* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Epoxidation of α-pinene mediated by cobalt(III) catalysts

Metal carbonyl wikipedia , lookup

Spin crossover wikipedia , lookup

Coordination complex wikipedia , lookup

Stability constants of complexes wikipedia , lookup

Oxidation state wikipedia , lookup

Metalloprotein wikipedia , lookup

Evolution of metal ions in biological systems wikipedia , lookup

Fischer–Tropsch process wikipedia , lookup

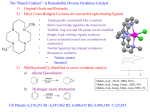

Epoxidation of α-pinene mediated by cobalt(III) catalysts Birinchi K Das DEPARTMENT OF CHEMISTRY GAUHATI UNIVERSITY GUWAHATI INDIA RRB2 RRB2 Conference, Conference, York York (2006) (2006) Green Chemistry is the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances. It also refers to the discovery of new chemistry and/or technology leading to prevention and/or reduction of environmental, health and safety impact at source. – JH Clark Atom Economy H H C H H H2, Ni C H C H H + % Yield = Actual yield of product Theoretical yield of product X 100 Molecular weight of atoms utilized % Atom economy = Molecular weight of all reactants used X 100 H C H H Some ways of practicing Green Chemistry • Catalysis • Use of good solvents or no solvents • Use of non-hazardous substances • Production of chemicals from renewable resources • Others Catalysis for Green Chemistry • important chemistry tool for implementing green • increasing selectivity • decreasing processing and separation agents • heterogeneous catalysts to make processes greener • catalysts can significantly lower the energy demands of many manufacturing processes PRODUCING CHEMICALS FROM RENEWABLE RESOURCES Advantages • Conservation of fossil resources • CO2 neutrality • Non-toxicity of raw materials • Biodegradable substances Disadvantages • Expensive raw materials • New technolgy requirements • Business logistics and infrastructure require development α-pinene Pinene is a bicyclic monoterpene. α-pinene is one of the two structural isomers found in nature, the other one being β-pinene. Both forms are important constituents of pine resin, they also occur in other plants. They are mostly obtained from turpentine, which is a clear liquid produced as a by-product of pulping of pine wood. Turpentine contains 58%-65% α-pinene and about 30% of β-pinene. α and β pinenes are fractionated by distillation. α and β pinenes are key components in the synthesis of flavour and fragrance chemicals used in tooth paste, detergents, shampoos… Selective oxidation of pinene gives important pharmaceutical and flavouring materials. OXIDATION CHEMISTRY ‘..one of the most essential and one of the most polluting chemical technologies...’ – Anastas & Warner Oxidation of hydrocarbon compounds Use of air as the oxidant rather than peroxides Catalyst stability Heterogeneous catalysts Metal leaching Selectivity to products Coordination Chemistry at the heart of Transition Metal Catalysed Oxidation COBALT CATALYSTS FOR OXIDATION Haber-Weiss cycle ? ROOH + Co(II) ROOH + Co(III) RO· + Co(III) + HO– RO2· + Co(II) + H+ ROOH + Co(III) RO· + Co(IV) + HO– ROOH + Co(IV) RO2· + Co(III) + H+ Feasibility of the first set of twin reactions is determined by the reduction potential for the Co3+/Co2+ couple. Suitable reduction potential for the Co4+/Co3+ couple may also permit the use of Co(III) compounds as catalysts. More on redox activity of cobalt ions Reversibility of electrochemical processes means retention of molecular structure during and after electron transfer. It is essential for redox catalysts that are expected to have a long lifetime. The Co3+/Co2+ redox couple has a suitable reduction potential of ~ +1.8 V to activate triplet O2 which is a powerful oxidant from a thermodynamic point of view, but is kinetically inert due to the necessity of overcoming the kinetic barrier involved in the triplet to singlet conversion. 3Σ g 1∆ g Metal ions activate O2 by accommodating dioxygen, at least momentarily, as either O2(superoxo) or O22- (peroxo) ligands. O22- has no unpaired electrons. O2- has one unpaired electron. But in its formation, triplet oxygen, which has two unpaired electrons, has already reacted to the presence of the metal ion in its proximity! Oxidation of olefins TWO PATHWAYS Epoxidation H2C Allylic oxidation C H CH2 Allylic position (saturated) Allyl groups have weaker C-H bonds (360 kJ/mol) compared to alkenes and alkanes (bond energies ~400 kJ/mol). This is why an allyl radical is more stable than an alkyl radical. Oxidation of α-pinene Uncatalysed autoxidation at 100°C in the dark leads to the formation of 9% verbenone, 16% verbenol, 13% α-pinene epoxide, 8% transpinocarveol, 2% trans-carveol and 1% myrtenal [1956]. Reaction scheme of α-pinene conversion O verbenone OH verbenol O OH α-pinene α-pinene oxide + + OH isopinocamphenone Lewis acid H2O/ H H OH isopinocamphenol O OH OH O 1,2-pinanediol OH trans carveol trans sobrerol campholenic aldehyde Rearrangement of α-pinene epoxide is known to produce over 100 products under various reaction conditions, particularly in presence of acid sites in the catalysts. Selectivity thus appears to be highly important in catalytic oxidation of α-pinene. Common Oxidants: Air, O2, TBHP, NaOCl, H2O2 or peroxy acids Catalysts reported Both homogeneous and heterogeneous • Zeolite encapsulated ruthenium and cobalt schiff base complexes (allylic oxidation); higher Ru activity. Air • Ti-HMS catalyst (Campholenic aldehyde). TBHP • (Zn-Al) Layered double hydroxide-hosted chiral sulfonatosalen manganese(III) complex catalysts (stereoselective epoxidation). Air or O2 • Mn(II) complex on montmorillonite clay. NaOCl • Co(OAc)2/bromide. O2 • Polystyrene supported Co(II) acetylacetonate complex (epoxidation). O2/sacrificial aldehyde • CoCl2, CoBr2, Co(OAc)2 and Co(NO3)2. Air Cobalt(III) oxidation catalysts • Co(II) compounds are important as (even industrial) catalysts. They are still good catalysts if environmental acceptability is not an issue. • Under ordinary circumstances Co(II) is very stable. • Once oxidized in presence of suitable ligands, Co(III) also may remain stable because ‘cobaltic complexes are kinetically inert’. • Thermal activation may be necessary in case of cobalt(III)-based oxidation catalysts. B. K. Das and J.H. Clark, Chem. Commun., 2000, 605 Investigation on the applicability of Co(III) systems for α-pinene (an olefin) oxidation Cubane-like cobalt(III) complexes . Co(NO3)2 6H2O + NaO2CR +L H2O2 (30%, v/v) MeOH Pink Solution Olive Green Complexes [Co4(µ3-O)4(µ-O2CR)4L4] L = pyridine or its derivatives such as 4-Mepy, 4-CNpy Co(III) Cubane Cluster [Co4(µ3-O)4(µ-O2CMe)4(NC5H5)4] Cyclic voltammogram E½ = +0.73 V In MeCN HOMOGENEOUS CATALYSIS Oxidation of α-pinene by compressed air under homogeneous conditions at atmospheric pressure has been investigated using [Co4III(µ3- O)4(µ-O2CC6H5)4(4-CNpy)4] as the catalyst. • Both epoxidation and allylic oxidation products are found to form O Catalyst I, ∆ Compressed Air α-pinene • + + OH α-pinene oxide Verbenol O Verbenone Effects of reaction temperature and catalyst concentration are studied Effect of Reaction Temperature on α-pinene Epoxidation 35 30 α-pinene oxide verbenol verbenone Reaction Conditions: α-pinene = 3.97mL (25mmol) 25 1,4 dioxane = 40mL Yield (%) 20 Amount of catalyst = 25mg 15 Oxidant, O2 = 15mL/min 10 T = 60, 80 & 100ºC Reaction time = 24h 5 0 60 80 100 0 Reaction temperature ( C) Effect of reaction temperature on α-pinene oxidation by [Co4III(µ3- O)4(µ-O2CC6H5)4(4-CNpy)4] Reaction Conversion temperature (%) (°C) Composition of product yield (%) α-Pinene oxide Verbenol Verbenone Other Products 60 6.97 3.5 1.28 2.19 0 80 30.62 9.73 5.07 7.9 7.92 100 66.84 31.43 4.76 15.19 15.46 Effect of Catalyst Concentration • The catalyst concentration was varied between 0.01mol% to 0.5mol%. • The reaction with the lowest amount of catalyst shows the highest conversion of 81.4% with a turnover frequency (TOF) of 105. • High selectivity of 62-68% for α-pinene oxide has been observed with 0.01mol% of catalyst at 100°C. Product Yield (selectivity) (%) Amount of catalyst Conversion (%) TON α-pinene oxide (%) Verbenol (%) Verbenone (%) Other products (%) 3mg, 0.01mol% 81.4 2520 48.0 (68) 4.53 16.97 11.89 25mg, 0.08mol% 66.8 288 31.43 4.76 15.19 15.46 150mg, 0.5mol% 63.2 48 33.07 4.83 13.98 11.33 100 Amount of Catalyst = 0.01mol% Yield (%) 80 α-pinene pineneoxide verbenol verbenone 60 40 20 0 0 5 10 15 20 25 Time (h) Effect of catalyst concentration on air oxidation of α-pinene Amount of catalyst = 0.08mol% 100 α -pinene α -pinene oxide verbenol verbenone Yield (%) 80 60 40 20 0 0 5 10 15 20 25 Time (h) Effect of catalyst concentration on air oxidation of α-pinene Am ount of catalyst = 0.5m ol% 100 α -pinene α -pinene oxide verbenol verbenone Yield (%) 80 60 40 20 0 0 5 10 15 20 25 Time (h) Effect of catalyst concentration on air oxidation of α-pinene HETEROGENEOUS CATALYSIS Immobilization of known homogeneous catalysts on porous supports provides a way towards eco-friendliness of chemical synthesis Work-up procedures become simpler Efficiency sometimes rises Strategies for Immobilisation Ion exchange Physisorption Covalent binding Encapsulation Incorporation into support framework Immobilisation of Co(III) cubanes on Hexagonal Mesoporous Silica O O Si O O O O Si O O CN n-DDA EtOH/H2O, RT HMS H2SO4(aq.) Catalyst A Co(III) Cubane Cluster ∆, H2O (MeCN) HMS COOH Immobilisation via ligand exchange CN Immobilisation of Co(III) cubanes on Hexagonal Mesoporous Silica TEOS CTES n-dodecylamine EtOH + H2O HMS-(CH2)2-CN H2SO4 (aq) CATALYST B Co(OAc)2 + 4-CNpy H2O HMS-(CH2)2-COOH In-situ immobilisation Scanning electron micrograph of the supported reagent Co4O4(O2CCH3)4(4-CNpy)4 on HMS CATALYST B Scanning electron micrograph of the supported reagent Co4O4(O2CCH3)4(4-CNpy)4 on HMS CATALYST B Scanning electron micrographs of the supported reagent Co4O4(O2CCH3)4(py)4 on HMS N2 Adsorption Data and Metal Loading of Cobalt(III) Cubane Complexes Supported on HMS BET Surface Area, m2/g Pore Volume (ml/g) % of Pores between 3.2-6.0 nm AAS Cobalt Loading mM/g Co4O4(O2CCH3)4(4-CNpy)4 620 0.57 91 0.99 Co4O4(O2CPh)4(4-CNpy)4 714 0.53 85 1.07 Co4O4(O2CCH3)4(py)4 426 0.51 36 0.86 Co4O4(O2CCH3)4(4-NH2py)4 542 0.71 40 1.7 Co4O4(O2CCH3)4(4-tBupy)4 376 0.28 25 1.23 Co4O4(O2CCH3)4(4-CNpy)4 (in situ prepared) 622 0.60 87 1.08 Immobilised Complex Ps/Po (Adsorption) = 0.9814 Adsorption isotherms for (a) HMS-(CH2) 2COOH and HMS-supported cobalt(III) catalysts prepared by immobilizing (b) Co4O4(O2CCH3)4(4-CNpy)4 and (c) Co4O4(O2CPh)4(4-CNpy)4 Type IV isotherms 1.1 Transmittance (%) 1.0 0.9 0.8 ν(CN) = ~ 2243 cm -1 0.7 0.6 0.5 HMS-COOH Co4O4(O2CCH3)4(4-CNpy)4 Immobilised catalyst 0.4 (in-situ) 0 2500 2000 1500 1000 -1 Wavenumber (cm ) 500 1.0 Transmittance (%) 0.9 0.8 0.7 0.6 0.5 0.4 2500 in-situ ligand exchanged 0 2000 1500 1000 500 -1 Wavenumber (cm ) Immobilised Co4O4(O2CCH3)4(4-CNpy)4 prepared in-situ Immobilised Co4O4(O2CCH3)4(4-CNpy)4 prepared via ligand exchange Effect of temperature on α-pinene epoxidation Catalyst B: Immobilised Co4O4(O2CCH3)4(4-CNpy)4 prepared in-situ 50 α-pinene oxide Reaction Conditions: verbenol verbenone α-pinene = 3.97mL (25mmol) 40 Yield (%) 1,4 dioxane = 40mL 30 Amount of catalyst = 0.09mol% Oxidant, O2 = 15mL/min 20 T = 60, 80 & 100ºC Reaction time = 24h 10 0 60 80 100 0 Reaction Temperature ( C) 0 100 α-pinene α-pinene oxide 90 verbenol verbenone 80 Yield (%) 70 60 50 Amount of Catalyst = 0.005 mol% 40 T = 100ºC 30 20 10 0 0 0 5 10 15 Time (h) 20 25 100 α-pinene α-pinene oxide 90 verbenol verbenone 80 Yield (%) 70 60 50 Amount of Catalyst = 0.02 mol% 40 T = 100ºC 30 20 10 0 0 0 5 10 15 Time (h) 20 25 100 Amount of Catalyst = 0.09 mol% α-pinene α-pinene oxide verbenol verbenone Yield (%) 80 60 T = 100ºC 40 20 0 0 0 5 10 15 TIme (h) 20 25 Homogeneous and Heterogeneous α-pinene epoxidation Catalyst Co/benz/4-CNpy Co/benz/4-CNpy Co/benz/4-CNpy Catalyst B Catalyst B Catalyst B Amount of catalyst (Co) 3 mg (0.01mol%) TOF α-pinene % GC Yield 2,3verbenol epoxypinane verbenone 105 18.87 48.01 4.53 16.97 25 mg (0.08mol%) 12 33.16 31.43 4.76 15.19 150 mg (0.5mol%) 2 36.79 33.07 4.83 13.98 24.22 24.21 8.51 16.33 5 mg (0.005mmol) 157 25 mg (0.02mmol) 38 27 41.08 8.05 14.36 100 mg (0.09mmol) 9 18.54 50.07 2.9 16.94 Reaction condition: α-pinene(25mmol), 1,4-dioxan(40mL), reaction time(24h), temperature(100ºC), ACKNOWLEDGEMENTS Rajesh Chakrabarty Green Chemistry Network Department of Science & Technology Government of India Ironwood Tree Mesua ferrea Nahar (Assamese) Nageswar (Sanskrit) The sweetly fragrant flowers do not smell of diesel in spite of the fact that this plant is gaining importance as a source of biodiesel. Nahar comes into full bloom around the middle of April when people celebrate a festival called Bihu in Assam. Boys and girls dance, make merry and sometimes they marry one another.