* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Methods of industrial production 1

Survey

Document related concepts

Catalytic triad wikipedia , lookup

Proteolysis wikipedia , lookup

Point mutation wikipedia , lookup

Metalloprotein wikipedia , lookup

Nucleic acid analogue wikipedia , lookup

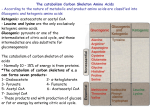

Peptide synthesis wikipedia , lookup

Fatty acid metabolism wikipedia , lookup

Genetic code wikipedia , lookup

15-Hydroxyeicosatetraenoic acid wikipedia , lookup

Fatty acid synthesis wikipedia , lookup

Specialized pro-resolving mediators wikipedia , lookup

Butyric acid wikipedia , lookup

Citric acid cycle wikipedia , lookup

Amino acid synthesis wikipedia , lookup

Transcript

Methods of industrial production 1 Methods of industrial production • Primary & secondary metabolites – Primary metabolites are produced during the growth phase of the microbe. Examples: amino acids, nucleotides, fermentation end products, and many types of enzymes – Secondary metabolites accumulate during periods of nutrient limitation and waste buildup. Examples: many antibiotics and mycotoxins – Primary metabolites are produced during active cell growth, and secondary metabolites are produced near the onset of stationary phase 2 3 4 Major products • Antibiotics – Examples: penicillin & streptomycin – The yield of both of these antibiotics are optimized by nutrient limitation (carbon & nitrogen) • Recombinant DNA products – Proteins produced from genes introduced into microbes via recombinant DNA techniques, such as enzymes, peptide hormones, recombinant vaccines 5 Major products • Amino acids – Glutamic acid (monosodium glutamate) is produced by regulatory mutants of Corynebacterium glutamicum that have a modified Krebs cycle that can be manipulated to shift -ketoglutarate to glutamate production – Lysine is produced by a Corynebacterium glutamicum strain in which homoserine lactone synthesis is blocked 6 Major products • Other organic acids – Acetic acid, citric acid, fumaric acid, gluconic acid, itaconic acid, kojic acid, lactic acid • “Speciality” compounds – A variety of drugs (cholesterol drugs, immunosuppressants, antitumor drugs), ionophores, enzyme inhibitors, pesticides • Biopolymers – Microbial-produced polymers, mostly polysaccharides, useful as thickening or gelling agents in foods, pharmaceuticals, paints, etc. 7 Major products • Biosurfactants – Microbial-produced detergents, such as glycolipids; used in bioremediation applications such as oil spill cleanups • Bioconversions – Using a microbe as a biocatalyst to convert a substrate into a desired product; for example, in the modification of steroid hormones 8 9 The picture shows the interrelationship of the main primary metabolic pathway for aromatic amino acid synthesis and the secondary metabolic pathways for a variety of antibiotics. 10 Productivities of fermentation compared to other processes 11 Chiral Hydroxy Acids from Carbonhydrate Metabolism • More than 5 million tons of starch are produced per year in the EU from agriculture products such as maize, wheat, barley and potatoes. • D-Glucose, the basic building unit of starch, can be formed in situ by the action of amylase enzymes. • The glucose can then be converted to a variety of commercially interesting hydroxy acids. • The commercially most important is citric acid, which is achiral, but a variety of chiral hydroxy acids are also produced by carbohydrate metabolism- 12 Chiral hydroxyacids available from industrial fermentations 13 2-Keto-D-gluconic acid • 2-Keto-D-gluconic acid is produced by fermentation of glucose with Acetobacter suboxydans and is an intermediate in the production of isoascorbic acid (isovitamin C) 14 L-Sorbose production by fermentation of D-Sorbitol • About 30 000 tons/a of ascorbic acid are produced by the Reichstein-Grussner process which dates from 1934. The key step in this process is the microbial oxidation of D-sorbitol to L-sorbose mediated by Acetobacter suboxydans. 15 Direct fermentation of glucose to 2-keto-L-gulonic acid by a recombinant strain of Erwinia herbicola 16 Amino acids • Amino acids are used for a variety of purposes. The food industry requires L glutamateas a flavour enhancer, or glycine as sweetener in juices, for instance. • The pharmaceutical industry requires the amino acids themselves in infusions - in particular the essential amino acids - or in special dietary foods. • And last, but not least, a large market for amino acids is their use as feed additives. The reason is that typical animal feed, like soybean meal for pigs, is poor in some essential amino acids, like methionine and lysine. 17 Overview 18 Overview (cont) 19 Classical strain development • Bacteria do not normally excrete amino acids in significant amounts because regulatory mechanisms control amino acid synthesis in an economical way so that the needs of the cell (for protein synthesis) are exactly matched by the synthetic processes. • There are no surplus amino acids and only a small pool of them exists within the cell to meet its immediate needs. Therefore, mutants have to be generated that over synthesize the respective amino acid. A great number of amino-acid-producing bacteria have been derived by mutagenesis and screening programmes. • This has involved the consecutive application of: • undirected mutagenesis, • selection for a specific phenotype, and • selection of the mutant with the best amino acid accumulation. 20 A genealogy of strains obtained by classical mutagenesis and screening, showing improved yield and some of the phenotypic characters of the mutants 21 -Ketoglutarate Family aKetoglutarate Glutamate Glutamine Proline Arginine 22 -Ketoglutamate to glutamate/glutamine Net Reaction: -Ketoglutarate + NH4+ + NADPH + ATP L-glutamate + NADP+ + ADP + Pi 23 L-Glutamate Sketch of main reactions of C. glutomicum connected with the citric acid cycle and of relevance for L-glutamate production. PyrDH, pyruvate dehydrogenase; PyrC, pyruvate carboxylase; PEPC, phosphoenolpyruvate carboxylase; GIuDH, glutamate dehydrogenase; KetogluDH, ketoglutarate dehydrogenase. 24 L-Glutamate • For the biotechnological production of L-glutamate by C. glutamicum, the intracellularly synthesised amino acid must be released from the cell. • This requires specific treatments to result in export of the amino acid by a presumed carrier. A specific carrier must be present since otherwise, in addition to the charged L glutamate, other metabolites and ions would also leak from the cell and the cell would not be viable. However, Lglutamate formation is still not fully understood. • The reason for this is that a wide ringe of treatments lead to the secretion of glutamate. These include: (i) growth under biotin limitation, (ii) addition of penicillin, (iii) addition of lysozyme, (iv) addition of surfactants, (v) use of oleic acid auxotrophs, and (vi) use of glycerol auxotrophs. • All these treatments apparently have the cell wall or the lipid membrane as the target in some way or another. 25 Verbesserung der Sekretion 26 Production process • • • • The most relevant factors influencing L-glutamate formation are the ammonium concentration, the dissolved 02 concentration and the pH. • Although, in total, a large amount of ammonium is necessary for sugar conversion to L-glutamate, a high concentration is inhibitory to growth as well to the production of L-glutamate. • Therefore, ammonium is added in a low concentration at the beginning of the fermentation and is then added continuously during the course of the fermentation. 27 Production process • The oxygen concentration is controlled, since under conditions of insufficient oxygen, the production of L-glutamate is poor and lactic acid as well as succinic acid accumulates, whereas with an excess oxygen supply the amount of αketoglutarate as a by-product accumulates. • For the actual fermentation, the production strains are grown in fermenters as large as 500 m3 . • After pre-cultivation, the onset of L-glutamate excretion is controlled by the addition surfactants such as polyoxyethylene sorbitan monopalmitate (Tween 40). 28 Production process • Yields of between 60 and 70% L-glutamate, based on the glucose used, have been reported. • At the end of the fermentation the broth contains L-glutamate in the form of its ammonium salt. • In a typical downstream process, the cells are separated and the broth is passed through a basic anion exchange resin. • Glutamate anions will be bound to the resin and ammonia will be released. This ammonia can be recovered via distillation and reused in the fermentation. 29 Production process • Elution is performed with NaOH to form monosodium glutamate (MSG) directly in the solution and to regenerate the basic anion exchanger. • From the eluates, MSG may be crystallised directly followed by further conditioning steps like decolorisation and sieving to yield a food-grade quality. 30 Biosynthese und Hochleistungsmutanten 31 A scheme of the material flow in an L-glutamate production plant. 32 Oxoloacetate Family Oxaloacetate Aspartate Asparagine Methionine Lysine Threonine 33 L-Lysine • Out of the twenty naturally occurring amino acids, L-Lysine is one of the 9 essential (histidine, isoleucine, leucine, lysine, methionine, phenylalanine, threonine, tryptophan and valine) and commercially important amino acids, ecumenically found in naturally occurring proteins of all living organisms. • Its major commercial form is L-Lysine-HCl (L-Lysine monohydrochloride). • It is mainly used as a feed additive in the animal feed industry, mixed with various common livestock such as cereals which do not contain sufficient levels of L-lysine for the livestock's nutritional requirements. 34 L-Lysine 35 Biosynthese und Hochleistungsstämme 36 Lysinfermentation 37 Lysine Production Approaches Corynebacterium glutamicum is widely used for the biotechnological production tons of L-glutamate, L-lysine and of several other amino acids. To obtain Lysine overproducer, besides the classical method of random mutagenesis, some metabolic engineering principles were also used for strain improvement Some well know targets for lysin overproduction are – deregulation of lysine production – Improved carbon precurser supply – Increased NADPH regeneration • Thus, L-lysine producing strains of the gram positive corynebacteria, especially Corynebacterium glutamicum, Brevibacterium flavum and Brevibacterium lactofermentum, have been used for the last fifty years for the industrial production of amino acids. 38 L-Lysin fermentation 39 Fermentation medium • In addition to physical parameters like pH, agitation and aeration rate, air saturation, temperature, dissolved CO2 and foaming, medium composition is a very important factor strongly influencing fermentation processes, often being object of extensive process development and optimization studies. • Common fermentation media for L-lysine production contain various carbon and nitrogen sources, inorganic ions and trace elements (Fe++, Mn++), amino acids, vitamins (biotin, thiamine-HCl, Nicothinamide) and numerous complex organic compounds. • An overexpression of genes is also achieved by optimizing the composition of the media and the culture technique in addition to physiological and genetic parameters . 40 CARBON SOURCE • Mutants of Corynebacterium and related microorganisms enable the inexpensive production of amino acids from cheap renewable carbon sources by direct fermentation. • Various carbohydrates are utilized individually or as a mixture for the production of L-lysine such as glucose, fructose, sucrose, molasses (sucrose, glucose, fructose etc.), maltose, blackstrap molasses, starch hydrolyzate (glucose, oligosaccharides), lactose, maltose, starch and starch hydrolysates, cellulose, cellulose hydrolysate, organic acids such as acetic acid, propionic acid, benzoic acid, formic acid, malic acid, citric acid and fumaric acid, alcohols such as ethanol, propanol, inositol and glycerol and certainly hydrocarbons, oils and fats such as soy bean oil, sunflower oil, groundnut oil and coconut oil as well as fatty acids such as e.g. palmitic acid, stearic acid and linoleic acid. 41 NITROGEN SOURCE • Various sources of nitrogen are utilized individually or as mixtures for the commercial and pilot scale production of L-lysine, including inorganic compounds such as gaseous and • aqueous ammonia, ammonium salts of inorganic or organic acids such as ammonium sulfate, ammonium nitrate, ammonium phosphate, ammonium chloride, ammonium acetate and ammonium carbonate. • Alternatively, natural nitrogen containing organic materials like soybeanhydrolyzate, soyprotein HCl-hydrolyzate (total nitrogen of about 7%), soybean meal, soybean cake hydrolysate, corn steep liquor, casein hydrolysate, yeast extract, meat extract, malt extract, urea, peptones and amino acids may also be utilized. 42 INFLUENCE OF OXYGEN • L-lysine fermentation is an aerobic process demanding large amounts of oxygen and strongly influenced by the air saturation in bioreactor. • Lactic acid is formed as a byproduct under anaerobic conditions, which is reconsumed after the establishment of aerobic conditions. 43 pH • The pH is a very important factor strongly influencing microbial fermentations. • Basic compounds such as sodium hydroxide, potassium hydroxide, ammonium hydroxide, calcium carbonate, urea, ammonia and gaseous ammonia, or inorganic acid compounds such as phosphoric or sulfuric acid and organic acids are utilized for controlling pH in L-lysine cultures at a pH ranging from 5 to 9. 44 The industrial production of antibiotics begins with screening for antibiotic producers . 45 46 47 Biosynthetic pathways for penicillin and cephalosporin. 48 Enzyme processes in the production of β-Lactam antibiotics • Penicillins and chephalosporins belong to the class of β-lactam antibiotics that are formed from the common precursor tripeptide isopenicillin N. • The β-lactam structure is formed by ring-closure reactions between Cys and Val,where (S)-Val is isomerized to ( R )-Val. • The β-lactam precursors of all penicillins and cephalosporins are produced by fermentation in fermentors of up 1000 m3. • The concentration of the products in the medium on completion of fermentation that takes between five and seven days, is up to 100 g/L penicillin and 20 g/L cephalosporin C. 49 Penicilline 50 Cephalosporine 51 Biosynthese und Genstruktur 52 Major antibiotics of clinical significance include the -lactam antibiotics penicillin and cephalosporin and the tetracyclines . 53 Syntheseweg 54 Syntheseschritte 55 Suitable Reactors and pH-controlling Buffers • The main reason for developing the enzyme process was to reduce the amount of problematic wast produced in the chemical process. This was successful, and wast production was reduced typically from 31 to 0,3 tons per ton 7-ACA synthesized. • Due to product inhibition, a CSTR is unfavorable, as much more enzyme is required for a given space time yield than for a packed-bed reactor. • The latter is not suitable in the deamination step as it is difficult to supply the necessary oxygen, and the pH will change along the lenght of the reactor. 56 Comparison of the old (chemical) and new (enzyme)processfor the hydrolysis of penicillin G 57 The graph shows the kinetics of the penicillin fermentation with Penicillium chrysogenum. 58 Penicillin production • Penicillin is a secondary metabolite of fungus ''Penicillium'' that is produced when growth of the fungus is inhibited by stress. It is not produced during active growth. Production is also limited by feedback in the synthesis pathway of penicillin. • The Penicillium cells are grown using a technique called fed-batch culture, in which the cells are constantly subject to stress and will produce plenty of penicillin. • The carbon sources that are available are also important: Glucose inhibits penicillin, whereas lactose does not. The pH and the levels of nitrogen, lysine, phosphate, and oxygen of the batches must be controlled automatically. 59 Penicillin variants • The term “ penicillin" is often used in the generic sense to refer to one of the narrow-spectrum penicillins, in particular, benzylpenicillin ( penicillin G). • Other types include: • Phenoxymethylpenicillin • Procaine benzylpenicillin • Benzathine benzylpenicillin • Benzylpenicillin potassium • Benzylpenicillin sodium nevertheless, penicillinis still the most common cause of severe allergic drug reactions. 60 Induced mutation of Penicillium chrysogenum Breeding of strain NRRL-B25 for production of penicillin Strain Mutagen NRRL-B25 Yield (U/ml) Time 250 1943 NRRL-X1612 X-rays 500 1943 NRRL-Q176 UV light 850 1945 NRRL-WIS-47-1564 UV light 850 1947 --- --- 50000 1977 61 A “classical” genetic technique for strain breeding Physical agents Mutagenic agents e.g. X-rays, g-rays, UV Chemical mutagens e.g. base analogs, nitrous acid, alkylating, arylating agents 62 Penicillin production improvement: a classical approach 63 Stamm-Verbesserung 64 Classical mutagenesis • Classical mutagenesis of microorganisms comprises exposing to ultraviolet light irradiation (UV), X-ray irradiation, radiation irradiation (e.g. exposing to UV radiation at 30oC for about180 sec) and chemical mutagen treatment (e.g. 250 or 500 mg/l N-methyl-N'-nitro-Nnitrosoguanidine (NTG) • at room temperature, 30 or 32°C for 10-30 min (e.g. in tris/maleic buffer of pH 6.0; cells are washed with 0.1M tris buffer of pH 7.2) • followed by mutant selection conducting replication on selective minimal agar plate mediaor LB agar plates. 65 66 UV Damage & photoreactivation of DNA UVL VL Photolyase 67 Tetracycline 68 69 Tetracycline 70 Fermentation und Aufarbeitung von Chlortetracyclin 71 Polyketid Antibiotika 72 Citric acid • Citric acid is the most important organic acid produced in tonnage by fermentation. Global production of citric acid in 2004 was about 1.4 million tonnes estimated by Business Communications Co. (BCC). • The citric acid market has been under pressure for more than two years and continues to oscillate with prices falling from $2/kg to $0.70–$0.80/kg. • About 64 % of U.S. citric acid usage in 2004 was for foods and beverages, 22 % for detergents and cleaning products and 10 % for pharmaceutical and nutritional products. About 2 % went into cosmetics and toiletries. Around 2 % were used in different applications. The actual price of citric acid is about $1 to $1.3 per kilo. In general, citric acid is commercially produced by submerged microbial fermentation of molasses; the fermentation process using Aspergillus niger is still the main source of citric acid worldwide. • 73 Microorganisms • A large number of microorganisms including fungi and bacteria such as Arthrobacter paraffinens, Bacillus licheniformis and Corynebacterium ssp., Aspergillus niger, A.aculeatus, A. carbonarius, A. awamori, A. foetidus, A. fonsecaeus,A. phoenicis and Penicillium janthinellum; and yeasts such as Candida tropicalis, C. oleophila, C. guilliermondii, C.citroformans, Hansenula anamola and Yarrowia lipolytica have been employed for citric acid production . • Most of them, however, are not able to produce commercially acceptable yields due to the fact that citric acid is a metabolite of energy metabolism and its accumulation rises in appreciable amounts only under conditions of drastic imbalances. • A. niger has remained the organism of choice for commercial production because it produces more citric acid per time unit. 74 Strains • Among the mentioned strains, the fungus A. niger has remained the organism of choice for commercial production because it produces more citric acid per time unit. • The problem in the production of citric acid for yeasts is the simultaneous formation of isocitric acid. • The main advantages of using A. niger are its ease of handling, its ability to ferment a variety of cheap raw materials, and high yields. • Industrial strains which produce commercial citric acid are not freely available and only a few can be obtained from international culture collections. 75 Citric acid production • The industrial citric acid production can be carried in three different ways: by • submerged fermentation, • surface fermentation and • solid-state fermentation or »Koji« process. 76 Submerged fermentation • The submerged technique is widely used for citric acid production. It is estimated that about 80 % of world production is obtained by submerged fermentation . • This fermentation process employed in large scale requires more sophisticated installations and rigorous control. • On the other hand, it presents several advantages such as higher productivity and yields, lower labour costs, lower contamination risk and labour consumption. • Submerged fermentation can be carried out in batch, fed batch or continuous systems, although the batch mode is more frequently used. • Normally, citric fermentation is concluded in 5 to 12 days, depending on the process conditions. 77 Surface fermentation • Liquid surface culture is the classic citric production process and was the first industrial manufacture; submerged fermentation was developed only after that. • Surface fermentation is still used in industries of small and medium scale because it requires less effort in operation, installation and energy cost. • The process is carried out in fermentation chambers where a great number of trays is arranged in shelves. The culture solution is held in shallow trays with capacity of 0.4 to 1.2 m3 and the fungus develops as a mycelial mat on the surface of the medium. 78 Surface fermentation • The trays are made of high purity aluminium, special grade steel or polyethylene, however steel trays supply better yields of citric acid . • The fermentation chambers are provided with an effective air circulation, which passes over the surface in order to control humidity and temperature by evaporative cooling. 79 Solid state fermentation • Solid-state fermentation, also known by »Koji« process, was first developed in Japan where abundant raw materials such as fruit wastes and mainly rice bran are available. It is the simplest method for citric acid production and it has been an alternative method for using agro-industrial residues. • Solid-state culture is characterized by the development of microorganisms in a low-water activity environment on an insoluble material that acts both as physical support and source of nutrients. • Some similarities are observed with the surface process since the fungus also develops on material surface. The substrate is solid and it is moistened to about 70 % moisture, depending on the substrate absorption capacity. The initial pH of the material is normally adjusted to 4.5–6.0 and the temperature ofincubation is about 28–30 °C. • 80 Product recovery • The recovery of citric acid from fermented broth is generally performed through three procedures: precipitation, extraction and adsorption (mainly using ion exchange resins). The first method is the most frequently used and it is applicable in all types of processes. The second one requires a fermented broth with little impurities. • In both of the methods there is the need to remove the fermented broth, micelles of the fungus, and materials in suspension by filtration . • Precipitation method is the classical method and it is performed by the addition of calcium oxide hydrate (milk of lime). The acid is transformed into tri-calcium citrate tetrahydrate, which is lightly soluble. The precipitate is recovered by filtration, treated with sulphuric acid forming calcium sulphate (gypsum), which is filtered off. • 81 Product recovery • Mother liquor of citric acid solution is treated with active carbon and passed through cation and anion exchangers. • Finally, the liquor is concentrated in vacuum crystallizers at 20–25 °C, forming citric acid monohydrate . Anhydrous citric acid is obtained at crystallization temperature higher than 36.5 °C. The crystals are separatedThe crystals are separated by centrifugation and the dry stage is conducted at a temperature bellow 36.5 °C for monohydrate product and above this for anhydrous product. • Generally, a bed flowing dryer is used. Two kinds of wastes are generated through precipitation technique: the microorganism residue contains proteins, amino acids, inorganic matter, sugar, colloid, pigment, biotin, etc., and the other is calcium sulphate. • The first one can be dried and used as forage or supplied to forage factory and the second can be supplied to cement factories. 82 Lists amino acids used in the food industry. 83 Clean rooms 84 Airborne classification in EU GMP 85 Federal Standard 209D Class Limits 86 ISO14644-1 Standard 87

![fermentation[1].](http://s1.studyres.com/store/data/008290469_1-3a25eae6a4ca657233c4e21cf2e1a1bb-150x150.png)