* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download cheese - Genootschap Melkkunde

Two-hybrid screening wikipedia , lookup

Citric acid cycle wikipedia , lookup

Nucleic acid analogue wikipedia , lookup

Metalloprotein wikipedia , lookup

Butyric acid wikipedia , lookup

Point mutation wikipedia , lookup

Catalytic triad wikipedia , lookup

Ribosomally synthesized and post-translationally modified peptides wikipedia , lookup

Peptide synthesis wikipedia , lookup

Protein structure prediction wikipedia , lookup

Genetic code wikipedia , lookup

Fatty acid synthesis wikipedia , lookup

Amino acid synthesis wikipedia , lookup

Fatty acid metabolism wikipedia , lookup

Biosynthesis wikipedia , lookup

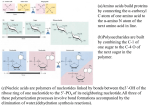

Enzymes for Flavour Development in Dairy Substrates Presented by: Blanca Camarasa Senior Business Manager Cheese composition Cheese consists of proteins and fat from milk, usually the milk of cows, goat, sheep or buffalo MILK : Protein Fat Lactose Water Cow’s milk 3.4% 3.7% 4.8% 88% Cheese making ENDOPEPTIDASE / EXOPEPTIDASE LIPASE / ESTERASE CHEESE : Protein Fat Mineral matters Water Cheddar 25% 33% (Min 50% solids) Max 39% water EMC Process Benefits of Using Enzymes in Dairy Flavour Texture Cost Savings Add Value Benefits of EMC as an Ingredient • Can give high value to out cuts of cheese and out of the spec batches. • Used in processed & analogue cheese, snacks, sauces or toppings. • EMC used at 1-3% • 1% EMC can replace 20% natural cheese • Gives consistent and flavour • Considerable cost savings when EMC is used instead of mature cheese. Hydrolysis of Fat with Lipase / Esterase Triglycerides are the major type of lipid in milk fat. Approximately 15 to 20 different fatty acids make up 90% of the milk fat. The major fatty acids in milk fat are straight chain fatty acids that are saturated and have 4 to 18 carbons (4:0, 6:0, 8:0, 10:0, 12:0, 14:0, 16:0, 18:0), monounsaturated fatty acids (16:1, 18:1), and polyunsaturated fatty acids (18:2, 18:3). Butyric acid (C4:0) Triglyceride (Triacylgycerol) Oleic acid (C16:1) Most of the short chain fatty acids are at the position 3 of the triglyceride molecule, and the longer fatty acids tend to be in the positions 1 and 2. Hydrolysis of Fat with Lipase / Esterase Esterase or Lipase Diacylgycerol Triglyceride (Triacylgycerol) Free fatty Acid (FFA) Lipases act at the water-oil interface (high activity toward water insoluble substrates) and esterases show highest activity toward water soluble substrates. Commercial lipases / esterases for EMC are generally produced from: - Animal sources : from bovine and porcine pancreatic tissues (pancreatin and pancreatic lipase) and the pregastric tissues of calf, lamb and goat kid (PGE). Animal lipases are highly specific for the liberation of free fatty acids (FFA) from the sn-1 and sn-3 positions. Butanoic acid (C4:0) is located mainly at the sn-3 position and is preferentially released by PGE enzymes. - Fungal sources (Penicillium spp., Aspergillus spp., Rhizopus spp., Rhizomucor spp., Mucor spp. or Candida spp.). Lipases derived from microbial sources tend to have a much wider range of activity and specificity. Hydrolysis of Fat with Lipase / Esterase: Impact on Flavour Impact on flavour in cheese: - FFA released upon lipolysis contribute directly to cheese flavour, especially short and medium-chain FFA. Long-chain FFA (> C12:0) are considered to play a minor role in cheese flavour due to their high perception thresholds. - Short and intermediate-chain FFAs have a considerably lower perception thresholds and each gives a characteristic flavour note: Impact on flavour in EMC: - Short chain FFA (C4:0-C6:0) : rancid, pungent, cheesy, sharp, piquant (Blue cheese / Italian-type EMC) - Medium chain FFA (C8:0-C14:0) : Buttery - Long chain FFA (>C14:0): Soapy It is important to find the right balance between short / medium / long chain FFAs to produce the desired flavour. Hydrolysis of Fat with Lipase/Esterase: Analysis of FFA FFAs in EMC or cheese can be analysed by Gas Chromatography (GC) to generate free fatty acid profiles (FFAP) 1/ Extraction lipids from EMC or cheese 2/ Purification / Isolation of the FFA 3/ Gas Chromatography (GC) 4/ Free Fatty Acid Profile (FFAP) L187P Hydrolysis of Fat with Lipase: FFAPs L187P “Cheddar” L338P “Blue notes” L801MDP - Microbial Pancreatin lipase FlavorproTM C (Microbial calf PGE ) - very high level of C4:0 and C6:0, “Piccante” flavour Catabolism of FFA : generation of other flavour compounds Lactones identified in blue cheese, Cheddar, ParmagianoReggiano Methyl ketones (due to the action of mould lipase) - blue cheese 38 esters were identified in Parmagiano-Reggiano cheese Ethyl ester – fruity notes Hydrolysis of Proteins by Proteases Proteins (polypeptides) are made of amino acids arranged in a linear chain and folded into a globular form. The amino acids are joined together by the peptides bond between the carboxyl and amino groups of adjacent amino acid residues. Peptide bond N-terminus Amino acid C-terminus Protein (>100 amino acids) Proteases (endo- or exopeptidases) are proteolytic enzymes that catalyze the hydrolysis of peptide linkages: Protease Hydrolysis of Proteins by Proteases Endopeptidase (also called endo-protease) catalyzes the cleavage of peptide bonds within a protein. ● Exopeptidase catalyzes the cleavage of the terminal (last) or next to last peptide bond from a protein. There are 2 types of exopeptidases: ● - Carboxypeptidase catalyses the removal of one or two amino acid residues from the C-terminus of the protein. - Aminopeptidase catalyses the removal of one or two single amino acid residue from the N-terminus of the protein. Aminopeptidase Endopeptidase Carboxypeptidase Hydrolysis of Proteins by Proteases : Effect on Flavour Commercial proteases are generally derived from lactic acid bacteria (LAB) or from Aspergillus oryzae. Acid, neutral or basic (alkaline) proteases are available. In cheese, small peptides and amino acids are hypothesised to be mainly responsible for the basic taste of cheese (contributing to the background flavour of cheese). Amino acids and hydrophilic peptides contribute to savoury flavour in cheese. In EMC production, the action of proteases will: - Develop a “savoury” flavour. - Create some bitterness (that can be controlled). - Decrease the viscosity (change of texture by breakdown of the casein network). Hydrolysis of Proteins by Proteases : Effect on Flavour Savoury flavour comes from: - Hydrophilic peptides (increase of flavour due to increase of solubility): medium and small peptides contribute to a brothy background flavour in many cheese varieties. - Amino acids which contribute directly to cheese flavour; as some amino acids taste sweet (e.g. Gly, Ser, Thr, Ala, Pro), sour (e.g. His, Glu, Asp), or bitter (e.g. Arg, Met, Val, Leu, Phe). Example: The principal amino acids in Cheddar cheese are Glu, Leu, Arg, Lys, Phe, and Ser. Bitterness is caused by the accumulation of short hydrophobic peptides. Although the bitter taste is considered a normal component of cheese taste, excessive bitterness is not desirable for cheese or EMC. Bitterness can be controlled by the use of debittering proteases : exopeptidases Hydrolysis of Proteins by Proteases: Glutamic Acid Release Free glutamic acid is responsible for umami flavour in cheese (Parmesan contains 1680 mg of glutamic acid for 100g of cheese). Flavorpro™ Umami is an exopeptidase with endopeptidase and glutaminase side activities releasing high level of glutamic acid (Glu) in EMC applications. Umami heightens the flavour profile which helps increase the apparent saltiness in EMC, as confirmed by external sensory analysis. EMC made with Flavorpro™ Umami can therefore be used for salt reduction in processed cheese applications. Hydrolysis of Proteins by Proteases: Catabolism of amino acids Aromatic amino acids (phenylalanine, tyrosine, tryptophan), branched-chain amino acids (leucine, isoleucine and valine) and methionine are the major precursors of other important aroma and flavour compounds. Branched-chain amino acids (Leu, Ile, Val) are converted into: -Specific aldehydes with malty flavours, - Alcohols with fruity and alcoholic flavours - Acids with sweaty and also sour, rancid, rotten, fruity and buttery flavours (depending on which amino acid, Leu, Ile or Val, is catabolised). Sulfur compounds (characteristic components of surface ripened cheeses – ie camembert, brie) Conclusion EMC cheese LIPASES Fat (triglycerides) Protein (caseins) Free fatty acids CHEESE FLAVOUR Can be varied depending on the lipase(s) used (specificity of FFA carbon chain length) - Short chain FFAs (C4:0-C6:0) : cheesy, sharp, piquant - Medium chain FFAs (C8:0-C14:0) : Buttery - Long chain FFAs (>C14:0): Soapy PROTEASES - Peptides - Amino acids SAVOURY NOTES Protease(s) specificity (endoand/or exopeptidase) and dosage will influence savoury taste, bitterness and EMC texture. Lipase(s) and/or protease(s) to be used will depend on the flavour profile needed www.biocatalysts.com ¦ [email protected] ¦ [email protected]