* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Feedback-induced catastrophic optical mirror damage

Optical aberration wikipedia , lookup

Laser beam profiler wikipedia , lookup

Ultraviolet–visible spectroscopy wikipedia , lookup

Vibrational analysis with scanning probe microscopy wikipedia , lookup

Ellipsometry wikipedia , lookup

Nonimaging optics wikipedia , lookup

Confocal microscopy wikipedia , lookup

Super-resolution microscopy wikipedia , lookup

Anti-reflective coating wikipedia , lookup

Magnetic circular dichroism wikipedia , lookup

Optical rogue waves wikipedia , lookup

Haptic technology wikipedia , lookup

Fiber-optic communication wikipedia , lookup

Retroreflector wikipedia , lookup

Photon scanning microscopy wikipedia , lookup

Optical amplifier wikipedia , lookup

Optical coherence tomography wikipedia , lookup

Silicon photonics wikipedia , lookup

Nonlinear optics wikipedia , lookup

Photonic laser thruster wikipedia , lookup

Passive optical network wikipedia , lookup

Ultrafast laser spectroscopy wikipedia , lookup

Interferometry wikipedia , lookup

Harold Hopkins (physicist) wikipedia , lookup

3D optical data storage wikipedia , lookup

Mode-locking wikipedia , lookup

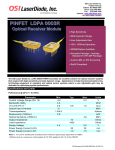

Feedback-induced catastrophic optical mirror damage (COMD) on 976nm broad area single emitters with different AR reflectivity Britta Leonhäuser, Heiko Kissel*, Andreas Unger, Bernd Köhler, and Jens Biesenbach DILAS Diodenlaser GmbH, Galileo-Galilei-Str. 10, 55129 Mainz, Germany ABSTRACT We have carried out a comprehensive study on 976nm single emitters with different AR coatings (1%, 3%, 4%, and 5%), which have been exposed to optical feedback to investigate damages caused by back-reflected light and how to prevent them. By observing the near-field pattern while varying the probe current, we got information about the influence on filamentation and on peak-power densities with and without external optical feedback. For constant feedback strength, filamentation became more pronounced and more dynamic with increasing current. We observed bistable and chaotic “jumping” of high-intensity filaments. For usual operation currents and external feedback strengths of ≥4%, single emitters with low AR coating show COMDs; their positions correlate with excessive peaking in the near-field pattern. Finally we found that an increasing AR reflectivity depletes the influence of feedback light on the near-field pattern as well as on the emission spectra and lowers the risk of COMD. Keywords: broad area laser, single emitter, external feedback, AR reflectivity, COMD 1. INTRODUCTION Today broad area semiconductor lasers (BALs) have found a wide range of industrial, medical, scientific, space and military applications including the pumping of solid-state, disk and fiber lasers [1]. These high-power diode lasers are the most efficient narrow-band light sources and convert up to 73 percent of electrical energy into light [2]. To achieve higher output powers, it has become common to increase the laser cavity lengths leading to improved thermal resistances but decreased wall-plug efficiencies. To prevent smaller wall-plug efficiencies, the reflectivity of the antireflection (AR) coating on the front facet has to be lowered. In this way, high output powers (up to 20W from a 100µm wide single emitter) and efficiencies of more than 65% are realized for cavity lengths of ≥ 4mm with AR~1%. High output powers also account for very high power densities at the front facet of BALs, which can destroy the devices [3,4]. Especially, in case of external optical feedback to a BAL (e.g. from optical components like micro-lenses or fiber ends), instabilities and sudden failures as well as accelerated degradation can occur [5,6]. We have observed, that the life time of usual 976nm laser diodes in pump modules is decreased compared to single laser diodes tested without optical feedback. The main failure cause with external optical feedback was catastrophic optical (mirror) damage [CO(M)D]. In this paper, we will report on the behavior of 976nm single emitters with different AR coatings (1%, 3%, 4%, and 5%), which have been exposed to different strengths of optical feedback to investigate damages by back-reflected light and how to prevent them. By observing the near-field pattern while varying the probe current, we got information about the influence on filamentation and on peak-power densities with and without external feedback. We have investigated the expected correlation between high-intensity filaments in the near-field pattern in case of optical feedback and the positions of CO(M)Ds. The near-field pattern is shown to be more stable in diodes with increasing AR reflectivity under external feedback – also lowering the risk of CO(M)D. *[email protected]; phone +49-6131-9226-227; fax +49-6131-9226-255; www.dilas.com 2. LASER DIODES WITH EXTERNAL FEEDBACK Let us first consider a BAL without optical feedback. Observing the near-field pattern of such a BAL, one may expect a top-hat shaped distribution. In fact, the near-field shows an intensity distribution with pronounced maxima and minima. This is due to nonlinear effects in the laser medium, such as nonlinear ohmic heating or nonlinear electron distribution as explained in Ref. [7]. The initial uniform wave front gets perturbed which leads to spatial modulation. Regions with larger wave front amplitudes cause more stimulated emission by electron-hole recombination. Therefore the electron concentration decreases and leads to an increased refractive index. Traveling through the medium, the wave front comes across regions with higher or lower refractive indices. There, the phase velocity is lowered or accelerated, which finally leads to a non-uniform intensity distribution, the so-called filamentation. The mathematical description of the filamentation development is given in Ref. [7]. The authors assume a semiconductor laser heterojunction amplifier under forward bias, where the electron concentration in the conduction band and the hole concentration in the valence band are high enough to cause stimulated transitions of the electrons into the valence band. They assemble an equation for the rate of these stimulated transitions per second and unit volume containing the density of states and a line shape function. Finding expressions for the density and the shape and substituting them into the rate equation, they get a general term that can be reduced to a simple form when the steady state is considered. This rate equation (see Eq.(2) in Ref. [7]) is related to the intensity, which is a function of x, y and z, the local coordinates. To analyze the development of instabilities, the electrical field has to be perturbed. Via the permittivity and the wave equation of the electromagnetic field one finally gets an expression for the perturbation growth that permits predication of the filamentation. In our experiments, we observed the near-field pattern to be stable at small injection currents. It changes its shape with increasing current (see e.g. Section 4.3). Because of the local intensity maxima, the BAL is likely to be destroyed by a CO(M)D in regions with enhanced wave front amplitudes or peak-power densities on the front facet, respectively, as will be shown later. The probability of CO(M)D occurrence increases when external optical feedback is applied to the laser diode; it increases the optical load at the outcoupling AR facet and also within the diode laser cavity. External optical feedback also changes the emission characteristics of a laser diode regarding spectrum [8] and near-field pattern as demonstrated in the following. An easy way to realize optical feedback is simply placing a mirror in front of a laser’s outcoupling facet. The mirror reflects the emitted light back into the laser cavity as schematically shown in Fig. 1. Figure 1. Scheme of an easy setup for external optical feedback. The electrical field of the back reflected light takes effect on the electrical field within the laser cavity. This influences the charged carrier density which varies the refractive index. As shown by Lang and Kobayashi [8], the optical length of the internal cavity changes with the refractive index and therefore the spectral behavior and the near-field pattern are modified. The mathematical description of semiconductor lasers with feedback can be found in Ref. [8]. One aligns the rate equation for lasing activity and adds a feedback term to it: ( ) { ( ) ( ( ) )} ( ) ⏟( ) ( ) , (1) where N(n) is the diode cavity longitudinal mode resonant frequency, the transient time, 0 the cavity loss of the diode cavity and is related to cavity parameters. Discussing the steady state conditions and the dynamic stability leads to the variation in the refractive index of the diode depending on the oscillation frequency, which is influenced by the interference of external and internal cavity. Furthermore, optical feedback can improve the spatial and temporal coherence properties of BALs [9,10]. 3. EXPERIMENTAL SETUP In our experiments, we used conduction-cooled 976nm single emitters with a p-contact width of 100µm and a cavity length of 4mm from several suppliers. They were cleaved from mini-bars used in DILAS pump modules [11] for an easier investigation of external optical feedback influence on the near-field distribution and the emission spectra compared to mini-bars with five emitters. The single emitters were mounted with AuSn on ceramic base plates. The experimental setup for the investigation of single emitters under defined external optical feedback is shown in Fig. 2. For better understanding, the laser beam is represented by a green line. The investigated laser diodes are conduction cooled by a Peltier element which is mounted on a water cooled copper block. The base plate temperature of the diodes is fixed to 20°C. The emitted laser beam is collimated by an aspheric plano-convex-lens (EFL = 8mm Asphericon 10-08 HPX-S). It passes through an uncoated wedge prism where it is split into several attenuated beams due to multiple reflections inside the prism. The diagnostic beam (2) is used to observe the near-field pattern and the spectral behavior with two CCD cameras (IDS 6240SE, resolution 1280x1024, 1.x MP). The main beam (1) is used to generate the optical feedback. The main beam (1) passes a beam-splitter cube (BSC 50:50 division ratio, effectively measured 56:44). The reflected beam is used to measure the optical output power of the laser diode using a calibrated optical power meter. The transmitted beam runs through a thin film polarizer (TFP), which angle was adjusted to control the feedback strength. Finally, the beam is reflected by a dielectric mirror (R = 99.5%) back into the laser diode via the BSC and TFP. The reflected beam from the BSC (not shown in Fig. 2) can be used to measure and control the feedback intensity. Figure 2. Experimental setup for external optical feedback: (1) feedback beam and (2) diagnostic beam. The external feedback strength is set as follows: First, the output power of the laser diode is measured behind the collimation lens. This power is defined as P0. Second, the optical power of the feedback beam is measured above the BSC via the reflected beam (not plotted in Fig. 2); it is named Pmess. The arithmetical Pmess yields from the transmitted BSC beam TBSC (56%), the thin film polarizer xpol and the reflected BSC beam RBSC (44%): . (2) The feedback beam is not reflected by the BSC, but two times transmitted. Therefor the feedback power is . (3) Further, the feedback power is defined as , (4) hence the expression (5) yields. The diagnostic beam (2) is split by a 50:50 beam splitter. The transmitted beam is imaged onto the near-field camera with an achromatic lens (f = 200mm Thorlabs AC254-200-B) to yield an image of the diode facet. The collimation associated with the imaging optics forms a telecentric optical system (4F optics). The reflected beam illuminates a grating (79l/mm Thorlabs GE2550-0863 Echelle Grating) via a tilted mirror and a lenssystem expanding the beam. The grating splits the beam into its spectral parts. Afterwards the beam is imaged onto a second camera using a plano-convex-lens (f = 150mm). Because the near-field information is kept, it is possible to investigate both near-field and spectrum at the same time. Due to mirrors in the optical path to the spectrometer, the laser beam is rotated about 90 degrees along the axis of propagation so that the y-direction of the camera depicts the slow-axis near-field pattern and the x-direction shows the spectrum. The optical feedback is adjusted by observing the beam position with a converter card and the changes in the spectrum using the spectral camera. First, one reflects the feedback beam near the emitted beam by tilting the reflecting mirror. This can be controlled with a converter card. With further tilting of the reflecting mirror, the beam is slid back into the diode. Now, changes in the spectrum can be observed. Because of the divergence and the spot width of the beam, there is a wide range where the spectrum of the diode responds. The best adjustment is reached, when the spectrum shows broadening and redshift and in addition to that the beat-frequencies of the internal and the external resonator modes as spikes on the spectrum. 4. RESULTS AND DISCUSSION In our experiments, we have observed the optical output power, the near-field pattern and near-field width as well as the emission spectra of laser diodes with different AR coatings (1%, 3%, 4%, and 5%) on the front facet for increasing injection currents with and without external optical feedback. We derived the peak-power densities and finally found a correlation between high-intensity filaments and catastrophic optical mirror damage (COMD). 4.1 Near-field distribution and width For the best fiber-coupling efficiency in our modules (200W out of a 200µm fiber) [11], a near-field width of ≤ 100µm at an injection current of 8A is required. We observed the near-field width of all diodes with AR coatings between 1% and 5% for an increasing injection current I, as shown in Fig. 3. At the nominal operation point of 8A, the near-field width is about 100µm for AR=1%, but increases up to 108µm for AR=5%. The differences in the near-field width between different AR coatings are significantly larger for I<7A and I>11A. (a) (b) Figure 3. Near-field width vs. injection current (a) without feedback and (b) with external optical feedback. With external optical feedback, the near-field width broadens compared to the free-running diodes (see also Fig. 4). We have chosen a feedback strength of 4%, because this is a realistic value met in the main applications of our 976nm pump modules [11]. Again, the diode with the highest AR coating has the widest, and the diode with the lowest AR coating has the smallest near-field width. Furthermore, Fig. 3 shows that the near-field width of the diodes with 4% AR coating is less influenced by the external optical feedback compared to the other diodes with AR<4%. (a) (b) Figure 4. (a) Near-field pattern without feedback and (b) with 4% external feedback for four different AR coatings. The near-field pattern without and with 4% external feedback for four different AR coatings at an injection current of 8A is shown in Fig. 4. Figure 4(a) depicts the case without external optical feedback. For AR=1%, the near-field distribution shows two broad filaments besides the center of the emitter. In comparison, the diode with AR=3% shows a more spiked intensity distribution. One can identify three filaments, one of them is pronounced. The diode with AR=4% shows three filaments as well, but all with comparable intensities. Finally, the diode coated with AR=5% exhibits a near-field with several small filaments, one of them a bit more pronounced, but we cannot observe the excessive peaking in the nearfield distribution found in diodes with AR ≤ 3%. With external optical feedback, the near-field pattern of the diodes changes its shape as shown in Fig. 4(b). The nearfield distribution of the low AR coated diode becomes multistable, when the external optical feedback is sufficient strong because of the strong dependence of the refractive index of the laser active region on the carrier density [8]. Thus, one of the two initial filaments is suddenly developed dramatically. The near-field distribution for AR=1% shown in Fig. 4(b) was taken in a moment, when the right part of the emitter was more pronounced. The diode with 3% AR coating shows the development of three pronounced filaments with a smaller power density on the front facet compared to AR=1%. In case of AR ≥ 4%, one can see more filaments that are less pronounced compared to diodes with smaller AR reflectivity. There are only small changes in the near-field distribution when external optical feedback is applied without significant changes in the power density on the front facet. Summarizing, we observed two intense filaments for the diode with AR=1%; one of them was dramatically amplified in case of external optical feedback. With increasing AR reflectivity, the number of filaments in the near-field distribution increases and the influence of external optical feedback on the near-field pattern decreases significantly. 4.2 Determination of peak-power density Comparing the life time of single diodes driven without optical feedback with diodes in pump modules [11] with external feedback, we observed a strong acceleration of the failure rate by a factor of up to 10 mainly caused by CO(M)Ds. Therefore we had to take a closer look at the power densities on the front facet. As explained in Section 2 and illustrated in Section 3, the front facets of the laser diodes are locally exposed to very high intensities. From the measured near-field pattern, we can derive the peak-power density of the strongest filament as shown in Fig. 5. We integrate the output power over the whole emitting area and give it a top-hat shaped form with the width B0 and the height H0 containing 95% of the overall output power. Then we take the height HF of the most intense filament and determine the superelevation in relation to H0. The peak-power density PPD is found by multiplying the superelevation with the output power divided by the near-field width and the emitter height HE. (6) Figure 5. Measured near-field pattern together with a corresponding top-hat distribution containing 95% of the optical output power (B0 - near-field width and HF - filament height). The derived peak-power densities PPD versus the injection current for the diodes with four different AR coatings are depicted in Fig. 6 together with the average power density (median) for a 1% AR coated diode. The average power density is not as straight as the power-current characteristics shown in Fig. 10 due to the varying horizontal near-field width (see e.g. Fig. 3). Figure 6(a) shows the results without external feedback. In this case, the diodes with low AR coating exhibit higher PPDs than the diodes with AR ≥ 4%. Furthermore, the diodes with AR ≥ 4% show a smoother filament development with increasing current. This behavior is the result of better near-field stability and homogeneity for diodes with a larger AR reflectivity manifested by the decreasing difference between the average power density (median) and the peak-power densities. We also observed fluctuations of the near-field distributions for a certain current over time and discovered a modification of its shape, if the injection current is high enough. This modification or instability of the near-field distribution occurs for I > 8A for the low AR coated laser diodes, whereas it is detected for AR ≥ 4% only for higher injection currents of I > 13A. (b) (a) Figure 6. Peak-power density at the position of near-field intensity maxima vs. injection current together with the average power density (median) of the 1% AR coated diode: (a) for the free-running diodes and (b) with external optical feedback. Figure 6(b) shows the results with external optical feedback. We observe an increase of the peak-power density for all diodes. The largest impact of external feedback was detected for diodes with AR=1%. At the nominal operation current of 8A, the peak-power density is twice the average value and comparable to the average power density for I = 15A. The influence of optical feedback on the peak-power density decreases with increasing AR reflectivity and becomes negligible for AR ≥ 4%. Fluctuations in the near-field distribution decreases simultaneously. 4.3 Near-field distribution vs. current For a better understanding, the modification of the near-field distribution or the development of filaments with increasing injection current can be displayed in false color diagrams. Such an illustration makes the importance of the peak-power density more obvious. (a) (b) Figure 7. False color illustration of the near field distribution vs. injection current for a 1% AR coated laser diode: (a) without optical feedback and (b) with feedback. Figure 7 visualizes the development of the near-field distribution for a laser diode with AR=1% - (a) without and (b) with external optical feedback. The maximum PPD is about 10.44 MW/cm² at I = 15A as shown in Fig. 7(a). One can see sharp intensity filaments with a high contrast to the deep intensity minima between these filaments. At the nominal operation point of I = 8A, there are only two pronounced filaments. Figure 7(b) shows the near-field pattern of the same diode with optical feedback. Please note, that the PPD increases up to 12.59 MW/cm² at I = 15A. In case of external feedback, only one filament is clearly pronounced. The locally increased power density on the front facet can lead to CO(M)D. (a) (b) Figure 8. False color illustration of the near field distribution vs. injection current for a 5% AR coated laser diode: (a) without optical feedback and (b) with feedback. Figure 8 illustrates the development of the near-field distribution for a laser diode with AR=5% - (a) without and (b) with external optical feedback. Without feedback, the PPD reaches a maximum of 8.15 MW/cm². Comparing the regions around the most intense filaments, the intensity contrast is small indicating a more homogeneous near-field distribution as shown in Fig. 7 for diodes with AR=1%. With external feedback, the PPD reaches a maximum of 9.67 MW/cm². Although the power density on the front facet is slightly increased, the intensity distribution with feedback shows the same small contrast between the between intensity maxima and minima for diodes with AR=5% without excessive peaking. 4.4 Correlation between high intensity filaments and catastrophic optical mirror damage The CO(M)D is a sudden failure mechanism which is well-known from edge-emitting diode lasers at very high optical output powers and very high power densities at the front facets and AR mirrors as well. External optical feedback increases the optical load at the outcoupling (AR) facet and also within the laser cavity. Even unintentional feedback influences the laser diodes in an uncontrollable way and can lead to CO(M)Ds [3-6]. Figure 9. Correlation of a high-intensity filament and a COMD for a 1% AR coated laser diode. The blue dotted line shows the near-field distribution without feedback, the red line is the near-field pattern with external optical feedback. In our experiments, we have simulated the occurrence of CO(M)Ds together with the influence of optical feedback on our 976nm pump diodes. A feedback strength of 4% was mentioned as a realistic value for our pump modules and for one of their main applications [11,12]. The blue line in Fig. 9 shows the typical near-field distribution for a laser diode with AR=1% without external optical feedback. A stepwise increase of the injection current up to 14.5A, i.e. twice the nominal output power, did not lead to CO(M)D events. The red line in Fig. 9 depicts the near-field distribution for the same laser diode with AR=1% and a feedback strength of 4%. The external feedback leads to the development of one intense filament. Our online monitoring of the near-field distribution and the output power proves the correlation between the position of high-intensity filaments and COMDs as shown in Fig. 9. The same experiment was carried out for laser diodes with AR coatings of 3%, 4%, and 5%. For AR ≥ 4%, we were not able to generate CO(M)D events with an external feedback strength of 4%. The increased AR reflectivity leads not only to a more homogeneous near-field distribution with and without external feedback as shown above, it also helps to avoid CO(M)Ds. 4.5 Power-current characteristics vs. AR coating A comparison of the power-current characteristics for single emitters from the same wafer with 1% and 5% AR coating is given in Fig. 10 with and without external optical feedback showing no significant differences, whereas the power conversion efficiency decreases slightly with increasing AR reflectivity. For AR=1%, the power conversion efficiency reaches its maximum at a smaller current and shows a steeper drop at currents of I > 11A compared to diodes with 5% AR coating. Figure 10. Optical output power and power conversion efficiency vs. forward current of conduction-cooled 976nm single emitters with 100µm emitter width and a cavity length of 4000µm with and without external optical feedback (FB) at a base plate temperature of 25°C: (a) with 1% AR coating and (b) with 5% AR coating. Table 1 summarizes the changes of the power conversion efficiency with increasing reflectivity of the AR coating. The maximum power conversion efficiency drops with 0.35% per percent AR coating, whereas the power conversion efficiency at the nominal operating current of I = 8A decreases with 0.5% per percent AR coating. Table 1. Maximum power conversion efficiency and power conversion efficiency at nominal operation current vs. AR coating for conduction-cooled 976nm single emitters with 100µm emitter width and a cavity length of 4000µm at a base plate temperature of 25°C without external optical feedback. AR coating Max. E-O efficiency E-O efficiency @ I = 8A 1% 66.1% 65.3% 3% 65.4% 64.2% 4% 65.1% 63.7% 5% 64.7% 63.2% With respect to the feedback sensitivity on the one hand and to the decreasing power conversion efficiency with increasing AR reflectivity on the other hand, we decided to use minibars with 4% AR coating in our pump modules [11]. 5. CONCLUSIONS In this paper, we have reported on the influence of external optical feedback on 976nm single emitters with different AR coatings on their front facets (1%, 3%, 4%, and 5%) in order to prevent damages caused by back-reflected light in usual applications of fiber coupled modules. By observing the near-field pattern while varying the injection current, we got information about the influence on filamentation and on peak-power densities with and without optical feedback. For AR=1%, one of two initial filaments at the nominal optical output power besides the center of the emitter (without back-reflected light) was strongly amplified. With external optical feedback, we observed the expected multistable laser operation [8]; chaotic “jumping” of the feedback-induced amplification between these two filaments finally leads to CO(M)Ds at the positions of high-intensity filaments with peak-power densities of more than 12.5 MW/cm2. We found, that an increasing AR reflectivity leads to a more uniform near-field distribution with an increasing number of filaments. Simultaneously, the influence of external optical feedback on the near-field pattern decreases significantly. Excessive peaking as observed for AR=1% does not occur for front facet coatings with AR≥4%; the peak-power density decrease by 23% without external feedback and by 28% with external optical feedback. This also means, that the increased AR reflectivity helps to avoid CO(M)Ds. Based on these results we decided to use minibars with 4% AR coating in our fiber laser pump modules. The large amount of CO(M)D events in case of external feedback compared to life tests on single diodes without optical feedback was no longer observed. REFERENCES [1] Diehl, R. (Ed.), “High-power diode lasers: Fundamentals, technology, applications (Topics in Applied Physics)”, Springer Berlin Heidelberg (2010). [2] Knigge, A., Erbert, G., Jonsson, J., Pittroff, W., Staske, R., Sumpf, B., Weyers, M., and Tränkle, G., “Passively cooled 940nm laser bars with 73% wall-plug efficiency at 70W and 25°C”, Electron. Lett. 41(5), 250-251 (2006). [3] Tomm, J.W., Ziegler, M., Hempel, M. and Elsaesser, T., “Mechanisms and fast kinetics of the catastrophic optical damage (COD) in GaAs-based diode lasers“, Laser Photonics Rev. 5(3), 422-441 (2011). [4] Henry, H.C., Petroff, P.M., Logan, R.A., and Merrit, F.R., “Catastrophic damage of AlxGa1−xAs double‐ heterostructure laser material”, J. Appl. Phys. 50(5), 3721-3732 (1979). [5] Takiguchi, Y., Asatsuma, T., and Hirata, S., “Effect of the threshold reduction on a catastrophic optical mirror damage in broad-area semiconductor lasers with optical feedback,” Proc. SPIE 6104, 61040X (2006). [6] Hempel, M., Chi, M., Petersen, P.M., Zeimer, U., Weyers, M., and Tomm, J.W., “The impact of external optical feedback on the degradation behavior of high-power diode lasers”, Proc. SPIE 8605, 86050L (2013). [7] Amrita and Sharma, A. K., “Filamentation instability in a semiconductor laser”, J. Appl. Phys. 94(1), 19-22 (2003). [8] Lang, R. and Kobayashi, K., “External optical feedback effects on semiconductor injection laser properties“, IEEE J. Quantum Electron. QE-16(3), 347-355 (1980). [9] Lobel, M., Petersen, P.M., and Johansen, P.M., “Single-mode operation of a laser-diode array with frequencyselective phase-conjugate feedback“, Optics Lett. 23(11), 825-827 (1998). [10] Chi, M., Thestrup, B., and Petersen, P.M., “Self-injection locking of an extraordinarily wide broad-area diode laser with a 1000 µm wide emitter“, Optics Lett. 30(10), 1147-1149 (2005). [11] Wolf, P., Köhler, B., Rotter, K., Hertsch, S., Kissel, H., and Biesenbach, J., “High-power, high-brightness and low-weight fiber coupled diode laser device“, Proc. SPIE 7918, 79180O (2011). [12] Becker, F., Neumann, B., Winkelmann, L., Belke, S., Ruppik, S., Hefter, U., Köhler, B., Wolf, P., and Biesenbach, J., „Multi-kW cw fiber oscillator pumped by wavelength stabilized fiber coupled diode lasers“, Proc. SPIE 8601, 860131 (2013).