* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Improved production of poly-γ-glutamate by newly Bacillus subtilis

Genetic code wikipedia , lookup

Gene expression programming wikipedia , lookup

Site-specific recombinase technology wikipedia , lookup

Genome (book) wikipedia , lookup

Gene expression profiling wikipedia , lookup

Nucleic acid analogue wikipedia , lookup

No-SCAR (Scarless Cas9 Assisted Recombineering) Genome Editing wikipedia , lookup

History of genetic engineering wikipedia , lookup

Designer baby wikipedia , lookup

Point mutation wikipedia , lookup

Microevolution wikipedia , lookup

Expanded genetic code wikipedia , lookup

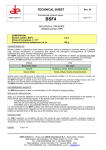

Improved production of poly-γ-glutamate by newly Bacillus subtilis 115 with high genetic competence Fengqing Wang*, Jinzhong Liang,Dawei Fu,Wei Wang Key Laboratory of Food Science and Engineering,College of Food Engineering, Harbin University of Commerce, Harbin city, Heilongjiang 150076, People,s Republic of China. *E-mail address: [email protected]. Abstract:A bacterium with high poly-γ-glutamate (γ-PGA)productivity was isolated from the traditional Japanese natto. This bacterium was classified as a Bacillus subtilis and designated B. Subtilis115. It harbors no plasmid with both naturally high γ-PGA productivity and genetic competence.Glutamate racemase gene(pgsE) was cloned and glutamate racemase activity was confirmed to have the possibility of existence in the cells,suggesting that the enzyme is involved in the D-glutamate supply.L-Glutamate significantly induced γ-PGA production, and highly molecular weight γ-PGA were synthesized. The volumetric yield reached 32.06 g/L in the presence of 7% monosodium glutamate. Molecular sizes of γ-PGA were changed by the salt concentration in the medium; γ-PGA with comparatively low molecular masses were produced in culture media containing high concentrations of NaCl. Culture parameters for highly productivity of γ-PGA were optimized. The yield of γ-PGA and viscosity of broth could reach to 33.8 g/L and 640mpa.s, respectively,with no pH control,3.0 L/min aeration and 150 rpm agitation for 72h.Due to the existence of the degrading enzyme(GGT and PgdS), the fermentation period was strictly controlled on the basis of the residual glucose concentration in the fermentation broth.An amplicon of 2807bp represents the γ-PGA-coding genes(pgsBCA) was obtained and sequenced.pgsB gene was cloned and expressed in Escherichia coli as the key gene of γ-PGA synthesis. Key words:poly(γ-glutamic acid);Bacillus subtilis;Culture condition;pgsBCA genes; 1.Introduction Polyglutamic acid (PGA) is a biodegradable, non-immunogenic and unusual anionic homopolyamide that is made of D- and L-glutamic acid units(Shih, 2001).γ-PGA depending on the attachment of the α-amino and γ-carboxy group. γ-PGA can either be composed of only L-glutamic acid residues (γ-L-PGA), only D-glutamic acid residues (γ-D-PGA) or both L- and D-glutamic acid residues (γ-LD-PGA). The molecular weight of γ-PGA varies from 100kDa to 2000kDa.γ-PGA is different from proteins, because glutamate is polymerized inside the cell via the γ-amide linkages and thus is synthesized in a ribosome-independent manner (Akagi, T.,2007;Bajaj, I. B.,2008). Hence, substances that inhibit translation of proteins, such as chloramphenicol, have no effect on the production of γ-PGA. Due to the γ-linkage of its component glutamate residues, γ-PGA is resistant to proteases, which cleave a-amino linkages(Candela,T.,2006). γ-PGA was first discovered by Ivonovics and Bruckner(Ivanovics, G.,1937ab) when a capsule of Bacillus anthracis was released into the medium upon autoclaving 1 (Shih, 2001).Another naturally occurring source of γ-PGA is the mucilage of natto (fermented soybeans – a traditional food in Japan),which contains a mixture of γ-PGA and fructan produced by Bacillus subtilis Sawamura(Shih, 2001;Candela, T.,2009) . γ-PGA is produced mostly by Grampositive bacteria, which include the genus Bacillus. It has also been reported that at least one Gram-negative bacterium (Fusobacterium nucleatum), some archaea and eukaryotes have the ability to produce γ-PGA(Candela, T.,2009;Weber, J.,1990;Hezayen, F. F.,2001) . γ-PGA has also been found in neurons of mice where it was covalently linked to tubulin(Eddé, B.,1990). Efforts have been made to insert the genes responsible for γ-PGA production into Escherichia coli and plants such as tobacco to gain more knowledge regarding the molecular mechanism of γ-PGA production(Tarui, Y.,2005;Ashiuchi, M.,1999) , and pgsB, pgsC and pgsA genes were identified as essential for its roduction. Recently, Cao et al.(Cao, M.,2013)also cloned and coexpressed the pgsBCA genes and glutamate racemase gene (racE/glr) into E. coli, and reported that the engineered E.coli strains had the ability to synthesize γ-PGA with excellent D-glutamate content due to racE integration. γ-PGA is an extremely important substance that has been exploited for a wide array of useful applications due to its unique properties,such as food, cosmetics, medicine, agriculture,oil recovery,water treatment and so on(Yasuzawa, M.,2011;Osera, C., 2009;Wang, Q.,2008;Kurosaki, T.,2009;Inbaraj, B. S., 2011;Ben-Zur, N.,2007;Inbaraj, B. S.,2012;Bhat, A. R., 2013;Lim, S., 2012;Tsao, C. T., 2011;Shyu, Y., 2010).The number of potential application for γ-PGA is still increasing. In this paper, the aims of this research were to isolate and identify new microbial sources of γ-PGA, characterize them, and optimize culture conditions for highly productivity of γ-PGA. The genes encoding γ-PGA was amplified,sequenced and cloned in Escherichia coli with the objectives of overproducing the polymer to suit commercial applications. 2 Materials and methods 2.1 Preparation of corn saccharification liquid The saccharification of corn starch was catalyzed by the double enzymes method. Corn powder,mixed with water in the tank by 1:3,were liquefied at 85℃ for 30min at pH 6.7-7.0 using the commercial thermostable α-amylase with an enzyme activity of 20KU/g.The temperature was rapidly decreased to about 60℃ ,and then the pH of corn saccharification liquid was adjusted to 4.5 with hydrochloric acid. Monosaccharide was formed using the commercial glucoamylase with an enzyme activity of 50KU/g for 4h. The reducing sugars, cellulose, and protein (weight ratio about 70:11:4) are the main components in the corn hydrolysate. The glucose monomer fraction after pre-saccharification was close to 25%. The level of release of glucose and nutrients (including protein) depended on saccharification time. Complete starch hydrolysis required more than 7 h of pre-saccharification time. 2.2 Isolation and screening of γ-PGA-producing strains The bacterial in the soil, Chinese traditional fermented soybean, fermented bean curd, Japanese natto and other fermented bean products were enriched cultivated in 2 medium MS,which was composed of 1.5% yeast extract,2.8% beef extract,6.5% glucose,3% soy peptone,0.3% KH2PO4,0.3% anhydrous sodium acetate,0.2% ammonium citrate,0.15%(v/v) Tween80,1% MgSO4•7H2O,0.5g/L MnSO4•4H2O,1.92% whey powder,0.95% casein hydrolyzate, 1.91% polyfructose.The culture solution were streaked onto Luria-Bertani (LB) agar plates containing 2% L-glutamic acid ,1.5% (w/v) agar and cultured at 37°C for 72 h.The bacterium was isolated from a highly mucous colony. Those bacterium were inoculated into 5 ml of LB medium and cultivated at 37°C for 20 h in a rotatory shaker at 150 rpm.In order to obtain a strain which could used corn saccharification liquid as the carbon source instead of glucose,the seed liquid was transferred to 250 mL Erlenmeyer flasks with 25mL fermentation medium composed of 5% L-glutamic acid,25mL(v/v)corn saccharification liquid (sugar degree 200.00g/L),0.4% peptone,1%NaCl.After culturing in a rotary shaker at 150 rpm and 37℃ for 48h,the concentration of γ-PGA in fermentation broth was measured and the bacterium with high yield was chosen for γ-PGA production.All shake experiments were run in triplicates. The strain was kept as lyophilized reference stocks in the China General Microbiological Culture Collection Center(CGMCC2283).For working purposes, bacterial were kept in 20% glycerol at -20°C. The strain was reactivated twice in LB broth, streaked onto LB agar plates and subcultured onto LB slants. Strain slants were kept under refrigeration until usage. 2.3 Identification and characterization of γ-PGA producer strain The best producer of γ-PGA was characterized and identified by 16S rDNA analysis and by morphological and physiological characteristics. DNA from a bacterial was extracted using the TIANamp Bacteria DNA Kit(TIANGEN) following the manufacturer instructions. PCR reaction was performed using the primers(10 μmol/L) 1 μL,10×PCR Buffer 5 μL,dNTP mixture 3 μL,Taq@ HiFi DNA polymerase(5 U/μL)1 μL and added ddH2O to 50 μL. The 16S rDNA was amplified using primers(27Fp6:AGAGTTTGATCCTGGCTCAG;1492R:GGYTACCTTGTTACGAC TT),PCR products were separated by agarose gel electrophoresis and the ethidium bromide-stained bands were visualized under UV light and taken pictures with gel imaging system(SIM International Group Co., Ltd). After confirmation, the remaining PCR mix was purified using TIANgel Midi Purification Kit (TIANGEN) and submitted to Sangon Biotech(Shanghai)Co.,Ltd for sequenced. Following sequence, the nucleotide sequence was subjected to BLAST sequence analysis using the NCBI (National Center for Biotechnology Information) website, and the nucleotide sequence was deposited in GenBank database.Morphological and biochemical characterization was performed according to the Manual of Bergey (Sneath PHA,1986) , and also included additional references. 2.4 Analytical procedures The concentration of extracellular γ-PGA was determined by alcohol precipitation(LIANG Jin-zhong,2013).The concentration of L-glutamic acid and glucose was measured by SBA-40D Bio-sensor with glucose oxidase electrode and L-glutamic acid oxidase(Shandong Science Academic Biological Institute, PR 3 China).The value of pH was read from the monitor of fermentor.The viscosity of the culture broth was measured by Digital Viscometer with a spindle SP-2 at 25℃(DNJ-5S,China). 2.5 The genes cloning and expression B. Subtilis115 and Escherichia coli were cultured at 37℃ in LB medium,which containing 0.5% (w/v) yeast power,1.0% (w/v) peptone,1.0% (w/v) sodium chloride. Ampicillin (100 mg/mL) was added to the medium when required. Escherichia coli trans1 was used for plasmid construction and Escherichia coli BL21(DE3) was transformed for pgsB expression.The plasmid of pET22b(+) is the shuttle vector,containing ampicillin resistance gene.The primers as follows: pgsBCA-F:CGGGATCCATGTGGTTACTCATTATAGCC;pgsBCA-R:CCCAAGC TTTTATTTAGATTTTAGTTTGTCAC;pgsB-F:CGGGATCCTGTGGTTACTCATTA TAGCCTGTGCTG;pgsB-R:CCCAAGCTTGCTTACGAGCTGCTTAACCTTG;pgsEF:CGGGATCCATGAAATTTGTCAAAGCTATCTGGC;pgsE-R:CCCAAGCTTTTTAT TGGCATTTACCGGTTC;ggt-F:CGGAATTCATGAAAAGAACGTGGAACGTCTG;ggtR:CGGCGGCCGCTTTACGTTTTAAATTAATGCCGATC;pgdS-F:CGGAATTCGTGAA CACACTGGCAAACTG;pgdS-R:CGGCGGCCGCTTGCACCCGTATACTTCCTGC; 3 Results and discussion 3.1 Screening and identification of γ-PGA-producing strains Of γ-PGA producer selected isolates, the number 115 strain which showed the highly mucous colony on isolation medium and produced high quantity of γ-PGA polymer in liquid medium (data not shown)was selected and intensely studied.The nucleotide sequence of 16S rDNA was compared to available sequences at NCBI GenBank database, and revealed 99% of similarity with several B.subtilis and Bacterium, and also to some Bacillus tequilensis and Bacillus amyloliquefaciens. Taxonomic studies have indicated that Bacillus species are very similar to each other with respect to 16S rDNA, and B. amyloliquefaciens is indeed closely related to B.subtilis on the basis of 16S-23S ITS nucleotide sequences(Porwal S,2009;Xu D,2003;Sumpavapol P,2010).Nevertheless,some physiological characteristics allowed distinguishing among these species(Sneath PHA,1986;Sumpavapol P,2010;Priest FG,1988; Reva ON,2001;Welker NE,1967;Kim KM,2009). The morphological and physiological characterization of 115 strain showed that it is aerobic, rod-shaped, spore-forming, catalase-positive, Gram(+) bacterium, capable of producing acid from glucose, as a typical Bacillus sp.(Sneath PHA,1986). The positive citrate reaction and oxidase test, growth at 50°C, no acid formation from lactose and sorbitol, and growth in NaCl 7% but not in NaCl 10 % allowed for different from other Bacillus species and for the identification of 115 as B. subtilis. All morphological and physiological characteristics for B. subtilis115 strain are shown in Table 1. Table 1 Physiological and morphological characterization of Bacillus subtilis 115 Characteristics Results Characteristics Shape Rod Acid from Gram stain + Glucose + Sporulation + L- arabinose + Nitrate reduction + Lactose - 4 Results Hydrolysis of Raffinose - Starch + Mannitol + Casein + Sorbitol - Gelatin + Growth at pH5.7 + Indole formation -b Growth at 50 °C + Voges-Proskauer test - Growth in 7 % NaCl + Citrate utilization + Growth in10 % NaCl - Catalase test + Oxidase test + Phenylalanine desaminase - +:Positive ;- Negative 3.2 Natural genetic competence of B. subtilis 115 Most B.subtilis (natto) harbor plasmid(s)(Meijer et al.1998) and are particularly unsuitable strains for genetic manipulation because of their lack of, or only slight,competence(Ashikaga et al. 2000). Thus, we examined whether B.subtilis115 harbors plasmids.DNA of B.subtilis115 was extracted by the method for plasmid preparation (Ashiuchi et al.1999);agarose gel electrophoresis revealed no band corresponding to a plasmid.PCR amplification of the rep gene, which is highly conserved in the B.subtilis (natto)plasmids(Meijer et al. 1998), was also negative. We thus judged B. subtilis 115 to be a plasmid-free γ-PGA producer. Thus,as long as we searched for a useful genetic marker,it is possible to constructed a transformable B.subtilis (natto) strain by genetic modification. 3.3 Glutamate-inducible γ-PGA production by B. Subtilis115 γ-PGA-producing bacteria are divided into two groups:glutamate-dependent and glutamate-independent producers(Kunioka 1994; Ito et al. 1996). In the former, the γ-PGA yield indeed increases upon addition of glutamate to the medium, but the bacteria can produce considerable γ-PGA even in the absence of glutamate because of the operation of the de novo pathway of L-glutamate synthesis (Kunioka 1994). We examined the effect of glutamate on γ-PGA production by B. subtilis 115. As shown in Table 2,Bacillus subtilis 115 depended on extracellular glutamate,it would not produce γ-PGA without glutamate in medium.The amount of γ-PGA increased with increasing glutamic acid addition to the medium,while the cell growth and cultrue broth viscosity decreased.It was a linear relationship between the molecular weight of γ-PGA and viscosity of the fermentation broth(data was not shown).In order to achieve high molecular weight γ-PGA,the concentration of sodium glutamate was chosen to add 7% in the production process.After a 48h incubation in the presence of 7% sodium glutamate, the γ-PGA yield reached 32.06 g/L. Table 2 Effect of monosodium glutamate concentration on γ-PGA formation in Erlenmeyer flasks. CDW γ-PGA Residual glucose Residual glutamate Cultrue broth viscosity (g/L) (g/L) (g/L) (g/L) (mPa·s) 0 1.99 0 48 0 0 10 3.12 8.63 0 3 135 20 3.26 11.74 0 11 210 monosodium glutamate (g/L) 5 30 3.18 14.52 0 20 360 40 3.64 16.77 0 30 510 50 3.90 22.46 1 37 600 60 4.01 24.77 2 45 861 70 4.17 32.06 6 54 870 80 3.50 31.18 11 64 660 90 3.22 30.11 15 71 525 100 3.92 29.82 15 78 240 The D-glutamate content was over 50% in every γ-PGA produced under the conditions used, suggesting that the bacterium possesses a synthetic pathway to produce D-glutamate, the main precursor of γ-PGA, from L-glutamate.To obtain a clue as to the nature of the D-glutamate synthetic pathway in B. subtilis 115, we attempted to clone the gene of glutamate racemase(pgsE) from the cells.As a result, the pgsE was successfully cloned(Fig.2). 3.4 Effects of salt on γ-PGA production We investigated the effects of salt on γ-PGA productivity of B.subtilis115 using a medium containing 7% monosodium glutamate and various concentrations of NaCl and found that the apparent viscosity of the culture medium increased and then decreased with increasing in salt concentration as showed in Fig.3. We also found the molecular weight of γ-PGA was positively correlated with the viscosity of fermentation broth(data not shown).The γ-PGA yields under the conditions tested: 30.4, 26.6, 32, 32.8 and 33.6g of γ-PGA were obtained per 1L of culture media containing 0.05, 0.5, 1, 1.5 and 2% NaCl, respectively.γ-PGAs with quite high viscosity(high molecular sizes)were synthesized in media containing concentrations of NaCl (1.5%).In contrast, under high saline conditions (2%),γ-PGA of comparatively low viscosity(low molecular sizes)were preferentially produced. 3.6 Effects of culture condition on γ-PGA production The importance of initial pH control to achieve efficient conversions of carbon sources to polymer products has been well documented for another microbial fermentation process(Moraine RA,1971).In order to evaluate the effect of initial pH and the necessity of pH control in the fermentation process on the γ-PGA production, fermentations were carried out under different initial pH and no pH control at 37°C for 48h.The pH of the culture medium was adjusted to 4.0-7.5 using 6 mol/L HCI and 10 mol/L NaOH. As shown in Fig.4, the yield of γ-PGA synthesis were observed at initial pH 4.0, 4.5, 5.0, 5.5, 6.0,6.5,7.0. The pH of the broth under no pH control was gradually decreased from 5.91 to 5.5 before 24 h and then gradually increased to 5.9 till the end of fermentation. Cromwick and co-workers(Cromwick AM,1996) reported that in the cultivation of B. licheniformis ATCC 9945,the pH was acidified from 7.4 to 5.6 between 48 and 96 h,at 37 °C,but B. subtilis 115 produced the highest concentration of γ-PGA under no pH control fermentation. As reported for B. licheniformis CCRC 12826(Shih IL,2001), where the initial pH of 6.5 dropped to 5.6 after 36 h of cultivation at 37 °C. Although pH played an important role in the γ-PGA production by other Bacillus strains, the experiments in this study indicated that strict 6 control of pH was not necessary.On the contrary, the rule of pH changing could be used to determine the fermentation was normal or not.In addition, the highest viscosity of the culture broth was also observed at no pH control fermentation. Therefore,further experiments were carried out without pH control during fermentation. The dissolved oxygen has been recognized as an important factor in aerobic fermentation affecting the nature and/or rate of metabolic product formation. Dissolved oxygen is often controlled by ventilation, stirring speed and tank pressure and fermented liquid properties of many factors in the fermentation process. Since γ-PGA is an extracellular polymer, the culture broth becomes highly viscous with γ-PGA production. The increased viscosity usually inhibits volumetric oxygen mass transfer, which leads to oxygen limitation. A similar phenomenon has been reported for xanthan, where it was shown that its volumetric yield could be improved by increasing the available oxygen through increased agitation rate and oxygen partial pressure in the air pumped through the fermentation vessel[43]. The fermentations were carried out at several aeration rates (0-3.0 L/min) and different agitation to evaluate the effect of oxygen on the γ-PGA production. As shown in Fig.5(AB), enhanced the rate of glucose consumption and γ-PGA synthesise were observed when aeration rates increased.The cell growth rate was fast, and the fermentation period was shortened.As shown in Fig.6, although the maximum rate of glucose consumption was observed at 300 rpm, γ-PGA concentration and viscosity were low at this agitation speed. This result might be due to high shear stress from the relatively rapid agitation rate. Further experiments were carried out at aeration rate of 3.0L/min and agitation speed of 150 rpm. As shown in Fig.7, the viscosity of fermentation broth was gradually increased until the glucose was completely consumption,and then decreased with the extension of fermentation time.Jeong JH reported(Jeong JH,2010)the molecular weight of the γ-PGA produced was decreased at the end of fermentation.The reduction of γ-PGA molecular weight at the end of fermentation might be due to γ-PGA depolymerase activity, which was verified by cloned the γ-PGA degrading enzymes gene(pgdS and ggt) in this study.The degradation of γ-PGA is considered to be the result of the synergistic action of PgdS and GGT enzyme(Kimura and Fujimoto, 2010; Kimura et al., 2004; Yao et al.,2009).The physical and chemical properties of PgdS and GGT were predicted online based on its amino acid sequence,as shown in Table 3,respectively.Ashiuchi M(Ashiuchi M,2003)and Suzuki andTahara(Suzuki T,2003)previously reported that the molecular weight of γ-PGA depolymerase from B. subtilis was 42 kDa and 44 kDa, respectively. γ-PGA depolymerase from B. subtilis RKY3 was relatively more expressed at the end of fermentation than the beginning of fermentation(Gwi-Taek Jeong,2014).Troy(Troy FA,1973)found B. licheniformis expressed γ-PGA depolymerase at the late stationary phase. Kunioka and Goto(Kunioka M,1994) also reported that B. subtilis IFO 3335 expressed γ-PGA depolymerase when cultivated in a medium containing only γ-PGA as the substrate.The concentration of glucose which is necessary for microbial growth energy and carbon sources,close to zero at the late of fermentation. γ-PGA as the only 7 substrate,the promoter of γ-PGA depolymerase gene was activated and induced expression at this time. Table 3 Analysis of physicochemical properties on γ-PGA degrading enzymes proteins Physicochemical properties PgdS GGT Formula C2056H3172N526O611S6 C2869H4520N752O881S17 Molecular weight 45227.3 64188.9 Number of amino acids 413 587 Theoretical pI 8.78 5.57 Total number of negatively charged 36 75 41 65 23.00 33.19 -0.215 -0.348 residues (Asp + Glu) Total number of positively charged residues (Arg + Lys) Instability index Grand average of hydropathicity (GRAVY) 3.5 Amplification of B. subtilis 115 specific γ-PGA biosynthesis genes (pgsBCA) using specific primer PCR The pgsBCA gene was amplified by PCR from B. subtilis115 as templet.As shown in Fig.9B,an amplicon of 2807bp was obtained.PCR fragment was purified and ligated in cloning vector pET22b(+).The sequence of pgsBCA genes was determined and shown in Fig.9A,the DNA sequence comprises three open reading frames (ORF), pgsB 1182 bp, pgsC 450 bp and pgsA 1143 bp(Fig.9). Current research supports the idea that γ-PGA synthetase is a membrane-associated modular protein complex (viz., PgsBCAE) with a Rossmann-type amide ligase-like PgsB component (Ashiuchi, M.,1999;Ashiuchi et al.,1999; 2001b; Urushibata et al., 2002). γ-PGA was synthesized at the active site of the synthase complex (PgsBCA). PgsB and PgsC together form most parts of the complex’s catalytic site, whereas PgsA seems to remove the elongated chain from the active site so that the next monomer can be added and may also be involved in transporting γ-PGA (Ashiuchi et al., 2001;Urushibata et al., 2002).Therefore, the expression of pgsB in E. coli was research as the key gene of γ-PGA synthesis.The pgsB gene was cloned on expression vector pET22b(+) and then expressed in E.coli BL21(DE3). Ampicillin was used to induce expression for 4h and the cell was collected by centrifugation.The degree of pgsB gene expression was investigated by polyacrylamide gel electrophoresis(Fig.10). 4. References Akagi, T., Baba, M. & Akashi, M.. Preparation of nanoparticles by the self-organization of polymers consisting of hydrophobic and hydrophilic segments: potential applications. Polymer (Guildf). 2007,48,6729-6747. Ashiuchi, M., Soda, K. & Misono, H.. A poly-γ-glutamate synthetic system of Bacillus subtilis IFO 3336: gene cloning and biochemical analysis of poly-γ-glutamate produced by Escherichia coli clone cells. Biochem Biophys Res Commun.1999,263, 6-12. 8 Ashikaga S, Nanamiya H, Ohashi Y, Kawamura F.Natural genetic competence in Bacillus subtilis OK2. J Bacteriol.2000,182:2411-2415. Ashiuchi M, Zakaria MM, Sakaguchi Y, Yagi T.Sequence analysis of a cryptic plasmid from Flavobacterium sp. KP1, a psychrophilic bacterium. FEMS Microbiol Lett.1999,170:243-249. Ashiuchi, M., Nawa, C., Kamei, T., Song, J.J., Hong, S.P.,Sung, M.H., et al. Physiological and biochemical characteristics of poly γ-glutamate synthetase complex of Bacillus subtilis. Eur J Biochem.2001,268:5321-5328. Ashiuchi M, Nakamura H, Yamamoto T, Kamei T, Soda K, Park C Sung MH, Yagi T and Misono H, Poly-γ-glutamate depolymerase of Bacillus subtilis: production, simple purification and substrate selectivity. 7 Mo/ Catai B: Enzyme.2003,23:249-255. Bajaj, I. B., Lele, S. S. & Singhal, R. S.. Enhanced production of poly (γ-glutamic acid) from Bacillus licheniformis NCIM 2324 in solid state fermentation. J Ind Microbiol Biotechnol.2008,35, 1581-1586. Ben-Zur, N. & Goldman, D. M.. γ-Poly glutamic acid: a novel peptide for skin care. Cosmetics Toiletries.2007,122, 65-74. Bhat, A. R., Irorere, V. U., Bartlett, T., Hill, D., Kedia, G., Morris, M. R.,Charalampopoulos, D. & Radecka, I.. Bacillus subtilis natto: a non-toxic source of poly-γ-glutamic acid that could be used as a cryoprotectant for probiotic bacteria. AMB Express.2013,3, 36. Cromwick AM, Birrer G and Gross RA, Effect of pH and aeration on γ-poly(glutamic acid) formation by Bacillus licheniformis in controlled batch fermentor cultures.Biotechnol Bioeng .1996,50:222-227. Candela, T. & Fouet, A.. Poly-gamma-glutamate in bacteria.Mol Microbiol.2006,60, 1091-1098. Candela, T., Moya, M., Haustant, M. & Fouet, A..Fusobacterium nucleatum, the first Gram-negative bacterium demonstrated to produce polyglutamate. Can J Microbiol.2009,55, 627-632. Cao, M., Geng, W., Zhang, W., Sun, J., Wang, S., Feng, J., Zheng, P.,Jiang, A. & Song, C.. Engineering of recombinant Escherichia coli cells co-expressing poly-γ-glutamic acid (γ-PGA) synthetase and glutamate racemase for differential yielding of γ-PGA. Microb Biotechnol.2013,6, 675-684. Eddé, B., Rossier, J., Le Caer, J. P., Desbruyères, E., Gros, F. &Denoulet, P.. Posttranslational glutamylation of alpha-tubulin.Science.1990,247, 83-85. Gwi-Taek Jeong,Jin-Nam Kim,Hwa-Won Ryu,Young-Jung Wee.Improved production of poly(γ-glutamic acid) by Bacillus subtilis RKY3 and its recovery from viscous fermentation broth as a biodegradable polymer.J Chem Technol Biotechnol.2014,89:728-734. Hezayen, F. F., Rehm, B. H., Tindall, B. J. & Steinbüchel, A..Transfer of Natrialba asiatica B1T to Natrialba taiwanensis sp. Nov. and description of Natrialba aegyptiaca sp. nov., a novel extremely halophilic, aerobic, non-pigmented member of the Archaea from Egypt that produces extracellular poly(glutamic acid). Int J Syst Evol Microbiol.2001,51, 1133-1142. 9 Ivanovics, G. & Bruckner, V. . Chemical and immunologic studies on the mechanism of anthrax infection and immunity. The chemical structure of capsule substance of anthrax bacilli and its identity with that of the B. mesentericus. Z. Immunitaetsforsc.1937a,90, 304-318. Ivanovics, G. & Bruckner, V.. The chemical nature of the immuno-specific capsule substance of anthrax bacillus.Naturwissenschaften .1937b,25, 250. Ito Y, Tanaka T, Ohmachi T, Asada Y.Glutamic acid independent production of poly(γ-glutamic acid) by Bacillus subtilis TAM-4. Biosci Biotechnol Biochem.1996,60:1239-1242. Inbaraj, B. S., Kao, T. H., Tsai, T. Y., Chiu, C. P., Kumar, R. & Chen,B. H.. The synthesis and characterization of poly(γ-glutamic acid)-coated magnetite nanoparticles and their effects on antibacterial activity and cytotoxicity. Nanotechnology.2011,22, 075101. Inbaraj, B. S. & Chen, B. H.. In vitro removal of toxic heavy metals by poly(γ-glutamic acid)-coated superparamagnetic nanoparticles. Int J Nanomedicine.2012,7, 4419-4432. Jeong JH, Kim JN, Wee YJ and Ryu HW, The statistically optimized production of poly(γ-giutamic acid) by batch fermentation of a newly isolated Bacillus subtilis RKY3. Bioresource Technol.2010, 101:4533- 4539. Kunioka M.Biosynthesis of poly(γ-glutamic acid) from L-glutamic acid, citric acid and ammonium sulfate in Bacillus subtilis IFO3335. Appl Microbiol Biotechnol.1994,40:867-872. Kimura K, Tran LS, Uchida I, Itoh Y.. Characterization of Bacillus subtilis γ-glutamyltransferase and its involvement in the degradation of capsule poly-γ-glutamate. Microbiology.2004,150:4115-4123. Kurosaki, T., Kitahara, T., Fumoto, S., Nishida, K., Nakamura, J.,Niidome, T., Kodama, Y., Nakagawa, H., To, H. & Sasaki, H..Ternary complexes of pDNA, polyethylenimine, and γ-polyglutamic acid for gene delivery systems. Biomaterials .2009, 30, 2846-2853. Kim KM, Kim MJ, Kim DH, Park YS, Kang JS.Characterization of Bacillus polyfermenticus KJS-2 as a Probiotic. J Microbiol Biotechnol.2009,19:1013-1018. Kimura K, Fujimoto Z. . Enzymatic degradation of poly-γ-glutamic acid. In: Hamano Y, editor. Amino-acid homopolymers occurring in nature. Berlin/Heidelberg: Springer. 2010,p 95-117. Lim, S., Kim, J., Shim, J., Imm, B., Sung, M. & Imm, J. . Effect of poly-γ-glutamic acids (PGA) on oil uptake and sensory quality in doughnuts. Food Sci Biotechnol.2012, 21, 247-252. LIANG Jin-zhong,WANG Feng-qing,ZHANG Lu-lu.Establishment of a kinetic model for γ-poly glutamic acid with batch fermentation. Science and Technology of Food Industry,2013,16:174-177. Moraine RA and Rogovin P, Xanthan biopolymer production at increased concentration by pH control. Biotechnol Bioeng.1971,13:381-391. Meijer WJJ, Wisman GBA, Terpstra P, Thorsted PB, Thomas CM,Holsappel S, Venema G, Bron S . Rolling-circle plasmids from Bacillus subtilis: complete 10 nucleotide sequences and analyses of genes of pTA1015, pTA1040, pTA1050 and pTA1060,and comparisons with related plasmids from Gram-positive bacteria. FEMS Microbiol Rev.1998, 21:337-368. Osera, C., Amati, G., Calvio, C. & Galizzi, A.. SwrAA activates poly-γ-glutamate synthesis in addition to swarming in Bacillus subtilis. Microbiology.2009,155, 2282-2287. Priest FG, Goodfellow M, Todd C.A Numerical Classi-fication of the Genus Bacillus. J Gen Microbiol.1988,134; 1847-1882. Peters HU, Herbst H, Hesselink PGM, Lunsdorf H, Schumpe A and Deckwer WD, The influence of agitation rate on xahthan production by Xanthomonas campestris.Biotechnol Bioeng .1989,34:1393-1397. Porwal S,Lai S, Cheema S, Kalia VC. Phylogeny in aid of the present and novel microbial lineages: diversity in Bacillus. PLoS One.2009,4:e4438. Troy FA, Chemistry and biosynthesis of poly(γ-glutamic) capsule in Bacillus licheniformis. J Biol Chem.1973,248:305-315. Sneath PHA. (1986) Endospore-forming gram-positive rods and cocci. In: Sneath PHA, Mair NS, Sharpe ME, Holt JG (eds) Bergey’s Manual of Systematic Bacteriology. Williams & Wil-kins, Baltimore . Shih, I. L., Van, Y. T., Yeh, L. C., Lin, H. G. & Chang, Y. N..Production of a biopolymer flocculant from Bacillus licheniformis and its flocculation properties. Bioresour Technol. 2001,78, 267-272. Suzuki T and Tahara Y, Characterization of the Bacillus subtilis ywtD gene, whose product is involved in γ-polyglutamic acid degradation. J Bacteriol.2003,185:2379-2382. Shyu, Y. & Sung, W.. Improving the emulsion stability of sponge cake by the addition of γ-polyglutamic acid. J Mar Sci Technol.2010,18, 895-900. Sumpavapol P, Tongyonk L, Tanasupawat S, Chokesajjawatee N, Luxanani P, Visessanguan W . Bacillus siamensis sp. Nov., isolated from salted crab (poo-khem) in Thailand. Int J Syst Evol Microbiol.2010,60:2364-2370. Tarui, Y., Iida, H., Ono, E., Miki, W., Hirasawa, E., Fujita, K., Tanaka, T.& Taniguchi, M.. Biosynthesis of poly-c-glutamic acid in plants: transient expression of poly-γ-glutamate synthetase complex in tobacco leaves. J Biosci Bioeng.2005,100, 443-448. Tsao, C. T., Chang, C. H., Lin, Y. Y., Wu, M. F., Wang, J. L., Young, T. H.,Han, J. L. & Hsieh, K. H. . Evaluation of chitosan/γpoly(glutamic acid) polyelectrolyte complex for wound dressing materials. Carbohydr Polym.2011,84, 812-819. Reva ON,Sorokulova IB, Smirnov VV.Simplified technique for identification of the aerobic spore-forming bacteria by phenotype. Int J Syst Evol Microbiol.2001,51:1361-1371. Urushibata, Y., Tokuyama, S., and Tahara, Y. Characterization of the Bacillus subtilis ywsC gene, involved in γ-polyglutamic acid production. J Bacteriol.2002,184:337-343. Welker NE, Campbell LL.Unrelatedness of Bacillus amyloliquefaciens and Bacillus subtilis. J Bacteriol.1967,94:1124-1130. 11 Weber, J.. Poly(gamma-glutamic acid)s are the major constituents of nematocysts in Hydra (Hydrozoa, Cnidaria). J Biol Chem .1990,265, 9664-9669. Wang, Q., Chen, S., Zhang, J., Sun, M., Liu, Z. & Yu, Z.. Coproducing lipopeptides and poly-γ-glutamic acid by solid-state fermentation of Bacillus subtilis using soybean and sweet potato residues and its biocontrol and fertilizer synergistic effects. Bioresour Technol.2008,99, 3318-3323. Xu D, Cote JC.Phylogenetic relationships between Bacillus species and related genera inferred from comparison of 3’ and 16S rDNA and 5’ and 16S-23S ITS nucleotide sequences. Int J Syst Evol Microbiol.2003, 53:695-704. Yao J, Jing J, Xu H, Liang J, Wu Q, Feng X, Ouyang P.. Investigation on enzymatic degradation of γ-polyglutamic acid from Bacillus subtilis NX-2. J Mol Catal B Enzym.2009,56:158-164. Yasuzawa, M., Edagawa, K., Matsunaga, T., Takaoka, H. & Yabutani,T.. Highly selective needle-type glucose sensors prepared by the immobilization of glucose oxidase on gamma-polyglutamic acid film.Anal Sci.2011,27, 337-340. 12