* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download AN ATTEMPT TO PRODUCE RECOMBINANT HORSE INSULIN D

Nucleic acid analogue wikipedia , lookup

Molecular cloning wikipedia , lookup

Therapeutic gene modulation wikipedia , lookup

Human–animal hybrid wikipedia , lookup

Genetic code wikipedia , lookup

Expanded genetic code wikipedia , lookup

Point mutation wikipedia , lookup

Genetic engineering wikipedia , lookup

Artificial gene synthesis wikipedia , lookup

History of genetic engineering wikipedia , lookup

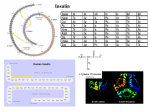

Batsaikhan.D and et al. (2016) Mongolian Journal of Agricultural Sciences №19 (03): 3-9 3 AN ATTEMPT TO PRODUCE RECOMBINANT HORSE INSULIN D.Batsaikhan1*, S.Lkhagvasuren1, B.Munkhtogtokh2, B.Tuvshin1, B.Bayar-Enkh1, Ya.Ganbold1 1-Institute of veterinary medicine, MULS 2-Research institute of animal husbandry, MULS *Email: [email protected] ABSTRACT The present study aimed to produce horse insulin by use of recombinant DNA technology. Because the hormones such as somatotropin, prolactin and leptin, which are practically applicable in veterinary medicine, are also peptides, they can be obtained on the basis of this model technology. To isolate total RNA, horse pancreas samples were collected in RNA stabilizing solution from local abattoirs, sent to the laboratory, and stored the samples in the freezer at -800C. Molecular biological reagents and kits for total RNA extraction, one step RT (reverse transcription)-PCR reactions, cloning, expression, and purification were used to produce equine proinsulin. Primers were designed from NCBI gene bank data and synthesized in Macrogen Inc, Korea. Obtained equine proinsulin was processed by enzymes trypsin and carboxypeptidase B to form mature insulin. The purity of insulin was assessed by SDS-PAGE. Molecular weight of insulin is approximately 6.0 kDa. The hormone was also measured by ELISA test and it was equal to 55 IU per ml of solution. Finally it can be concluded equine insulin with 55 IU/ml activity can be produced by recombinant DNA technology. KEY WORDS: Equine, pancreas, proinsulin, gene, primer, cloning, purification INTRODUCTION Insulin is a protein hormone produced by B cells of islet of Langerhans in the pancreas, its molecular weight is about 5,800 dalton. It is a dipeptide consisting of 2 chains, A and B. Insulin acts on most body tissues, except the encephalon. Insulin increases glucose uptake in cells, the synthesis of glycogen and fatty acids, the formation of triglycerides, and promotes the active transport of amino acids in cells, especially muscle cells, thereby increasing the concentration of metabolites necessary for protein synthesis and enhancing synthesis. In 1921, Canadian scientists Frederick G. Banting and Charles H. Best successfully purified insulin from a dog's pancreas [1]. Structures of insulin in the different species are very similar. In the study of horse and whale insulin as compared to insulin of other mammals such as cattle, swine and sheep, the only differences found were in the three residues occupying positions 8-10 in the glycil (A) chain [2]. Also, human insulin differs from swine insulin by only amino acid residue, while it differs from horse by 2, cattle by 3 and sheep, goat and cat by 4 [3]. Proinsulin or prohormone of insulin is a single-chain polypeptide of approximately 9 kDa with three intrachain disulfide bridges, the number of amino-acid residues varying somewhat with species (78 in dog, 81 in cattle and sheep, 84 in cod and pig, 4 Batsaikhan.D and et al. (2016) Mongolian Journal of Agricultural Sciences №19 (03): 3-9 86 in horse, human, and rat). It is cleaved into insulin and C (or connecting)-peptide. Synthesized in the pancreatic B cells, it is normally present at about 5% of the concentration of insulin, and is secreted in small amounts into the blood [4]. Over the years scientists made continual improvements in producing insulin. Researchers continued to improve insulin but the basic production method remained the same for decades. Insulin was extracted from the pancreas of cattle and pigs and purified. Then in the early 1980s biotechnology revolutionized insulin production. Researchers had already decoded the chemical structure of insulin in the mid 1950s. They also determined the exact location of the insulin gene at the top of human chromosome 11 [5]. By 1977, a research team had spliced a rat insulin gene into a bacterium that then produced insulin. In the 1980s, researchers used genetic engineering to manufacture a human insulin [5,6]. As reported by Chang et al, 1998 proinsulin which was prepared by the same procedure showed a maximum refolding yield of 57% at the same molar concentration at pH 10.5 [7]. In other study, 5-8 mg of partially purified, S-sulfonated human proinsulin was normally obtained from 1L of cultured bacteria [8]. In 1982, the Eli Lilly Corporation produced a human insulin that became the first approved genetically engineered pharmaceutical product. Without needing to depend on animals, researchers could produce genetically engineered insulin in unlimited supplies [1]. Despite, insulin is less applicable in veterinary medical practices, camel (Camelus dromedarius) recombinant insulin was produced and characterized to use in down stream biotechnological and disease treatment applications in Saudi Arabia, because camels suffer from fetal diseases, which may have an effect on the country’s economy [9]. In this study, we aimed to make an attempt of producing recombinant equine insulin, and characterize molecular weight and hormonal activity of the obtained insulin preparation to use the technology model for further studies of production of some peptide hormones important for veterinary medical practices by rDNA technology. MATERIALS AND METHODS Sample collection and RNA extraction Horse pancreas samples were taken from 3 adult horses, slaughtered in an abattoir in Nalaikh district, UB city. Pancreas were removed and weighed, and tissue samples were quickly cut into slices less than 0.5 cm in thickness and immediately submerged into 100 ml sterile glasses containing RNA Stabilization solution within approximately 20 min after sacrificing horses. Total RNAs were extracted from pancreas by use of total RNA extraction kit (Amersham Biosciences) according to the manufacturer’s protocol. Pre-weighed (~100 mg) of pancreatic tissues were removed from RNA stabilization solution and extraction buffers and immediately submerged into 1.5 ml tube containing 225 μl beta-mercaptoethanol. Samples were homogenized thoroughly by tissue grinder. Samples were centrifuged at 10,000 x g for 15 min at room temperature and supernatants were dispensed carefully by vacuum aspiration. After washing RNA pellets the samples were centrifuged at high speed for 5 min and supernatants were aspirated without disrupting pellets. The tubes were incubated on ice and washed with 1.5 ml ice-cold 70% ethanol. Samples were centrifuged at 10,000 x g and the ethanol supernatants were discarded carefully. RNA pellets were dissolved in 100 to 200 μl of DEPCtreated water and incubated on ice for 15 min. The yield and purity of RNA were assessed by spectrophotometric analysis. Reverse transcription and cDNA amplification First-strand cDNA of equine proinsulin was synthesized by use of AccuPower RocketScript RTPCR Premix kit as described in the manufacturer’s instruction (Bioneer). Both the forward and reverse primers for amplification of horse proinsulin cDNA were designed on the basis of NCBI sequences of equus caballus insulin cDNAs (Accession XM-001496805). Equuscaballusinsulin-1-F (5`-CCA GCA GGT CAC CGT-3`) and Equuscaballusinsulin-2-R (5`-AGT TGC AAT AGT TCT CCA GC-3`) were synthesized (Macrogen Inc) and utilized to amplify horse proinsulin cDNA. Thermocycling conditions were 60ºC for 30 min, 95ºC for 5 min followed by denaturing at 95ºC for 30 seconds and annealing at 55ºC for 30 seconds and extension at 72ºC for a minute. The final extension cycle was at 72ºC for 5 min. The PCR amplicons were analyzed by 1.5% agarose gel electrophoresis. Molecular cloning of equine proinsulin cDNA In order to insert amplified equine proinsulin cDNA into a linearized plasmid vector pCRT4/NT-TOPO of TOPO-TA one-step cloning strategy (Invitrogen), the kit was used according to manufacturer’s instructions. Two microliter of fresh PCR product was mixed with Batsaikhan.D and et al. (2016) Mongolian Journal of Agricultural Sciences №19 (03): 3-9 1 μl salt solution in a microcentrifuge tube, and the total volume was brought up to 5 μl by ddH2O. One microliter of linearized pCRT4/NT-TOPO vector was added and the reaction mix was incubated at room temperature for 5 min. Then the reaction mix was incubated on ice and 1 μl was used directly to transform competent One Shot TOP10- E. coli DH10B (Invitrogen). The transformed cells were plated on LB plates containing 100 mg/ml ampicillin. The plates were incubated at 37ºC overnight to grow colonies. Bacterial colonies were screened by growing 10 to 20 single colonies in 6 ml of LB media containing 100 mg/ml ampicillin for 6 to 8 hours. Expression and purification of equine proinsulin Recombinant equine proinsulin expression was induced by addition of 1 mM iso-propyl-β-thiogalactopyranoside (IPTG) for 4 h at 30 0C in 55.5 mM glucose in Luria-Bertani (LB) medium. Induction was followed by purification of protein using AccuPrep 5 His-tagged protein Purification kit (Bioneer) as described in the instruction of manufacturer. Protein purity was assessed by SDS-PAGE. Cleavage of equine proinsulin Equine proinsulin protein was dissolved in 100 mM Tris/H3PO4, pH 7.5, containing 0.1 % Tween 20 to protein concentrations of 2 mg/ml. Trypsin (Sigma Aldrich) and carboxypeptidase B (Sigma Aldrich) were added to trypsin/ protein ratios of 2:2000 (by mass) and carboxypeptidase B/protein ratios of 1:1000 (by mass). After 30 min, the digestion was stopped by decreasing the pH to 3 by adding acetic acid. Acetonitrile to 20% was added in order to stabilize the cleavage products. Insulin measurement Insulin activity was measured by equine insulin ELISA test kit (Endocrine Technologies Inc) according to the manufacturer’s instruction. RESULTS Pancreas of three horses were taken after slaughtering and a pancreas weighed 314.3±3.5 g in average (Fig.1). Pancreatic tissue samples was excised less than 0.5 mm in thickness from tail portion and placed in RNA stabilization solution for total RNA isolation, because this part contains highest number of Langerhans islets, beta cells of which produce insulin. Figure 1. A pancreas taken from horse carcass within 20 minutes after slaughtering After isolation of total RNA. Both forward and reverse primers were designed by NCBI primerBLAST software and synthesized in Macrogen Inc. Also, equine proinsulin amino acid sequence known from literatures was converted to the DNA nucleotide sequence by using online In-silico Sequence Conversion tool and attempts to design primers of equine proinsulin were made and they were synthesized also in Macrogen Inc. However, the former primers were selected in the present study. Then equine proinsulin cDNA was produced from total RNA using a ready to use lyophilized mastermix containing all components for first strand cDNA synthesis and PCR reaction in one tube. Electrophoregram shows the cDNA molecule encoding equine proinsulin consists of approximately 260 bp nucleotides (Fig.2). 6 Batsaikhan.D and et al. (2016) Mongolian Journal of Agricultural Sciences №19 (03): 3-9 Figure 2. Equine proinsulin cDNA molecule of approximately 260 bp nucleotides Figure 2. Equine proinsulin cDNA molecule of approximately 260 bp nucleotides The equine proinsulin gene was cloned using contain non-recombinant vector are killed upon non-recombinant are killed The equine proinsulin genevector was (figure cloned 3),using plating. The DNA insert wasvector not sequenced and upon after linearized pCRT4/NT-TOPO and contain The insertexpression, was not sequenced and after linearized vector (figure 3), and plating. induction of DNA proinsulin the hormone was expressed pCRT4/NT-TOPO in E.coli. The vector pCRT4-TOPO of proinsulin expression, hormone was expressed in selection E.coli. ofThe vector pCRT4-TOPO purified by use of AccuPrep Histhetagged protein allowed direct recombinant via disruption induction by kit usewith of Ni-NTA AccuPrepmagnetic His tagged allowed of recombinant via disruption purification silica protein resins. of lethaldirect E.coliselection gene, ccdB and blue/white screening purified purification kit with Ni-NTA magnetic silica resins. of lethal E.coli gene, ccdB and blue/white screening is not required, because ligation of PCR product Then the proinsulin was cleaved by using Trypsin proinsulin cleaved by using is not required, because ligation of PCR (SigmatheAldrich) andwas carboxypeptidase B Trypsin (Sigma disrupts expression of lacZalpha-ccdB geneproduct fusion Then (Sigma Aldrich) and carboxypeptidase B (Sigma disrupts expression of lacZalpha-ccdB gene fusion permitting growth of only positive recombinant Aldrich) as described in materials and methods permitting of onlyandpositive section. as described in materials and methods protein upongrowth transformation bacterialrecombinant cells, which Aldrich) protein upon transformation and bacterial cells, which section. Figure 3. Plasmid map of pCR4 containing horse proinsulin gene Figure(taken 3. Plasmid map ofTA pCR4 containing proinsulin gene from TOPO cloning manualhorse by Invitrogen) (taken from TOPO TA cloning manual by Invitrogen) The molecular weight of recombinant horse insulin is approximately 6.0 kDa by SDS polyacrylamide gel The molecular weight electrophoresis (Fig.4). of recombinant horse insulin is approximately 6.0 kDa by SDS polyacrylamide gel electrophoresis (Fig.4). Batsaikhan.D and et al. (2016) Mongolian Journal of Agricultural Sciences №19 (03): 3-9 7 Figure 4. Electrophoregram of purified equine insulin by SDA-PAGE Because total amount of the hormone produced in this experiment was lower and insufficient to be used for insulin measurement in rabbits according US pharmacopea, equine insulin was measured by equine insulin ELISA test and the amount was equal to 50 IU per ml protein solution. DISCUSSION Our study can be the first attempt to obtain equine insulin by use of recombinant DNA technology, although equine insulin, including its amino acid and nucleotide sequences, structures and physic-chemical characteristics has been investigated and reported [1, 2, 3]. But, there is no any study toward cloning and characterizing peptide hormones in animals by recombinant DNA technology in our country. As a result of the present study, a model technology for production of recombinant equine insulin was initially being developed in order to use this example for further studies on production of various protein hormones important in veterinary medical practices, besides of its possible use for various purposes. Human insulin is essentially important for curing diabetes mellitus, because approximately 150 million people have diabetes mellitus worldwide, and that this number may well double by the year 2025 [10]. Therefore, results of human insulin studies are extensively reported in the literatures. While companies still sell a small amount of insulin produced from animals-mostly porcine-from the 1980s onwards, insulin users increasingly moved to a form of human insulin created through recombinant DNA technology. According to the Eli Lilly Corporation, 95% of insulin users in most parts of the world take some form of human insulin in 2001. Some companies have stopped producing animal insulin completely. Companies are focusing on synthesizing human insulin and insulin analogs, a modification of the insulin molecule in some way [1]. Synthesizing human insulin is a multi-step biochemical process that depends on basic recombinant DNA techniques and an understanding of the insulin gene. Manufacturers manipulate the biological precursor to insulin so that it grows inside simple bacteria. While manufacturers each have their own variations, there are two basic methods to manufacture human insulin. One method of manufacturing insulin is to grow the two insulin chains separately. This will avoid manufacturing each of the specific enzymes needed. Manufacturers need the two mini-genes: one that produces the A chain and one for the B chain. Since the exact DNA sequence of each chain is known, they synthesize each minigene's DNA in an amino acid sequencing machine, the two chains are then mixed together and joined by disulfide bonds through the reduction-reoxidation reaction. An oxidizing agent (a material that causes oxidization or the transfer of an electron) is added. Starting in 1986, manufacturers began to use another method to synthesize human insulin. They started with the direct precursor to the insulin gene, proinsulin, the connecting sequence between the A and B chains is spliced away [11] with enzymes such as trypsin and carboxipeptidase B [12] and the resulting insulin is purified. Although the amino acid sequence of insulin varies among species, certain segments of the molecule are highly conserved, including the positions of the three disulphide bonds, both ends of the A chain and the C terminal residues of the B chain [13]. In addition to human insulin, insulin protein from different species such as rabbit, sheep, pig, dog, horse, elephant and camel has been studied closely. Despite the species diversity, insulin from all investigated animals 8 Batsaikhan.D and et al. (2016) Mongolian Journal of Agricultural Sciences №19 (03): 3-9 harbors a close homology to human insulin. The harbors a close homology to human insulin. The amino differences give to each species' insulin a harborsacid a close homology human insulin. The amino acid differences give each species' insulin a slightly different structure and activity because the amino acid differences giveand each species' insulinthea slightly different structure activity because whole protein folds and around on itself and has slightlyinsulin different structure activity because the whole insulin protein folds around on itself and has very where it interacts the wholespecific insulin locations protein folds around on itselfwith and has very specific locations where it interacts with the insulin receptorlocations on the cell. Theitsequence porcine very specific where interactsof the insulin receptor on the cell. The sequence ofwith porcine insulin and human insulin is almost identical, but not insulin receptor on the cell. The sequence of porcine insulin and human insulin is almost identical, but not exactly – it differs by one amino acid. Equine but insulin insulin and insulin is almost identical, not exactly – it human differs by one amino acid. Equine insulin is different by two amino acids, while bovine insulin exactly – it differs by one amino acid. Equine insulin is different by two amino acids, while bovine insulin by three from It is acids, of interest point out that is different byhuman. two amino whileto insulin by three from human. It is of interest tobovine point out that the newly developed analogs like out Lispro, by three from human. Itinsulin is of interest to point that the newly developed insulin analogs like Lispro, Aspart anddeveloped Glargine; also differ the newly analogsfrom like “human Lispro, Aspart and Glargine; insulin also differ from “human insulin” in two or more also amino acids.from Theoretically Aspart and Glargine; “human insulin” in two or more aminodiffer acids. Theoretically changes in amino acid could affect the solubility and insulin” in two or more amino acids. Theoretically changes in amino acid could affect the solubility and diffusion properties of insulin molecules [14]. changes in properties amino acid could affect the solubility[14]. and diffusion of insulin molecules Clinical efficacy of insulin clearly does not depend on diffusion properties of insulin molecules [14]. Clinical efficacy of insulin clearly does not depend on the species of insulin used. clearly A number ofnot clinical trials Clinical efficacy of insulin does depend on the species of insulin used. A number of clinical trials have clearly shown that animal insulins and human the species insulinthat used.animal A number of clinical trials have clearlyofshown insulins and human insulins are comparable their clinical The have clearly shown thatin insulinsefficacy. and human insulins are comparable inanimal their clinical efficacy. The duration of action of human insulin is slightly shorter insulins are comparable in their clinical efficacy. The duration of action of human insulin is slightly shorter CONCLUSION duration of action of human insulin is slightly shorter CONCLUSION CONCLUSION As a result of the present study, the following As a result of the present study, the following conclusions made: As a resultcan of be present study, the following conclusions can bethe made: 1. Pancreas of Mongolian weighs 314.3±3.5 g conclusions be made: horse 1. Pancreascan of Mongolian horse weighs 314.3±3.5 g in average, equine proinsulin cDNA 314.3±3.5 nucleotides 1. in Pancreas of equine Mongolian horse weighs average, proinsulin cDNA nucleotidesg have approximately 260 bp length, and molecular in average, equine proinsulin cDNA have approximately 260 bp length, andnucleotides molecular weight and hormonal activity of recombinant have approximately 260 activity bp length, molecular weight and hormonal ofand recombinant equine insulin is 6.0 kDa and 55.0 IU/ml weight and hormonal of recombinant equine insulin is 6.0 activity kDa and 55.0 IU/ml respectively. equine insulin is 6.0 kDa and 55.0 IU/ml respectively. respectively. ACKNOWLEDGEMENT ACKNOWLEDGEMENT ACKNOWLEDGEMENT We should thank to S.Davaasuren, researcher of We should thank to S.Davaasuren, researcher of Molecular laboratory, Dr.V.Batbaatar, We should genetics thank to S.Davaasuren, researcher of Molecular genetics laboratory, Dr.V.Batbaatar, researcher of Laboratory of microbiology and Molecular of genetics laboratory, Dr.V.Batbaatar, researcher Laboratory of microbiology and researcher of Laboratory of microbiology and REFERENCES REFERENCES REFERENCES 1. Lorenzi R.D., Gritti C. 2010. Towards the First 1. Lorenzi R.D., Gritti C. 2010. Towards the First European 1. Recombinant Lorenzi R.D.,Drug GrittiInsulin, C. 2010. TowardsMolecular the First Recombinant Drug Insulin, European Molecular Biology laboratory, 64 p Recombinant Drug Insulin, European Molecular Biology laboratory, 64 p 2. Harris J.I., Sanger F.64 1956. differences in Biology laboratory, p Species 2. Harris J.I., Sanger F. 1956. Species differences in insulin, Archives of Biochemistry and 2. insulin, Harris J.I., Archives Sanger F. 1956. differences in of Species Biochemistry and Biophysics, 65: 427-458 insulin, Archives of Biochemistry and Biophysics, 65: 427-458 3. Zundorf I., Dingermann 2001. Vom Rinder-, Biophysics, 65: 427-458 T., 3. Zundorf I., Dingermann T., 2001. Vom Rinder-, Schweine-, Pferde-insulin zum Human insulin: 3. Schweine-, Zundorf I., Dingermann T.,zum 2001. Vom Rinder-, Pferde-insulin Human insulin: Die biotechnische und gentechnische InsulinSchweine-, Pferde-insulin zum Human insulin: Die biotechnische und gentechnische InsulinHerstellung, Pharmazie ingentechnische unserer Zeit, Nr.1: 27Die biotechnische und InsulinHerstellung, Pharmazie in unserer Zeit, Nr.1: 2732 Herstellung, Pharmazie in unserer Zeit, Nr.1: 2732 4. Cammack R., Atwood T., Campbell P., Parish H., 32 4. Cammack R., Atwood T., Campbell P., Parish H., A., R., Vella F., T., Stirling J. 2006. Oxford 4. Smith Cammack Atwood Campbell P., Parish H., Smith A., Vella F., Stirling J. 2006. Oxford Smith A., Vella F., Stirling J. 2006. Oxford than animal insulins [15]. Therefore, equine insulin, than animal insulins [15]. Therefore, equine insulin, different withinsulins only two amino acid residues also than animal [15]. Therefore, equinecan insulin, different with only two amino acid residues can also be used for human medicine in association with above different with onlymedicine two amino acid residues canabove also be used for human in association with issues. Human synthetic M-proinsulin waswith obtained be used for human medicine in association above issues. Human synthetic M-proinsulin was obtained in 30-35% yield after purification either anion issues. Human synthetic M-proinsulin wasby obtained in 30-35% yield after purification either by anion exchange chromatography on Q-Sepharose or acid in 30-35%chromatography yield after purification either byoranion exchange on Q-Sepharose acid precipitation [16]. Lee et al. [17] purified human exchange chromatography on Q-Sepharose or acid precipitation [16]. Lee et al. [17] purified human proinuslin from cellular plasma by purified use of DEAE precipitation [16]. Lee et al. [17] human proinuslin from cellular plasma by use of DEAE sephacell Sephadex columns andoftheDEAE yield proinuslinand from cellularG-200 plasma by use sephacell and Sephadex G-200 columns and the yield was 35%. All insulin preparations in Australia are sephacell G-200 columns and the yield was 35%.and AllSephadex insulin preparations in Australia are standardized to insulin contain 100 IU/ml and typical daily was 35%. All inaaAustralia are standardized to contain preparations 100 IU/ml and typical daily dose in human is 0.7 IU/kg per and day [18]. Only 2 standardized to contain IU/ml typical daily dose in human is 0.7 100 IU/kg per day a[18]. Only 2 insulin preparations, concentrated at 40 U/ml are dose in human is 0.7 IU/kg per day [18]. Only insulin preparations, concentrated at 40 U/ml are2 registered for veterinary use or treatment diabetes insulin preparations, concentrated at 40of are registered for veterinary use or treatment ofU/ml diabetes in dogs and cats [19]. In our study, content of insulin registered for veterinary use or treatment of diabetes in dogs and cats [19]. In our study, content of insulin is IU percats ml of solution. Further andofdetailed in 55 dogs In our study, content insulin is 55 IUand per ml[19]. of solution. Further and detailed studies may have important implications and would is 55 IUmay perhave ml of solution.implications Further and studies important anddetailed would provide a framework to disease association and gene studies may have important implications provide a framework to disease associationand andwould gene analysis within diverse populations. provide a framework to disease association and gene analysis within diverse populations. analysis within diverse populations. 2. 2. 2. An attempt of recombinant DNA technology for An attempt of recombinant DNA technology for producing insulin DNA demonstrates An attempt equine of recombinant technologythat for producing equine insulin demonstrates that recombinant peptide hormone productionthat is producing equine insulin demonstrates recombinant peptide hormone production is possible to be made under laboratory condition recombinant hormone production is possible to bepeptide made under laboratory condition and further studies are necessary toward down possible to be made under laboratory condition and further studies are necessary toward down streaming technology for production of down other and furtherthis studies are necessary toward streaming this technology for production of other peptide hormones, which are practically streaminghormones, this technology of most other peptide whichfor areproduction practically most applicable in veterinary medicine. peptide hormones, which are practically most applicable in veterinary medicine. applicable in veterinary medicine. immunology and our colleagues in our institute for immunology and our colleagues in our institute for their kind andand invaluable assistances andinstitute advices to immunology our colleagues in our their kind and invaluable assistances and advicesfor to do such a complicated scientific work. their kind and invaluable assistances do such a complicated scientific work.and advices to do such a complicated scientific work. 5. 5. 5. 6. 6. 6. 7. 7. 7. Dictionary of Biochemistry and Molecular Dictionary of Biochemistry and Molecular Biology (2ndof ed), Oxford University 736 p Dictionary and press, Molecular Biology (2nd ed),Biochemistry Oxford University press, 736 p Owerbach D., Bell G.I., Rutter W.L., Shows T.B.p Biology (2nd ed), Oxford University press, Owerbach D., Bell G.I., Rutter W.L., Shows736 T.B. 1980. The insulin gene is located on chromosome Owerbach D., Bellgene G.I.,isRutter W.L., Shows T.B. 1980. The insulin located on chromosome 11 in humans, Nature, 82-84on chromosome 1980. The insulin gene286: is located 11 in humans, Nature, 286: 82-84 Chan S.J., Weiss J., Konrad M., White T., Bahl 11 in humans, Nature, 286: 82-84 Chan S.J., Weiss J., Konrad M., White T., Bahl C., Marks D., Steiner D.F.T.,1981. ChanYu S.J.,SD., Weiss J., Konrad M., White Bahl C., Yu SD., Marks D., Steiner D.F. 1981. Biosynthesis and periplasmic segregation of C., Yu SD., and Marks D., Steiner D.F. 1981. Biosynthesis periplasmic segregation of human proinsulin in Escherichia coli. PNAS 9: Biosynthesis and periplasmic segregation human proinsulin in Escherichia coli. PNAS of 9: 5401-5405. human proinsulin in Escherichia coli. PNAS 9: 5401-5405. Chang S.G., Kim D.Y., Choi K.D., Shin J.M., 5401-5405. Chang S.G., Kim D.Y., Choi K.D., Shin J.M., Shin H.C. 1998. Human production from Chang S.G., Kim D.Y., insulin Choi K.D., Shin J.M., Shin H.C. 1998. Human insulin production from aShin novel mini-proinsulin high receptor H.C. 1998. Humanwhich insulinhas production from a novel mini-proinsulin which has high receptor binding Biochem. J. 329: a novel activity. mini-proinsulin which has631-635. high receptor binding activity. Biochem. J. 329: 631-635. binding activity. Biochem. J. 329: 631-635. Batsaikhan.D and et al. (2016) Mongolian Journal of Agricultural Sciences №19 (03): 3-9 8. Cowley, D.J., Mackin R.B. 1997. Expression, purification and characterization of recombinant human proinsulin, FEBS Letters 402: 124-130 9. Al-Swailem A.M., Al-Fageeh M.B., Alyamani E.J., Shehata M.M., Al-Shammari TA. 2008. Characterization of recombinant Arabian camel (Camelus dromedarius) insulin. African Journal of Biotechnology , 7 (18): 3389-3394 10. Diabetes mellitus, Available from: http://www.who.int/mediacentre/factsheets/fs13 8/en/ 11. Hober S., Uhlen M. 2005. Enhanced recovery and folding of recombinant proteins using fusion protein strategies In Protein Engineering in Industrial Biotechnology, Edited by L.Alberghina. Amsterdam, Harwood Academic Publishers, 374 p 12. Jonasson P., Nilsson J., Samuelsson E., Moks T., Stahl S., Uhlen M. 1996. Single-step trypsin cleavage of a fusion protein to obtain human insulin and its C peptide, Eur. J. Biochem. 236, p 656-661 13. Steiner D.F., Chan S.J., Welsh J.M., Kwok S.C.1985. Structure and evolution of the insulin gene. Annu. Rev. Genet., 19: 463-484 9 14. Jacobs S. 1985. Insulin receptor: purification and structure. In Insulin: its Receptor and Diabetes, Edited by M.D.Hollenberg. Marcel Dekker, New York, 39-55 15. Mohan V., 2002. Which insulin to use? Human or animal? Curr. Sci., 12, p 315-316 16. Gardner Q.A. 2009. Recombinant Human Insulin and its Precursors, PhD thesis, University of Punjab, Lahore, Pakistan, 308p 17. Lee S.Y, Ko J.H., Choi M.H., Nam D.H. 1996. Fermentation and purification of lacZ-fused single chain insulin precursor for (B30Homoserine) human insulin. Biotechnol.Bioprocess Eng, 1: p 9-12 18. Bryant B.J., Mary K. 2011. The endocrine pancreas and management of diabetes mellitus. In Pharmacology for Health Professional, 3rd ed., Elsevier, Australia, 705-706 19. Thompson A., Lathan P., Fleeman L. 2015. Review: Update on insulin treatment for dogs and cats: insulin dosing pens and more. Veterinary Medicine: Research and Reports, 6: 129-142