* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Determination of Optimal Glucose Concentrations

Gene expression profiling wikipedia , lookup

Promoter (genetics) wikipedia , lookup

Secreted frizzled-related protein 1 wikipedia , lookup

Gene expression wikipedia , lookup

Silencer (genetics) wikipedia , lookup

Cell culture wikipedia , lookup

Artificial gene synthesis wikipedia , lookup

List of types of proteins wikipedia , lookup

Gene regulatory network wikipedia , lookup

Process Biochemistry, Vol. 31, No. 5, pp. 499-506, 1996

Couvrieht 0 1996 Elsevier Science Ltd

Printed-i; &eat Britain. All rights resewed

0032-9592/96 $15.00 +O.OO

0032-9592(95)00093-j

:LSEVIER

Determination of Optimal Glucose Concentrations

for Glucoamylase Production from PlasmidHarboring and Chromosome-Integrated

Recombinant Yeasts using a WC2 Promoter

Hyung Joon Cha & Young Je Yoo*

Department of Chemical

Seoul 151-742, Korea

(Received

4 September

Engineering

and The Institute

1995; accepted 21 December

for Molecular

Biology and Genetics,

Seoul National

University,

1995)

During foreign protein production using a promoter such as SUC2, which is

controllable by the glucose concentration in the culture broth, it is important to

determine the optimal glucose concentration for maximum protein production.

The optimal glucose concentrations for maximal production of glucoamylase in

plasmid-harboring recombinant yeast MMY2SUCSTA culture and in

chromosome-integrated

recombinant yeast MMY2SUCSTA-I

culture were 0.13

and 0.09 g litre - ‘, respectively. Using glucose feeding to maintain these optimal

glucose concentrations, the extracellular glucoamylase productivities of fedbatch culture were increased (12-fold in MMy2SUCSTA

and 23-fold in

MMY2SUCSTA-I)

over simulation results from batch cultures.

The yeast Saccharomyces cerevisiae is widely

used as a recombinant

host that expresses

foreign genes and secretes proteins.’ Glucoamylase (EC 3.2.1.3) which is used to saccharify

starchy feed stocks in commercial processes for

glucose and ethanol productions,

is not produced by S. cerevisiae. With this in mind, the

STA gene (glucoamylase gene of Saccharomyces

diastaticus) was chosen as a glucoamylase gene

source for this research.2 The STA gene used

was cloned from a wild type S. diastaticus

DS101.3

When a heterologous

gene is cloned into

yeast, a promoter of the heterologous gene may

usefully be replaced by a yeast promoter. Regulated promoters which control gene expression

INTRODUCTION

One of the principal tools in new biotechnology

is the recombinant

DNA technique

which

allows us to manipulate

directly the genetic

material of individual cells. By inserting forgein

genetic information into fast-growing microorganisms, foreign gene products such as proteins

may be produced at higher rates and yields than

possible with other cellular systems. Recombinant microorganisms

may be divided into

plasmid-harboring

recombinant

cells

and

chromosome-integrated

recombinant cells.

*To whom correspondence

should be addressed.

499

500

Hyung Joon Cha, Young Je Yoo

by changes of medium composition, addition of

chemicals, or change of cultural conditions are

commonly used for foreign protein production.4’5 In this research, the SUC2 promoter

regulated by glucose in the culture broth was

used6,7 and has the following advantages.

Firstly, the problems of the host’s growth inhibition and plasmid

instability

due to the

expression of the plasmid gene can be reduced

since the SUC2 promoter is a regulatable promoter. Secondly, since the SUC2 promoter is

affected only by glucose, the addition of an

inducer is unnecessary in comparison with other

inducible promoters.

Also, the problem

of

medium substitution does not exist in comparison with other repressible promoters.

When using a promoter controllable by the

glucose concentration in the culture broth (such

as SUC2 promoter), the close control of glucose

concentration

is essential and it is very importthe

optimal

glucose

ant

to

determine

concentration for maximum protein production,

In this research, optimal glucose concentrations

for higher production of foreign glucoamylase

from plasmid-harboring

and chromosome-integrated recombinant

yeasts were determined

with special consideration

for expression and

secretion.

MATERIALS AND METHODS

Strains and culture medium

Saccharomyces cerevisiae MMY2 (a, ura3-52,

sta’, stal0) strain was used as the host, Recombinant

plasmids YEpSUCSTA

and YIpSUCSTA containing the glucoamylase coding

STA gene fused with the SUC2 promoter and

original STA signal sequence were transformed

into the host. The transformants

were named

MMY2SUCSTA

(plasmid-harboring

recombiand

MMY2SUCSTA-I

nant

yeast)’

(chromosome-integrated

recombinant

yeast).’

Yeast was grown at 30°C in semi-synthetic minimal medium containing 0.2% MgS04 - 7H20,

0.2% (NH4)$04,

0.1% KH2P04,

0.025%

CaC&. 2H20, 0.2% yeast extract, 0.3% bactopeptone, 1% glucose, 1% starch, and 50 mM

succinate. Starch was used as a carbon source

for glucoamylase biosynthesis.8

Measurements of cell mass and glucoamylase

activity

Estimations of cell mass as absorbance were

carried out with a spectrophotometer

(Kontron;

UVICON930)

at 600 nm. To measure glucoamylase activity, O-7 ml culture supernatant was

incubated in 0.1 ml 1 M sodium acetate buffer

(pH 5.0) and 0.2 ml 8% soluble starch (Junsei)

at 50°C for 30 min and boiled at 100°C for

5 min to inactivate glucoamylase. Glucose produced by the action of glucoamylase on soluble

starch was assayed using a glucose-diagnostic kit

(Sigma, No. 510). Units of glucoamylase activity

are defined as 1 ymol of glucose released per

1 min.

Cell fractionation

Cells were harvested,

washed with 10 mM

sodium azide, suspended in lysis buffer (0.1 M

sodium acetate (pH 5.0) 10 mM sodium azide,

1 mM EDTA and 0.1% (v/v) Triton X-100) and

mechanically lysed by vortexing with glass beads

(Sigma, 425-600 microns). After intermitent

vortexing and cooling on ice, the suspension

was harvested by centrifugation

at 12 000 rpm

at 4°C for 15 min, and the supernatant used for

enzyme assay.

Simulation of foreign glucoamylse production

in recombinant yeast culture

The parameters of model equations were estimated from experimental data of batch culture

using the least-squares

regression

method.

Determination

of optimal glucose concentration

and simulation of recombinant

yeast culture

were performed using MATLAB software (version 4.0, The MathWorks,

Inc.). Ordinary

differential equations of model equations were

solved using the 2nd and 3rd order RungeKutta method.

RESULTS AND DISCUSSION

Foreign glucoamylase production from plasmidharboring and chromosome-integrated

recombinant yeasts

In order to compare the characteristics of cultures of chromosome-integrated

recombinant

yeast (MMY2SUCSTA-I)

and plasmid-harboring recombinant

yeast (MMY2SUCSTA),

a

Glucoamylase production in recombinant yeasts

number of cultivations were carried out. Since

r,hanges of pH were very small and expression

of glucoamylase occurred normally in this pH

range of the culture, control of pH was not

liecessary in the fermentation

experiments (see

1.6

- 6.6

h

‘:

1.2 22 - 6.4

=

-7

ob

d- 6.2

i

X

S - 6.0 a

.4

6

0

- 5.8

??

0.;

.03

J 5.6

r

c

1

VI

.z

J

.02

.e

.g

Y

s

.a

75 0

70 z

e

65 ;

.O'

0

E

60 gj

a

55

50 +

Extra activi

d

E”

8 0.00

a

0

;;

2

”

4

6

8

10

Culture time (h)

(A)

10

1 1.6

, 6.6

7

1.2 t

2

8’1

s

gq

.a z3

4-

6.4

6.2

X

6.0 &

0

.4 s

2??

^

0+

.020

1

4

,015

i

0

I

5.6

0.0

100

3

95 k

E

12 .OlO

3

g

s

90 g

.$

jj ,005

a5

E"

g 0.000

0

s

B

5.8

2

4

6

8

d

80 +

10

Culture time (h)

(6)

Fig. 1. Batch profiles of plasmid-harboring

recombinant

yeast MMY2SUCSTA

culture (A) and chromosome-integratred recombinant yeast MMY2SUCSTA-I

culture (B).

501

Fig. 1). The patterns of cell growth and glucose

consumption

were similar in both types of

recombinant yeast culture. The profiles of pH

were similar to the pattern of glucose consumption in both recombinant yeasts. While the pH

in the culture broth decreased depending on the

cell growth, the decrease of pH was small

because succinate added to the medium played

a role in protecting the decrease of pH. In the

case of MMY2SUCSTA,

plasmid

stability

depended on glucoamylase expression. As the

expression of glucoamylase increased then plasmid stability decreased. In contrast, the genetic

stability of the chromosome-integrated

recombinant yeast MMY2SUCSTA-I

remained good.

Glucoamylase was produced late in the culture

in both recombinant

yeast cultures since the

SUC2 promoter was regulated by glucose concentration in the culture broth as previously

reported.‘.‘. I0 In the case of MMY2SUCSTA,

glucoamylase synthesis began below 7 g litre-’

glucose concentration

and secretion occurred

below 5 g litre ~ ’ (Fig. l(A)). Expression of

glucoamylase then increased rapidly but secretion increased slowly as glucose concentration

in the culture broth decreased. In the case of

MMY2SUCSTA-I,

glucoamylase

synthesis

began below 4 g litre- ’ glucose concentration

and secretion below 2 g litree’ (Fig. l(B)).

Expression

of glucoamylase

then

rapidly

increased

and

secretion

of glucoamylase

increased slowly as with MMY2SUCSTA.

The

behaviour of the two yeasts with respect to

glucose concentration

clearly differed. These

might be due to a gene dosage (the number of

copies of a given gene present in a cell) effect.’ ’

Since MMY2SUCSTA had a high plasmid copy

number (20-40) transcription regulation of the

SUC2 promoter by glucose in the recombinant

plasmid was not tight. In contrast, MMY2SUCSTA-I had three copy numbers of the desired

gene, expression of glucoamylase was tightly

regulated by glucose and the optimal glucose

concentration

for maximum expression of glucoamylase

was lower

from

that

in the

plasmid-harboring

recombinant yeast culture.

Determination of optimal glucose concentration

for glucoamylase production

The determination

of optimal glucose concentration for protein production is important from

a biotechnological

point of view. In this

research, we considered glucoamylase secretion

502

Hyung Joon Cha, Young Je Yoo

as well as glucoamylase expression in the determination of optimal glucose concentration.

The

optimal glucose concentration

for maximum

production of foreign glucoamylase, the specific

expression rate and the specific secretion rate of

each recombinant yeast were calculated as functions of glucose concentration

in the culture

broth. The mass balance for total glucoamylase

protein can be written asi2,13

d(PTX)

x

=F

dt

”

d(f’d)

dt

Fern

G

(kp + G + G2/kpi) ’

(3)

where

K= specific

secretion

rate

(h-l),

PMX=extracellular

glucoamylase activity (units

ml-‘).

The specific secretion rate K was related to

cell growth condition

(data not shown).‘3,‘4

(1)

where Fp=specific expression rate (units mg ~ ’

cell h-l),

PTX=total

glucoamylase

activity

(units mll’),

t=operation

time (h), X=cell

mass (g litre-‘).

The SUC2 promoter used in this work, is

regulated by glucose concentration

in the culture broth. When the glucose concentration

is

high, the expression

of SUC2 promoter

is

repressed. However, when glucose is decreased

to a threshold concentration

then expression is

not repressed. Thus, to consider glucose repression on the expression of SK2

promoter, a

glucose repression term (G’/kpi) is introduced

into the specific expression rate Fp’2,13

Fp=

=K(P-&-PM@,

0.0

(2)

where FP,,,=maximum specific expression rate

(units mgg’ cell hh’), G=glucose

concentration

in the

culture

broth

(g litre-‘),

kp=constant

of specific expression

rate (g

litre - ’), kpi = repression

constant

of specific

expression rate (g litre-‘).

The specific glucoamylase expression rate FP

of MMY2SUCSTA is indicated in Fig. 2(A) and

its maximum value calculated to be O-054 units

mg-’ cell h- ’. Maximum expression of plasmid-harboring

yeast occurs

at a glucose

concentration

of 0.17 g litre-’ in the culture

broth.

Similarly,

the specific glucoamylase

expression

rate

of chromosome-integrated

recombinant

yeast MMY2SUCSTA-I

is indicated in Fig. 2(B) and its maximum value

calculated as O-026 units mg-’ cell hh’. In this

case, maximum expression occurs at a glucose

concentration

of 0.13 g litre-‘.

The mass

balance for secreted glucoamylase13 is

*-

.025

I

.5

1.0

1.5

2.0

2.5

3.0

, .4

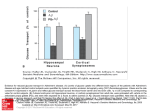

Fig. 2. Optimal glucose concentrations

for maximum

specific expression rate and specific secretion rate in plasmid-harboring

recombinant

yeast MMY2SUCSTA

(A)

and chromosome-integrated

recombinant

yeast MMY2SUCSTA-I

(B). SER: specific expression

rate; SSR:

specific secretion rate; SOR: specific optimal rate.

503

Glucoamylase production in recombinant yeasts

Since specific growth rate was a function of

glucose concentration,

the specific secretion

rate may also be described as a function of

glucose concentration.‘”

described below and the optimization was performed in fed-batch culture as shown in Fig. 3.

PI =mF

K=

GIG

a+pG

’

{Productivity} =mp

{‘$V,!)”

1,

(4)

where K,=maximum

specific secretion

rate

I h-r),

m=constant of specific secretion rate (g

litreel), /?=constant of specific scretion rate.

The dependence of specific secretion rates on

glucose concentration

in both recombinant

yeasts is indicated in Fig. 2. In both recombihant yeasts, the specific secretion rate increased

with increase in glucose and finally reached

s,aturation.

The optimal glucose concentration

might

exist between the specific expression rate and

rhe specific secretion rate. The optimal glucose

concentration

for maximum extracellular gluco<imylase activity was calculated through two

equations of specific expression rate (eqn 2)

tend specific secretion rate (eqn 4). In the case

,)f MMY2SUCSTA,

the optimal glucose con::entration for specific expression rate was 0.17 g

litre-’ (Fig. 2(A)) but, the optimal glucose conzentration for both specific expression rate and

specific secretion rate was 0.76 g litree’. In the

zase of MMY2SUCSTA-I,

the optimal glucose

concentration

for specific expression rate was

9.13 g litreel and the optimal glucose concentration for both specific expression rate and

specific secretion rate was O-25 g litre-’ (Fig.

2(B)). In this case, the difference between two

optimal glucose concentrations was smaller than

that of MMY2SUCSTA

since the slope of the

specific secretion rate of MMY2SUCSTA-I was

larger in the region of low glucose concentration. This calculation was performed using only

eqn (2) for specific expression rate and eqn (4)

for specific secretion rate. Values calculated in

this manner can be used in simulation or real

experiment for fed-batch culture. However, in

the real culture, many other factors that affect

final extracellular product concentration

exist

including, expression level, secretion capacity,

genetic stability, final operation

time, final

vessel volume, and culture type. Therefore, in

order to determine real optimal glucose concentration, glucoamylase

productivity

(unit h-‘)

was used using a performance

index (PI) as

(5)

where V,=final vessel volume (litre).

A fixed final vessel was used as a constraint

condition, the initial vessel volume being set as

0.5 litre and final vessel volume set as 2 litre. In

the case of MMY2SUCSTA,

the optimal

glucose concentration

for the desired extracellular glucoamylase

productivity

was 0.16 g

1itre-l and its value was close to the optimal

Glucose concentration

(g litre-‘)

(4

I

I

I

Glucose concentration

I

I

(g litre-‘)

W

of optimal glucose concentrations

Fig. 3. Determination

for maximum

glucoamylase

productivity

in fed-batch

culture of plasmid-harboring

recombinant

yeast MMY2SUCSTA (A) and chromosome-integrated

recombinant

yeast MMY2SUCSTA-I

(B). Initial and final conditions;

X+=0.1 g litre-‘,

X- =O*Og litre-‘,

X=0*1 g litre-‘,

G=S g litre-‘, Gr=20 g litre- , V,,--05 lure, and l/f=2 litre. X + : plasmid-harboring

cells, X - : plasmid-free cells,

X: chromosome-integrated

cells, P,W/t:

extracellular

glucoamylase productivity and P,XV/t: total glucoamylase

productivity.

504

Hyung Joon Cha, Young Je Yoo

value for specific expression rate (O-17 g litre-‘)

(Fig. 3(A)), while that for total glucoamylase

productivity was 0.13 g litre-‘. In the case of

MMY2SUCSTA-I,

the optimal glucose concentrations

for

the

desired

extracellular

glucoamylase productivity and for total glucoamylase productivity were equal and their value

was 0.09 g litre-’ (Fig. 3(B)). These optimal

glucose concentrations

(O-16 and 0.09 g litre-‘)

were closer to the glucose concentrations

for

maximum specific expression rate (O-17 and

0.13 g litre-‘) than those for maximum specific

expression rate and specific secretion rate (0.76

and 0.25 g litre-‘). The reason for this may be

that expression was rate-limiting

for overall

foreign glucoamylase production

compared to

secretion in both recombinant yeasts.

Simulation of foreign glucoamylase production

using optimal glucose concentration

Simulations of foreign glucoamylase production

in fed-batch cultures of plasmid-harboring

and

chromosome-integrated

recombinant

yeasts

were performed using optimal glucose concentrations for 30 h operation times as shown in

Fig. 4. Glucose feeding rate was calculated

using growth conditions to maintain the optimal

glucose concentration

in the culture broth as

shown below.‘”

!g-G&

1

P

-++m

Y

f=

Cultu~

time(b)

(4

xv’

(6)

where Gf=glucose concentration

in the feed (g

litre-‘),

GOPT=optimal

glucose concentration

for glucoamylase production (g litre-‘), (O-16 g

litre-’ for MMY2SUCSTA

and 0.09 g litre-’

MMY2SUCSTA-I),

m =maintenance

coeffivolume

(litre),

YXG=yield

cient, V=vessel

coefficient, p=specific growth rate (h-l). This

equation includes state variables (cell mass and

vessel volume) and feed rate was calculated

using these state variables. As shown in Fig.

4(A), cell mass reached a maximum at 20 h in

the MMY2SUCSTA

culture. A larger fraction

of total cells was occupied by plasmid-free cells

in the final culture period and the internal

glucoamylase expression was therefore maximal

at 25 h and then decreased. The final extracellular glucoamylase

activity was O-215 units

ml-’ and the productivity was 13.0 units h-‘.

5

10

15

20

Cnlbtime(h)

2s

30

1

(61

Fig. 4. Simulation results for fed-batch culture of plasmid-harboring

recombinant

yeast MMY2SUCSTA

(A)

and chromosome-integrated

recombinant

yeast MMY2SUCSTA-I

(B). Initial conditions;

X+ =O.l g litre-‘,

X-=O.Og

litre-‘,

X=0*1 g litre-‘,

G=S g litre-‘,

Gf=20 g litreP’, V,=O5 lit re, and t,=30 h. X+: plasmidharboring cells, X - : plasmid-free cells, XT: total cells, X:

chromosome-integrated

cells, G: glucose concentration,

P,X: intracellular

glucoamylase

activity, PMX: extracellular glucoamylase activity and PTX: total glucoamylase

activity.

505

Glucoamylase production in recombinant yeasts

Table 1. Summary of simulation results for glucoamylase

chromosome-integrated

recombinant yeasts

production

in fed-batch

culture

Chromosome-integrated

MMy2SlJCSTA-I

Plasmid-harboring yeast

MMYZSUCSTA

Batch culture

Fed-batch culture

(30 h culture time)

Fed-batch culture

(2 litre final vessel volume)

using plasmid-harboring

and

yeast

Productivity

(units h ‘)

Relative

increase

Productivity

(units h _ ‘)

Relative

increase

1.2

13.0

1.0

10.8

0.8

1I.9

1.0

14.9

14.0

11.7

18.4

23.0

This pattern became more marked with an

increase of plasmid-free

cell fraction in the

initial culture. In contrast, cell mass steadily

increased in the case of MMY2SUCSTA-I

(Fig.

4(B)). The glucoamylase activity continued to

increase and the final extracellular glucoamylase

activity was 0.274 units ml-‘; while the extracellular

glucoamylase

productivity

reached

11.9 units hh ‘. When using final operation time

as a constraint

condition,

the extracellular

glucoamylase

productivities

of both recombinant yeasts were similar. This resulted from a

final small vessel volume of the chromosomeintegrated yeast culture. In the case of using

final vessel volume as a constraint condition,

the final extracellular glucoamylase productivity

of the chromosome-integrated

yeast culture was

31.4% larger (18.4 units hh’) than that of plasmid-harboring

yeast culture (14.0 units hh’).

This resulted from higher genetic stability and

higher secretion efficiency (68.1% compared to

48.7% of MMY2SUCSTA).

These simulation results of foreign glucoamylase production using fed-batch culture of the

plasmid-harboring

recombinant

yeast MMY2SUCSTA

and the chromosome-integrated

recombinant yeast MMY2SUCSTA-I

are summarized in Table 1. By using glucose feeding to

maintain optimal glucose concentrations

(0.16 g

litre - ’ in MMY2SUCSTA and 0.09 g litre - ’ in

MMY2SUCSTA-I),

the final glucoamylase productivities of fed-batch cultures were increased

(11*7-fold in MMY2SUCSTA

and 23-O-fold in

MMY2SUCSTA-I)

compared to those of the

batch culture when using final vessel volume as

a constraint condition.

ACKNOWLEDGEMENT

This research was supported by the Genetic

Engineering Research Fund from the Ministry

of Education, Korea.

REFERENCES

1. Kingsman,

production

S. M., Kingsman, A. J. & Mellor, J., The

of mammalian proteins in Saccharomyces

cerevisiae. Trends Biotechnol., 5 (1987) 53-7.

2. Yamashita,

I., Suzuki, K. & Fukui, S., Nucleotide

sequence of the extracellular glucoamylase gene STA 1

in the yeast Saccharomyces diastaticus. J. Bactetiol.,

161 (1985) 567-73.

3. Ahn, J. H., Regulation

of glucoamylase gene expression in Saccharomyces cerevisiae var. diastaticus. PhD

thesis, Seoul National

University,

Seoul, Korea, 1994.

study of instability of

recombinant

plasmid pPLc23trpAl

in E. coli using

two-stage continuous culture system. Biotech. Bioeng.,

4. Siegel, R. & Ryu, D. Y., Kinetic

27 (1985) 28-33.

5. Da Silva, N. A. & Bailey, J. E., Influence

of plasmid

origin and promoter

strength

intermentations

of

recombinant yeast. Biotech. Bioeng., 37 (1991) 318-24.

6. Chu, F. K. & Maley, F., The effect of glucose on the

synthesis and glycosylation of the polypeptide moiety

of yeast external invertase. J. Biol. Chem., 255 (1980)

6392-7.

7. Carlson, M. & Botstein, D., Two differentially

regulated mRNAs with different 5’ ends encode secreted

and intracellular

forms of yeast invertase. Cell, 28

(1982) 145-54.

8. Cha, H. J., Yoo, Y. J., Ahn, J. H. & Kang, H. S.,

Expression of glucoamylase

gene using SUC2 promoter in Saccharomyces cerevisiae. Biotech. Lett., 14

(1992) 747-52.

9. Cha, H. J. & Yoo, Y. J., Comparison

of characteristics between plasmid-harboring

and chromosomeintegrated recombinant

Saccharomyces cerevisiae cultures. Kor J. Chem. Eng., (1995) (in press).

10. Marten, M. R. & Seo, J. H., Localization of cloned

invertase in Saccharomyces cerevisiae directed by the

WC2 and MF 1 signal sequences. Biotech. Bioeng., 34

(1989) 1133-9.

506

Hyung Joon Chu, Young Je Yoo

11. Stockhaus, J., Eckes, P., Blau, A., Schell, J. & Willand dosage-dependent

mitzer,

L., Organ-specific

expression of a leaf/stem specific gene from potato

after tagging and transfer into potato and tobacco

plants. Nucleic Acids Res., 15 (1987) 3479-91.

12. Patkar, A., Seo, J. H. & Lim, H. C., Modeling and

optimization

of cloned

invertase

expression

in

Sx$w;myces

cerevisiae. Biotech. Bioeng., 41 (1993)

13. Cha, H. J., Biosynthesis

and secretion of foreign

glucoamylase

using plasmid-harboring

and chromosome-integrated

recombinant

Saccharomyces

cerevisiue. PhD thesis, Seoul National

University,

Seoul, Korea, 1995.

14. Park, S. J. & Ramirez, W. F., Dynamics of foreign

protein secretion from Saccharomyces cerevisiae. Biotech. Bioeng., 33 (1989) 272-81.