* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Anionic polymerization

Survey

Document related concepts

Transcript

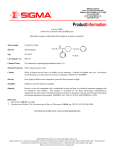

Anionic Polymerization 1. Introduction 2. Stereoregular Polymers 3. Anionic Polymerization - Initiators, monomers and mechanism - “Living” polymers, copolymerization 4. Coordination Polymerization - Ziegler-Natta polymerization 5. Cationic Polymerization 1. Introduction An ionic polymerization is an addition polymerization in which the growing chain ends bear a negative or a positive charge. These two alternative mechanisms are associated with different catalyst systems and different reaction conditions. Anionic polymerization Cationic polymerization 2. Stereoregular Polymers Ionic and coordination polymerizations can provide access to polymers that have a stereoregular structure. Any monomer molecule that possesses an symmetric center at a skeletal atom has the capacity to form stereoregular polymers. 2.1 Isotactic polymers Isotactic polymers are characterized by the presence of only one symmetry type of monomer residue in the chain. Ability to crystallize readily This is a consequence of the fact that the regular disposition of substituent groups along the chain permits the molecule to assume a regular helical conformation and allows adjacent chains to pack together in an ordered manner. H H H H H H H R R R R 2.2 Syndiotactic polymers Alternating configuration of residues Ability to crystallize readily because of the opportunities that exist for the formation of helices and for efficient chain packing Polyvinyl alcohol H R R H H R R H 2.3 Atactic or heterotactic polymers Contain no regular sequence of monomer residues along the chain Because of this structure, low tendency for crystallization Polyvinyl alcohol H R H R H R R H 3. Anionic and Coordination Polymerization 3.1 Initiators for Anionic Polymerization Radical anions (sodium naphthalenide) must be prepared from naphthalene and a sodium mirror in an ether type solvent. 3.2 Monomers for anionic polymerization Typical monomers, styrene, methyl methacrylate, and acrylonitrile The important thing to remember is that monomers which are suitable for anionic polymerization generally contain electronwithdrawing substituent groups. 3.3 A typical experimental procedure Figure. Apparatus for the anionic polymerization of styrene with the use of n-butyllithium as an initiator. 3.4 The Mechanism of anionic polymerization - Initiation - Propagation - Chain transfer or chain branching does not occur to any appreciable extent with anionic systems, and this is especially true if the reaction is carried out at low temperatures. - Termination Occurs either accidentally or deliberately when the active chain end reacts with a molecule of carbon dioxide or with water, alcohols or other protonic reagents. Example Styrene Polymerization_Initiator (n-butyllithium) Initiation: CH3CH2 CH Li + CH2 CH CH3CH2 CH CH2 CH Li CH3 CH3 Propagation: CH2 CH Li + CH2 CH CH2 CH CH2 CH Li Termination: CH2 CH Li + H OH CH2 CH2 + Li OH Characterization of Anionic Polymerization 1) In general, anion exist as not ion, but ion pair (gegen ion or counter ion or zwitter ion). More complex than radical polymerization 2) The rate of polymerization is fast at low temperature. 3) Termination not exist. (It occurs by accident.) When termination take places, it is occurred by proton of solvent or transfer agent, which is transfer of segment. Termination 1) Proton donor (H2O or ethanol) H CH2 C :- + C2H5OH CH2 CH2 + C2H5O 2) Hydride elimination, if there is no impurities 3) Polar monomer CH3 CH3 CH2 C:- Li+ + CH2 C COOCH3 COOCH3 CH3 O CH3 CH2 C C C CH2 COOCH3 + + Li CH3O 4) Backbiting or intramolecular reaction Cyclic trimer at the end of chain 3.5 “Living” Polymers The term “living” polymer is applied to ionic polymerizations that are not terminated. 1) Initiation occurs when an electron is transferred from sodium to the monomer to generate a radical anion 2) Dimerization of the radical anion then takes place to form a dianion 3) Propagation can then occur at both ends of the dimer by the insertion of monomer molecules into the ionic bonds. Sodium naphthalenide functions as a catalyst in a very similar way. The naphthalene radical anion either transfer an electron to the monomer to form a monomer radical anion, or the naphthalene radical anion itself may initiate monomer polymerization directly. - Electron transfer agents Initiation is very fast! Resonance hybrid styryl radical-anion Dianion One of the characteristic of “living” polymer systems is that they yield polymers with very narrow-weight distributions. Number of molecules The narrow molecular-weight distribution is largely a consequence of the rapidity of the initiation step. Chain length Extremely narrow molecular-weight distribution that is characteristic of anionic and radical-anionic polymerization products. 3.6 Copolymerization Because many anionic chain ends remain “alive,” particularly at low temperatures, even through the monomer has been consumed, chain growth can be restarted by the addition of more of the same monomer or addition of a different monomer. If a different monomer is added, a copolymer is formed. BBBBBAAAAACH2 2HCAAAAABBBBB Styrene-Butadiene-Styrene (SBS) Triblock copolymers Butadiene Living polystyrene Living styrene-butadiene block copolymer Dichlorodimethylsilane The end copolymer is capped with a dichlorosilane Dichlorodimethylsilane Another chain of living polystyrene Styrene-butadiene-styrene triblock copolymer Summary Anionic polymerization - Initiators (alkyl metal) - Initiation and propagation - Living polymers