* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Transducer

Ground (electricity) wikipedia , lookup

Electric machine wikipedia , lookup

Stepper motor wikipedia , lookup

Power inverter wikipedia , lookup

Electrical ballast wikipedia , lookup

Electrical substation wikipedia , lookup

Ground loop (electricity) wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Electromagnetic compatibility wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Current source wikipedia , lookup

Mechanical filter wikipedia , lookup

Mechanical-electrical analogies wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Integrating ADC wikipedia , lookup

Three-phase electric power wikipedia , lookup

Magnetic-core memory wikipedia , lookup

Surge protector wikipedia , lookup

History of electric power transmission wikipedia , lookup

Power electronics wikipedia , lookup

Schmitt trigger wikipedia , lookup

Buck converter wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Voltage regulator wikipedia , lookup

Stray voltage wikipedia , lookup

Voltage optimisation wikipedia , lookup

Transformer wikipedia , lookup

Alternating current wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Switched-mode power supply wikipedia , lookup

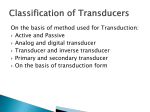

SVMIT ELECTRICAL Prepared By : - Rohan Kapadia Bhargav Khambhata Pradeep Malaviya Hemik Patel Snehal Mistry (016) (017) (018) (019) (020) Displacement Transducer LVDT & RVDT Transducer • A transducer is a device that convert one form of energy to other form. It converts the measurand to a usable electrical signal. • In other word it is a device that is capable of converting the physical quantity into a proportional electrical quantity such as voltage or current. • The physical quantity to be measured can be temperature, pressure, displacement ,flow,vibration etc. • Input Pressure (Physical quantity) Output Transducer Voltage (electrical quantity) Classification Transducers On The Basis of principle Used Active/Passive Primary/Secondary Analog/Digital Transducers/ Inverse Transducers Capacitive Transducers Inductive Resistive may be classified according to their application, method of energy conversion, nature of the output signal, and so on. Classification based on displacement Transducers Temperature Transducers Pressure Transducers Displacement Transducers Flow Transducers Others Displacement Measurements • Used to measure directly and indirectly the size, shape, and position of the organs. • Displacement measurements can be made using sensors designed to exhibit a resistive, inductive, capacitive or piezoelectric change as a function of changes in position. 6 Displacement Transducers • A measuring transducer that converts a linear or angular displacemen -t into an electric, mechanical, pneumatic, or other signal suitable for recording, longdistance transmission, or further conversion. • For linear measurement we can use LVDT (Linear Variable Displacement Transducer/ Linear Variable Differential Transformer). and for rotary measurement we can use RVDT (Rotary Variable Differential Transformer) LVDT :- Linear Variable Displacement Transducers/Transformers • Electromechanical transducer – Coupled to any type of object/structure – Converts the rectilinear motion of an object into a corresponding electrical signal – Measures Displacement !!!!!!!! • The linear variable differential transformer (LVDT) is an Inductive variable type displacement transducer. • Liner variable differential transformer excitation to such devices is normally a sinusoidal voltage of amplitude 3 to 15 rms and frequency of 60 to 20,000Hz. o Principle • It works on the phenomenon of electromagnetic induction. L i Where: L= inductance = magnetic flux i = electric current o Construction • It consists of a primary coil and secondary coil all in linear arrangement, with a magnetic core free to move inside the coils. The core is normally made of nickel iron alloy and has longitudinal slot as shown in figure to reduce eddy current . • When core slides through transformer, a certain number of coils are affected. • This generates a unique voltage . How Does An LVDT Work? This figure illustrates what happens when the LVDT's core is in different axial positions. The LVDT's primary winding, P, is energized by an AC source of constant amplitude. The magnetic flux thus developed is coupled by the core to the adjacent secondary windings, S1 and S2. If the core is located midway between S1 and S2, equal flux is coupled to each secondary so the voltages, E1 and E2, induced in each winding are equal. At this midway core position, referred to as the null point, the differential voltage output, (E1 - E2) is zero. As shown here, if the core is moved closer to S1 than to S2 , more flux is coupled to S1 and less to S2, so the induced voltage E1 is increased while E2 is decreased, resulting in the differential voltage (E1 - E2). Conversely, if the core is moved closer to S2, more flux is coupled to S2 and less to S1, so E2 is increased as E1 is decreased, resulting in the differential voltage (E2 E1). The phase angle of this AC output voltage, Eout, referenced to the primary excitation voltage, stays constant until the center of the core passes the null point, where the phase angle changes abruptly by 180 degrees, as shown graphically in this diagram. This 180 degree phase shift can be used to determine the direction of the core from the null point by means of appropriate circuitry. As this diagram shows, the polarity of the output signal represents the core's positional relationship to the null point. Graphical representation Friction – Free Operation Zero displacement can be measured. Single Axis Sensitivity Most LVDT’s have open bore holes. Null Point Repeatability Electromagnetic coupling Limited only by electrical noise. Low risk of damage NO mechanical contact between core and coil (usually). Infinite Mechanical Life Infinite Resolution Features !!! Effects of other axes are not felt on the axis of interest. Environmentally Robust Stable/Strong sensors – good for structural engineering tests!!! Types • Free Core o o Frictionless Operation Possible Mechanically Coupled Core • Guided Core o o Bearings with Friction, Stiction, etc. Spring- or Air-Loaded Core • ADVANTAGES :• Generally Less Expensive • ADVANTAGES :• Usually Simpler to Install • Many Ranges and Sizes to Choose • Perceived as More Expensive • More Complicated to Install • More Limited Selection of Ranges and Limited to Short Strokes Uses • • • • • • • • • Automation Machinery Civil/Structural Engineering Power Generation Manufacturing Metal Stamping/Forming Pulp and Paper Industrial Valves R & D and Tests Automotive Racing RVDT:-Rotary Variable Differential Transformer • It is a type of electrical transformer used for measuring angular displacement. • It is an electromechanical transducer that provides a variable alternating current (AC) output voltage that is linearly proportional to the angular displacement of its input shaft. When energized with a fixed AC source, the output signal is linear within a specified range over the angular displacement. • (RVDT) is used to measure rotational angles and operates under the same principles as the LVDT sensor. Whereas the LVDT uses a cylindrical iron core, the RVDT uses a rotary ferromagnetic core. The two induced voltages of the secondary windings, vary linearly to the mechanical angle of the rotor, θ: and Where G is the gain or sensitivity. The second voltage can be reverse determined by: The difference gives a proportional voltage :- and the sum of the voltages is a constant: , • This constant gives the RVDT great stability of the angular information, independence of the input voltage or frequency, or temperature, and enables it to also detect a malfunction. Advantages o Relative low cost due to its popularity. o Solid and robust, capable of working in a wide variety of environments o No friction resistance, since the iron core does not contact the transformer coils, resulting in an very long service life. o High signal to noise ratio and low output impedance. o Negligible hysteresis. o Infinitesimal theoretical resolution. In reality, angle resolution is limited by the resolution of the amplifiers and voltage meters used to process the output signal. o No permanent damage to the RVDT if measurements exceed the designed range. Disadvantages o The core must be in contact (directly or indirectly) with the measured surface which is always possible or desirable. not Uses o Tachometers o Magnetic speed sensors o Optical decoders o Variable reluctance tachometers o Accelerometers o Eddy-current tachometers etc. Thank you…!!!