* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download On Continuous Magnetically Enhanced Centrifugation in Large

Classical mechanics wikipedia , lookup

State of matter wikipedia , lookup

Work (physics) wikipedia , lookup

Magnetic field wikipedia , lookup

Electromagnetism wikipedia , lookup

Fundamental interaction wikipedia , lookup

Superconductivity wikipedia , lookup

Neutron magnetic moment wikipedia , lookup

Aharonov–Bohm effect wikipedia , lookup

Standard Model wikipedia , lookup

Magnetic monopole wikipedia , lookup

Electromagnet wikipedia , lookup

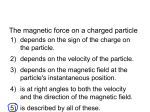

Lorentz force wikipedia , lookup