* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Chap16 Microbial Polysaccharides

Genetic code wikipedia , lookup

Microbial metabolism wikipedia , lookup

Nucleic acid analogue wikipedia , lookup

Amino acid synthesis wikipedia , lookup

Citric acid cycle wikipedia , lookup

Biosynthesis wikipedia , lookup

15-Hydroxyeicosatetraenoic acid wikipedia , lookup

Butyric acid wikipedia , lookup

Specialized pro-resolving mediators wikipedia , lookup

Biochemistry wikipedia , lookup

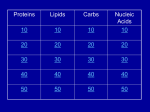

Chap 16 Microbial polysaccharides, single cell oils and polyhydroxyalkanoates I. Introduction When microorganisms are supplied with excess glucose or other C- or N- sources, they may produce one or more storage compounds. Storage compounds in different organisms: yeast and fungi: bacteria: The storage compounds are usually hydrophobic and may be seen as distinct inclusions within the cells. Some microorganisms may excrete large amounts of polysaccharides into the medium in addition to accumulating intracellular reserve compounds. The synthesis of these intra- and extracellular products is promoted when: II. Microbial polysaccharides Introduction Polysaccharides accumulate as storage compounds, e.g. glycogen. The EPS may remain associated with the cell as a capsule or slime or simply dissolved in the medium, depending on the chemical structure and how vigorously the culture is agitated. On solid media, large slimy colonies may be produced. Advantages and disadvantages of microbial EPS: 1 Plant polysaccharides are produced on a vast scale and at a low price, but microbial EPS can be produced year-round and product quality is more consistent. The fermentation process is more costlynot suitable for cheap products. General Properties: EPS increase the viscosity and flow characteristics and are commonly used as thickening (known as “gum“ in the industry) (增稠穩定劑用於濃縮果汁、蠔油等), gelling (食品膠) and emulsifying (可降低油相與水相的不相容性,提高乳化能力) agents. Two types: Neutral: no ionizable groups (e.g. dextran) Acidic: possess carboxyl group from e.g. glucuronic acid and/or pyruvate residues (e.g. Xanthan). Divalent cations can cross-link polysaccharide chains to produce a strong gel. Xanthan (黃原膠) A large, complex polysaccharide (Mr>106 Da) composed of glucose, mannose, and pyruvate on the side chain (see Fig. 16.3). The pyruvate content depends on the bacterial strain and culture conditions. Produced from the fermentation of Xanthomonas campestris (Gram- 黃單孢桿菌) The most important commercial microbial polysaccharide (20,000 tons/yr). Kelco is the principal manufacturer. Used as High viscosities at low shear rates stabilize suspensions, yet provide good flow properties when poured or spooned from the container. At the processing stage, low viscosity at high-shear rates makes xanthan gum solutions easily pumped and poured. 2 Widely used for stabilization, suspension, gelling and viscosity control in the food industry (食品膠). Can also be used for water-based paints and other domestic and industrial uses. Dextran (葡聚糖) First commercial microbial EPS by Pharmacia (for 50 yrs) An -glucan containing various linkages, depending on the production organism (in Gram + and Gram- bacteria). Unlike other EPS which are synthesized within the cells, The MW of dextran can be manipulated by hydrolysis of the solvent-precipitated polymer using exo- or endo-dextranases or mild acid treatment, so as to change the properties. Applications: prevention of thrombosis (血栓形成), use in wound dressings to absorb fluid; used as chromatographic resin Other EPS: Gellan, Pillulan, alginate….. Production of polysaccharides Usually produced in batch culture in stirred tank bioreactors. Excretion of polysaccharide increases the viscosity of the culture. This limits the attainable polysaccharide concentration because it becomes difficult to achieve adequate mixing and O2 transfer. Also, the power requirement is high and the cost of heat removal to maintain the temperature is increased. Polysaccharide synthesis generally commences during growth and continues in the stationary phase. High C/N ratio in the medium is desired. The N source (limiting substrate) is set to produce the desired biomass. Additional C source can be added after growth cessation. 3 III.Single cell oils Introduction Lipids: triacylglycerols composed of three fatty acids attached to a three carbon (glycerol) backbone. The cellular roles of lipids include: storage compounds (e.g. fats), components of cell membrane (e.g. phospholipids), hormones (e.g. steroids). All lipids share the same common structure but the physical properties vary enormously, from hard waxy solids at RT (fats) to translucent liquids (oils). The structure of the fatty acids accounts for the properties of lipids. Fatty acids: the building blocks of lipids Nomenclature (Table 16-1): Trivial names (Palmitic acid: 棕梠酸, -linolenic acid: 亞麻酸 ;arachidonic acid:花生烯酸; DHA:二十二碳六烯酸) are more commonly used than systematic names (too long). Numeric designation: e.g. 18:3(n-6). 18: # of carbons in the acyl chain; 3: indicates the number of double bonds; (n-6) indicates which series the fatty acid belongs to (Fig. 16.18) and denotes the position of the last double bond relative to the terminal methyl group. Most commercially important oils (from cells) are produced by eucaryotic microorganisms such as fungi, yeast as well as algae (prokaryotes tend to accumulate PHB/A) and normally contain 16-24 carbon atoms and can possess up to 6 double bonds. 4 In general, lipids that are rich in unsaturated fatty acids are liquid at room temperature whereas lipids containing saturated fatty acids are solids. When fatty acids are synthesized de novo from acetyl-CoA and malonyl-CoA (also derived from acetyl-CoA) by the enzyme complex fatty acid synthase, they are saturated. Acetyl-CoA + 7 malonyl-CoA +14 NADPH palmitoyl-CoA (16:0CoA) + 7 CoA-SH + 7CO2 +14 NADP+ Double bonds are added to form unsaturated acid by fatty acid desaturases. Nutritional importance of polyunsaturated fatty acids (PUFAs) Animals can make palmitic acid (16:0) and carry out subsequent desaturation and elongation reactions (Fig. 15.26). But animals are incapable of 12 and 15 desaturation. But these essential fatty acids (linoleic acid, 18:2 (n-6); -linolenic acid, 18:3 (n-3)) are required by the body. For the conversion of certain fatty acids (e.g. arachidonic acid) into the eicosanoids, which are important in functions like blood clotting. Some diseases (e.g. rheumatoid arthritis, multiple sclerosis, etc.) are associated with the inability to desaturate fatty acids (though other factors are also involved) and may be relieved by increased intake of PUFAs. 5 Two PUFAs, arachidonic acid and DHA, have been implicated in the development of brain and eye function in new-born infants. Microorganism as oil factories Commercial oils are usually obtained from plants or animals (cheap source). Single cell oils can only compete with the most expensive specialty oils. Only very long chain PUFA-rich oils for human consumption for which no convenient plant or animal source currently exists can fit this purpose. Plant sources: Can produce essential unsaturated fatty acids, e.g. linoleic acid (18:2) from sunflower and rape seed oils; -linolenic acid (18:3 (n-3)) from linseed (亞痲子) oils. But can not produce long chain PUFA (>18 carbon long) Animal sources: Sources of up to 22-carbon PUFA (e.g. in fish oils), but in small quantities, making the processing difficult and expensive. Possible transfer of disease-causing agents in animal oils and the risk of pollutants persisting in fish oils are potential problems. Eucaryotic microorganisms source: Can produce a variety of PUFAs (see Table 16.3 which lists several organisms for commercial production) Some can accumulate large quantities of single PUFA in their cell lipids, simplifying oil processing. No ethical or religious problems. Can be guaranteed free of harmful contaminants. Current applications for single cell oils Arachidonic acid [20:4(n-6)] Produced from soil fungus Mortierella alpina, which can accumulate up to 50% (w/w) of dry weight as lipid, of which as much as 40% can be arachidonic acid. Processes using this organism has been developed by Zeneca-Roche (UK) Docosahexaenoic acid (DHA, 22:6(n-3)) 6 Produced commercially by Martek Biosciences (Maryland, US) using marine algae C.cohnii, and Omega-Tech (Colorado, in collaboration with Monsanto) using Schizochytrium. Can be used in baby milk formula. Fish oil is also a source but it contains 20:5 (n-3) which can not be separated using conventional oil processing. 20:5 (n-3) can not be used in baby milk formula. IV. Microbial polyhydroxyalkanoates (PHA) Introduction PHA are intracellular C- and energy reserve compounds in many bacteria. They can be isolated from bacteria with chloroform. PHA are linear polyesters composed of hydroxyl acid monomers. 3hydroxyacid monomers are the most common. PHA are biodegradable plastics and can be broken down by bacteria and fungi in the environment. The biodegradability makes PHA of commercial interest for use as package plastics. PHA as reserve materials in bacteria: PHA accumulate within the cells as granules. Some bacteria can accumulate up to 80% of their dry weight (the cells become swollen). Polyhydroxybutyrate (PHB) is the most common among PHA. PHB is a polyester composed of In batch cultures, 7 PHB is also produced when growth of aerobic bacteria is restricted by O2. PHA composition and properties Most PHA are Physical properties depend on the constituent monomers. For example, The composition of PHA is dependent both on the organism and the carbon source available during polymer accumulation. For example, The composition of PHB/V is thus controlled by varying the concentrations of glucose and propionic acid in the medium during the polymer accumulation phase. Regulation of PHB metabolism During the growth phase, 3-ketothiolase (catalyzing AcetylCoAacetoacetyl-CoA) is inhibited by free coenzyme A and little PHB is synthesized. When growth ceases or is restricted, metabolism of acetyl-CoA via the TCA cycle decreases as a result of inhibition of citrate synthase by NADH. The decrease in coenzyme A concentration relieves the inhibition of 3-ketothiolase and the surplus acetyl-CoA is channeled into the production of PHB. 8 Biosynthesis of PHB/V and other PHA In R. eutropha, PHB/V can be produced from glucose and propionic acid (3HV monomer is made exclusively from the latter). Pseudomonas olelvorans produces PHA from organic acids and alkanes. For example, PHA produced from n-octanoic acid or n-octane contains high proportion of 3hydroxyoctanoate. Biopol-a commercial biodegradable plastic made from PHA PHB was first found in 1926 by the Institut of Pasteur, but the first patent for production and recovery was published in the late 1960s. In the 1980’s, ICI (UK) developed a high-density fermentation and downstream process for the production and recovery of Biopol (the trade name used for the range of polymers manufactured by ICI). The process was subsequently acquired by Monsanto (US). Biopol was first used as a shampoo bottle. The greatest demand was for packaging and disposable products. But the cost was too high to compete with conventional plastics and production ceased in 1998. The fermentation of R. eutropha is run in a two-stage process. The first stage is the biomass production phase (P is chosen to be depleted at the end because P is relatively expensive) and the second stage is the polymer accumulation phase. Downstream processing involves cell rupture and solubilization of components other than PHA. The polymer is washed and recovered by centrifugation. Medical applications: 9 The degradation rate of PHB is too low for the plastic to be useful for degradable sutures (縫線), but PHB can be used for more durable implants (e.g. bone plates, wound dressings (敷料)). Production of PHA by recombinant bacteria As long as the genes responsible for the polymer biosynthesis are cloned, E. coli is suitable for PHA production (Gram+ bacteria are not suitable because the thick cell wall limits the accumulation of polymer and makes product recovery difficult). E. coli grows more rapidly than R. eutropha and produces at least as much polymer. But some E. coli require more complex media and cannot match the high cell density possible with R. eutropha. Current research work mostly focuses on the PHB production, but PHB/V and other PHA have also been produced. 10