* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Micrometers Vernier caliper

Electric machine wikipedia , lookup

History of electric power transmission wikipedia , lookup

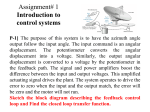

Spark-gap transmitter wikipedia , lookup

Mains electricity wikipedia , lookup

Voltage optimisation wikipedia , lookup

Buck converter wikipedia , lookup

Ignition system wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Magnetic core wikipedia , lookup

Alternating current wikipedia , lookup

Transformer wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Rotary encoder wikipedia , lookup

Motion Sensors Displacement, velocity and acceleration 1 Dimensional measurement Micrometers Vernier caliper • • • One complete revolution = 0.5 mm (usually) With 50 divisions, each division movement corresponds to 0.01 mm If user can control every one-fifth of a division, a resolution of 0.002 mm is possible 2 Height & depth measurement Gauge blocks Dial gauge: typical resolution 0.01 mm Height & depth gauges 3 Resistive potentiometer Linear potentiometer Rotary potentiometer (a) circular; (b) helical Types: wire-wound, carbon-film and plastic-film (according to resistance element) 4 Linear Variable Differential Transformer (LVDT) • • • • Inductive displacement sensor. Transformer with 1 primary & 2 secondary coils, connected in series opposition Output voltage (difference between induced voltages) is proportional to core displacement Zero reading when core is centered Primary Secondary Rotary differential transformer 5 Eddy current sensor • • • • • Inductive displacement sensor. Coil is excited at high frequency (typically 1 MHz) This induces eddy current in the target Eddy current alters the inductance of the probe coil This change can be translated into a voltage proportional to the air gap 6 Piezoelectric transducers • A piezoelectric material generates charge when deformed • Induced charge leaks away with time • Piezoelectric transducers are not suitable for static or slowly-varying dispalcements 7 Optical encoders (incremental) • Measure instantaneous angular position of a shaft • Output is in the form of pulses to be counted 8 Optical encoders (coded-disc) • Output is in the form binary numbers to give absolute measure of shaft position Float encoder 9 Other rotational motion sensors • Gyroscopes • Tachometers • Mechanical flyball Gyroscope Photoelectric tachometer 10 Mechanical flyball Vibration Measurement 11 12 13 14 15 Energy Harvesting Source: J.K. Ward and S. Behrens, “Adaptive learning algorithms for vibration energy harvesting”, Smart Materials & Structures 17 (2008) 035025 1-9. 16 Vibration-based Energy Harvesting Source: B.P. Mann and N.D.Sims, “Energy harvesting from the nonlinear oscillations of magentic levitation”, Journal of Sound and Vibration (2008) in press. 17 18 19