* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download trade : boilermaker

Voltage optimisation wikipedia , lookup

Printed circuit board wikipedia , lookup

Stray voltage wikipedia , lookup

Electrical engineering wikipedia , lookup

Resilient control systems wikipedia , lookup

Ground (electricity) wikipedia , lookup

Three-phase electric power wikipedia , lookup

Portable appliance testing wikipedia , lookup

Electronic engineering wikipedia , lookup

Alternating current wikipedia , lookup

Electric machine wikipedia , lookup

Electromagnetic compatibility wikipedia , lookup

Electrical substation wikipedia , lookup

Surface-mount technology wikipedia , lookup

Mains electricity wikipedia , lookup

Fault tolerance wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Induction motor wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Electrician wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Stepper motor wikipedia , lookup

Earthing system wikipedia , lookup

Nuclear electromagnetic pulse wikipedia , lookup

Electrical wiring wikipedia , lookup

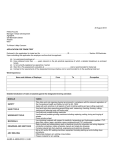

WORKPLACE EXPOSURE TRAINING SCHEDULE TRADE: ELECTRICIAN PAGE 1 ____________________________________________________________________________________________________________________ Name of Apprentice: …………………………………………………….. ID #: ………………………………………… Name of Employer: ………………………………………………….…… Physical Address: …………………………………….…………………………………………… Name of Designated Artisan: ……………………………………..…….. Designated Trade: ………………………… Assist only MODULE CODE OBJECTIVES INDUCTION ID1 Recall applicable sections of the Manpower Training (Act No 56, 1981), with special reference to discipline and legal responsibilities. Recall terms and conditions of apprenticeship as Gazetted 26 July 1991. Recall applicable grievance procedures. Recall applicable disciplinary procedures. Recall company rules and procedures. Recall quality assurance procedures. ID2 ID3 ID4 ID5 ID6 SF1 SAFETY SF2 HAND TOOLS SF3 SF4 SF5 HT1 HT2 HT3 WORKSHOP TOOLS MATERIALS HT4 WT1 WT2 WT22 ME1 AGRI-4-4006-FOU-13-00 Recall relevant regulations of the following Acts: (where applicable) Occupational Health and Safety Act (Act No 85, 1993). Minerals Act and Regulations (Act No 50, 1991). Attend a standard industrial safety course accredited by the industry. Recall safety in welding and gas cutting. Attend a first aid course. Identify relevant colour markings and symbolic safety signs. Identify measuring, checking, forming, cutting, marking and fastening tools and tooling aids. Use measuring, checking, forming, cutting, marking and fastening tools and tooling aids. Maintain measuring, checking, forming, cutting, marking and fastening tools and tooling aids. Use hand tools applicable to the trade. Use fixed and portable drilling machines. Use fixed and portable grinding machines including replacing, setting, truing and ringing of wheels. Dress a grinding wheel. Recall the physical properties and characteristics of metals. (With reference to ME3). App Emp Date Signature: ………………………………… Signature: ………………………………… Need supervision App Emp Date Independent Work App Emp Date WORKPLACE EXPOSURE TRAINING SCHEDULE TRADE: ELECTRICIAN PAGE 2 ____________________________________________________________________________________________________________________ Assist only MODULE CODE OBJECTIVES ME3 Identify the following conducting materials with respect to conductivity, current carrying capacity and temperature: copper and aluminium. Identify and use the following insulating materials with respect to resistivity, temperature and hydroscopic qualities: PVC, glass fibre, resins, tapes, varnishes, epoxy compounds and PVC compounds Recall symbols and abbreviations used on electrical circuits for schematic and wiring diagrams, connection schedules, cables schedules, layouts and single-line drawings. Recall symbols and abbreviations as used on engineering drawings. Recall symbols and abbreviations pertaining to electronic circuit diagrams. Interpret electrical drawings. Interpret engineering drawings. Interpret electronic circuit diagrams. Compile material lists from electrical, engineering and electronic drawings. Make free hand sketches of existing circuits and installations including mechanical components. Mark off a project applicable to the trade. Mark off projects for manufacturing using all standards markingoff techniques and tools. Fabricate a project applicable to the trade. Sharpen chisels. Sharpen drills. Dress screwdrivers. Sharpen punches. Identify and set up AC and/or DC welding machines, equipment including starting up and shutting down procedures.. Differentiate between arc welding consumables. Prepare material for arc welding. Tack and arc weld workpieces incidental to the trade using manual metal arc welding techniques. Identify and set up oxygen-fuel gas welding equipment including light up, adjustment of gas pressures and shut down procedures. ME4 DRAWINGS AND SKETCHES DSE1 DSE2 DSE3 DSE4 DSE5 DSE6 DSE7 DSE8 MARKING OFF MO1 MT9 HAND SKILLS HS1 HS2 HS3 HS4 HS5 AO1 ARC WELDING AO2 AO3 AO4 GAS WELDING GW10 AGRI-4-4006-FOU-13-00 App Emp Date Need supervision App Emp Date Independent Work App Emp Date WORKPLACE EXPOSURE TRAINING SCHEDULE TRADE: ELECTRICIAN PAGE 3 ____________________________________________________________________________________________________________________ GW11 GW12 GW13 Differentiate gas welding consumables. Prepare material for gas welding. Gas weld workpieces incidental to the trade. Assist only MODULE CODE OBJECTIVES GAS CUTTING AND HEATING GC1 Identify and assemble gas cutting and heating equipment, including light up and shut down procedures. Select nozzles and gas pressures for cutting and heating different materials of various thicknesses. Hand cut and heat materials incidental to the trade. Recall overhead crane hand signals. Demonstrate overhead crane hand signals. Use the following equipment: chain block : 2 ton max; shackles : 2 ton max; chain slings : 2,5 ton max; wire rope slings : 20 mm diameter Select and connect the following panel meters and interpret the readings: voltmeter, ammeter, energy meter (KWH). GC2 BASIC LIFTING TECHNIQUES GC3 BG2 BG3 BG4 ELECTRICAL MEASURING INSTRUMENTS (PANEL MOUNTED) ELECTRICAL TESTING INSTRUMENTS (PORTABLE) MJ1 SOFT SOLDER SS1 FAULT FINDING SS2 FA2 ET1 FA6 AGRI-4-4006-FOU-13-00 Identify and use the following instruments for safety and fault finding as used for electrical systems up to 750 volts: voltage tester, multimeter, insulation tester, oscilloscope, earth leakage polarity tester, phase rotation tester and signal generator. Prepare and solder the following: Hard copper, Soft copper Solder electronic components onto a printed circuit board. Fault find on the following: control panels, distribution boards, contactors, relays, insulators, fuse holders and motor control gear. Fault find on the following equipment: - Control panels - Distribution boards - Contactors and relays - Insulators - Fuse and holders The following AC heavy current motor control equipment and the practical application of fault finding techniques: - Open circuit - Short circuits App Emp Date Need supervision App Emp Date Independent Work App Emp Date WORKPLACE EXPOSURE TRAINING SCHEDULE TRADE: ELECTRICIAN PAGE 4 ____________________________________________________________________________________________________________________ - Under voltage relay faults - Retaining faults - Single phase faults - Mechanical faults Specific faults applicable to panels and the diagnosis of the specific fault symptoms of each panel as a result of its purpose and composition. Assist only MODULE CODE OBJECTIVES CONDUCTORS CO1 Recall the current carrying capacity of conductors according to length and cross-sectional area. Join conductors by the following methods: . crimping . soldering Insulate conductors. Make off and join multi and single core, standard PVC armoured cable up to 16mm² 4 core, (1200 volt insulation). Identify ratings of cables by current, voltage and temperature. Recall methods of storing cables. Terminate PVC cables (up to 1200 volts insulation) for entry into cable end box using mechanical and compression methods. Identify XLPE cables. Maintain repair and test the following equipment: control panels, distribution boards, contactors, relays, switchgear, circuit breakers, timers, isolators, fuse holders, motor control gear, electrical machines, protective devices and lighting systems. Design and wire the following with reference to the applicable drawings: panels, starters, motors, motor control gear, electrical distribution systems, protective systems, lighting systems including discharge and fluorescent lamps. Mount, wire and connect the following: . switch boards; distribution boards; motor control gear; isolators; electrical equipment Introduction to wire-ways including the following: . racks; trunking; flexible conduit Design and wire control and main circuit to which the following single phase machines can be connected: (take into consideration protection and safety equipment that must be used) CO2 CO3 CA1 CABLES CA2 CA3 CA4 ELECTRICAL EQUIPMENT CA5 EE1 WIRING WI1 INSTALLATIONS IN1 IN2 A C MACHINES AC9 AGRI-4-4006-FOU-13-00 App Emp Date Need supervision App Emp Date Independent Work App Emp Date WORKPLACE EXPOSURE TRAINING SCHEDULE TRADE: ELECTRICIAN PAGE 5 ____________________________________________________________________________________________________________________ - Capacitor start motor - forward and reverse - Capacitor start, capacitor run motor - forward and reverse. Design and wire the following control and main circuit to which 3 phase squirrel cage induction motor can be connected: (take into consideration protection and safety equipment that must be used) Direct on line forward and reverse Automatic Star-Delta Auto transformer Constant torque motor (2 speed) AC10 Assist only MODULE CODE OBJECTIVES AC11 Design and wire the following control and main circuit to which a three phase slip ring induction motor can be connected i.e. Hand and automatic controlled resistance starter or current limiting starters (take into consideration protection and safety equipment that must be used). Connect three phase and three single phase transformers in various combinations to obtain various voltages. Before commissioning test the following AC machines electrically and mechanically: After commissioning fault find the following AC machines: Capacitor start motor Capacitor start capacitor run motor 3 phase squirrel cage induction motor 3 phase slip ring motor Transformers Auto-transformers Connect, test and fault find the following DC machines: . series motor . shunt motor . compound motor Identify the following electronic components: - Resistors - wire wound up to 10 watts - carbon and metal oxides (1 watt) - Capacitors - electrolytic and ceramic; Diodes; Transistors; Thyristors Construct, solder and fault find the following electronic circuits: bi-stable multi vibrator, stable multi vibrator, mono-stable multi vibrator, elementary SCR speed control. - AC16 AC17 AC18 D C MACHINES DC1 ELECTRONICS EL1 EL2 AGRI-4-4006-FOU-13-00 App Emp Date Need supervision App Emp Date Independent Work App Emp Date WORKPLACE EXPOSURE TRAINING SCHEDULE TRADE: ELECTRICIAN PAGE 6 ____________________________________________________________________________________________________________________ EL3 ON THE JOB EXPERIENCE AND INDEPENDENT WORK EL5 EX1 AGRI-4-4006-FOU-13-00 Use a dual- trace oscilloscope up to 20 MHZ to identify: - Wave forms (DC & AC) - Average values - Peak values - Frequencies - RMS values Programme and use P. L. C. systems. On the job experience and independent work should cover at least 80% of all modules plus at least 4 machines in the module machines to ensure as wide as possible field of experience and must take place under supervisory control.