* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download 45.1 Inter-conversions between the functional groups

Discodermolide wikipedia , lookup

Elias James Corey wikipedia , lookup

Homoaromaticity wikipedia , lookup

Ring-closing metathesis wikipedia , lookup

Physical organic chemistry wikipedia , lookup

Wolff–Kishner reduction wikipedia , lookup

Wolff rearrangement wikipedia , lookup

Strychnine total synthesis wikipedia , lookup

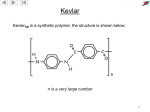

Hydroformylation wikipedia , lookup

Chapter 45 Inter-conversions of carbon compounds 45.1 Inter-conversions between the functional groups 45.2 Considerations in planning a synthetic route 45.3 Laboratory preparation of simple carbon compounds P. 1 / 70 Key terms Progress check Summary Concept map P. 2 / 70 45.1 Inter-conversions between the functional groups Carbon compounds possessing different functional groups usually have different physical and chemical properties. Example: chloroethane (CH3CH2Cl) and ethanol (CH3CH2OH) Same structure except the difference in functional groups. P. 3 / 70 Chloroethane: gas under room conditions slightly soluble in water soluble in organic solvents Ethanol: liquid under room conditions soluble in both water and organic solvents 45.1 Inter-conversions between the functional groups P. 4 / 70 (a) (b) Figure 45.1 (a) Chloroethane is a gas under room conditions. It is largely used as a blowing agent in foamed plastics. (b) Ethanol is very soluble in water. It is dissolved in water in alcoholic drinks. By converting one or more functional groups to another, we can synthesize compounds with desired properties (e.g. solubility, melting and boiling points, chemical reactivity, etc.). 45.1 Inter-conversions between the functional groups P. 5 / 70 Chemists have been working hard to make new carbon compounds that are more useful. In organic synthesis, chemists change the functional groups of carbon compounds. They cannot do this without knowledge of the inter-conversions of functional groups. 45.1 Inter-conversions between the functional groups P. 6 / 70 Reactions of alkanes Conversion Example Alkane haloalkane CH3CH2CH2CH3 (excess) → CH3CH2CH2CH2X (major product) Reactions of alkenes Conversion Example Reagents and conditions X2 (X: Cl or Br), UV light or heat Reagents and conditions Type of reaction Substitution Type of reaction Alkene alkane CH3CH=CH2 → CH3CH2CH3 H2, Pt Addition Alkene dihaloalkane CH3CH=CH2 → CH3CHXCH2X X2 (X: Cl, Br or I) in organic solvent Addition Alkene haloalkane CH3CH=CH2 → CH3CHXCH3 (major product) HX (X: F, Cl, Br or I) Addition Table 45.1 Summary of typical reactions of different functional groups. 45.1 Inter-conversions between the functional groups P. 7 / 70 Reactions of haloalkanes Conversion Example Haloalkane alcohol CH3CH2CH2X → CH3CH2CH2OH (X: F, Cl, Br or I) Reactions of alcohols Conversion Example Reagents and conditions NaOH(aq) Reagents and conditions Type of reaction Substitution Type of reaction Alcohol haloalkane CH3CH2CH2OH → CH3CH2CH2X HX or PX3 (X: Cl, Br or I) Substitution Alcohol alkene CH3CH2CH2OH → CH3CH=CH2 Conc. H2SO4, heat or Al2O3, heat Dehydration 1° alcohol aldehyde CH3CH2CH2OH → CH3CH2CHO Cr2O72–(aq)/H+(aq), heat Oxidation 1° alcohol carboxylic acid CH3CH2CH2OH → CH3CH2COOH Cr2O72–(aq)/H+(aq), heat Oxidation 2° alcohol ketone CH3CH(OH)CH3 → CH3COCH3 Cr2O72–(aq)/H+(aq), heat Oxidation Table 45.1 Summary of typical reactions of different functional groups. 45.1 Inter-conversions between the functional groups P. 8 / 70 Reactions of aldehydes and ketones Conversion Example Reagents and conditions Type of reaction Aldehyde carboxylic acid CH3CH2CHO → CH3CH2COOH Cr2O72–(aq)/H+(aq), heat Oxidation Aldehyde 1° alcohol CH3CH2CHO → CH3CH2CH2OH 1. LiAlH4, dry ether 2. H+(aq) or NaBH4, H2O Reduction Ketone 2° alcohol CH3COCH3 → CH3CH(OH)CH3 1. LiAlH4, dry ether 2. H+(aq) or NaBH4, H2O Reduction Reactions of carboxylic acids Conversion Example Reagents and conditions Type of reaction Carboxylic acid ester CH3CH2COOH → CH3CH2COOCH2CH3 CH3CH2OH, conc. H2SO4, heat Esterification Carboxylic acid 1° alcohol CH3CH2COOH → CH3CH2CH2OH 1. LiAlH4, dry ether 2. H+(aq) Reduction Table 45.1 Summary of typical reactions of different functional groups. 45.1 Inter-conversions between the functional groups P. 9 / 70 Carboxylic acid amide CH3CH2COOH → CH3CH2CONH2 1. PCl3 2. NH3 Amide formation Reactions of esters Conversion Example Reagents and conditions Type of reaction Ester carboxylic acid + alcohol CH3CH2COOCH2CH3 CH3CH2COOH + CH3CH2OH H+(aq), heat Acid hydrolysis Ester carboxylic acid + alcohol CH3CH2COOCH2CH3 → CH3CH2COOH + CH3CH2OH 1. OH–(aq), heat 2. H+(aq) Alkaline hydrolysis Reactions of amides Reagents and conditions Type of reaction Conversion Example Amide carboxylic acid CH3CH2CONH2 → CH3CH2COOH + NH4+ H+(aq), heat Acid hydrolysis Amide carboxylic acid CH3CH2CONH2 → CH3CH2COOH + NH4+ 1. OH–(aq), heat 2. H+(aq) Alkaline hydrolysis Table 45.1 Summary of typical reactions of different functional groups. 45.1 Inter-conversions between the functional groups P. 10 / 70 Dihaloalkanes Amides Esters X2 (in organic solvent) Carboxylic acids [O], ∆ H2, Pt Alkenes (CnH2n) conc. H2SO4, ∆ For 1º [O], ∆ or Al2O3, ∆ Alcohols (ROH) [R] or [R] HX Alkanes (CnH2n+2) Aldehydes Ketones X2 Haloalkanes (RX) UV light or ∆ [O] – Cr2O72–(aq)/H+(aq) [R] – 1. LiAlH4, dry ether [R] – NaBH4, water 2. H+(aq) * ∆ = heat Figure 45.2 Summary of methods of converting one functional group to another. 45.1 Inter-conversions between the functional groups P. 11 / 70 Multi-step synthesis Some functional groups can be converted to another directly but some cannot. Multi-step synthesis is needed. An alkane can be converted to a haloalkane first. Haloalkane is then allowed to react with sodium hydroxide solution to give the required alcohol. The synthesis involves two steps. 45.1 Inter-conversions between the functional groups P. 12 / 70 Multi-step syntheses require more than one step, and so one or more intermediate compounds are produced. Example 3 steps are required to convert compound W to compound Z. 2 intermediate compounds (X and Y) are produced. W reagent condition X reagent condition Y reagent condition 45.1 Inter-conversions between the functional groups P. 13 / 70 Z Key point In order to convert a chosen starting material to a target molecule, it requires a single step or multiple steps. In either case, interconversions between functional groups are usually needed. 45.1 Inter-conversions between the functional groups P. 14 / 70 Inter-conversions between alkanes, alkenes, haloalkanes and alcohols Alkanes and alkenes are important starting materials in organic syntheses. Alkanes are obtained from the fractional distillation of petroleum. Alkenes are obtained from the cracking of higher members of the homologous series of alkanes. 45.1 Inter-conversions between the functional groups P. 15 / 70 Dihaloalkanes X2 (in organic solvent) H2, Pt Alkenes conc. H2SO4, ∆ or Al2O3, ∆ Alcohols HX Alkanes X2 UV light or ∆ Haloalkanes * ∆ = heat Figure 45.3 Inter-conversions between alkanes, alkenes, haloalkanes and alcohols. 45.1 Inter-conversions between the functional groups P. 16 / 70 The following route can be used to convert ethane (an alkane) to ethanol (an alcohol). Alcohols Alkanes Haloalkanes 1st step: conversion of ethane to chloroethane. CH3–CH3 Cl2 UV light or heat ethane CH3–CH2–Cl chloroethane 45.1 Inter-conversions between the functional groups P. 17 / 70 2nd step: conversion of chloroethane (the intermediate compound) to ethanol (the end product). CH3–CH2–Cl NaOH(aq) CH3–CH2–OH chloroethane ethanol The overall process can then be represented by the following synthetic route. CH3–CH3 ethane Cl2 UV light or heat NaOH(aq) CH3–CH2–Cl CH3–CH2–OH chloroethane ethanol 45.1 Inter-conversions between the functional groups P. 18 / 70 Ethanol can also be converted to ethane. The synthetic route is: CH3–CH2–OH ethanol conc. H2SO4 heat CH2=CH2 H2,Pt ethene CH3–CH3 ethane In the above examples, two compounds, ethane and ethanol, can be inter-converted by using different reagents and conditions. Example 45.1 Example 45.2 Class practice 45.1 45.1 Inter-conversions between the functional groups P. 19 / 70 Inter-conversions between alcohols, aldehydes, ketones, carboxylic acids, esters and amides Many organic compounds find important uses as pharmaceuticals, pesticides, perfumes and dyes. Figure 45.4 Many synthetic dyes are organic compounds containing oxygen and nitrogen. They can be used to colour fabrics. 45.1 Inter-conversions between the functional groups P. 20 / 70 These compounds include alcohols, aldehydes, ketones, carboxylic acids, esters and amides. The inter-conversions between alcohols, aldehydes and carboxylic acids are redox reactions. Carboxylic acids can be converted to esters and amides, and vice versa. 45.1 Inter-conversions between the functional groups P. 21 / 70 Esters Amides Carboxylic acids [O], ∆ Alcohols For 1º [O], ∆ Aldehydes [R] or [R] [O] – Cr2O72–(aq)/H+(aq) [R] – 1. LiAlH4, dry ether 2. H+(aq) [R] – NaBH4, water * ∆ = heat Ketones Figure 45.5 Inter-conversions between alcohols, aldehydes, ketones, carboxylic acids, esters and amides. Concept check 45.1 Inter-conversions between the functional groups P. 22 / 70 Alcohols are often used as the starting materials for different oxygen-containing compounds. Example: Convert propan-1-ol (an alcohol) to ethyl propanoate (an ester) Esters Carboxylic acids Alcohols Aldehydes 45.1 Inter-conversions between the functional groups P. 23 / 70 Learning tip A primary alcohol can be oxidized to carboxylic acid by heating the reaction mixture under reflux. The synthetic route is: Cr2O72–(aq)/H+(aq) propan-1-ol heat propanoic acid CH3CH2OH, H+(aq) heat ethyl propanoate Example 45.3 Class practice 45.2 45.1 Inter-conversions between the functional groups P. 24 / 70 Inter-conversions between functional groups of common homologous series To convert a compound without oxygen to a compound with oxygen, a synthetic pathway that includes an alcohol as one of the intermediates should be taken. 45.1 Inter-conversions between the functional groups P. 25 / 70 Compounds without oxygen Compounds with oxygen Esters Amides Dihaloalkanes Carboxylic acids X2 (in organic solvent) H2, Pt Alkenes conc. H2SO4, ∆ or Al2O3, ∆ [O], ∆ Alcohols For 1º [O], ∆ Aldehydes [R] or [R] HX Alkanes X2 UV light or ∆ Ketones Haloalkanes [O] – Cr2O72–(aq)/H+(aq) [R] – 1. LiAlH4, dry ether 2. H+(aq) [R] – NaBH4, water * ∆ = heat Figure 45.6 Inter-conversions between alcohols and other functional groups. 45.1 Inter-conversions between the functional groups P. 26 / 70 Example: Convert ethene (an alkene) to ethanal (an aldehyde) Alkenes Alcohols Aldehydes Haloalkanes 45.1 Inter-conversions between the functional groups P. 27 / 70 The synthetic route is: NaOH(aq) HCl ethene chloroethane ethanol distil off 2– + Cr2O7 (aq)/H (aq) when formed ethanal Example 45.4 Example 45.5 Class practice 45.3 45.1 Inter-conversions between the functional groups P. 28 / 70 45.2 Considerations in planning a synthetic route Chemists try to synthesize the desired compounds with the lowest costs in organic syntheses. They would consider a number of factors in planning a synthetic route. 1. Availability of starting materials and reagents The starting materials and reagents of a synthetic route should be readily available and cheap. P. 29 / 70 2. Rate of reactions Many organic reactions are slow. Reactions can be speeded up by using catalysts and a high temperature. Lead to a higher production cost. 3. Percentage yield of the synthetic route Organic syntheses seldom give a 100% yield since organic reactions seldom go to completion or by-products may be produced. 45.2 Considerations in planning a synthetic route P. 30 / 70 Example: Direct conversion of chloroethane to ethanol by sodium hydroxide solution NaOH(aq) CH3CH2Cl CH3CH2OH One mole (64.5 g) of chloroethane never gives one mole (46.0 g) of ethanol. 45.2 Considerations in planning a synthetic route P. 31 / 70 If only 23.0 g of ethanol is produced, the percentage yield of ethanol actual mass of ethanol obtained × 100% = theoretical mass of ethanol calculated 23.0 g × 100% = 46.0 g = 50% Key point Percentage yield of a product actual mass of the product obtained × 100% = theoretical mass of the product calculated 45.2 Considerations in planning a synthetic route P. 32 / 70 4. Number of steps in the synthetic route If an organic synthesis consists of several steps, the overall yield will be reduced after each step. Example Three-step synthesis in which each step has a yield of 60%: W 60% X 60% Y 60% 45.2 Considerations in planning a synthetic route P. 33 / 70 Z 60 60 60 The overall yield will be × × = 21 .6% 100 100 100 Therefore, a synthetic route should include as few steps as possible. Ethene Ethene Ethanol Ethane Chloroethane Route (1) Ethanol Chloroethane Route (2) Figure 45.7 Possible synthetic routes for the conversion of ethene to ethanol. 45.2 Considerations in planning a synthetic route P. 34 / 70 Ethene is converted to chloroethane in two steps in route (1) but in three steps in route (2). Yield of route (1) is higher than that of route (2). 5. By-products formed in the synthetic route ethane chloroethane ethanol ......... Route (3) ethene chloroethane ethanol ......... Route (4) Both routes involve two steps. 45.2 Considerations in planning a synthetic route P. 35 / 70 First step of route (3) produces not only the desired intermediate (chloroethane), but a mixture of haloalkane by-products such as 1,1dichloroethane, 1,2-dichloroethane, 1,1,1trichloroethane, etc. Formation of by-products reduces the efficiency of the synthesis. Some of the unwanted haloalkanes may cause the depletion of the ozone layer. They are harmful to the environment. Think about 45.2 Considerations in planning a synthetic route P. 36 / 70 Hydrohalogenation of ethene in route (4) produces only the desired intermediate (chloroethane) which will then be converted. The best synthetic route should produce little or no by-products. Harmful by-products should be avoided in organic syntheses. 45.2 Considerations in planning a synthetic route P. 37 / 70 Key point In planning a synthetic route for carbon compounds, the following factors have to be considered: • Availability of starting materials and reagents • Rate of reaction • Percentage yield • Number of steps • By-products formed Activity 45.1 STSE connections 45.1 45.2 Considerations in planning a synthetic route P. 38 / 70 45.3 Laboratory preparation of simple carbon compounds Preparation of ethanoic acid In the laboratory, ethanoic acid is usually prepared by the oxidation of ethanol. An acidified potassium dichromate solution can be used as the oxidizing agent. Ethanol is first oxidized to ethanal, and then to ethanoic acid. P. 39 / 70 To ensure complete oxidation of ethanol to ethanoic acid, excess oxidizing agent is used. The reaction mixture is heated under reflux for 20 to 30 minutes. ethanol loses 2 hydrogen atoms ethanal gains 1 oxygen atom ethanoic acid 45.3 Laboratory preparation of simple carbon compounds P. 40 / 70 Step 1: Heating the reaction mixture under reflux Function of the reflux condenser is to condense vapour formed from the mixture during heating. It helps to prevent the loss of volatile organic substances by evaporation on prolonged heating. 45.3 Laboratory preparation of simple carbon compounds P. 41 / 70 water out reflux condenser hot vapour condenses on the cold inner wall of the condenser water in reflux condenser pearshaped flask water out water in water bath anticondensed liquid returns to bumping granule the flask ethanol + acidified potassium dichromate solution pear-shaped flask anti-bumping granule water bath ethanol + acidified potassium dichromate solution heat Figure 45.8 Oxidizing ethanol to ethanoic acid by heating under reflux. 45.3 Laboratory preparation of simple carbon compounds P. 42 / 70 Ethanol is first oxidized to ethanal. The ethanal vaporizes and condenses in the reflux condenser. The liquid drops back into the reaction flask and is then further oxidized to ethanoic acid. 45.3 Laboratory preparation of simple carbon compounds P. 43 / 70 Step 2: Distilling the product mixture thermometer water out (to sink) thermometer pear-shaped flask Liebig condenser pear-shaped flask anti-bumping granule product mixture heat product mixture receiver adaptor water in (from tap) Liebig condenser receiver adaptor water out anti-bumping granule test tube (as receiver) water in aqueous solution of ethanoic acid aqueous solution of ethanoic acid Figure 45.9 Distilling ethanoic acid from the product mixture. 45.3 Laboratory preparation of simple carbon compounds P. 44 / 70 Distil the product mixture and collect the liquid that boils between 110°C and 114°C. The distillate obtained is an aqueous solution of ethanoic acid and it has a strong smell of vinegar. To obtain pure ethanoic acid, the aqueous solution of ethanoic acid is redistilled. The liquid that boils between 116°C and 118°C is collected as distillate. 45.3 Laboratory preparation of simple carbon compounds P. 45 / 70 The percentage yield of ethanoic acid can be calculated from the amount of ethanoic acid obtained. Percentage yield of ethanoic acid actual mass of ethanoic acid obtained = theoretical mass of ethanoic acid calculated Example 45.6 Experiment 45.1 × 100% Experiment 45.1 45.3 Laboratory preparation of simple carbon compounds P. 46 / 70 Preparation of ethyl ethanoate In the laboratory, ethyl ethanoate is prepared by heating a mixture of ethanoic acid and ethanol in the presence of an acid catalyst. The process is known as esterification. H+(aq) ethanoic acid ethanol heat ethyl ethanoate 45.3 Laboratory preparation of simple carbon compounds P. 47 / 70 water Learning tip Concentrated sulphuric acid has two functions in the laboratory preparation of ethyl ethanoate: 1. It acts as a catalyst. 2. It removes water, shifting the equilibrium of esterification to the product side. Esterification is a reversible reaction. 45.3 Laboratory preparation of simple carbon compounds P. 48 / 70 Step 1: Heating the reaction mixture under reflux Equal volumes of ethanoic acid and ethanol are mixed and concentrated sulphuric acid is added to the mixture. The mixture is then heated under reflux. SBA note Addition of concentrated sulphuric acid to the mixture of ethanol and ethanoic acid is highly exothermic. Hence, the acid should be added to the mixture slowly with cooling (in an ice-water bath) and shaking. 45.3 Laboratory preparation of simple carbon compounds P. 49 / 70 water out reflux condenser hot vapour condenses on the cold inner wall of the condenser condensed liquid returns to the flask water in pear-shaped flask a mixture of ethanol, ethanoic acid and conc. H2SO4 anti-bumping granule reflux condenser water out water in pear-shaped flask anti-bumping granule heat Figure 45.10 Heating a mixture of ethanol, ethanoic acid and concentrated sulphuric acid under reflux. 45.3 Laboratory preparation of simple carbon compounds P. 50 / 70 a mixture of ethanol, ethanoic acid and conc. H2SO4 Step 2: Distilling the product mixture To separate the organic compounds (i.e. unreacted ethanol, unreacted ethanoic acid and the product ethyl ethanoate) from the aqueous solution, twothirds of the product mixture is distilled off. This distillate should have a much lower percentage of water and relatively higher percentages of ethanol, ethanoic acid and ethyl ethanoate. 45.3 Laboratory preparation of simple carbon compounds P. 51 / 70 thermometer thermometer water out (to sink) Liebig condenser pearshaped flask product anti-bumping mixture granule water in heat (from tap) Liebig condenser pear-shaped flask receiver adaptor product mixture receiver adaptor water out anti-bumping granule water in test tube (as receiver) solution of organic compounds Figure 45.11 Distilling off two-thirds of the reaction mixture in order to separate the carbon compounds from the aqueous solution of the product mixture. 45.3 Laboratory preparation of simple carbon compounds P. 52 / 70 Step 3: Removing unreacted ethanoic acid and traces of sulphuric acid from the distillate The distillate is mixed with excess sodium carbonate solution. Sodium carbonate reacts and removes any acidic substances (unreacted ethanoic acid and traces of sulphuric acid) in the distillate. The lower aqueous layer is discarded. 45.3 Laboratory preparation of simple carbon compounds P. 53 / 70 2CH3COOH(aq) + CO32–(aq) → 2CH3COO–(aq) + H2O(l) + CO2(g) 2H+(aq) + CO32–(aq) → H2O(l) + CO2(g) excess sodium carbonate solution filter funnel organic layer aqueous layer separating funnel distillate obtained in step 2 beaker (b) (a) Figure 45.12 (a) Adding excess sodium carbonate solution removes unreacted ethanoic acid and traces of sulphuric acid in the distillate. (b) Discarding the aqueous layer. 45.3 Laboratory preparation of simple carbon compounds P. 54 / 70 Step 4: Removing unreacted ethanol from the distillate The organic layer is then mixed with excess calcium chloride solution. Calcium chloride reacts and removes any unreacted ethanol in the organic layer. An aqueous layer forms and is discarded. 45.3 Laboratory preparation of simple carbon compounds P. 55 / 70 CaCl2(aq) + 4CH3CH2OH(l) → CaCl2․4CH3CH2OH(aq) excess calcium chloride solution filter funnel organic layer aqueous layer separating funnel organic layer beaker (b) (a) Figure 45.13 (a) Adding excess calcium chloride solution removes unreacted ethanol in the organic layer. (b) Discarding the aqueous layer. 45.3 Laboratory preparation of simple carbon compounds P. 56 / 70 Step 5: Removing traces of water from the distillate Add a few lumps of anhydrous calcium chloride to the organic layer. The anhydrous calcium chloride is a drying agent that removes remaining traces of water from the organic layer. Filter the organic layer and obtain the filtrate. 45.3 Laboratory preparation of simple carbon compounds P. 57 / 70 separating funnel anhydrous calcium chloride spatula organic layer conical flask (a) (b) organic layer Figure 45.14 (a) Pouring the organic layer to a conical flask. (b) Adding anhydrous calcium chloride removes traces of water in the organic layer. 45.3 Laboratory preparation of simple carbon compounds P. 58 / 70 glass rod fluted filter paper residue filter funnel pear-shaped flask Figure 45.15 Filtering the organic filtrate layer into a pear-shaped flask to obtain filtrate for further distillation. 45.3 Laboratory preparation of simple carbon compounds P. 59 / 70 Step 6: Re-distillation to obtain a second distillate (pure ethyl ethanoate) The filtrate obtained is then redistilled and the liquid that boils between 74°C and 79°C is collected as distillate. The distillate is ethyl ethanoate. Class practice 45.4 Experiment 45.2 Experiment 45.2 45.3 Laboratory preparation of simple carbon compounds P. 60 / 70 Key terms 1. 2. 3. 4. 5. 6. 7. inter-conversion 互換 intermediate compound 中間化合物 multi-step synthesis 多步驟合成 organic synthesis 有機合成 percentage yield 百分產率 reflux condenser 回流冷凝器 synthetic route 合成路線 P. 61 / 70 Progress check 1. What is the importance of inter-conversions between functional groups in organic compounds? 2. What is a multi-step synthesis? 3. What reagents and conditions are needed for the inter-conversions between alkanes, alkenes, haloalkanes and alcohols? 4. What reagents and conditions are needed for the inter-conversions between alcohols, aldehydes, carboxylic acids, esters and amides? P. 62 / 70 5. What is the role of alcohols for the interconversions between compounds with oxygen and compounds without oxygen? 6. What are the essential features of a good synthetic route? 7. What is the percentage yield of a product in a synthetic process? 8. What are the steps in the laboratory preparation of ethanoic acid? 9. What are the steps in the laboratory preparation of ethyl ethanoate? Progress check P. 63 / 70 Summary 45.1 Inter-conversions between the functional groups 1. 2. 3. Some common reactions that can bring about a change in functional groups are summarized inFigure 45.2 on p.6. Multi-step synthesis is the process of converting a readily available compound into the desired product in more than one step. The inter-conversions between alkanes, alkenes, haloalkanes and alcohols are summarized in Figure 45.3 on p.7. P. 64 / 70 4. 5. The inter-conversions between alcohols, aldehydes, ketones, carboxylic acids, esters and amides in Figure 45.5 on p.11. We can divide carbon compounds into two main groups: one with oxygen and one without. If we want to convert a compound without oxygen to a compound with oxygen, a synthetic pathway that includes an alcohol as one of the intermediates should be taken. Refer to Figure 45.6 on p.13 Summary P. 65 / 70 45.2 Considerations in planning a synthetic route 6. Percentage yield of a product actual mass of the product obtained × 100% = theoretical mass of the product calculated 7. In planning a synthetic route for carbon compounds, the following factors have to be considered: - Availability of starting materials and reagents - Rate of reaction Summary P. 66 / 70 - Percentage yield - Number of steps - By-products formed 45.3 Laboratory preparation of simple carbon compounds 8. In the laboratory, ethanoic acid is usually prepared by heating ethanol under reflux with acidified potassium dichromate solution. Ethanoic acid is collected in the distillate by distillation of the product mixture. It is then purified by redistillation. Summary P. 67 / 70 9. In the laboratory, ethyl ethanoate is prepared by heating a mixture of ethanoic acid and ethanol under reflux in the presence of an acid catalyst. Ethyl ethanoate is collected in the distillate by distillation of the product mixture. Unreacted ethanol, ethanoic acid and water are removed from the distillate. Ethyl ethanoate is then purified by redistillation. Summary P. 68 / 70 Concept map HX or PX3 Dihaloalkanes NaOH(aq) Alkanes H2, Pt X2 (in organic solvent) conc. H2SO4 or Al2O3, Alkenes ∆ Alcohols HX X2, UV light or ∆ HX or PX3 Haloalkanes NaOH(aq) P. 69 / 70 Esters R’OH, H+(aq), ∆ (For 1°) Cr2O72–(aq)/H+(aq), ∆ (1) LiAlH4, dry ether (2) H+(aq) Carboxylic acids (For 1°) Cr2O72–(aq)/H+(aq), ∆ Alcohols H+(aq), ∆ or 1. OH–(aq), ∆ 2. H+(aq) 1. PCl3 2. NH3 H+(aq), ∆ or 1. OH–(aq), ∆ Cr2O72–(aq)/ 2. H+(aq) H+(aq), ∆ Aldehydes (1) LiAlH4, dry ether (2) H+(aq) or NaBH4, H2O (For 2°) Cr2O72–(aq)/H+(aq), ∆ Ketones (1) LiAlH4, dry ether (2) H+(aq) or NaBH4, H2O Concept map P. 70 / 70 Amides