* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download document 8947106

Electromagnetism wikipedia , lookup

Field (physics) wikipedia , lookup

Condensed matter physics wikipedia , lookup

Lorentz force wikipedia , lookup

Neutron magnetic moment wikipedia , lookup

Magnetic monopole wikipedia , lookup

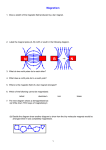

Magnetic field wikipedia , lookup

Aharonov–Bohm effect wikipedia , lookup