* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Scanning Probe Microscopy

Anti-reflective coating wikipedia , lookup

Super-resolution microscopy wikipedia , lookup

X-ray fluorescence wikipedia , lookup

Confocal microscopy wikipedia , lookup

Optical coherence tomography wikipedia , lookup

Optical flat wikipedia , lookup

Retroreflector wikipedia , lookup

Chemical imaging wikipedia , lookup

Reflection high-energy electron diffraction wikipedia , lookup

Rutherford backscattering spectrometry wikipedia , lookup

Gaseous detection device wikipedia , lookup

Surface plasmon resonance microscopy wikipedia , lookup

Scanning tunneling spectroscopy wikipedia , lookup

Vibrational analysis with scanning probe microscopy wikipedia , lookup

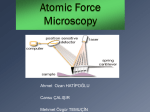

Scanning Probe Microscopy Binnig & Rohrer Nobel prize 1986 SPM Principles • • All of the techniques are based upon scanning a probe just above a surface whilst monitoring some interaction between the probe and the surface. The interaction that is monitored in: STM - is the tunnelling current between a metallic tip and a conducting substrate which are in very close proximity but not actually in physical contact. AFM - is the van der Waals force between the tip and the surface; this may be either the short range repulsive force (in contact-mode) or the longer range attractive force (in noncontact mode). SPM • For the techniques to provide information on the surface structure at the atomic level: the position of the tip with respect to the surface must be very accurately controlled (to within about 0.1 Å) by moving either the surface or the tip. It is possible to accurately control the relative positions of tip and surface by ensuring good vibrational isolation of the microscope and using sensitive piezoelectric positioning devices. • the tip must be very sharp - ideally terminating in just a single atom at its closest point of approach to the surface. STM If the tip is biased with respect to the surface, electrons can tunnel between the two, provided the separation of the tip and surface is sufficiently small - this gives rise to a tunnelling current. • The direction of current flow is determined by the polarity of the bias. If the sample is biased -ve with respect to the tip, then electrons will flow from the surface to the tip, whilst if the sample is biased +ve with respect to the tip, then electrons will flow from the tip to the surface. STM Quantum mechanical tunnelling permits particles to tunnel through a potential barrier which they could not surmount according to the classical laws of physics. The probability of tunnelling is exponentiallydependent upon the distance of separation between the tip and surface : the tunnelling current is therefore a very sensitive probe of this separation. STM Modes • • Imaging of the surface topology may then be carried out in one of two ways: in constant height mode A plot of the tunnelling current v's tip position therefore shows a periodic variation which matches that of the surface structure. in constant current mode Normal way of imaging the surface is to maintain the current constant whilst the tip is scanned across the surface by adjusting the tip's height above the surface so that the tunnelling current does not vary with the lateral tip position. The image is then formed by plotting the tip height (strictly, the voltage applied to the z-piezo) v's the lateral tip position. STM Links & Images • Scanning Tunneling Microscopy Tutorial • IBM STM Gallery • Veeco Nanotheatre Nickel (110) Xenon on Nickel (110) When you look through the hole in the xenon atom you see a nickel atom located directly beneath. Evidently, xenon binds to the on-top site. More Xenon on Nickel (110) HOPG AFM 1. Laser 2. Mirror 3. Photodetector 4. Amplifier 5. Register 6. Sample 7. Probe 8. Cantilever An atomically sharp tip is scanned over a surface with feedback mechanisms to maintain the tip at a constant force (to obtain height information), or height (to obtain force information) above the sample. Tips are typically made from Si3N4 or Si, and extended down from the end of a cantilever. A diode laser is focused onto the back of the reflective cantilever. As the tip scans the surface of the sample, moving up and down with the contour of the surface, the laser beam is deflected into a dual element photodiode which measures the difference in light intensities between the upper and lower photodetectors, and then converts to voltage. AFM • Resolution depends on the tip sharpness AFM Modes • • • In contact AFM electrostatic and/or surface tension forces from the adsorbed gas layer pull the scanning tip toward the surface. It can damage samples and distort image data. Therefore, contact mode imaging is heavily influenced by frictional and adhesive forces compared to non-contact or tapping mode. Non-contact imaging generally provides low resolution and can also be hampered by the contaminant layer which can interfere with oscillation. TappingMode AFM was developed as a method to achieve high resolution without inducing destructive frictional forces both in air and fluid. With the TappingMode technique, the very soft and fragile samples can be imaged successfully. Also, incorporated with Phase Imaging, the tapping mode AFM can be used to analyze the components of the membrane. Images • Phase imaging of a polymer blend AFM Images AFM image of short DNA fragment with RNA polymerase molecule bound to transcription recognition site. 238nm scan size. Courtesy of Bustamante Lab, Chemistry Department, University of Oregon, Eugene OR Images • 10 µm scan Tapping Mode image of a CD (left) and a DVD (right) surface disc.