* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download The Shale Gas Revolution: A Methane-to

Chemical potential wikipedia , lookup

Bioorthogonal chemistry wikipedia , lookup

Transition state theory wikipedia , lookup

Chemical weapon proliferation wikipedia , lookup

Stoichiometry wikipedia , lookup

Al-Shifa pharmaceutical factory wikipedia , lookup

Chemical weapon wikipedia , lookup

Catalytic reforming wikipedia , lookup

Chemical Corps wikipedia , lookup

California Green Chemistry Initiative wikipedia , lookup

Gaseous signaling molecules wikipedia , lookup

Chemical plant wikipedia , lookup

Gasification wikipedia , lookup

Continuous distillation wikipedia , lookup

Aliso Canyon gas leak wikipedia , lookup

Chemical industry wikipedia , lookup

Cracking (chemistry) wikipedia , lookup

Hydroformylation wikipedia , lookup

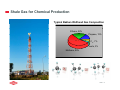

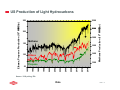

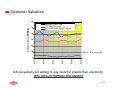

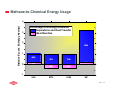

The Shale Gas Revolution: A Methane-to-Organic Chemicals Renaissance? Or Methane: Fuel or Feedstock? Eric E. Stangland 2014 Frontiers of Engineering I i Irvine, California C lif i Dow.com Shale Gas for Chemical Production Typical Bakken Wellhead Gas Composition Ethane, 22% Propane, 13% C4+, 7% Inerts, 3% Methane, 55% Source: Wocken et al, EERC presentation at 21st Williston Basin Petroleum Confernece, 2013 EES — 2 Steam Cracking of Alkanes Natural Resources Feedstock Cracker Complex Olefins Products Separation EES — 3 Light Hydrocarbon Cracker-8, TX Modern plant can make 1500 kta ethylene, or 171,000 kg/hr (376,000 lb/hr). EES — 4 US Production of Light Hydrocarbons 2000 200 1800 150 Methane 1600 100 1400 Ethane 1200 P Propane Methane Production n (109 MMB Btu) 2200 2014 2012 2010 2008 2006 2004 2002 2000 1998 1996 1994 50 1992 Ethan ne, Propan ne Productiion (103 MM MBtu) 250 Source: ICIS pricing, EIA Date EES — 5 Chemical Investment Due to Shale Gas 2023 Projections US Gulf Cost Feedstock Pricing 30 148 capital investment projects worth $100 B Methane (Henry Hub) 25 Propane (Mt. Belvieu) Naptha (Mt. Belvieu) 20 15 637,000 direct/indirect new chemical jobs 10 Date 1/1//2013 1/1//2011 1/1//2009 1/1//2007 1/1//2005 0 1/1//2003 5 1/1//2001 Fee edstock Value ($ $/MMBtu) Ethane (Mt. Belvieu) $244 B in new economic output Source: ICIS pricing, EIA Source: American Chemistry Council EES — 6 2012 US Methane Utilization in kta NH3 Fuel 516,782 (98.5%) 5,683 (74%) Other 1,295 (17%) CH4 CO + H2 Methanol 667 (9%) Chemicals 7,645 (1.5%) H2O CO2 GTL fuels CH3OH NH3 By comparison, 2012 Ethylene Capacity = 24,000 kta Plenty of methane available for chemical use EES — 7 Dilemma: Fuel or Feedstock? C Current t Future? Risk vs. Reward EES — 8 Customer Valuation Consumer Va alue ($/MMBtu)) 60 Methane (Henry Hub) US Retail Electricity US LPDE (Liner Grade) Contract 50 40 30 20 10 Source: ICIS pricing, EIA 7//1/2013 1//1/2013 7//1/2012 1//1/2012 7//1/2011 1//1/2011 0 US consumers are willing to pay more for plastic than electricity. Wh not turn Why t rn methane into plastic? EES — 9 Known Methane-to Chemical-Routes (not-inclusive) Methanol-to-Olefins (MTO) Syngas Methanol Olefins Separation O2 (ASU) Oxidative O dat e Methane et a e Coup Coupling g (OC (OCM)) Olefins Separation O2 (ASU) Methane Pyrolysis Acetylene/ Syngas Hydrogenation Separation CO methanation O2 ((ASU)) EES — 10 Total Retained d Carbon n Efficien ncy (%) Methane-to-Chemicals Efficiency vs. Cost 80 70 OCM SCE 60 MTO 20% 31% 49% 58% 44% 42% 56% 50 IIncreasing i Sustainability? MP 35% 40 30 65% 20 Total fixed capital by section POX CxHy reaction 10 Electricity Generation Reactant/product separation 0 0 10 20 30 40 50 Process Thermodynamic Efficiency (%) EES — 11 Routes to Ethylene Methanol-to-Olefins (MTO) Syngas/ Methanol Olefins Separation Ethylene Separation Ethylene Separation Ethylene O2 (ASU) Oxidative O dat e Methane et a e Coup Coupling g (OC (OCM)) Olefins O2 (ASU) Olefins EES — 12 Distillation… Established E t bli h d ttechnology h l Easily scaled Low capital, low risk L Low energy efficiency ffi i …accounts for 90-95% of all separations in the petrochemical industry and up to 30% of overall industry energy usage. EES — 13 Light Hydrocarbon Cracker-8, TX C Cryogenic i Di Distillation till ti T Train i C ki ffurnaces Cracking EES — 14 Next Generation Chemical Plant What technology technolog is needed to utilize tili e all components of shale gas for organic chemical production? EES — 15 New Chemistry Metal-loaded zeolite New catalysts that utilize oxygen to convert methane (alkanes), exclusively to olefins Butadiene Isoprene Isobutylene Cyclopentadiene New chemistries from lighter hydrocarbons to supplement C4 and C5 shortages EES — 16 New Mass-transfer Agents Support Short-term: hybrid schemes Selective Layer Membrane Distillation Column High-temperature stable porous metals and ceramic p membranes with high flux & selectivity MOFs L Long-term: t Distillation Di till ti replacement l t S Silver-salt Ionic Liquid BF4H3C Carbons Ag+ X- N N CH2 H2C CH2 CH3 Membrane Cascade Absorption/Adsorption Sorbents S b t with ith significantly i ifi tl hi higher h selective capacity EES — 17 Improved Computation and Logic TS3 20 CH2O + SO2+ H• TS2 10 •CH3 + SO3 CH3SO3• (2E) CH3O• + SO2 -10 CH3SO3• (2A2) -20 TS1: CH3SO3 r(C-S)=2.06 Å CH3OSO2• CH2O + HOSO• -30 prediction profiler - desirability 100 50 -70 0 Hybrid and advanced plants will q advanced process p control require 2 reaction 4i coordinate di 6 8 . -1.16 X1 0.77 X2 2 0 0 2 -2 CO2 + H2O + •SH 0 -60 2 -2 TS2: CH3OSO2 r(C-O)=2.30 Å -50 TS3: CH3OSO2 r(C-O)=2.00 Å r(C-S)=2.26 Å 0 -40 -2 enthalpyy (H, kcal/mol) 0 1.49 X3 Advanced ab initio modeling with p y informatics and highg complementary throughput experimentation EES — 18 New US Chemical Industry is Dawning EES — 19 Methane-to-Chemical Energy Usage Re elative Exc cess Entha alpy Neede ed 4 3 Percentage g of Enthalpy py Utilization Separations and Heat Transfer Ideal Reaction 2 92% 1 81% 0 71% 71% 8% 19% 29% 29% MTO OCM -1 1 SCE MP EES — 20