* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Bleaching Chemiclas for the Kraft Pulping Industry

Survey

Document related concepts

Transcript

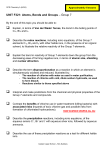

BLEACHING CHEMICALS FOR THE KRAFT PULPING INDUSTRY The pulp used to make paper is brown when first produced. For most applications this is unacceptable, so it is bleached to make it white. The chemicals used to do this are chlorine (Cl2), caustic soda (NaOH) and chlorine dioxide (ClO2). Chlorine and caustic soda are produced by electrolysis of solutions of NaCl. In this solution it is the water, not the Na+ion, that is reduced. The two solutions are separated by a membrane that allows Na+ ions but not OH- ions to pass through, so that the chlorine and caustic soda do not mix. The reactions occurring are: At the anode: 2Cl- (aq) At the cathode: 2Na+ + 2H2O + 2eOverall: → → 2NaCl + 2H2O + electrical energy → Cl2(g) + 2e2NaOH + H2(g) 2NaOH + Cl2(g) + H2(g) The chlorine dioxide is produced in a three step process using the reactions given below. Step 1 Step 2 Step 3 NaCl + 3H2O + electrical energy → NaClO3 + 3H2 H2 + Cl2 → 2HCl NaClO3 + 2HCl → ClO2 + ½Cl2 + NaCl + H2O Overall ½Cl2 + 2H2O → ClO2 + 2H2 In addition to producing aqueous Cl2, NaOH and ClO2, the plant produces excess NaClO3 and HCl, and produces NaOCl and liquid Cl2 as byproducts. These are sold for making commercial bleaches and for water treatment. INTRODUCTION While unbleached kraft pulps are strong, their brown colour limits their use to grades which do not require a white fibre. Kraft pulps can be bleached to produce a white fibre. Bleaching kraft pulps can be done in a number of ways, in New Zealand bleaching is done using a combination of chlorine dioxide (ClO2), oxygen (O2) and caustic soda (NaOH, also known as sodium hydroxide). Caustic soda is produced by electrolysis of brine (aqueous sodium chlroide), and the coproduced chlorine can be used to manufacture the chlorine dioxide required by the bleaching plant. Oxygen can be produced either cryogenically (cooling air until it liquifies and using the boiling point difference to separate O2 from N2) or using the PSA process (see article). The processes involved in making Cl2, NaOH and ClO2 also lead to the production of HCl, NaOCl and NaClO3 as well. Some of these are used on site, and some are sold. IV-Forestry-D-Chemical Bleaching-1 Uses of products and byproducts Chlorine, Cl2 Chlorine is used in liquid form for pulp bleaching. It is also a starting material for HCl and NaOCl production. Liquid chlorine is sold for uses such as water treatment. Sodium hydroxide, NaOH All the caustic soda produced is used for pulp bleaching. Chlorine dioxide, ClO2 All the chlorine dioxide produced is used for pulp bleaching. Hydrochloric acid, HCl Internally, hydrochloric acid is used in ClO2 manufacture, pH control and the regeneration of ion exchange resins (see article). It is also sold to the metals industry (for metal cleaning and pickling) and the chemical cleaning industry. Sodium hypochlorite, NaOCl This is one of the active ingredients of commercial bleaches such as "Janola". Excess chlorine is used to make NaOCl for sale to bleach manufacturers. Sodium chlorate, NaClO3 This is a starting material for ClO2 manufacture. Any excess is sold to other manufacturers for a variety of uses including the production of weed killer, matches and fireworks and the refining of uranium ore. THE CHLORINE/CAUSTIC SODA MANUFACTURING PROCESS These two chemicals are produced concurrently. The three processes outlined below have all been used to produce them commercially, although only the latter process is still in use in New Zealand. The mercury cell process This is the oldest process. In this process the electrolyser cell consists of an anode (made of graphite or titanium) and a cathode formed by mercury. Brine is introduced into the cell. Cl2 gas forms at the anode and bubbles out of solution. At the cathode, sodium (Na) forms an amalgam with the mercury cathode. The sodium/mercury amalgam is removed from the cell and is reacted with water to form caustic soda (NaOH) and hydrogen gas (H2). The main disadvantage of this process is that the products and plant effluent are contaminated with mercury, and for this reason all mercury cell electrolysers were decommissioned many years ago. The diaphragm process A brine solution is pumped into the cell where the anode and cathode are separated by an asbestos diaphragm. Cl2 gas is formed at the anode, and the NaOH is recovered from the solution leaving the cell (a mixture of depleted brine and NaOH). The main disadvantage of this process is that the NaOH has to be recovered by evaporation which requires a further large energy input. IV-Forestry-D-Chemical Bleaching-2 The membrane cell process This process was developed to eliminate the use of mercury and to reduce the energy required to produce the NaOH solution. It was developed by Asahi Chemical Industry Co Limited of Japan. Here a titanium anode and a steel cathode are used, separated by a cation exchange membrane which allows Na+ ions to migrate to the cathode, but prevents OH- ions from going the other way. This results in the formation of Cl2 at the anode, and NaOH on the cathode side. Step 1 - Anolyte preparation The solution that enters the electrolysis cell on the anode side is called the "anolyte". It is essentially a very pure solution of brine (water saturated with NaCl). Anolyte is prepared as follows. Depleted brine from the electrolysis cells is kept in a storage tank. This is a solution of NaCl dissolved in water, but it is below the saturation point. The first stage of anolyte preparation is to remove some of this solution from the anolyte tank and pump it through a bed of raw salt in the saturator. This has brine added to the bottom and salt added to a hopper from the top. This brine contains small amounts of metal cations such as Ca2+, Ni2+ and Fe3+, as well as the Na+. These must be removed before the solution goes to the electrolysis cell to prevent the formation of insoluble hydroxides which would clog up the electrolyser membrane. They are removed by adding various chemicals including barium carbonate (BaCO3), sodium carbonate (Na2CO3) and ferric chloride (FeCl3), which cause the cations to precipitate out. The precipitates are then removed in a settling tank. The brine is then filtered to remove colloidal precipitates and passed through two cation exchange columns. Metal ions (except Na+) are removed to form a very pure solution of NaCl. Finally a small amount of HCl is added, to neutralise any OH- that gets into the solution during electrolysis. Step 2 - Catholyte production Catholyte is a solution of NaOH (about 19.4 wt% NaOH). It is prepared by pumping back most of the NaOH-containing solution from the electrolyser, and diluting it back to 19.4% NaOH with water. The water used is deionised water that has been used to scrub the hydrogen gas formed in the electrolysers. Step 3 - Electrolysis The anolyte and catholyte solutions then enter the electrolysis cell. The anolyte enters on the anode side of the membrane at the bottom corner of the cell and exits from the opposite top corner of the cell. Similarly, the catholyte also enters at the bottom of the cell, but on the cathode side. Inside the cell chloride ions are oxidised to form chlorine gas and the water on the cathode side is reduced to form hydroxide ions, as given in the reactions below: At anode: 2Cl- (aq) → Cl2(g) + 2eAt cathode: 2Na+ + 2H2O + 2e→ 2NaOH + H2(g) Overall: 2NaCl + 2H2O + electrical energy → 2NaOH + Cl2(g) + H2(g) The electrolysis cell The electrolysis takes place in electrolysers consisting of 42 cells in series. The cells are held in a frame, with one side of the cell frame being the anode (made of titanium) and the other IV-Forestry-D-Chemical Bleaching-3 being the cathode (made of carbon). A large DC current flows from the cathode to the anode along the length of the electrolyser. As electrolysis takes place the sodium ions are attracted to the cathode and the OH- ions are attracted to the anode. However, to ensure that NaOH and Cl2 do not react together to form sodium hypochlorite, the two chemicals are produced in compartments separated by a cation exchange membrane that allows Na+ ions through, but restricts OH- migration. This means that Cl2 forms on the anolyte side and NaOH forms on the catholyte side. A small amount of OH- does pass through the membrane, but this is neutralised by the acid that was added to the anolyte. The membrane used at Carter Holt Harvey Pulp & Paper’s Kinleith mill is a perfluoro carboxylic acid membrane with thegeneral chemical structure given below. CF2 CF2 CF CF2 O CF2 CF CF3 n O CF2 COOH Figure 1 gives a schematic representation of an electrolysis cell. Note that 0 refers to current efficiency, the fraction of the current that is actually used to produce Cl2. This is less than one because the oxidation of water to oxygen competes with the chlorine oxidaiton at the anode. Some details of the electrolyser operating conditions are given below: • • • Number of Electrolysers Number of Cells per Electrolyser Power Supply • • • Cell voltage Power consumption 2 42 20 kA DC at 160 V. The electrolysers are operated in parallel and receive 10 kA each. 3.0 - 4.0 V 2200 - 2400 DC kWhr/t NaOH Step 4 - Cl2 and NaOH recovery The anolyte leaving the cell is a two phase mixture of depleted brine and chlorine gas. A cyclonic separator is used to separate the chlorine gas from the solution and the depleted brine is returned to the anolyte tank. The chlorine gas is scrubbed by incoming anolyte solution, and then used to form liquid chlorine, sodium hypochlorite and hydrochloric acid. A cyclonic separator separates the caustic solution from the hydrogen gas. The caustic solution returns to the catholyte tank and the hydrogen gas enters the bottom of the scubber to be scrubbed by incoming catholyte solution. The caustic is now ready to be used for paper bleaching, and the hydrogen gas is used later on in the process for HCl production. IV-Forestry-D-Chemical Bleaching-4 Steel Ti η(Na+ + OH-) + ½H2 ½Cl2 + ηNa Cl- + e- Na+ + H2O + eNa+ + OH- + ½H2 ½Cl2 (1-η)OH- OH- (1-η)HCl ηNaCl H2O - RSO 3 RCOO - Figure 1 a chlor/alkali electrolysis cell Chlorine/Caustic balance As shown above the overall reaction to produce Cl2 and NaOH is: 2NaCl + 2H2O + electrical energy → Cl2 + 2NaOH + H2 Now the species involved have the following molecular weights: NaCl = 58.5 g mol-1 H2O = 18 g mol-1 = 71 g mol-1 Cl2 NaOH = 40 g mol-1 H2 = 2 g mol-1 Thus for every tonne of Cl2 produced, 1.13 tonnes of NaOH is also produced. This means that the pulp mill must either keep the NaOH:Cl2 consumption ratio very close to 1.1:1, or purchase extra NaOH. Overseas, pulp mills generally purchase all the NaOH and Cl2 that they need, but New Zealand is a sufficiently far away from commercial chlor/alkali plants to make importing these chemicals prohibitively expensive. Hence the amount of NaOH able to be produced is strictly limited by the amount of Cl2 that can be used for bleaching, or for producing other chemicals, or which can be sold. If the 1.1:1 ratio is exceeded, expensive imported caustic soda must be purchased. IV-Forestry-D-Chemical Bleaching-5 THE CHLORINE DIOXIDE MANUFACTURING PROCESS Chlorine Dioxide (ClO2) has been used as a bleaching chemical commercially for many years. The first ClO2 plants were installed at overseas mills in 1946. Over the years a large number of processes have been developed to produce ClO2, and these are summarised in Table 1. All of the processes are based on the reduction of chlorate (using Cl-, CH3OH or SO2) in the presence of either sulphuric or hydrochloric acid. Table 1 - ClO2 Production Processes Process NaCl Byproducts Yield / % Na2SO4 High 0.6 6.9 95† HCl/NaCl High — — 95† Mathieson SO2 High — 3.4 89† Salted Matheson SO2/NaCl High 0.15 4.7 90 - 93† Solvay CH3OH 9 - 11N — 3.5 87† Salted Solvay CH3OH/HCl 9 - 11N 0.12 4.0 87† CH3OH 9 - 11N — 1.5 96 NaCl Low 0.6 2.3 95 HCl/NaCl 3 - 4N 0.6 1.15 95 Na2SO4 3 - 4N 0.1 1.4 95 HCl/NaCl Low — — 91 - 95‡ R2H R8 R3/SVP R3H R7 Integrated Notes: ‡ Acidity Cl21 R2 † Reducing agent Produces acid effluent Has no byproducts The early processes (eg R2, Mathieson, Solvay) produce a highly acidic effluent (which can be troublesome to dispose of), together with large amounts of saltcake (Na2SO4). The acid effluent can be added to black liquor (see section on kraft pulping) as a make up chemical in the regeneration stage provided that the amount of Na2SO4 does not exceed the mills requirements and that precautions are taken to minimise emissions of H2S when the acid reacts with sulphides in the black liquor. However, these conditions are quite hard to meet and these processes are now out of favour because of the high production of Na2SO4. 1 Cl2 and Na2SO4 quantities given in tonnes of Cl2 or Na2SO4 per tonne of ClO2 produced. IV-Forestry-D-Chemical Bleaching-6 At Kinleith two processes have been used. From 1972 to 1991 the SVP process (also known as the R3 process) was used. The basic reaction occurring here is: NaClO3 + NaCl + H2SO4 → ClO2 + ½Cl2 + Na2SO4 + H2O There is a competing reaction which produces no ClO2: NaClO3 + 5NaCl + 3H2SO4 → 3Cl2 + 3Na2SO4 + 3H2O Catalysts are added to encourage the ClO2 producing reaction. From 1991 the process used in New Zealand has been the integrated process, which involves producing sodium chlorate and HCl and then reacting them together to form ClO2. This process is not used much internationally because of the high capital costs of the electrolyser, but interest in the process is increasing. It is ideal for New Zealand because it allows the Kinleith mill to be completely self sufficient for NaOH while providing the bleaching chemicals necessary to bleach pulp. The reactions involved are given below: NaCl + 3H2O + electricity → NaClO3 + 3H2 H2 + Cl2 NaClO3 + 2HCl Cl2 + H2O → 2HCl → ClO2 + ½Cl2 + NaCl + H2O → ClO2 + 2H2 Step 1 - Sodium chlorate production Sodium chlorate is produced by electrolysing salt using a chlor/alkali cell without the cation exchange membrane. The overall reaction occurring is: NaCl + 3H2O + electrical energy → NaClO3 + 3H2 Some of the operating conditions for the integrated plant are listed below: Chlorate Cell Power Supply No of cells Cell Voltage Power Consumption 57 kA DC at 135 V 40 2.0 - 3.0 V about 5000 kWhr/t chlorate Step 2 - HCl production Hydrogen chloride is formed by burning chlorine in a slight excess of hydrogen without oxygen. The gases are originally obtained in the chlor/alkali cells, and are regenerated at various subsequent process steps such as chlorate production. H2(g) + Cl2(g) → 2HCl(g) The hydrogen chloride gas is absorbed in demineralised water to form 33wt% hydrochloric acid. Step 3 - Chlorine dioxide generation Chlorate solution and 33 wt% HCl are mixed in the generator to produce ClO2 and Cl2. The ClO2 is extracted by preferential absorption into chilled water. Some Cl2 is recycled to the generator where together with air it is used to dilute the ClO2 to reduce the concentration of IV-Forestry-D-Chemical Bleaching-7 ClO2 and hence the likelihood of decomposition. The remaining Cl2 is added to the Cl2 from the chlor/alkali plant to make the required HCl. As the reaction in the generator procedes NaCl builds up in solution. This is sent back to the chlorate cells where it is converted back by electrolysis to NaClO3. PLANT SAFETY Chlorine dioxide Chlorine dioxide is a very unstable compound, it is considered too hazardous to transport. For this reason chlorine dioxide is always produced on the site where it is used. The parameters which must be controlled to minimise decomposition of the ClO2 are: i) keep concentration low (typically < 10% by volume) ii) shield from ultraviolet (uv) light iii) keep uncontaminated iv) keep cool Sodium chlorate Cryatallised chlorate has to be handled with care. When heated dry chlorate releases O2, which can lead to spontaneous combustion and explosions. Once alight, a fire accelerated with chlorate cannot be put out by smoothering (eg CO2 extinguisher), but must be quenched with large amounts of water. ANCILLIARY PROCESSES Liquid chlorine production The Cl2 gas from the anolyte tank is saturated with water, making the Cl2 very corrosive to steel. As the equipment used to process and store liquid chlorine is made from steel the first step in processing the Cl2 for liquefaction is to remove the water from the gas. The water is removed by contacting the gas with concentrated sulfuric acid (about 98 wt% H2SO4) which absorbs the acid. The Cl2 is then compressed to 550 kPa using a two stage reciprocating compressor to reduce the temperature at which it will liquefy. The gas is then cooled in a heat exchanger (using an ammonia refrigeration system) to produce liquid chlorine. As ammonia reacts violently with chlorine, the ammonia is used to cool kerosene which is in turn used to cool the Cl2.to produce liquid chlorine. In this way the chance of an explosion if the heat exchanger leaked is minimised. Sodium hypochlorite production Cl2 not used to make HCl and liquid chlorine is made into sodium hypochlorite (hypo2) solution. The Cl2 gas is reacted with NaOH to form the hypo in a very fast, very exothermic reaction as follows: Cl2 + 2NaOH(aq) → NaOCl(aq) + H2O The hypo solution is produced at a concentration about 165 g available Cl2 L-1. 2 Note that in this context "hypo" refers to sodium hypochlorite while in photography it refers to sodium thiosulfate. IV-Forestry-D-Chemical Bleaching-8 The hypo system is used to remove chlorine from process streams before they are vented to atmosphere and is also used to safely dispose of chlorine during process upsets such as shut downs and power failures. THE ROLE OF THE LABORATORY The chemical plant is an area where chemical reactions and electrochemistry are applied in continuous processes. Regular monitoring of these reactions is vital, and therefore the plant has it’s own laboratory, and testing is carried out by plant operators around the clock. Many of the processes in each plant are similar with routine testing including brine strength, control of brine treatment systems, safety gas checks, strength of caustic soda, hydrochloric acid, sodium hypochlorite, sulphuric acid in chlorine driers, scrubbers, filters, ion exchanger regeneration chemicals and so forth. The Kinleith Mill has a central Analytical Laboratory capable of carrying out a wide range of testing for all areas of the site it services. This laboratory interfaces with the chemical plant by providing test results which would be outside the scope of a plant lab to perform. or which uses instrumentation unsuitable for an industrial environment. Chlor-alkali plant Routine analyses include ppb level determination of metal ions in the purified brine. Elements such as Ca, Mg, Ba, Fe and Ni can “poison” the ion exchange membranes in the electrolysers, and these are monitored by daily checks on the brine feed and anolyte circulation. Currently graphite furnace atomic absorption spectrophotometry is used. The high sodium chloride concentrations (150 - 300 gram per litre) and low detection limit requirements (1 ppb) call for careful analysis programs to minimise interference effects. Elevated levels (above 20ppb) of these metals are indicative of a problem with the ion exchange columns, or contamination from additives or corrosion. Hydrochloric acid and demineralised water purity are monitored as these enter the brine circuit also. By-products from the chemical plant are sold to chemical suppliers, local authorities and other manufacturers. The laboratory tests these chemicals as they are despatched to check conformity to specification, and reports results to customers. Chlorate & Chlorine Dioxide Plant The chlorate and chlorine dioxide processes are more tolerant of contamination, but are less tolerant of changes in the process conditions. The plant carries out most of it’s own testing to ensure the conditions are maintained. During commissioning and plant optimisation the laboratory profiles the chlorine dioxide generator, analysing inputs, and compartment by compartment composition. This includes chlorate, chloride, acid strength, dissolved gases, and gas composition. From this information decisions are made on temperature, dilution air, and feed ratios. Mass balances and overall plant efficiency can be derived. Wet chemistry methods are used for these analyses. Sampling technique is critical, all samples are diluted directly into chilled water to minimise gas-off and to quench the reactions in order to “freeze” the chemical conditions in the compartment at the time. IV-Forestry-D-Chemical Bleaching-9 The Analytical Laboratory checks raw materials and water supplies, and trouble shoots problems in both plants. Chemists work with the plant staff to optimise the process, reduce losses, and improve reliability of equipment. Test chemicals and standard solutions are supplied to the plant lab from here also. Article written by Stephen Kast (Carter Holt Harvey) with information on the laboratory provided by Steven Hope (Supervisor, Analytical Laboratory, Carter Holt Harvery Pulp and Paper). Editing by Heather Wansbrough. IV-Forestry-D-Chemical Bleaching-10