficiency was obtained when larger particles were used. Using the Boundary Element Method and the Finite Element Method to solve for the electric field distribution, Tanasescu et al. [ 3 8 ] developed a mathematical model t o calculate the charged particle trajectories in an electrostatic field. Neglecting the spatial charge. the particle trajectories were deterrnined by integrating two non-linear ordinary differential equations governing the axial and the radial acceleration of the particles. The air velocity was computed by solving the Navier-Stokes equation for small flow rates. The particle trajectories were computed for charge-to-mass ratios both from the Pauthenier charging equation and the experimental charge measurement. Ali 151 presented a mathematical mode1 for t h e trajectories of charge powder particles in an EPC system by considering the electrostatic and the aerodynamic forces acting on the particles. The model employed an iterative technique wherein the Charge Simulation Method was used t o compute the electric field and the Method of Characteristics was used to compute the charge density distribution in the interelectrode space between the g u n a n d the target plane. The airflow was interpolated €rom experimental rneasurements using a hot wire anemometer. Neglecting the space charge from powder particles, several powder particles were simulated for size range of 10-40 p m diameter and charge-to-mass ratios of 0.01-0.1 rnClkg. In this thesis, a new numerical technique is developed employing the Finite Element Method (FEM), the Method of Characteristics (MOC) and the Particle-In-Cell (PIC) Method to simulate t h e motions of t h e charged powder particles in an EPC process. The powder charge and the ionic charge density are included i n the numerical mode1 by calculating the combined electric field, space charge and the trajectories of powder particle recursively until a self-consistent solution is obtained. CHAPTER 3 Mathematical Model of Powder Coating Process 3.1 Model and Assumptions As usual in numerical simulation, some idealizing assumptions have to be made in order to simplify the problem. Using the cylindrical coordinate system and the axial symmetry of the model. only one half of the geometry of the EPC unit from the g u n nozzle to the target needs to be rnodeled, as shown in Figure 3 . 1 . The mode1 consists of a 2-cm diameter dielectric g u n nozzle' located at a distance S away from the target plane. A small corona wire of 0.5-mm diameter is placed at t h e center of the gun nozzle. The wire is assumed to be connected to a high voltage supply and t h e corona discharge is produced continuously along the hemispherical tip of the corona wire. The target is considered as an infinite circular plate connected to ground. A plate radius of 0.6-rn (twice the gun-to-target distance) is found sufficient to represent the infinite target plate. The powder particles are assumed to be fluidized b y the bed hopper and uniformly distributed. Each particle has identical ' Measuremests are taken h m an electrostatic powder gun in the W O AERC Iaboratory. size and characteristics and al1 exit the gun nozzle with the same velocity. Gunnovfe Free space I H.V.corona wire Figure 3.1 Geometry of the electrostatic powder coating unit. The electrostatic fieid in the space charge area is governed by the following subset of Maxwell equations where E is the vector of t h e electric field intensity, E is t h e permittivity and p is the space charge density. The set of partial differential equations can be rewritten by introducing a scalar function called the electric potential CI defined as The electric potential U satisfies the Poisson equation shown below The space charge from the corona wire moves towards t h e grounded target plane and this creates an electric current with the magnitude related to the electric field and the space charge density as where p is t h e charge mobility and J is the vector current density. The movement of the space charge must satisfy the current continuity as The trajectories of the powder particles are calculated by considering al1 the forces acting on the particle. These forces are expressed by Newton's second equation where Fr is the drag force, Fe is the electrostatic force and F, is the gravitational force. Because the particles are charged, they contribute to the space charge density that affects the electric field in equation ( 3 . 4 ) . Equations ( 3 . 4 ) to (3.7) govern the particle trajectories in an EPC system. The problem can be considered as a simultaneous set of partial differential equations. Because of t h e non-linear character of the problem, it is very difficult to obtain an analytical solution and it must be solved numerically. The following sections discuss several numerical techniques for calculating the particle trajectories, electric field and the space charge distribution of the EPC system. 3.2 Particle Trajectories Ang and Lloyd [6] have suggested that the motion of the powder particles in the EPC process is governed b y the electrostatic and t h e aerodynamic forces. In normal operating condition, the particle motion i s governed by t h e air velocity in the early stage of the trajectories and then carried t o the grounded workpiece by the electrostatic forces. For small particles, these forces can be modeled b y the Basset. Boussinesq and Oseen's ( ~ ~ 0 ) " c p a t i o n as (air drag) (gravity) (electrostatic) (local pressure gradient effect) ) (apparent mass acceieration) -- -(af -q dr + 60' JGJ dr r O - ,/= (Basset memory term) - " Baw[8] proposed a modined BBO equation based upon the addition of a t e m for the Magnus effect abich is a force perpendicular to the velocity of the particle due to spia The BBO's equation is a complete equation describing the forces acting u p o n a srnall spherical particle moving i n a fluid. In our case, it is the powder particles travelling through air. The solution of the full BBO's equation is very complicated and requires integration in t h e last two terms. Soo (371 and Klinzing [22] stated that if the density of the particles is much greater than the density of the fluid, then the pressure gradient, the apparent mass acceleration and the memory terms would contribute very little to the net force acting on the particle. Since the density of most powder material is i n the order of 10' ( k g / m 3 ) compared to 1.2 for air, we can simplify t h e BBO's equation to just the first three terms: air drag, gravity and electrostatic forces. 3.3 Finite Element Method The Finite Element Method (FEM) is a numerical technique for solving partial differential equations such as the Laplace or Poisson equation. The method can provide numerical results with good accuracy assuming that the discretization is sufficiently fine. The basic idea of the FEM is to divide the problem domain into some number of srna11 elements and interpolate the solution over each element by a simple function. The linear interpolation function for a triangular element is given as where N I , N2,and N3 are the shape functions for the nodal points 1 to 3 U , . UI and Ujare the potential values at the nodes. The space charge density distribution can also b e approxirnated in the same way as According to the variational principle, the problem of solving the Poisson equation is equivalent to t h e problem of finding an extremum of the energy functional. The element energy of the triangle can be defined as where the second term represent the force function (source) within the element. The gradient of the potential given by equation (3.9) can be calculated from the following equation Assuming that the charge density is known for each node. the source integral may be written as Substituting equations ( 3 . 9 ) and ( 3 . 1 2 ) into ( 3 . 1 1). the element energy equation becomes Equation ( 3 . 1 4 ) can be rewritten in matrix form as are two new characteristic matrices defining the triangular element. The total energy associated with the whole domain is the sum of al1 the individual element energies By assembling al1 the individual matrices into one global matrix, the energy function of the whole domain is defined as Applying the energy extremum principle, W should be differentiated with respect to al1 nodal potentials a s for i=1,2, ... n This gives a set of n equations with unknown nodal values of potential The relation between the electric field and the potential is given i n equation ( 3 . 3 ) . Having evaluated the potential for al1 the nodes within the domain, it is then possible to evaluate the electric field using equat ion (3.12). 3.4 Method of Characteristics O n e of the most efficient techniques for space charge evaluation is the Method of Characteristics (MOC). The method was first derived by Waters et al. [39],who investigated the drifting o f an unipolar ion cloud with mobility p. Perhaps the unique thing about the MOC is that it transforms the partial differential equation governing the evolution of charge density into a first order ordinary differential equation along a specific space-time trajectory. This space-time trajectory, or so-called characteristic line, is a path on which the ions are drifting in the electric field region. The ordinary differential equation can easily be integrated yielding an analytical solution in terms o f t h e initial charge density and the time needed by the ions to migrate from one point to another. The law governing the conservation of charge is given as: where J is the current density and defined as Assuming that the diffusion coefficient D is negligible, substituting J into equation ( 3 . 1 9 ) and simplifying o n e obtains W e can define the characteristic line as and the partial differential equation ( 3 . 2 1 ) is transformed into an ordinary differential equation along the characteristic line g i v e n by equation ( 3 - 2 2 ) . Integration o f the differential equation ( 3 . 2 3 ) yields where po is the charge density at the starting of the characteristic line and t is the elapsed time. By making an estimate of the charge density po, we can evaluate the space charge density in the interelectrode space from the corona wire towards the target plane. A s discussed in chapter 3.1, the motion of each particle can be determined by balancing al1 the forces acting o n the particles along its trajectories from the gun to the workpiece. The calculations usually require large memory and are very time consuming for large number of particles such as in an EPC systern. Methods such as the Particle-In-Ce11 (PIC) [18] are used to irnprove the computing process while maintaining the accuracy requirements. The advantage of t h e PIC method is that i t couples the electric field and the powder particle distribution. At every point along the particle trajectory, the powder charge is calculated and added to the ionic charge density produced by the corona discharge. The electric field and the particle trajectories are calculated repeatedly until a self-consistent particle trajectory is obtained. In order to simplify the problem, the powder particles are assumed to have equal size and exit the gun nozzle at a uniform speed. An elernentary cylindrical volume dv containing many particles, is divided into sorne number of toroidal rings (n,) o f equal thickness as s h o w n i n Figure 3 . 2 . Al1 the particles in the toroidal volume are represented b y a super particle and its equivalent charge can be calculated as At any time step, t h e charge of the super particle is assigned t o a triangle mesh according to the formula where p represents the powder charge density, i is the toroid ring number, A is the triangle area, and raveis an average radius of the triangular element. FEM mesh , . 7 Y S m . - . . . . * * 6 6 i l - Figure 3.2 Charge assignment using Particle-In-Cell method 3.6 Airflow Aoalysis The airflow emanating from the gun nozzle was computed by solving the Navier-Stokes equation [3 O] by assuming steady viscous laminar flow. The Navier-Stokes equation governing the airflow in the cylindrical CO-ordinates is given as where v , and v, are two unknown components of the velocity vector. The equation can be simplified b y introduction of two new scalar variables: t h e stream function function is defined a s and t h e vorticity (v and the vorticity w . The stream Using the above definitions, we can rewrite the Navier-Stokes equations in term o f the vorticity and the stream function a s The air w a s assumed t o exit the n o z z l e at a uniform velocity, V.O. Neglecting the corona wire, the boundary conditions can b e formulated as shown in Figure 3 . 3 . Figure 3 -3 Boundary conditions for airflow model. The two equations ( 3 . 3 2 ) and ( 3 . 3 3 ) can b e solved iteratively using the F E M by first assuming the vorticity o = O and solving equation ( 3 . 3 2 ) for y. Then vis substituted into equation ( 3 . 3 3 ) and soived for o. The process is repeated continuously until a converging process is obtained for y and o. CHAPTER 4 Numerical Simulation of EPC System 4.1 Description of Corn puter Program I n order to simulate the corona charging EPC system, a cornputer software has been developed incorporating the algorithrn previously described in chapter 1.2. The software consists o f a main program and several subroutines'. which functions are to carry out a specific task. There are three basic tasks in the algorithm: Calculate the electric field using F E M Caiculate the space charge using MOC Determine the powder particles trajectories The programs are compiled on an IBM 850 PowerPC with 100 Mhz clock speed. The main program acts as an interface and iteratively calls these subroutines according to the flowchart shown in Figure 4.1. There are two iterative processes in the program: an inner and an outer loop. See subroutine flowcharts in the apgendiu 1 Calculate the air velocity distribution 1 Apply FEM to sobe Laplace equation, ampute E + Appiy MOC to caicuiate the space c b g e disaibution - 4 - Determine the trajectories of powder particles r Update the charge densiîy d i s t r i i o n 1 - Recompute E solving the Poisson equation post pmcesing of output data A Figure 4 . 1 Flowchan of cornputer program. E r r l f l % , , e r r t f S % ) : assumed errors for inner and outer loops Ec: electric field on the surface of corona wire En: onset electric field eom Peek's formula The program s t a r t s by calculating t h e air velocity distribution. It then applies the F E M t o calculate the initial electric field distribution by solving the Laplace e q u a t i o n . From the calculated field. the M O C is applied to calculate t h e ion density and the B B O ' s equation is integrated t o determine the powder particle trajectories. The next step is t o interpolate the space c h a r g e density frorn both t h e free ions and the powder charge. With an updated space charge distribution, the electric field is recalculated a l o n g with the space charge and t h e powder trajectories. This process constitutes the inner l o o p o f t h e program and i s iterated until a self-consistent solution for t h e electric field and the space charge density i s obtained. I n the outer loop, t h e space charge density o n the corona wire surface is iterated until t h e electric field and t h e c h a r g e density satisfy Kaptzov conditions [4]. According to this hypothesis, t h e electric field o n the corona wire s u r f a c e remains constant at t h e value resulting from Peek's formula defined a s where Rw is the radius of t h e corona wire and 6 is t h e air density which is related t o the a b s o t u t e room temperature and pressure a s If the surface of t h e corona wire is not smooth as in most practical cases, it is necessary to introduce a roughness factor f, which has a value of less than unity. Then equation (4.1) becomes 4.2 Electric Field Calculation using FEM The geometry mode1 shown in Figure 3.1 is initially discretized into a number of triangular elements (approximately 3200 nodes). The Delaunay Triangulation Method [1 I l is used for the refinement process to produce a set of triangles close to equilateral ones as possible. Because the electric field changes very rapidly around the corona wire, very fine mesh is allocated i n this region and the triangle sizes increase gradually approaching the target plane. A potential Il,,, is assigned to t h e boundary nodal points at t h e surface of t h e corona wire and zero potential is assigned to the boundary nodal points at the target plane. The domain is assumed to be initially free of charge (Laplacian field) and calculated using t h e FEM. Since a11 the matrices involved in the FEM are symmetric. sparse. and banded. they can be stored in a halfbandwidth format. This technique reduces the storage requirement for the matrix. In order to minimize the bandwidth, the Cuthill-McKee algorithm was applied to number the nodes. The minimum bandwidth can b e achieved by minimizing the difference between the lowest and the highest node number of any single element in the domain. Then the equations ( 3 . 9 ) and ( 3 . 1 2 ) are solved t o calculate the nodal potentials and the electric field distribution within the domain. 4.3 Space Charge Calculation using MOC The ionic charge distribution of the corona discharge is calculated using the MOC described in chapter 3 . 4 . The electric field along t h e tip of the corona wire is shown in Figure 4 . 2 - Wherever the electric field exceeds the onset field on the surface of the corona wire, the surface is assumed to go into corona and emits ions. These ions then forrn a space charge cloud propagating towards the target plane. Figure 4 . 2 . Electric field at t i p of corona wire surface Initially, twenty characteristic lines are set at the emitting surface but this changes as the iteration process proceeds. The space charge density at the corona wire surface where the first characteristic l i n e begins, po,, is estimated first. Then, the charge density at al1 other points i s calculated using the following formula pot = po!cosB, The initial estimation of the charge density is very important for the quick convergence of the process. I t requires some previous experience and general knowledge of relationship between the current and the surface charge density at the corona wire. While a good estimate of the charge density, po,, closer to the physical value generally gives a faster convergence and reduces the computing tirne; a poor estimate may slow down the convergence and in some cases, it can lead to instability. Using the calculated electric field distribution, the charge density is computed along each characteristic line using the equations (3.22) and (3.24). The characteristic line in ( 3 . 2 2 ) can be approximated by a finite difference equation as In t h e above equation, we can select a fixed time or a fixed distance for the trajectory step. Because the distance from the corona wire to the target plane is given, it was found that it is easier to set the step along the z-axis, A t . Then, the time increment can be calculated as NOTE TO USERS Page(s) not included in the original manuscript and are unavailable from the author or university. The manuscript was microfilmed as received. This reproduction is the best copy available. where a, 1 and y are three unknown coefficients which can be determined from the known charge density at the nodes of the constructed triangle element. At the vertices of each triangle. the following equations can b e written: Treating these equations as a set of 3 equations with 3 unknowns, we can calculate a, and y as functions of p,, p,. pi and substitute these values back into equation (4.8) t o calculate the charge density p(r.z) Any node outside the last characteristic line is considered free of ions drifting toward the area and is assigned a zero charge density. This process is carried out for al1 t h e nodal points of the FEM mesh to determine t h e charge density distribution produced by the corona discharge. ...._.-- -.._. -.._. .a.. point on the , - .-.. a *.: Figure 4 . 4 Interpolation of charge density at FEM mesh nodes 4.4 Calculating the Powder Particle Trajectories The powder particle trajectories are calculated using the %BO'S equation in ( 3 . 8 ) . Because of the large number of particles with many different sizes and shapes, it is very difficult, if not impossible, to sirnulate the motion of every particle in an EPC process. Therefore, the following simplifying assumptions are made in the calculation: the particles are spherical and uniformly distributed at the gun nozzle al1 particles have identical size and characteristics there are no particle-particle or particle-fluid interactions the particle exit velocity is given the particles are charge-free when they exit the gun (no tribo-charge) the particles acquire an unipolar charge instantly at a charging zone near the corona wire the particles experience constant acceleration and velocity over each time step From the BBO's equation. the particle acceleration at any given point can be calculated as where CD is the drag coefficient and v, and v , are the air velocities. The air velocities are interpolated from the airflow calcuIation described in chapter 3.5 (this airflow distribution is assumed to b e constant throughout the calculation process). Another assumption made is that the powder particle exits the g u n nozzle at a known velocity and contains no net charge. The particle continues t o move until it cornes into contact with the ions produced by the corona discharge. I t then acquires al1 of the charge instantly and is transported to the target. Using the calculated charge density from the MOC, the diameter of the ionic charge cloud is found equal to the diameter of the gun nozzle at 5-mm away from the corona wire. The particles are assumed to have made contacts with the ions at that point and acquire an unipolar charge instantly. The electric field at the charging point is found to be approximately 1 x 1 o6 Vlm. This value is substituted into the Pauthenier formula in (2.3) to determine the magnitude of the particle charge to mass ratio. The particle velocity can be found by integrating the accelerarion equation using Euler's method as and similarly for the particles trajectories = pzi + U p z , At PC+i = Pr, + U r , 4.5 Convergence of the Iterative Process As mentioned earlier, the algorithm consists of two iterative loops. The inner loop requires the convergence of the electric field and the charge density distribution, and the outer loop requires the convergence of the electric field and the space charge to satisfy Kaptzov condition at the corona wire surface. After the charge density has been interpolated and updated, the electric field is recalculated using the F E M . For every nodal point within t h e domain, the electric field is compared with the previously calculated field. The process is repeated iteratively until a self-consistent solution for the electric field and the space charge is obtained. The criterion used for the convergence is for i=l,2,3 .. . . n where E,'*' is the electric field at node itb in the krh iteration step. In general, the process converges very fast and requires on average 3-4 iterations for accuracy better than 1%. The handling of the outer loop is a little more difficult. It requires the adjusting of the space charge density on the corona wire surface to satisfy the Kaptzov condition. The boundary condition requirement is that the electric field on the emitting surface of the corona wire b e equal to the Peek's onset field. En. With the electric field on the corona wire surface shown in Figure 4.2. the field can be suppressed to Peek's onset field by altering the charge density at the starting points of the characteristic lines. For any lines whose electric field at the starting point is greater than En. the charge density will be modified according to t h e formula where p,, is the charge density at the starting points of line i in the k C h iteration. K is the charge density coefficient and Ec, is the electric field at the starting point of the line. For any lines whose electric field is smaller than Eo, the charge density is assigned zero and considered not to be emitting any space charge. The iterations are stopped when the electric field of al1 the points at the corona wire surface are within 5% of Peek's onset field. CHAPTER 5 Simulation Results and Discussions 5.1 Simulation of EPC System Using the geometry model shown i n Figure 3.1 and the assumptions made in the previous chapter, t h e developed numericai algorithm is used to calculate the trajectories of the powder particles for a typical operating condition of an EPC process. The dimensions of the model and other system variables are given in Table 5 . 1 . The particle trajectories are calculated and compared for different operating parameters such as: applied voltages charge to mass ratios particle sizes mass transfer rates g u n position relative t o target plane. - -- - Table 5.1 Parameters of the EPC System -- length of corona wire, L w radius of corona wire, R , length o f gun nozzle, L , radius of gun nozzle. R, radius of target plate. Rt distance from gun to target. S corona wire voltage, CI, i o n mobility, p mass transfer rate, rn , t mean radius o f powder particle, r, powder density, p, charge to mass ratio. Q A4 particle eject velocity. v , ~ gravitational constant, g 5.2 Electric Field Distribution As discussed earlier. the trajectories of the powder particles are governed by the aerodynamic and t h e electrostatic forces. Therefore, it is very important t o know the distribution o f the electric field within t h e system. The electric field is presented in Figures 5 . 1 to 5 . 4 . Figure 5 . 1 shows the electric field distribution within the problem domain. The field consists o f both the applied (Laplacian) field and the space charge field. It is observed that t h e electric field is very high near t h e corona wire and decreases rapidly when moving away from the wire. The intensity o f the applied electric field is directly related to the applied voltage between t h e corona wire and the grounded target. If the applied voltage increases, it increases t h e applied field which in turn increases the space charge field. After a rapid decrease near the corona wire, the electric field begins t o level off and decreases slowly for much of the remaining area. The electric field strength in t h e particle trajectory region is in the order of 10' Vlm which coincides with t h e values used by H u g h e s [ 2 0 ] , Cross [14] and Bright et. al. [IO]. Figure 5 . 2 shows the component o f the electric field in t h e axial direction E,. while Figure 5.3 shows the component o f the electric field in t h e radial direction Er. Figure 5.4 s h o w s the contour plot o f al1 field components in t h e high field region near the corona wire. Figure 5.1 Electric field distribution in EPC system Figure 5.2 Axial component of electnc field in EPC system. 3 3.5 4 4.5 5 5.5 6 Figure 5.3 Radial component of electnc field in EPC systern 6.5 Figure 5.4 Contour plot of the electric field near corona wire. 5.3 Charge Density Distribution The space charge density distribution is shown in Figures 5 . 5 and 5 . 6 . Figure 5.5 shows a contour plot of the ions density produced by the corona discharge. The free ions spread out to form a cone-shaped cloud drifting towards the grounded target. T h e magnitude of the space charge density is found to be near the estimated charge density of 2 x 1 0 ' ~c h 3 . This indicates that the initial estimate of the charge density at the corona wire is good and the program converges rather quickly. The magnitude of the space charge density depends on the applied voltage at the corona wire. An increased applied voltage produces a higher ion density as required to suppress the electric field to Peek's onset field at t h e corona wire surface. Figure 5 . 6 shows a threedimensional view of the space charge density distribution. The charge density consists of both the free ionic charge and the powder charge. The powder charge density is found to b e small as compared to the ionic charge density. Moyle & Hughes [29] estimated that i n normal corona charging operations, the space charge is made u p of 0.5% powder charge and 99.5% of free ions. Figure 5.5 Ions density distribution produced by corona discharge. Figure 5.6 Space charge density distribution of EPC system 5.4 Particle Trajectories Figure 5 . 7 shows the trajectories of the powder particles from the gun to the target plane separated by 0 . 3 m (other parameters are: LI,=- 100kV. Q M=-1 . 3 m U k g (Pauthenier limit), r P = 3 0 p m , m t= lgls). As discussed in chapter 3.5, each trajectory represents a number of charged powder particles. As the particle leaves the gun, it becomes charged and experiences a strong electrical force acting along t h e trajectory. The axial component of the electric field is responsibIe for driving the particles to the target while the radial component of the electric field diverges the particles in the radial direction. A higher field intensity causes the powder particles to spread out further in the radial direction and increases the coating area on the target plane. The results of the simulation show the radius of the coating area approaches the coating distance from the gun to the target plane. The particles form a layer covering an area of approximately 0.2m radius when the gun-to-target separation is 0.3m. This is relative to Ali [ 5 ] measurements of 0 . h radius for 0.25111 gun-to-target separation. Figure 5 . 8 shows the velocity vectors of the particles along the trajectories. It is observed that the particle travels at a similar velocity for most of the distance from the gun t o the target. The particle is ejected from the gun at a constant velocity until it is charged by the negative ions produced by the corona discharge. The particle is then accelerated and the velocity increases rapidly because of the high field intensity near t h e corona wire. As the particle moves away from the corona wire toward the target, the field begins to decay and the velocity decreases until it reaches the terminal velocity. For this particular operating condition. it is noted thst the terminal velocity is higher than the ejecting velocity of 1.0 m/s at the gun nozzle. This can be explained by the high electrical force exerted on the particle because of the high charge to mass ratio (Pauthenier limit). If the particle charge to mass ratio decreases, then the electrical force acting on the particle also decreases and lowers the terminal velocity. This is shown in Figure 5 . 9 when the particle charge to mass ratio is reduced to -0.2 m C / k g (Singh minimum Q ,M for particle adhesion to grounded workpiece). Figure 5.10 shows the electric field vectors along the particle trajectories. The field vectors are pointing towards the gun nozzle because of the negative polarity of the applied voltage at the corona wire. Figure 5 . 1 1 shows the electric field (E, E,, and E r ) of the farthest particle trajectory from the axis. The field inteosity E, decreases when t h e particle moves towards the grounded target. The radial component of t h e electrical field, Er also shows a similar relationship and decreases when moving towards the target. Meanwhile, the axial component of the electric field, E, decreases along t h e trajectory and then increases near the target. This electric field behavior is typical for al1 wire-plane corona systems. Figure 5.7 Powder trajectories in EPC sy stem. Figure 5.8 Particle velocity vectors dong trajectories in EPC syaem. (Pauthenier Q/M =- 1- 3mC/kg) Figure 5.9 Velocity vectors with smaller charge to m a s ratio. (Minimum QM=-O.lrnC!kg) Figure 5.10 Electric field vecton dong pamcle uajectories in EPC ?stem. Figure S. 1 1 Electric field dong the tan trajectories from g m to taqet. Figure 5.12 Axial component of air velocity along axial a i s . Figure 5 . 1 3 shows the particle trajectories as function of the applied voltage. Only the furthest trajectories for each simulation are shown in order to compare the powder cone shape from the gun to the target plane. The results show a direct relationship between the cone shape and the applied voltage. An increase of 10 kV enlarges the coating radius of the target area by approximately 2 cm. This relationship can be explained by analyzing the electric field and the charge density distribution. When the applied voltage increases. it elevates the electric field intensity. which in turn increases the powder charging and the space charge density produced by the corona discharge. Higher charge density produces a higher space charge field and causes stronger dispersion of the powder. A stronger dispersion indicates that the particles are more spread out in the radial direction and thus build up a wider layer covering the target plane. I n some EPC processes. the increasing of applied voltage may be the easiest way to increase the charging but this also produces more free ions that can cause earlier onset back ionization and leads to poor quality finishing. Figure 5 . 1 4 shows the particle trajectories as function of the charge to mass ratio. The trajectories are simulated for particle charge to mass ratios €rom -1.3 rnClkg (Pauthenier limit) t o -0.2 mC/kg (Singh minimum QIM requirement for particle adhesion to any grounded workpiece). The results show the particles with higher charge to mass ratio experience a higher electrical force and are spread out further along the target plane. Figure 5 . 1 5 shows the particle trajectories as function of the particle size. The particle trajectories are calculated for panicle radii from 10 to 50 prn. Because of low inertia, the small particles are more affected by the aerodynamic forces in the early stage of the trajectories. The results show that the 10 pm particles are more dispersed at the gun nozzle, but then form a relatively focused beam and give a smaller cone radius than larger particles. Figure 5 . 1 6 shows the particle trajectories as function of the mass transfer rate. There is a little difference in the particle trajectories when the mass transfer rate is increased frorn l g / s to 3 g/s. The computation process tries to simulate more particles travelling from the gun towards the target. This creates a shift i n the charge density distribution within the system. More ions are transferred to the powder particles as it increases the powder charge density while lowers the ioaic charge. There is little change in the electric field distribution and this is portrayed i n t h e particle trajectories. In Figure 5 . 1 7 , the target has been moved closer towards the gun nozzle (from O.3m to 0.2). The result shows a similar trajectory pattern as in Figure 5.7. The powder particles build a denser layer covering a smaller area on the target plane. Figure 5.13 Particle trajectories as function of applied voltage. (@W1.3mC/kg, rp=3O ~ ~ r n / 1ig/s,S=O. = 3 m) Figure 5.14 Puticle trajectories as function of charge to mass ratio. ( U p1OOkV, rP=30pm,m/t=l g/s,S=O.3 m) Figure 5.15 Particle trajectories as function of particle radius. (&= iOOW,Q;M=-O.SmClkg,m~lg/s,S=û.3rn) Figure 5.16 Particle trajectories as function of mass transfer rate. (UW=1OOkV,QfM=l .3mC/kg,rp=30pm,S=0.3m) Figure 5.17 Particle trajectories for smaller gun-to-target separation. (UW=100kV,Q,W- 1. 3 m C l k g , r p = 3 0 p ~ m lg/s,S=O.Zm) '~ CHAPTER 6 Conclusions and Recommendations 6.1 Conclusions The numerical algorithm for simulating the particle trajectories in the corona-charging powder coating system has been presented in this thesis. The Finite Element Method for calculating the electric field strength and the Method of Characteristics for determining the ionic charge density were used in conjunction with t h e Particle-In-Ce11 Method to simulate the powder particle trajectories from the g u n to the target plane. The problem was computed iteratively until a selfconsistent solution for the electric field, particle trajectories and the space charge density distribution was obtained. The simulation results showed a highly non-uniform electric field distribution near the corona wire. The field decreased rapidly near the wire and then leveled off for much of the particle trajectory area. The space charge density produced by the corona discharge forrned a conelike shape in the interelectrode space between the corona wire and the target plane. The magnitude of the charge density was related to the applied voltage between the corona wire and t h e grounded target. A higher voltage produced more ionic charge which in turn, increased the space charge field and dispersed the powder particles Further in the radial direction. The particles form a layer covering a target area with radius close to the gun-to-target separation. The algorithm was used to study the powder particle trajectories as functions of several application parameters o f the coating process. The following relationships were obtained: Increased applied voltage: It has a strong effect on the particle trajectories as it produces a higher electric field and charge density. The particles experience a higher electrostatic force, which causes more dispersion and increases the coating area. Increased charge to mass ratio: The particles experience a higher electrostatic force because of the higher particle charge. It increases the particle terminal velocity and spreads the particles further i n the radial direction. Decreased the particle size: Small particles (10pm)are dispersed more when emanating from the gun and are influenced more by t h e mechanical force. fncreased mass transfer rate: It increases the powder charge density but decreases the ionic charge density. There is little change in the electric field and the particle trajectories. Decreased gun to target distance: Powder particles deposit across a smaller target area and produce a thicker layer. 6.2 Recommendations Because of the complexity of the EPC process involving many parameters that govern t h e electrostatic and the mechanical forces acting on the powder particles, an exact model of the practical coating process was difficuit to achieve. The numerical algorithm presented in this thesis provided a further understanding of the electric field, space charge density and the powder trajectories in the EPC system. However. there are still many modifications that can be implemented to improve the accuracy of the simulation process. Here are some recornrnendations that can be considered for further development of the numerical model. Include the non-uniform particle size and shape distribution. T h e current model assumes that the particles are sphericai with identical sites. Include the influences by the environment conditions such as . temperature, humidity, surface roughness of corona wire etc . . . as these affect the charge density produced by the corona discharge. Model the particles with different charge and include the charge decay. Hughes [ 2 0 ] suggests that about 60% of the powder particles are charged in a normal EPC process. Carry out experimental measurements of the particle trajectories t o compare with the simulation results. Include the booth (recovering) airflow and the ion wind i n the model. Model the target with corners and cavities or use different shapes such as sphere or cylinder. The different target shapes would create different electric field and airflow distribution. One of the most difficult tasks in the simulation is t o calculate the aerodynamic forces acting on the particles. The current simulation is carried out based on the assumptions that there is no interaction between the particles and the carrying airflow. The air velocity is calculated by solving the Navier-Stokes equation assuming viscous laminar flow. For most commercial coating processes, the Reynolds number is much higher and the flow develops into a turbulent flow. The full solution for such cases is very difficult because o f t h e turbulent characteristic of the flow and the distortion from the particle interactions. This challenge is left for future development. [ 11 Abramovich, G. N., Tne 7heory of T11rbufentJets, MIT Press, Cambridge, Mass.. 1963. [ 21 Abuaf, N. and Gutfinger C ., Trajectones of Charged Solid Parttcles in an Air Jet under the Ifluence of on Electrostatic Field, Int. J. Multiphase Flow, vol. 1 ( 1974)- pp. 5 13-523. [ 31 Adamiak, K., Numerical Modefing of Tribo-Charge Powder Casting Systems, Journal of Electrostatics, vol. 40 & 41 (1987), pp. 395-400. [ 41 Adamiak, K., Simulation of Corona in Wue-hicî Electrostatic Precipitator by Means of the Boundary Element Methoci, IEEE Transactions on Industry Applications. vol. 30, No. 2, MadApr 1994, pp. 38 1-386. [ 51 Ali, F. S., Studes d Modeling in Electrostutic Pow&r Cwring, M. E. Sc. Thesis, University of Western Ontario, 1994. [ 61 Ang, M.L.and Lloyd, P . J., Imestigutim of Charged Particle Trajectories in Eiectrostolic Powder Cwring Systems, ht.J. Multiphase Flow, vol. 13, No. 6, (1987). pp. 823-836. [ 71 Arîarnonov, A.F. and Vereshchagus LP., MuthematicalM&f of Electrostatic Air Spraying rmd S m e Numerical Experimenz Results, J o d of Electrostatics, vol. 23 (1989), pp. 463-468. . [ 81 Base, T.E & Behaviotcr of Aerosol Partides in a Computed Tr~rb-dent Flow M d l , hceedings of the Sixth Symposium on Turbulence in Liquids, University of Missouri-Rolla, (1979). pp. 78-85. [ 91 Bassett. J. D., Corbett, R. P. and Cross J., The Self-hzling of E~ecfros!aticPowder Cmring, m.Phys. C o d Ser. No. 27, (1975). pp. 221-227. [ 1O] Bright, A W.and Bas= J ., 19 75 P h r and Equipmen!for the AppIication of Powder Cmtintgs, Presented at Particle Workshop on Electrostatic Powder Coaiing, Chernical Engineering Dept., Loughbourough Univ. of Technology, Leics, pp. 1 19- 1 26. [ 1 11 Cendes, E. J., Shanton, D. and Shahnasser. H.,Magnetic Field C'tation using DeIauruzy TrzmguIar rmd Compiementary Finite EIement Method, EEE Trans. Magnetics, vol. 19, No. 6, (1983), pp. 255 1-2554. [12] Chapra S. C. and Canale, R. P., Numerical Methods for Engineers, 2& Edition, McGraw-Hill, Publishing Company, 1988. [13] Cross, J., Adhesion of Eecnostatic Powder Cwrings, hst. Phys. C o d Ser. No. 27, ( 1 975), pp. 202-214. [141 Cross, J. A., Electrostatics: Principles, Problems, rmd Applications, IOP hiblishing Lirnited, 1987. [15] Crowley, J. M..F u ~ e r r t ~ofi Applied s EIectrosrarics. Krieger Publishing Company, Flonda, 199 1 . [16] Diguang, 2.and Dexuan, X., ArzuZysrS of the Currentfor a Negative Point-teP l m e Corona Discharge in Air, Journal of Electrostatics, vol. 25 (1990), pp. 22 1-229. [17] Elmoursi, A and Speck C.E., SimuIurion of Spce C k g e in Unbounded Geomerries. IEEE Transactions on industry Applications, vol. 26, No. 2, MadApr 1990, pp. 3 84-392. [ 1 81 Hockney, R.W., Cornputer Sindation using Particles, McGraw-Hill Inc ., 198 1. [ 191 Hughes. J . F.. Powder Cwting TechnoIogy, J o u d of Electrostatics, vol. 23 ( 1989), pp. 3-23. [ 201 Hughes, I. F..Efectrostutic Particle Chargng: IIndstrial ond Heaith Cme Applications, John Wiley & Sons hc.,Toronto, 1997. [ 2 11 Kleber, W., Electrostatrc Powder Gun Design, Jounial of Electrostatics, vol. 30 ( 1993), pp. 393-402. [ 221 K l i ~ n g G. , E., G d o l i d Transport, McGraw-Hill Book Co.. Inc.. New York, 1981, [ 231 Lami. E., Mattachini, F.. Gallimiberti, L, Tuni, R and Tromboni, U.,A Numerical Procechrre for Compuîing the Voitage-îuwent Chorccteristics in Electrostatic Precipitator Conflgurutions, Journal of Electrostatics, vol. 3 4 ( 1 995), pp. 3 85-3 99. [ 241 Makin, B.and Bims, 1.. Diagnostic ~mtmrnenl for Efechostatrc Powder Cmting, Journal of Electrostatics, vol. 1 6 ( 1985). pp. 259-266. [ 251 Makin, B.,Diagnostic Testing fo lnprove EIectrostatic Powder Coatikg, Journal of Electrostatics, vol. 23 ( l989), pp. 263-27 1 . [ 261 Mazumder, M.K.,Wankum D.L., Sims, RA., Moutain, J.R., Chen, H., Pettit, P. and Chaser, T., Ihjhence of Powder Properries on the Performance of Electrosatic Cmting Procesr, Journal of Electrostatics, vol. 40 & 4 1 (1 997), pp. 369-374. [ 271 Miller, L. K. and Quilici, A E., Joy of C, John Wiley & Sons, hc., Toronto, 1993. [ 281 Moore, A D.,Electrostafics d i t s Applications, John Wiley & Sons, Inc., 1973. [ 291 Moyle, B.D. and Hughes, J.F., Powder C&g - Cormm vernrs Tribu Chmgmg, Journal of Electrostatics, vol. 16 ( 1 985), pp. 277-286. [ 301 Niomiya, N. and Onishi, K.,Flow anaiysis using a PC,CRC Press Inc., 199 1. [ 3 11 Press, W.H., Rannery, B., Teukolsky, S. A. and Vetterling W . T., Numerical Recipes in C,Cambridge University Press, 1990. [ 321 Reddy. V.,Pd e r Spray Techn0I0~e.s d 7heir Selectim. Plating and Surface Finishing, June 1989, pp. 34-38. [ 331 Sigmond, R. S.. 77ie Unipolar C o r o S~p c e Charge Flow Problem, Journal of Electrostatics, vol. 18 ( l986), pp. 249-272. [ 341 Silvester. P.P. and Ferrari, R L., Finie Elemenisfor ElectricaI Engrnering, Cambridge University Press, New York, 1983. [ 351 Sin& S., O'Neill, B.C. and Bright, A W., A Purantenir Sa& of EIectrosraric Powder Coaling, Journal of Electrostatics, vol. 4 (1 978). pp. 325-3 34. [ 361 Sin& S., ChmgingCbacteriStics of Sonie Paw&rs used in Electrostatratrc Cwring, IEEE Transactions on Industry Applications, vol. IA- 17, No. 1 , IanlFeb 198 1, pp. 12 1124. [ 3 71 Sm, S. L.. FIuid Oymmics of Mult+se .. Systems, Blaisdell Publishing Co Mass., 1967. [ 381 Tanasesu, F.T., C r d u c . K.. Tom, 1. and Ionescu, I., Chmged P d e Trajectories in E l e c a ~ s t Fiel., ~c J o u d of Electrostatics, vol. 23 ( 1 %9), pp. 45 3-462. [ 3 91 Waters, (1970). R T.,Rikard, T.E. S. and Stark W.B., Roc. Roy. Soc. London Ser. A3 15, [ 401 Wheaton, K.R., n e Behavïour of Solid P41ijcIes in Ttwbulent Cias Flows, Ph.D . Thesis, Univmity of Western Ontario, 1988. [ 4 11 White, H. J., Imhîstnaal Electrostutic Precipiation, Addison-Wesley Publishing, Massachusetts, USA, 1963. [ 421 Wu,S., Electrosfatic Chmgng wd Deposition of Pawrter Cmtings, Polym.-Piast. Technol. Engng 7, (1976), pp. 1 19-220. [ 431 The Student Edition of Matlab. The MathWorks Inc., 1992. Figure A 1 An eiectrostatic powder coating unit manufactured b y Wagner. Figure ~ 2 'Powder flow of a Bat spray gun nozzle. p p * These pictures are obtained from internet wirh premission from Wagner (www.wagner-systems.com). 90 get local &ces each eiemem for calculate the elecbic fidd postg-P of elecîric field &ta Figure A3 Flowchart of Finite Elemem subroutine. 1 calculate the emiîting angle at comna wire 1 caldate the initial charge density. PO, I & malute the electric field E calculate the auial trajeztory disbnce. ct! I ( 1 determine the charge density. p 1 Uneqmiate the charge deasi~y pst processingof charge density data I - Figure A4 Flowchart of a subroutine evduating space charge density using M W . 1 caicuiate the equivalern charge a d air velocities 1 calculate the paruele acceleratim I a calculate the particle velocities 1 caldate the ne= particle pWtim I Figure A5 Flowchart of a subroutine evaluating the particle trajectones.