* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

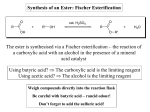

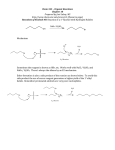

Download Development of Catalytic Ester Condensations and Hydrolysis of

Discodermolide wikipedia , lookup

Kinetic resolution wikipedia , lookup

Hofmann–Löffler reaction wikipedia , lookup

Baylis–Hillman reaction wikipedia , lookup

Bottromycin wikipedia , lookup

Wolff–Kishner reduction wikipedia , lookup

Ring-closing metathesis wikipedia , lookup

Physical organic chemistry wikipedia , lookup

Ene reaction wikipedia , lookup

Hydroformylation wikipedia , lookup

Petasis reaction wikipedia , lookup