* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Fin Heat Transfer Rate

Space Shuttle thermal protection system wikipedia , lookup

Intercooler wikipedia , lookup

Building insulation materials wikipedia , lookup

Solar air conditioning wikipedia , lookup

Dynamic insulation wikipedia , lookup

Cogeneration wikipedia , lookup

Underfloor heating wikipedia , lookup

Heat exchanger wikipedia , lookup

Thermoregulation wikipedia , lookup

Copper in heat exchangers wikipedia , lookup

Heat equation wikipedia , lookup

R-value (insulation) wikipedia , lookup

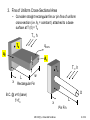

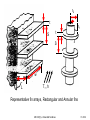

Heat Transfer Heat Transfer from Extended Surfaces ME 327(6) – Extended Surfaces 1 of 32 Heat Transfer from Extended Surfaces 1. General Considerations – Extended Surface refers to a solid material in which energy is transferred by conduction within its boundaries and by convection/radiation between its boundaries and the surroundings – Fins are extended surfaces used primarily to enhance the heat transfer rate between the solid fins and an adjoining fluid – For a constant surface temperature Ts , heat transfer rate can be increased by increasing h or reducing the temperature T of the surroundings. None of these measures is usually practicable – Heat transfer rate is usually increased by employing extended surfaces to increase the heat transfer area by convection – Fin material should have high k to limit temperature variation from its base to the tip (want T=Tbase) T∞, h T∞, h A q = hA (Ts - T∞) Bare Surface Ts, A ME 327(6) – Extended Surfaces Finned Surface Ts 2 of 32 Fin Examples Liquid Flow Gas Flow Liquid Flow Gas Flow t w r x x Straight fin of uniform cross section Straight fin of nonuniform cross section x Annular fin ME 327(6) – Extended Surfaces Pin fin 3 of 32 2. General Conduction Analysis – Consider the energy balance for a differential area of an extended surface shown below: dqconv qx+dx qx x • dAs Ac(x) dx Assumptions • • • • 1-D, S.S, conduction in the x direction with constant k Radiation from surface negligible or qr = 0 No heat generation or g = 0 h is uniform over the entire surface ME 327(6) – Extended Surfaces 4 of 32 • Energy Balance yields: qx qx dx dqconv where dqconv h dA s (Ts T ) Substituting dT dT d dT kA c kA c k A c dx hdA s T T dx dx dx dx or d2T 1 dA c dT 1 h dA s (T T ) 0 2 A dx dx A k dx s dx c c • General form of the energy equation for extended surfaces. Solution is obtained by applying appropriate B.C.’s to obtain temperature distribution and subsequent heat flow ME 327(6) – Extended Surfaces 5 of 32 3. Fins of Uniform Cross-Sectional Area – Consider straight rectangular fins or pin fins of uniform cross-section (i.e. Ac = constant ) attached to a base surface at T (0) = Tb T∞, h Tb qconv qf Ac t T ∞, h Tb x L w Rectangular Fin B.C. @ x=0 (base) T=Tb D L x Pin Fin ME 327(6) – Extended Surfaces 6 of 32 d2T 1 dA c dT 1 h dA s (T T ) 0 2 A dx dx A k dx s dx c c • Since Ac = constant dA c 0 dx • Surface area As = P x , where P is the Perimeter dA s P dx d2T hP T T 0 • Heat equation reduces to: (1) 2 kA dx c • Assumptions: – 1-D, S.S. conduction, no energy generation ( g = 0), and constant Ac – To simply (1), Define excess temperature as: d dT T∞=Constant and dx dx ( x ) T( x ) T d2 2 m 0 2 dx (2) where m2 Sub. into (1) hP kA c General Solution to (2) is ( x ) C1emx C2e mx ME 327(6) – Extended Surfaces 7 of 32 • Hyperbolic functions 1 x sinh( x ) e e x 2 cosh( x ) e x e x sinh( x ) tanh( x ) x e e x cosh( x ) • 1 x e e x 2 See table B-1 is Appendix B of Text for values of hyperbolic functions for x = 0 to 10 B.C.’s 1. θ(x=0) = Tb - T∞ = θb 2. at x = L (tip condition) – This corresponds to any of the following four physical conditions (Cases A to D): • Case (A): Convection heat transfer from the tip. ME 327(6) – Extended Surfaces 8 of 32 • Energy Balance at tip surface yields: qconv kA c Tb qf = qb hA c T(L ) T dT dx T ∞, h θb x=0 dT kA c hA c T(L ) T dx x L x=L or ME 327(6) – Extended Surfaces d k h (L ) dx x L 9 of 32 • From the general solution ( x ) C1emx C2emx • At x = 0, (0) b C1e0 C2e0 C1 C2 • At x = L , where h(L) k d dx h C1emL C2emL km C2emL C1emL (3) (4) • Equations (3) and (4) are then solved to obtain C1 and C2. C1 and C2 are substituted to obtain the general solution: cosh m(L x ) h mk sinh m(L x ) b cosh mL h mk sinh m(L x ) ME 327(6) – Extended Surfaces 10 of 32 • Total heat energy transferred by fin (qf) may be evaluated from Fourier’s Law: d qf qb kA c dx x 0 • Knowing θ(x), qf is estimated to be: sinh mL h mk cosh mL qf hPkA c b cosh mL h mk sinh mL or qf M sinh mL h mk cosh mL cosh mL h mk sinh mL where M hPkA c b • And θb is the temperature difference (excess) at the base, θ b = Tb - T∞ ME 327(6) – Extended Surfaces 11 of 32 • Case (B): Adiabatic condition at the tip (Negligible Convection at tip) • Temperature Distribution is: cosh m(L x ) b cosh mL qf qL x=L and x=0 qf M tanh( mL ) θb d 0 dx θL where M hPkA c b ME 327(6) – Extended Surfaces 12 of 32 • Case (C): Prescribed Temperature at the Tip • Temperature Distribution is: L sinh(mx ) sinh m(L x ) b b sinh(mL ) and qf M cosh mL L θb b sinh mL qf x=L x=0 θ= θL where M hPkA c b ME 327(6) – Extended Surfaces 13 of 32 • Case (D): Infinite Fin ( L → ∞, θL → 0) • Temperature Distribution is: e mx b L , (L ) 0 T T and qf M where x=0 T T 0 θb M hPkA c b ME 327(6) – Extended Surfaces 14 of 32 ME 327(6) – Extended Surfaces 15 of 32 Fin Performance 1. Fin Effectiveness (εf) εf = ____Fin Heat Transfer Rate____ Heat Transfer Rate Without Fin f • • qf hA c,b b θb= Tb-T∞ θb qf Ac εf ≥ 0, typically ≥ 2 Etc... Ac,b is the fin’s cross-sectional area at the base. In the case of an infinite fin (case D) 1 2 hPkA c b kP f hA c,b b hA c,b b hA c qf ME 327(6) – Extended Surfaces 16 of 32 1 2 hPkA C b kP f hA c,b b hA c,b b hA c qf Typical h values Effectiveness is enhance by: Process 1. Materials with high k (copper, aluminum alloys, etc.) 2. High P/A ratios (example: thin, closely space fins of compact heat exchangers) 3. Transfer between two fluids: Fins are used to enhance the heat transfer to the fluid with the lower h (to give maximum q). This is usually the gas side. For adiabatic tip, 98% of maximum heat transfer is reached when mL = 2.3 Fin’s Length L ≤ 2.3m m h (W / m2 K) Free Convection Gases 2 -25 Liquids 50 -1000 Forced Convection Gases 35 -250 Liquids 50 -20,000 with Phase Change Boiling or Condensation 2500 -100,000 hP kA c ME 327(6) – Extended Surfaces 17 of 32 2. Fin Resistance (R t,f) Tb T b qf R t,f R t,f b R t,f qf qf Tb R t,f and b qb Rt,b q f f qb T 1 R t,b hA c,b qb Rt,b f Rt,f Tb R t,b T 1 hA c,b • If the fin is to enhance heat transfer, its resistance must not exceed that of the exposed base. ME 327(6) – Extended Surfaces 18 of 32 3. Fin Efficiency q qf f f qmax hA f b qf b R t,f Where Af = surface area of fin = PL for the straight fin R t,f 1 hA f f qf Tb • For the adiabatic tip condition, f M tanh mL hPL b where T R t,f M hPkA c b or tanh mL f mL • For straight fins with active tip (convection at the tip) tanh mLc f mLc sinh mL h mk cosh mL Use simple M form and Lc qf cosh mL h mk sinh mL f qmax hPL b ME 327(6) – Extended Surfaces 19 of 32 1. Rectangular cross-section P = 2 W when W > t Af = 2 W Lc Ap = Profile area = Lc t w L Lc = L + t/2 Lc = corrected fin length with adiabatic tip assumption – Error due to assumption of adiabatic tip is negligible for t 2 ht 0.06 k – Areas required to calculate heat transfer rate (q) ? q hA f f Tb T Need: Af, Lc, Ap tanh mLc f mLc 1 2 1 2 2h 3 hP Lc 2 L c mL c kA kA c p – Properties needed to determine the fin efficiency (f) ? • Graphs have fin efficiency as a function of: h Lc kA p 3 ME 327(6) – Extended Surfaces 1 2 2 20 of 32 2. Triangular Cross-Section Af = 2 w [L2 + (t/2)2]1/2 Lc = L Ap = L t/2 t 2 L 3. Parabolic Cross-Section Af = 2.05 w [L2 + (t/2)2]1/2 Lc = L Ap = L t/3 4. Annular Fins A f 2 r22C r12 Lc L t 2 r2c r2 t 2 A p Lc t w t 2 r1 t ME 327(6) – Extended Surfaces L r2 L 21 of 32 • 3.18 ME 327(6) – Extended Surfaces 22 of 32 • 3.19 ME 327(6) – Extended Surfaces 23 of 32 Fins With Non-Uniform Cross Sectional Area • In an annular fin t is constant but the cross sectional area (2 π r t) varies with r. • General form of fin equation is: d2T 1 dT 2h T T 0 2 r dr kt dr where m2 2h kt d2 1 d 2 m 0 2 r dr dr or and T T • This is the modified Bessel Equation of order zero, with general solution of the form: (r ) C1I0 (mr ) C2K 0 (mr ) where I0 = Modified zero order Bessel function of First kind K0 = Modified zero order Bessel function of Second kind ME 327(6) – Extended Surfaces 24 of 32 d 0 • With θ(r1) = θb and adiabatic tip such that dr r2 C1 and C2 are determined and the temperature distribution is: I0 (mr1)K1(mr2 ) K 0 (mr1)I1(mr2 ) b I0 (mr1)K1(mr2 ) K 0 (mr1)I1(mr2 ) Where dI0 (mr ) I1(mr ) d(mr ) dK 0 (mr ) K1(mr ) d(mr ) Modified Bessel function of first kind Modified Bessel function of second kind • Bessel functions are tabulated in appendix B (text) ME 327(6) – Extended Surfaces 25 of 32 qf kA c,b dT dr r r1 d qf k 2r1t dr r r1 K (mr )I (mr ) I (mr )K (mr ) qf 2kr1tbm 1 1 1 2 1 1 1 2 K 0 (mr1)I1(mr2 ) I0 (mr1)K1(mr2 ) f qf 2h r22 r12 b R t,f 1 h A f f Table 3-5 shows the efficiency and surface area for common fin geometries. Profile area and Volume are also shown. V wAp ME 327(6) – Extended Surfaces 26 of 32 ME 327(6) – Extended Surfaces 27 of 32 ME 327(6) – Extended Surfaces 28 of 32 ME 327(6) – Extended Surfaces 29 of 32 • Actual fin heat transfer rate, qf, could be calculated from qmax using the expression: qf f qmax f (hA f b ) • Overall Surface Efficiency For Fin Array qt qt o qmax hA t b Where qt hA b,bare b NhA f f b = Total heat transfer rate and A t A f A b,bare = total exposed area Thus: NAf 1 f o 1 At Where N = total number of fins ME 327(6) – Extended Surfaces 30 of 32 r2 t r1 t S S w L T ∞, h Representative fin arrays, Rectangular and Annular fins ME 327(6) – Extended Surfaces 31 of 32 Problem 3.116 ME 327(6) – Extended Surfaces 32 of 32