* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Other types of electromagnetic clutches

Magnetic monopole wikipedia , lookup

Electromagnetic compatibility wikipedia , lookup

Wireless power transfer wikipedia , lookup

Lorentz force wikipedia , lookup

Electromotive force wikipedia , lookup

Multiferroics wikipedia , lookup

Magnetoreception wikipedia , lookup

High voltage wikipedia , lookup

Hall effect wikipedia , lookup

Magnetohydrodynamics wikipedia , lookup

Electric motor wikipedia , lookup

Force between magnets wikipedia , lookup

Scanning SQUID microscope wikipedia , lookup

Alternating current wikipedia , lookup

Magnetochemistry wikipedia , lookup

Superconductivity wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Electromagnetism wikipedia , lookup

Eddy current wikipedia , lookup

Superconducting magnet wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Induction heater wikipedia , lookup

Induction motor wikipedia , lookup

Stepper motor wikipedia , lookup

Faraday paradox wikipedia , lookup

Magnetic core wikipedia , lookup

Galvanometer wikipedia , lookup

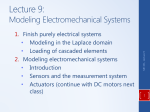

ELECTROMAGNETIC CLUTCHES & BRAKE Electromagnetic clutches operate electrically, but transmit torque mechanically. This is why they used to be referred to as electro-mechanical clutches. Over the years, EM became known as electromagnetic versus electro mechanical, referring more about their actuation method versus physical operation. Since the clutches started becoming popular over 60 years ago, the variety of applications and clutch designs has increased dramatically, but the basic operation remains the same.Single-face clutches make up approximately 90% of all electromagnetic clutch sales. This article mainly deals with these types of clutches. Alternative clutch designs are mentioned at the end of this article. Construction Electromagnetic clutch Horseshoe magnet red silver iron Double Flux clutch Triple flux clutch Ogura Industrial Typical 2 pole clutch Operation of a clutch Triple flux rotor with banana slots and bridges A horseshoe magnet (A-1) has a north and south pole. If a piece of carbon steel contacts both poles, a magnetic circuit is created. In an electromagnetic clutch, the north and south pole is created by a coil shell and a wound coil. In a clutch, (B1) when power is applied, a magnetic field is created in the coil (A2 blue). This field (flux) overcomes an air gap between the clutch rotor (A2 yellow) and the armature (A2 red). This magnetic attraction, pulls the armature in contact with the rotor face. The frictional contact, which is being controlled by the strength of the magnetic field, is what causes the rotational motion to start. The torque comes from the magnetic attraction, of the coil and the friction between the steel of the armature and the steel of the clutch rotor. For many industrial clutches, friction material is used between the poles. The material is mainly used to help decrease the wear rate, but different types of material can also be used to change the coefficient of friction (torque for special applications). For example, if the clutch is required to have an extended time to speed or slip time, a low coefficient friction material can be used and if a clutch is required to have a slightly higher torque (mostly for low rpm applications), a high coefficient friction material can be used. In a clutch, the electromagnetic lines of flux have to pass into the rotor, and in turn, attract and pull the armature in contact with it to complete clutch engagement. Most industrial clutches use what is called a single flux, two pole design (A-2). Mobile clutches of other specialty electromagnetic clutches can use a double or triple flux rotor (A-4). The double or trip flux refers to the number of north/south flux paths (A-6), in the rotor and armature. These slots (banana slots) (A-7) create an air gap which causes the flux path to take the path of least resistance when the faces are engaged. This means that, if the armature is designed properly and has similar banana slots, what occurs is a leaping of the flux path, which goes north south, north south (A-6). By having more points of contact, the torque can be greatly increased. In theory, if there were 2 sets of poles at the same diameter, the torque would double in a clutch. Obviously, that is not possible to do, so the points of contact have to be at a smaller inner diameter. Also, there are magnetic flux losses because of the bridges between the banana slots. But by using a double flux design, a 30%-50% increase in torque, can be achieved, and by using a triple flux design, a 40%-90% in torque can be achieved. This is important in applications where size and weight are critical, such as automotive requirements. The coil shell is made with carbon steel that has a combination of good strength and good magnetic properties. Copper (sometimes aluminum) magnet wire, is used to create the coil, which is held in shell either by a bobbin or by some type of epoxy/adhesive. To help increase life in applications, friction material is used between the poles on the face of the rotor. This friction material is flush with the steel on the rotor, since if the friction material was not flush, good magnetic traction could not occur between the faces. Some people look at electromagnetic clutches and mistakenly assume that, since the friction material is flush with the steel, that the clutch has already worn down, but this is not the case. Clutches used in most mobile applications, (automotive, agriculture, construction equipment) do not use friction material. Their cycle requirements tend to be lower than industrial clutches, and their cost is more sensitive. Also, many mobile clutches are exposed to outside elements, so by not having friction material, it eliminates the possibility of swelling (reduced torque), that can happen when friction material absorbs moisture. Basic operation The clutch has four main parts: field, rotor, armature, and hub (output) (B1). When voltage is applied the stationary magnetic field generates the lines of flux that pass into the rotor. (The rotor is normally connected to the part that is always moving in the machine.) The flux (magnetic attraction) pulls the armature in contact with the rotor (the armature is connected to the component that requires the acceleration), as the armature and the output start to accelerate. Slipping between the rotor face and the armature face continues until the input and output speed is the same (100% lockup). The actual time for this is quite short, between 1/200th of a second and 1 second.Disengagement is very simple. Once the field starts to degrade, flux falls rapidly and the armature separates. One or more springs hold the armature away from the rotor at a predetermined air gap. Voltage/current - and the magnetic field Right hand thumb rule:If a piece of copper wire was wound, around the nail and then connected to a battery, it would create an electro magnet. The magnetic field that is generated in the wire, from the current, is known as the “right hand thumb rule”. (V-1) The strength of the magnetic field can be changed by changing both wire size and the amount of wire (turns). EM clutches are similar; they use a copper wire coil (sometimes aluminum) to create a magnetic field. The fields of EM clutch can be made to operate at almost any DC voltage, and the torque produced by the clutch or brake will be the same, as long as the correct operating voltage and current is used with the correct clutch. If a 90 V clutch, a 48 V clutch and a 24 V clutch, all being powered with their respective voltages and current, all would produce the same amount of torque. However, if a 90 V clutch had 48 V applied to it, this would get about half of the correct torque output of that clutch. This is because voltage/current is almost linear to torque in DC electromagnetic clutches. A constant power supply is ideal if accurate or maximum torque is requiried from a clutch. If a non regulated power supply is used, the magnetic flux will degrade, as the resistance of the coil goes up. Basically, the hotter the coil gets the lower the torque will be, by about an average of 8% for every 20°C. If the temperature is fairly constant, but there may not be enough service factor in your design for minor temperature fluctuation. Over-sizing, the clutch would compensate for minor flux. This will allow the use a rectified power supply which is far less expensive than a constant current supply. Based on V = I × R, as resistance increases available current falls. An increase in resistance, often results from rising temperature as the coil heats up, according to: Rf = Ri × [1 + αCu × (Tf - Ti)] Where Rf = final resistance, Ri = initial resistance, αCu = copper wire’s temperature coefficient of resistance, 0.0039 °C-1, Tf = final temperature, and Ti = initial temperature. Torque Burnishing can affect initial torque of a clutch but there are also factors that affect the torque performance of a clutch in an application. The main one is voltage/current. In the voltage/current section, it was shown why a constant current supply is important to get full torque out of a clutch. When considering torque, is dynamic or static torque more important? For example, if a machine is running at a relatively low rpm (5 – 50 depending upon size) then dynamic torque is not a consideration since the static torque rating of the clutch will come closest to where the application is running. However, if a machine is running at 3,000rpm and the same full torque is required the result will not be the same because of the difference between static and dynamic torques. Almost all manufacturers put the static rated torque for their clutches in their catalog. If a specific response time is needed, the dynamic torque rating for a particular clutch at a given speed is required. In many cases, this can be significantly lower. Sometimes it can be less than ½ of the static torque rating. Most manufacturers publish torque curves showing the relationship between dynamic and static torque for a given series of clutch. (T-1) Over-excitation Over-excitation is used to achieve a faster response time. It’s when a coil momentarily receives a higher voltage then its nominal rating. To be effective the over excitation voltage must be significantly, but not to the point of diminishing returns, higher than the normal coil voltage. Three times the voltage typically gives around ⅓ faster response. Fifteen times the normal coil voltage will produce a 3 times faster response time. For example, a clutch coil that was rated for 6 V would need to put in 90 V to achieve the 3 times factor.With over-excitation the in-rush voltage is momentary. Although it would depend upon the size of the coil the actual time is usually only a few milliseconds. The theory is, for the coil to generate as much of a magnetic field as quickly as possible to attract the armature and start the process of acceleration or deceleration. Once the over excitation is no longer required the power supply to the clutch or brake would return to its normal operating voltage. This process can be repeated a number of times as long as the high voltage does not stay in the coil long enough to cause the coil wire to overheat. Clutch wear It is very rare that a coil would just stop working in an electromagnetic clutch. Typically, if a coil fails it is usually due to heat which has caused the insulation of the coil wire to break down. The heat can be caused by high ambient temperature, high cycle rates, slipping or applying too high of a voltage. Bushings can be used in some clutches that have low speed, low side loads or low operating hours. At higher loads and speeds, bearing mounted field/rotors and hubs are a better option. Like the coils, unless bearings are stressed beyond their physical limitations or become contaminated, they tend to have a long life and they are usually the second item to wear out.The main wear in electromagnetic clutches occurs on the faces of the mating surfaces. Every time a clutch is engaged during rotation a certain amount of energy is transferred as heat. The transfer which occurs during rotation wears both the armature and the opposing contact surface. Based upon the size of the clutch or brake, the speed and the inertia, wear rates will differ. For example a machine that was running at 500 rpm with a clutch and is now sped up to 1000 rpm would have its wear rate significantly increased because the amount of energy required to start the same amount of inertia is a lot higher at the higher speed. With a fixed armature design a clutch will eventually simply cease to engage. This is because the air gap will eventually become too large for the magnetic field to overcome. Zero gap or auto wear armatures can wear to the point of less than one half of its original thickness, which will eventually cause missed engagements.Designers can estimate life from the energy transferred each time the brake or clutch engages. Ee = [m × v2 × τd] / [182 × (τd + τl)] Where Ee = energy per engagement, m = inertia, v = speed, τd = dynamic torque, and τl = load torque. Knowing the energy per engagement lets the designer calculate the number of engagement cycles the clutch or brake will last: L = V / (Ee × w) Where L = unit life in number of cycles, V = total engagement area, and w = wear rate. Other types of electromagnetic clutches Multiple Disk Clutches Introduction - Multiple Disk clutches are used to deliver extremely high torque in a relatively small space. These clutches can be used dry or wet (oil bath). Running the clutches in an oil bath also greatly increases the heat dissipation capability, which makes them ideally suited for multiple speed gear boxes and machine tool applications. How it works - Multiple disk clutches operate via an electrical actuation but transmit torque mechanically. When voltage /current is applied to the clutch coil, the coil becomes an electromagnet and produces magnetic lines of flux. These lines of flux are transferred through the small air gap between the field and the rotor. The rotor portion of the clutch becomes magnetized and sets up a magnetic loop, which attracts both the armature and friction disks. The attraction of the armature compresses (squeezes) the friction disks, transferring the torque from the in inner driver to the out disks. The output disks are connected to a gear, coupling, or pulley via drive cup. The clutch slips until the input and output RPMs are matched. This happens relatively quickly typically (.2 - 2 sec). When the current/voltages are removed from the clutch, the armature is free to turn with the shaft. Springs hold the friction disk away from each other, so there is no contact when the clutch is not engaged, creating a minimal amount of drag. Electromagnetic tooth clutches Introduction - Of all the electromagnetic clutches, the tooth clutches provide the greatest amount of torque in the smallest overall size. Because torque is transmitted without any slippage, clutches are ideal for multi stage machines where timing is critical such as multi stage printing presses. Sometimes, exact timing needs to be kept, so tooth clutches can be made with a single position option which means that they will only engage at a specific degree mark. They can be used in dry or wet (oil bath) applications, so they are very well suited for gear box type drives.They should not be used in high speed applications or applications that have engagement speeds over 50 rpm otherwise damage to the clutch teeth would occur when trying to engage the clutch. How it Works – Electromagnetic Tooth clutches operate via an electric actuation but transmit torque mechanically. When voltage/current is applied to the clutch coil, the coil becomes an electromagnet and produces magnetic lines of flux. This flux is then transferred through the small gap between the field and the rotor. The rotor portion of the clutch becomes magnetized and sets up a magnetic loop, which attracts the armature teeth to the rotor teeth. In most instances, the rotor is consistently rotating with the input (driver). As soon as the clutch armature and rotor are engaged, lock up is 100%. When current/voltage is removed from the clutch field, the armature is free to turn with the shaft. Springs hold the armature away from the rotor surface when power is released, creating a small air gap and providing complete disengagement from input to output. Electromagnetic particle clutches Introduction – Magnetic particle clutches are unique in their design, from other electro-mechanical clutches because of the wide operating torque range available. Like a standard, single face clutch, torque to voltage is almost linear. However, in a magnetic particle clutch torque can be controlled very accurately. This makes these units ideally suited for tension control applications, such as wire winding, foil, film, and tape tension control. Because of their fast response, they can also be used in high cycle application, such as card readers, sorting machines, and labeling equipment. How it Works – Magnetic particles (very similar to iron filings) are located in the powder cavity. Without any voltage/current they sit in the cavity. However, when voltage/current is applied to the coil, the magnetic flux that is created tries to bind the particles together, almost like a magnetic particle slush. As the voltage/current is increased, the magnetic field builds, strengthening the binding of the particles. The clutch rotor passes through the bound particles, causing drag between the input and the output during rotation. Depending upon the output torque requirement, the output and input may lock at 100% transfer.When voltage/current is removed from the clutch, the input is free to turn with the shaft. Since the magnetic particle is in the cavity, all magnetic particle units have some type of minimum drag associated with them. Hysteresis-powered clutch Introduction – Electrical hysteresis units have an extremely high torque range. Since these units can be controlled remotely, they are ideal for testing application where varying torque is required. Since drag torque is minimal, these units offer the widest available torque range of any electromagnetic product. Most applications involving powered hysteresis units are in test stand requirements. Since all torque is transmitted magnetically, there is no contact, so no wear occurs to any of the torque transfer components providing for extremely long life. How it works – When the current / voltage is applied to the field, it creates magnetic flux. This passes into the rotor portion of the field. The hysteresis disk physically passes through the rotor, without touching it. These disks have the ability to become magnetized depending upon the strength of the flux (this dissipates as flux is removed). This means, as the rotor rotates, magnetic drag between the rotor and the hysteresis disk take place causing rotation. In a sense, the hysteresis disk is pulled after the rotor. Depending upon the output torque required, this pull eventually can match the input speed, giving a 100% lockup. When current / voltage is removed from the clutch, the armature is free to turn and no relative force is transmitted between either member. Therefore, the only torque seen between the input and the output is bearing drag. Electromagnetic brakes operate electrically, but transmit torque mechanically. This is why they used to be referred to as electro-mechanical brakes. Over the years, EM brakes became known as electromagnetic, referring to their actuation method. Since the brakes started becoming popular over sixty years ago, the variety of applications and brake designs has increased dramatically, but the basic operation remains the same. Single face electromagnetic brakes make up approximately 80% of all of the power applied brake applications. This article mainly concentrates on these brakes. Alternative designs are shown at the end of this article. Construction Horseshoe magnet red silver iron A horseshoe magnet (A-1) has a north and south pole. If a piece of Iron contacts both poles, a magnetic circuit is created. In an electromagnetic brake, the north and south pole is created by a coil shell and a wound coil. In a brake, the armature is being pulled against the brake field. (A-3) The frictional contact, which is being controlled by the strength of the magnetic field, is what causes the rotational motion to stop. All of the torque comes from the magnetic attraction and coefficient of friction between the steel of the armature and the steel of the brake field. For many industrial brakes, friction material is used between the poles. The material is mainly used to help decrease the wear rate. But different types of material can also be used to change the coefficient of friction (torque) for special applications. For example, if the brake was required to have an extended time to stop or slip time, a low coefficient material can be used. Conversely, if the brake was required to have a slightly higher torque (mostly for low RPM applications), a high coefficient friction material could be used.In a brake, the electromagnetic lines of flux have to attract and pull the armature in contact with it to complete brake engagement. Most industrial applications use what is called a single-flux two-pole brake. The coil shell is made with carbon steel that has a combination of good strength and good magnetic properties. Copper (sometimes aluminum) magnet wire, is used to create the coil, which is held in shell either by a bobbin or by some type of epoxy/adhesive.To help increase life in applications, friction material is used between the poles. This friction material is flush with the steel on the coil shell, since if the friction material was not flush, good magnetic traction could not occur between the faces. Some people look at electromagnetic brakes and mistakenly assume that, since the friction material is flush with the steel, that the brake has already worn down, but this is not the case. Basic OperationThere are three parts to an electromagnetic brake: field, armature, and hub (which is the input on a brake) (B-2). Usually the magnetic field is bolted to the machine frame (or uses a torque arm that can handle the torque of the brake). So when the armature is attracted to the field the stopping torque is transferred into the field housing and into the machine frame decelerating the load. This can happen very fast (.1-3sec).Disengagement is very simple. Once the field starts to degrade flux falls rapidly and the armature separates. A spring(s) hold the armature away from its corresponding contact surface at a predetermined air gap.[4] Electromagentic brake Torque Burnishing can affect initial torque of a brake but there are also factors that affect the torque performance of a brake in an application. The main one is voltage/current. In the voltage/current section we showed why a constant current supply is important to get full torque out of the brake.When considering torque, the question of using dynamic or static torque for the application is key? For example, if running a machine at relatively low rpm (5 – 50 depending upon size) there is minimal concern with dynamic torque since the static torque rating of the brake will come closest to where it is running. However, when running a machine at 3,000rpm and applying the brake at its catalog torque, at that rpm, is misleading. Almost all manufacturers put the static rated torque for their brakes in their catalog. So, when trying to determine a specific response rate for a particular brake, the dynamic torque rating is needed. In many cases this can be significantly lower. It can be less than half of the static torque rating. Most manufacturers publish torque curves showing the relationship between dynamic and static torque for a given series of brake. Over Excitation Electromagnetic-Power-Off-Brake Over-excitation is used to achieve a faster response time. It is when a coil momentarily receives a higher voltage than its nominal rating. To be effective, the over-excitation voltage must be significantly, but not to the point of diminishing returns, higher than the normal coil voltage. Three times the voltage typically gives around 1/3 faster response. Fifteen times the normal coil voltage will produce a 3 times faster response time.With over-excitation, the in-rush voltage is momentary. Although it would depend upon the size of the coil, the actual time is usually only a few milliseconds. The theory is, for the coil to generate as much of a magnetic field as quickly as possible to attract the armature and start the process of deceleration. Once the over-excitation is no longer required, the power supply to the brake would return to its normal operating voltage. This process can be repeated a number of times as long as the high voltage does not stay in the coil long enough to cause the coil wire to overheat. Wear It is very rare that a coil would just stop working in an electromagnetic brake. Typically if a coil fails it is usually due to heat which has caused the insulation of the coil wire to break down. That heat can be caused by high ambient temperature, high cycle rates, slipping or applying too high of a voltage. Most brakes are flanged mounted and have bearings but some brakes are bearing mounted and like the coils, unless bearings are stressed beyond their physical limitations or become contaminated, they tend to have a long life and they are usually the second item to wear out.The main wear in electromagnetic brakes occurs on the faces of the mating surfaces. Every time a brake is engaged during rotation a certain amount of energy is transferred as heat. The transfer, which occurs during rotation, wears both the armature and the opposing contact surface. Based upon the size of the brake, the speed and the inertia, wear rates will differ. With a fixed armature design a brake will eventually simply cease to engage. This is because the air gap will eventually become too large for the magnetic field to overcome. Zero gap or auto wear armatures can wear to the point of less than one half of its original thickness, which will eventually cause missed engagements. Other Types of Electromagnetic Brakes Electromagnetic Power Off Brake Electormagnetic Power Off Brake Spring Set Introduction - Power off brakes stop or hold a load when electrical power is either accidentally lost or intentionally disconnected. In the past, some companies have referred to these as "fail safe" brakes. These brakes are typically used on or near an electric motor. Typical applications include robotics, holding brakes for Z axis ball screws and servo motor brakes. Brakes are available in multiple voltages and can have either standard backlash or zero backlash hubs. Multiple disks can also be used to increase brake torque, without increasing brake diameter. There are 2 main types of holding brakes. The first is spring applied brakes. The second is permanent magnet brakes. How It Works Spring Type - When no electricity is applied to the brake, a spring pushes against a pressure plate, squeezing the friction disk between the inner pressure plate and the outer cover plate. This frictional clamping force is transferred to the hub, which is mounted to a shaft. Permanent Magnet Type – A permanent magnet holding brake looks very similar to a standard power applied electromagnetic brake. Instead of squeezing a friction disk, via springs, it uses permanent magnets to attract a single face armature. When the brake is engaged, the permanent magnets create magnetic lines of flux, which can turn attract the armature to the brake housing. To disengage the brake, power is applied to the coil which sets up an alternate magnetic field that cancels out the magnetic flux of the permanent magnets. Both power off brakes are considered to be engaged when no power is applied to them. They are typically required to hold or to stop alone in the event of a loss of power or when power is not available in a machine circuit. Permanent magnet brakes have a very high torque for their size, but also require a constant current control to offset the permanent magnetic field. Spring applied brakes do not require a constant current control, they can use a simple rectifier, but are larger in diameter or would need stacked friction disks to increase the torque. Electromagnetic Particle Brake Magnetic Particle Brake Introduction - Magnetic particle brakes are unique in their design from other electro-mechanical brakes because of the wide operating torque range available. Like an electro-mechanical brake, torque to voltage is almost linear; however, in a magnetic particle brake, torque can be controlled very accurately (within the operating RPM range of the unit). This makes these units ideally suited for tension control applications, such as wire winding, foil, film, and tape tension control. Because of their fast response, they can also be used in high cycle applications, such as magnetic card readers, sorting machines and labeling equipment. How It Works - Magnetic particles (very similar to iron filings) are located in the powder cavity. When electricity is applied to the coil, the resulting magnetic flux tries to bind the particles together, almost like a magnetic particle slush. As the electric current is increased, the binding of the particles becomes stronger. The brake rotor passes through these bound particles. The output of the housing is rigidly attached to some portion of the machine. As the particles start to bind together, a resistant force is created on the rotor, slowing, and eventually stopping the output shaft. When electricity is removed from the brake, the input is free to turn with the shaft. Since magnetic particle powder is in the cavity, all magnetic particle units have some type of minimum drag associated with them. Electromagnetic Hysteresis Power Brake Electomagnetic Hysteresis Power Brake Introduction - Electrical hysteresis units have an extremely wide torque range. Since these units can be controlled remotely, they are ideal for test stand applications where varying torque is required. Since drag torque is minimal, these units offer the widest available torque range of any of the hysteresis products. Most applications involving powered hysteresis units are in test stand requirements. How It Works - When electricity is applied to the field, it creates an internal magnetic flux. That flux is then transferred into a hysteresis disk passing through the field. The hysteresis disk is attached to the brake shaft. A magnetic drag on the hysteresis disk allows for a constant drag, or eventual stoppage of the output shaft. When electricity is removed from the brake, the hysteresis disk is free to turn, and no relative force is transmitted between either member. Therefore, the only torque seen between the input and the output is bearing drag. Multiple Disk Brakes Electromagnetic Multiple Disk Brake Introduction - Multiple disk brakes are used to deliver extremely high torque within a small space. These brakes can be used either wet or dry, which makes them ideal to run in multi speed gear box applications, machine tool applications, or in off road equipment. How It Works - Electro-mechanical disk brakes operate via electrical actuation, but transmit torque mechanically. When electricity is applied to the coil of an electromagnet, the magnetic flux attracts the armature to the face of the brake. As it does so, it squeezes the inner and outer friction disks together. The hub is normally mounted on the shaft that is rotating. The brake housing is mounted solidly to the machine frame. As the disks are squeezed, torque is transmitted from the hub into the machine frame, stopping and holding the shaft. When electricity is removed from the brake, the armature is free to turn with the shaft. Springs keep the friction disk and armature away from each other. There is no contact between breaking surfaces and minimal drag.