* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

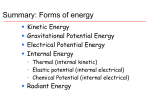

Download basics of heat transfer

Black-body radiation wikipedia , lookup

Temperature wikipedia , lookup

Calorimetry wikipedia , lookup

Thermodynamic system wikipedia , lookup

Second law of thermodynamics wikipedia , lookup

Heat capacity wikipedia , lookup

Insulated glazing wikipedia , lookup

First law of thermodynamics wikipedia , lookup

Thermal comfort wikipedia , lookup

Heat exchanger wikipedia , lookup

Thermal conductivity wikipedia , lookup

Heat equation wikipedia , lookup

Dynamic insulation wikipedia , lookup

Thermoregulation wikipedia , lookup

Adiabatic process wikipedia , lookup

Countercurrent exchange wikipedia , lookup

Atmospheric convection wikipedia , lookup

Copper in heat exchangers wikipedia , lookup

Heat transfer physics wikipedia , lookup

Thermal radiation wikipedia , lookup

R-value (insulation) wikipedia , lookup

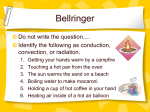

Heat transfer wikipedia , lookup

Hyperthermia wikipedia , lookup