* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Neutral ionic liquid [BMIm]BF4 promoted highly selective

Organic chemistry wikipedia , lookup

Acid dissociation constant wikipedia , lookup

Electrochemistry wikipedia , lookup

Multi-state modeling of biomolecules wikipedia , lookup

Photopolymer wikipedia , lookup

Rate equation wikipedia , lookup

Enantioselective synthesis wikipedia , lookup

Chemical bond wikipedia , lookup

Asymmetric induction wikipedia , lookup

Chemical thermodynamics wikipedia , lookup

Catalytic reforming wikipedia , lookup

Kinetic resolution wikipedia , lookup

Photosynthetic reaction centre wikipedia , lookup

Transition state theory wikipedia , lookup

Acid–base reaction wikipedia , lookup

Hypervalent molecule wikipedia , lookup

Chemical reaction wikipedia , lookup

Photoredox catalysis wikipedia , lookup

Process chemistry wikipedia , lookup

Chemical equilibrium wikipedia , lookup

Physical organic chemistry wikipedia , lookup

Ring-closing metathesis wikipedia , lookup

Stoichiometry wikipedia , lookup

Supramolecular catalysis wikipedia , lookup

Hydrogen-bond catalysis wikipedia , lookup

Liquid–liquid extraction wikipedia , lookup

Bioorthogonal chemistry wikipedia , lookup

Click chemistry wikipedia , lookup

Nucleophilic acyl substitution wikipedia , lookup

Hydroformylation wikipedia , lookup

Petasis reaction wikipedia , lookup

Lewis acid catalysis wikipedia , lookup

Ionic compound wikipedia , lookup

Nanofluidic circuitry wikipedia , lookup

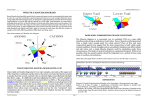

Journal of Molecular Catalysis A: Chemical 246 (2006) 70–75 Neutral ionic liquid [BMIm]BF4 promoted highly selective esterification of tertiary alcohols by acetic anhydride Zhiying Duan, Yanlong Gu, Youquan Deng ∗ Center for Green Chemistry and Catalysis, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, Lanzhou 730000, China Received 23 July 2005; received in revised form 17 October 2005; accepted 17 October 2005 Available online 22 November 2005 Abstract Esterification of tert-butanol by acetic anhydride, a typical acid–base catalytic reaction, was conducted with excellent selectivity and high yield in a neutral ionic liquid [BMIm]BF4 (1-butyl-3-methylimidazolium tetrafluoroborate). Many other tertiary alcohols could also be successfully converted to the corresponding esters in [BMIm]BF4 . Separation of product and recovery and reuse of ionic liquid are all convenient in this system. Here, the need for catalysts is avoided through the use of catalytically active ionic liquids as solvents. © 2005 Elsevier B.V. All rights reserved. Keywords: [BMIm]BF4 ; Esterification; Tertiary alcohol; Acetic anhydride 1. Introduction Esterification of normal alcohols by carboxylic acids using homogeneous acid catalysts has been well known [1]. Carboxylic acid esters of tertiary alcohol are useful for the production of agrochemicals, coatings, dyes and solvents [2]. Esters of unsaturated tertiary alcohol are also important intermediate in organic synthesis [3]. However, the preparation of carboxylic acid esters of tertiary alcohols by an acid catalyzed process is very difficult because of the very high reactivity of tert-alcohols. Take synthesis of tert-butanol esters, for example, under acidic condition, tert-butanol undergoes dehydration to iso-butylene, even at room temperature. Earlier methods used for the synthesis of tert-butanol esters are either highly cumbersome or involves the use of highly toxic reagents, such as ketene and acetyl chloride [4–7]. Although tert-butanol could be esterified by acetic anhydride itself, the major drawback of this method for producing tert-butyl acetate is that the reaction is somewhat sluggish, since the absence of a catalyst restricts the production rates. When a catalyst is used to improve the reaction rate, a variety of unwanted by-products are often produced making the production of pure tert-butyl acetate more difficult [8]. Recently, Choudhary and co-workers have reported the highly selective esterification ∗ Corresponding author. Fax: +86 931 4968116. E-mail address: [email protected] (Y. Deng). 1381-1169/$ – see front matter © 2005 Elsevier B.V. All rights reserved. doi:10.1016/j.molcata.2005.10.017 of tert-butanol by acetic anhydride using mesoporous Si-MCM41, clay and alumina supported metal Lewis acid, such as InCl3 and GaCl3 , as catalyst [9–11]. However, these metal species are toxic or expensive. Hence, there is a need to develop an environmentally benign method for the esterification of tert-alcohols. Ionic liquids are a new class of solvents entirely composed of ions. Their use as an environmentally friendly alternative for conventional solvents has gained much attention recently [12–14]. Esterification reactions have been extensively investigated in many ionic liquids so far, because of the importance of this transformation both in organic synthesis and chemical industry as well as immiscibility of ester with ionic liquids, which allows easy separation of products. We firstly reported esterification of carboxylic acids with alcohols in acidic chloroaluminate ionic liquids [15]. Then, many acidic ionic liquids, including SO3 H-functionalized imidazolium ionic liquids [16,17], ionic liquids with acidic counteranion and protonated N-alkylimidazolium ionic liquids have been used in esterification reactions [18,19]. Some particular esterification reactions, such as transesterification of -ketoesters [20] and synthesis of ferrocenyl esters [21], could also been conducted in ionic liquids combined with an acidic catalyst. It is worthy noted that the esterification reactions carried out in ionic liquids, with an exception of enzyme catalysis, are conducted at acidic conditions in the most cases. In continuation of our research in esterification, we report herein, for the first time, highly selective synthesis of tertalcohol acetates from tert-alcohols and acetic anhydride in ionic Z. Duan et al. / Journal of Molecular Catalysis A: Chemical 246 (2006) 70–75 Scheme 1. liquid [BMIm]BF4 . Different from known catalytic systems, this reaction could be successfully proceeded in neutral ionic liquid without any additional acidic catalyst. Functionalized acidic or basic ionic liquids, however, seems to be unsuitable for this reaction (Scheme 1). 2. Experimental 2.1. Materials and reagents Anhydrous organic solvents were dried and then distilled prior to use. tert-Butanol, tert-amyl alcohol, 2-methyl-3-butyn2-ol, 3-methyl-1-pentyn-3-ol, 3,5-dimethyl-1-hexyn-3-ol, 2methyl-3-buten-2-ol and acetic anhydride were not purified prior to use. All other chemicals used for synthetic procedures were reagent grade or better. 2.2. Preparation of the ionic liquids The ionic liquids were synthesized using the methods described in previously published papers [12,16] and stored in an exsiccator filled with KOH. Tertiary amine-functionalized ionic liquid [MEnIm]PF6 is prepared by the reaction of 1methylimidazole with 2-diethylamine ethyl chloride hydrochloride in ethanol. After 24 h under reflux, the ethanol is removed in vacuum and the solid residue dissolved in a large amount of water that is brought to pH 8 by the addition, in small portions, of solid K2 CO3 . Subsequent ion exchange with KPF6 in water at 60 ◦ C gives the product salt. After drying under vacuum at 80 ◦ C, the product was obtained in 84% yield as a relatively viscous liquid. δH (400 MHz, CD3 COCD3 ) 0.89 (6H, t, J = 6.8 Hz), 2.55 (4H, q, J = 6.8 Hz), 2.81 (2H, t, J1 = 5.6 Hz, J2 = 6.4 Hz), 3.85 (3H, s), 4.22 (2H, t, J1 = 6.4 Hz, J2 = 5.6 Hz), 7.70 (1H, d, J = 6.4 Hz), 7.72 (1H, d, J = 6.0 Hz), 9.02 (1H, s). 2.2.1. Synthesis of tert-alcohol esters All reactions were conducted in a 90 ml autoclave with a glass tube inside equipped with magnetic stirring. In each reaction, 4.5 ml ionic liquid, 10 mmol alcohol and 12 mmol acetic anhydride were successively introduced and reacted at 60 ◦ C for desired period. After the reaction, cooled the autoclave to room temperature (when using tert-butanol as substrate, the autoclave should be cooled to −40 ◦ C), then the reaction mixture was analyzed by GC. The isolation of organic compounds with ionic liquid was conducted by direct distillation or vacuum distillation. Purification of desired was performed as follow: (1) remove acetic acid and residual acetic anhydride by extraction of water (20 ml × 3) and (2) the hydrophobic organic residue was further purified using a short column of silica gel (2 cm in length, 0.5 cm in diameter, acetate–hexane, 1:9) to afford the pure product. Qualitative and quantitative analyses of organic products 71 were conducted with a HP 6890/5973 GC/MS and a HP 1790 GC equipped with a FID detector. The concentration of reactant and product was directly given by the system of GC chemstation according to the area of each chromatograph peak. Tert-butyl acetate: Colorless liquid (1.04 g, 88%); δH (300 MHz, CD3 COCD3 ) 1.42 (9H, s), 1.89 (3H, s); ν (cm−1 ) 1739 (C O), 1265 and 1173 (O C O); GC–MS: 101, 78,57, 43. Anal. Calcd for C6 H12 O2 (116.16): C, 62.04; H, 10.41. Found: C, 62.15; H, 10.67. Tert-amyl acetate: Colorless liquid (1.12 g, 87%); δH (300 MHz, CD3 COCD3 ) 0.87 (3H, t, J = 7.7 Hz), 1.39 (3H, s), 1.73–1.80 (2H, m), 1.96 (3H, s); ν (cm−1 ) 1736 (C O), 1261 and 1161 (O C O); GC–MS: 115, 101, 55, 43. Anal. Calcd for C7 H14 O2 (128.17): C, 65.59; H, 11.01. Found: C, 65.74; H, 10.87. 2-Methyl-3-butyn-2-acetate: Colorless liquid (1.11g, 88%); δH (300 MHz, CD3 COCD3 ) 1.63 (6H, s), 1.95 (3H, s), 2.94(1H, s); ν (cm−1 ) 1742 (C O), 3291 (C H), 2119 (C C), 1248 and 1137 (O C O); GC–MS: 111, 98, 83, 67, 43; Anal. Calcd for C7 H10 O2 (126.15): C, 66.64; H, 7.99. Found: C, 66.91; H, 7.87. 3-Methyl-1-pentyn-3-acetate: Colorless liquid (1.11g, 83%); δH (300 MHz, CD3 COCD3 ) 0.99 (3H, t, J = 5.4 Hz), 1.60 (3H, s), 1.79–2.01(2H, m), 1.95 (3H, s), 2.96 (1H, s); ν (cm−1 ) 1745 (C O), 3289 (C H), 2114 (C C), 1243 and 1128 (O C O); GC–MS: 125, 111, 97, 79, 69, 53; Anal. Calcd for C8 H12 O2 (140.18): C, 68.54; H, 8.63. Found: C, 68.68; H, 8.78. 3,5-dimethyl-1-hexyn-3-acetate: Colorless liquid (1.36g, 81%); δH (300 MHz, CD3 COCD3 ) 0.97–1.00 (6H, m), 1.66 (3H, s), 1.71–1.88(2H, m), 1.96–2.01(1H, m), 1.95 (3H, s), 2.89 (1H, s); ν (cm−1 ) 1747 (C O), 3288 (C H), 2117 (C C), 1240 and 1138 (O C O); GC–MS: 153, 125, 111, 93, 84, 77, 69; Anal. Calcd for C10 H16 O2 (168.23): C, 71.39; H, 9.59. Found: C, 71.49; H, 9.68. 2.3. Characterization procedures The FTIR spectra of the ionic liquids were recorded on NicoLET 5700 Fourier transform infrared spectrophotometer using pyridine as a probe for acidity measurement. The pyridine used was dried with KOH and distilled over 5 Å molecular sieves and solid KOH. The IR samples were prepared by mixing pyridine with ionic liquid in a given mass ratio of pyridine/ionic liquid = 1:3, and then spreading into liquid films on KBr windows. 1 H NMR (300 MHz) spectra of products were obtained as solutions in CD3 COCD3 . Chemical shifts were reported in parts per million (ppm, δ) and referenced to TMS. 3. Results and discussion 3.1. Effect of different ionic liquids on the reactivity Because the esterification of tert-butanol by acetic anhydride has considered as a typical acid-catalytic reaction, acidic or basic ionic liquids may be effective catalysts for the synthesis tert-butyl acetate. In our previous works, SO3 H-functionalized imidazolium ionic liquids have been used as an effective catalyst Z. Duan et al. / Journal of Molecular Catalysis A: Chemical 246 (2006) 70–75 72 Scheme 2. Functionalized ionic liquids used in the esterification of tert-butanol by acetic anhydride. for the addition of carboxylic acids to olefins and the oligomerization of branched olefins [22,23]. Thus, the esterification of tert-butanol was primarily investigated in this kind of ionic liquid ([MBsIm][TfO], Scheme 2). However, a lot of iso-butene and its oligomers (branched olefins of C8 and C12) were detected in the reaction mixture and the desired tert-butyl acetate was obtained in a selectivity of 13% although tert-butanol was completely consumed after 4 h reaction (Table 1, Entry 1). It indicated that dehydration of tert-butanol to produce iso-butene and the consequent oligomerization of iso-butene are predominant reactions in the present conditions. Subsequently, another protonated acidic ionic liquid [HMIm]BF4 (in Scheme 2), which has proved to be a green and cost-effective acidic catalyst in many organic reactions [24,25], was evaluated in the esterification of tert-butanol under the same conditions. Same as observed in ionic liquid [MBsIm][TfO], the conversion of tert-butanol was completely consumed, however, selectivity to tert-butyl acetate was only 37% (Entry 2). Although the oligomerization of iso-butene was inhibited in certain case, tert-butanol was still readily dehydrated to iso-butene in [HMIm]BF4 . Synthesis tert-butyl acetate from tert-butanol and acetic anhydride could also be promoted by a basic catalyst [8]. If the imidazolium cation of ionic liquid was modified with a tertiary amine, it should be a weaker basic medium ([MEnIm]PF6 , Scheme 2). In the above esterification, this new ionic liquid represents a better activity compared with the former two acidic ionic liquids. Conversion of tert-butanol and selectivity to tertbutyl acetate are all more than 70% (Table 1, Entry 3). However, the reaction mixture became a white and highly viscous colloid after the reaction, and the ionic liquid probably reacted with the produced acetic acid. Our previous investigations on the conversion of tert-butanol revealed that the reactivity of tert-butanol could be greatly improved by the use of tetrafluoroborate ionic liquids as media [26,27]. Therefore, we consequently investigated the esterification reaction of tert-butanol in [BMIm]BF4 , which is considered as a neutral polar solvent. To our surprising, 93% conversion and 99% selectivity to tert-butyl acetate were obtained under the identical conditions (Table 1, Entry 4). This unusual observation promoted us to further investigate the effects of other ionic liquids on the esterification reaction. The rate of the formation of tert-butyl acetate in [BMIm]BF4 at 60 ◦ C seemed to be slightly higher than that observed with [EMIm]BF4 , [BMIm]NO3 and [BMIm][PhSO3 ]. It is important to note that the selectivities to tert-butyl acetate are all close to 100% in these ionic liquids (Entries 5–7). When using [BMIm]PF6 as medium, a lot of isobutene was detected beside desired tert-butyl acetate (Entry 8). It may contribute to the acidic hydrofluoric acid (HF) which comes from the decomposition of [BMIm]PF6 [28], thus tert-butanol could be readily dehydrated to iso-butene. To determine whether the use of ionic liquid [BMIm]BF4 as medium was an essential factor to realize the high conversion and excellent selectivity, the same reaction was carried out in absence of medium or in traditional organic solvents. As described in Table 1, the conversion of tert-butanol was only 14% without solvent, and 9% in the present of organic solvent at the best (Table 1, Entries 9–12). These results clearly show the determining role of [BMIm]BF4 in this reaction. 3.2. Optimization of reaction conditions Consequently, the reaction condition was optimized using [BMIm]BF4 as solvent, and the results were listed in Table 2. Theoretic ratio of tert-butanol to acetic anhydride is 1:1 in this reaction. However, the magnitude of tert-butanol conversion was only 78% when using equal amount of tert-butanol and acetic Table 1 Scanning of various ionic liquids on esterification of tert-butanol by acetic anhydridea Entry Solvents Conversion of alcohol (%) Selectivity to ester (%) 1 2 3 4 5 6 7 8 9 10 11 12 [MBsIm][TfO] [HMIm]BF4 [MEnIm]PF6 [BMIm]BF4 [EMIm]BF4 [BMIm]NO3 [BMIm][PhSO3 ] [BMIm]PF6 – CH3 CN Toluene CHCl3 100 100 72 93 87 80 82 99 14 9 5 6 13 37 71 99 99 99 99 61 100 99 100 100 a Solvent, 4.5 ml; tert-butanol, 0.74 g; acetic anhydride, 1.22 g, reaction temperature, 60 ◦ C; reaction time, 4 h. Z. Duan et al. / Journal of Molecular Catalysis A: Chemical 246 (2006) 70–75 73 Table 2 Condition optimization of the esterification in ionic liquid [BMIm]BF4 a Entry Ratio of anhydride to alcohol (M/M) Temperature (◦ C) Reaction time (h) Conversion of alcohol (%) Selectivity to ester (%) 1 2 3 4 5 6 7 1:1 1:1.2 1:1.2 1:1.2 1:1.2 1:1.2 1:1.2 60 60 45 75 60 60 60 4 4 4 4 2 3 5 78 93 59 99 58 86 95 99 99 99 87 99 99 99 a [BMIm]BF4 , 4.5 ml; tert-butanol, 0.74 g. anhydride after 4 h reaction at 60 ◦ C (Entry 1). A satisfactory result could be obtained using an anhydride/alcohol ratio of 1.2. Conversion of tert-butanol would be decreased with the decrease of reaction temperature or the reaction time (Entries 3, 5 and 6). Although the reactivity of tert-butanol could be improved when the reaction temperature was elevated to 75 ◦ C, the formation of iso-butene could also be indulged; therefore, the selectivity was disturbed (Entry 4). It is known that the dehydration of tertbutanol to iso-butene is a reversible process, therefore, it is not surprising that higher temperature is the booster to render this type of reaction toward formation of iso-butene. When the reaction time was further increased, the conversion of tert-butanol almost keeps constant and as a result, 4 h seems to be suitable for this reaction in [BMIm]BF4 . 3.3. Esterification of C4 alcohols with acetic anhydride in [BMIm]BF4 The reactivity of primary and secondary alcohols has also been investigated in our system, and the results are listed in Table 3. n-Butanol and 2-methyl-1-propanol could be esterified by acetic anhydride in [BMIm]BF4 , however, the reactions seems to be sluggish and the conversions of alcohols were less than 35% even the reaction time was prolonged to 10 h. In the case of 2-butanol, the corresponding ester could be obtained in 55% of alcohol conversion. Different from reaction of tertbutanol, ester was the sole product in the reactions of primary and secondary alcohols. Ranu et al. reported the yields of acylation reactions of alcohols by acetic anhydride could be improved by removal of produced acetic acid [29]. In our system, the conversion of primary and secondary alcohols may also be increased to some extent by analogous technology. 3.4. Esterification of acid–unstable alcohols in ionic liquid [BMIm]BF4 Having these results in hand, other tertiary alcohols have been subjected to the conditions of Table 3. It is worthy noted that the produced ester and other organic compounds (the produced acetic acid, un-reacted acetic anhydride and alcohol) in our systems could be simply separated form the reaction mixture by distillation under reduced pressure. This allows easy recovery and reuse of ionic liquid [BMIm]BF4 . From Table 4, tert-butyl acetate was obtained in an isolated yield of 88% (Entry 1) by distillation and consequent column chromatography. Then, another 1 equiv. of alcohol and 1.2 equiv. of acetic anhydride were added to the recovered ionic liquid. Similar results were obtained even ionic liquid [BMIm]BF4 was reused in the fifth time (Table 4, Entry 7). Under the same conditions, tert-amyl alcohol could be esterified by acetic anhydride to produce the corresponding acetate with a yield of 87% (Entry 2). Tertiary propargylic alcohols have been considered are acid-unstable and tend to polymerize in [BMIm]PF6 , which reveals acidic under moisture conditions from our previous investigation [30]. Fortunately, these alcohols could readily be esterified by acetic anhydride in ionic liquid [BMIm]BF4 , and the yields of them are all more than 80% (Entries 3–5). It should be pointed that the produced propargylic acetates are important synthetic intermediates [3], Table 3 Esterification of C4 alcohols by acetic anhydride in ionic liquid [BMIm]BF4 a Entry Reaction time (h) Conversion of alcohol (%) Selectivity to ester (%) 1 10 30 100 2 10 34 100 3 4 55 100 4 4 93 99 a Alcohols [BMIm]BF4, 4.5 ml; alcohol, 0.74 g; acetic anhydride, 1.22 g, reaction temperature, 60 ◦ C. Z. Duan et al. / Journal of Molecular Catalysis A: Chemical 246 (2006) 70–75 74 Table 4 Esterification of acid–unstable alcohols in ionic liquid [BMIm]BF4 a Entry Alcohols Products Reaction time (h) Yields (%) 1 4 88 2 4 87 3 4 88 4 6 83 5 10 81 6 4 68b 4 87 7c a b c [BMIm]BF4 , 4.5 ml; alcohol, 10 mmol; acetic anhydride, 1.22 g, reaction temperature, GC yield. Reused in the fifth time. therefore, this esterification process in [BMIm]BF4 should be a valuable method in organic synthesis. When using 2-methyl3-buten-2-ol, which could be easily dehydrated to produce 2methyl-1,3-butadiene under acidic condition, as substrate, the yield of ester was 68% (Entry 6). These results indicated that our method is applicable in esterification of many tertiary alcohols. 3.5. [BMIm]BF4 is a neutral ionic liquid before and after the esterification reaction Water is present in ionic liquids of the type we studied, even after a moderate drying procedure [31]. Neutral [BMIm]PF6 liberates traces of HF when it comes in contact with moisture or heated at high temperature [28]. Considering the esterification being a typical acid-catalysis reaction and the high reactivity of [BMIm]BF4 ionic liquid, we preliminarily investigated the acidic property of the used [BMIm]BF4 . After the reaction, the PH test paper displayed pale green color in the presence of the reaction mixture indicative of neutral of [BMIm]BF4 . Alternatively, the Lewis and Brønsted acidity of the ionic liquid has been determined using pyridine as a probe molecule by monitoring the bands in the range of 1400–1700 cm−1 arising from its ring vibration modes [32,33]. The FTIR spectra of neat pyridine show a band at 1437 cm−1 (Fig. 1). On mixing pyridine with ionic liquid [BMIm]BF4 (both the fresh and the fifth used ionic liquids are tested), the spectra of the two cases show no band near 1450 or 1540 cm−1 , which indicate the presence of the Lewis acid sites and Brønsted acid sites respectively. Then, we believe that the [BMIm]BF4 is a neutral ionic liquid before and after the reac- 60 ◦ C. tion. As to the reaction mechanism of this process, it is not clear at this stage. The understanding of the mechanism of catalysis in ionic liquids is still in its infancy. The ionic liquids are composed only of ions, such ionic nature can affect the course of the reactions. It can be conjectured that the strong electrostatic field possessed by the dialkyl imidazolium cation mediated with the counterion, may play an important role in initiating the desired reaction and a traditional acid or base catalytic mechanism was not involved. It should be pointed out here, using the viewpoint that [BMIm]BF4 would be decomposed as a acidic medium to explain the high reactivity of tert-butanol, especially the excellent selectivity to the correspongding iso-butene acetate seems to be unreasonable. Fig. 1. FT-IR spectra of (a) pure pyridine; (b) pyridine + fresh [BMIm]BF4 ; (c) pyridine + the fifth used [BMIm]BF4 (pyridine/ionic liquid = 1:3 by weight in (b and c). Z. Duan et al. / Journal of Molecular Catalysis A: Chemical 246 (2006) 70–75 4. Conclusion In conclusion, we have developed an unusual esterification method for acid unstable tertiary alcohols using neutral ionic liquid [BMIm]BF4 as highly selective catalyst and solvent. It should be particularly pointed out that some functionalized acidic or basic ionic liquids are all less selective in the same conditions. Many functionalized tertiary alcohols, such as propargylic alcohols and allyl alcohol could be successfully converted to the corresponding acetates with good to excellent isolated yields in our system. This simple and effective process is attractive for the chemical industry and green organic synthesis. Acknowledgement This work was financially supported by National Natural Science Foundation of China (No. 20225309, 20533080). References [1] S. Patai (Ed.), The Chemistry of Carboxylic Acid and Esters, New York, Wiley, 1969. [2] (a) G.W. Anderson, F.M. Callaham, J. Am. Chem. Soc. 82 (1960) 3359; (b) K.A. Williams, S.L. Cook, P.W. Turner, US Patent 6,657,075 (2003).; (c) R. Kroker, G. Nestler, W. Schmitt, W. Schumm, US Patent 6,756,506 (2004). [3] (a) H. Okumoto, S. Nishihara, H. Nakagawa, A. Suzuki, Synlett 217 (2000); (b) K. Kato, Y. Yamamoto, H. Akita, Tetrahedron Lett. 43 (2002) 6587. [4] E.M. Kaiser, R.A. Woodruff, J. Org. Chem. 35 (1970) 1198. [5] S. Takimoto, J. Inanaga, J. Katsuki, M. Yamaguchi, Bull. Chem. Soc. Jpn. 49 (1976) 2335. [6] A. Armstrong, I. Brackenridge, R.F.W. Jackson, J.M. Kirk, Tetrahedron Lett. 29 (1988) 2483. [7] K. Nagasawa, S. Yoshitake, T. Amiya, K. Ito, Synth. Commun. 20 (1990) 2033. 75 [8] K. Nagasawa, K. Ohhashi, A. Yamashita, K. Ito, Chem. Lett. (1994) 209. [9] V.R. Choudhary, K. Mantri, S.K. Jana, Microporous Mesoporous Mater. 47 (2001) 179. [10] V.R. Choudhary, K. Mantri, S.K. Jana, Catal. Commun. 2 (2001) 57. [11] M. Salavati-Niasari, T. Khosousi, S. Hydarzadeh, J. Mol. Catal. A: Chem. 235 (2005) 150. [12] R. Sheldon, Chem. Commun. (2001) 2399. [13] H. Olivier-Bourbigou, L. Magan, J. Catal. Mol. A: Chem. 182–183 (2002) 419. [14] P. Wasserscheid, W. Keim, Angew. Chem. Int. Ed. 39 (2002) 3772. [15] Y. Deng, F. Shi, J. Peng, K. Qiao, J. Mol. Catal. A Chem. 165 (2001) 33. [16] (a) A.C. Cole, J.L. Jensen, I. Ntai, K.L.T. Tran, K.J. Weave, D.C. Forbes, J.H. Davis, J. Am. Chem. Soc. 124 (2002) 5962; (b) D.C. Forbes, K.J. Weaver, J. Mol. Catal. A Chem. 214 (2004) 129; (c) J.H. Davis Jr., Chem. Lett. 33 (2004) 1072. [17] K. Qiao, C. Yokoyama, Chem. Lett. 33 (2004) 472. [18] J. Fraga-Dubreuil, K. Bourahla, M. Rahmouni, J.P. Bazureau, J. Hamelin, Catal. Commun. 3 (2002) 185. [19] H.P. Zhu, F. Yang, J. Tang, M.Y. He, Green Chem. 5 (2003) 38. [20] B. Wang, L.M. Yang, J.S. Suo, Tetrahedron Lett. 44 (2003) 5037. [21] C. Imrie, E.R.T. Elago, C.W. McCleland, N. Williams, Green Chem. 4 (2002) 159. [22] Y. Gu, F. Shi, Y. Deng, J. Mol. Catal. A Chem. 212 (2004) 71. [23] Y. Gu, F. Shi, Y. Deng, Catal. Commun. 4 (2003) 597. [24] G. Zhao, T. Jiang, H. Gao, B. Han, J. Huang, D. Sun, Green Chem. 6 (2004) 75. [25] H.H. Wu, F. Yang, P. Cui, J. Tang, M.Y. He, Tetrahedron Lett. 45 (2004) 4963. [26] F. Shi, H. Xiong, Y. Gu, S. Guo, Y. Deng, Chem. Commun. (2003) 1054. [27] K. Qiao, Y. Deng, N. J. Chem. (2002) 667. [28] H. Shen, Z.M.A. Judeh, C.B. Ching, Tetrahedron Lett. 44 (2003) 981. [29] B.C. Ranu, S.S. Dey, A. Hajra, Green Chem. 5 (2003) 44. [30] Y. Gu, F. Shi, Y. Deng, J. Org. Chem. 69 (2004) 391. [31] M. Kosmulski, J. Gustafsson, J.B. Rosenholm, Thermochim. Acta 412 (2004) 47. [32] E.P. Parry, J. Catal. 2 (1963) 371. [33] Y. Yang, Y. Kou, Chem. Commun. 226 (2004) 227.