* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Chemical Transport Model - Technical Description

Freshwater environmental quality parameters wikipedia , lookup

Chemical weapon wikipedia , lookup

Gas chromatography–mass spectrometry wikipedia , lookup

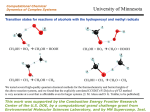

Chemical reaction wikipedia , lookup

Chemical equilibrium wikipedia , lookup

Atomic theory wikipedia , lookup

Al-Shifa pharmaceutical factory wikipedia , lookup

Chemical Corps wikipedia , lookup

Chemical potential wikipedia , lookup

Physical organic chemistry wikipedia , lookup

Equilibrium chemistry wikipedia , lookup

Stoichiometry wikipedia , lookup

Transition state theory wikipedia , lookup

Biosequestration wikipedia , lookup

Determination of equilibrium constants wikipedia , lookup

Chemical thermodynamics wikipedia , lookup