* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download New Developments in Transmission Electron Microscopy for

Metallic bonding wikipedia , lookup

X-ray fluorescence wikipedia , lookup

Electron mobility wikipedia , lookup

History of molecular theory wikipedia , lookup

Marcus theory wikipedia , lookup

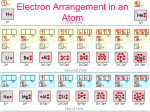

Atomic orbital wikipedia , lookup

X-ray photoelectron spectroscopy wikipedia , lookup

Synthesis of carbon nanotubes wikipedia , lookup

Rutherford backscattering spectrometry wikipedia , lookup

Photoredox catalysis wikipedia , lookup

Condensed matter physics wikipedia , lookup

Chemical imaging wikipedia , lookup

Oxidative phosphorylation wikipedia , lookup

Scanning electrochemical microscopy wikipedia , lookup

Microbial metabolism wikipedia , lookup

Super-resolution microscopy wikipedia , lookup

Nanochemistry wikipedia , lookup

Electron transport chain wikipedia , lookup

Photosynthetic reaction centre wikipedia , lookup

Light-dependent reactions wikipedia , lookup

Atomic theory wikipedia , lookup

Electron configuration wikipedia , lookup

Electron-beam lithography wikipedia , lookup