* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Hyundai Accent 2005 Pump

Survey

Document related concepts

Stepper motor wikipedia , lookup

Opto-isolator wikipedia , lookup

Mains electricity wikipedia , lookup

Alternating current wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Portable appliance testing wikipedia , lookup

Stray voltage wikipedia , lookup

Ignition system wikipedia , lookup

Phone connector (audio) wikipedia , lookup

Electric vehicle conversion wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Transcript

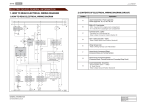

Hyundai Accent 2005 Pump SERVICE MANUAL Applies to: Accent 2005 GROUP Fuel System DTC Troubleshooting Procedures DTC - P2405 GENERAL DESCTIPTION The DM-TL (Diagnostic Module Tank Leakage) is used to monitor the evaporative system for leaks. The diagnostic module consists of an air filter, an electrical driven air pump, a change-over valve and a 0.02 inch orifice for reference measurement . Heated type Module applied to improved Leakage Detection Module. Using the heated DM-TL can completely eliminate the humidity influence. So, the Leakage detection is never stopped caused by the current fluctuation (due to dew effects at extreme high humidity). DTC DESCRIPTION If the value exceeds threshold value, the PCM judged this as a fault and DTC is set. DTC DETECTING CONDITION Item Detecting Condition Possible cause Monitoring Strategy ? DM-TL : pump motor current ? Current at reference mode phase < 12 ? Leakage on EVAP. SYSTEM Ma ? Faulty DMTL. Enable Conditions ? Faulty PCM Diagnostic Time ? 10 sec Threshold value Fail Safe SPECIFICATION DMTL Motor Normal Parameter At 20?(68?F) Resistance approximately 118 ? SCHEMATIC DIAGRAM 8/8/2006 SIGNAL WAVEFORM AND DATA MONITOR DTC STATUS This is the inspection procedure to determine whether it is present DTC or memoried one by monitoring the current signal or by using the function of oscilloscope with Hi-scan pro. 1. Connect scantool to Data Link Connector(DLC). 2. Warm up the engine to normal operating temperature. 3. Evap. Leakage TestEvaporative Emissions Systems (EVAP) Leak Tests can be run by the Scan Tool. The tests are automated and provide either a pass-fail result or directions to check for DTCs. 8/8/2006 A. B. C. D. Connect scantool to Data Link Connector(DLC). Warm up the engine to normal operating temperature. Perform "07 EVAP. LEAKAGE TEST" mode Is DTC P2405 set again? ? Go to "W/Harness Inspection" procedure. ? Fault is intermittent caused by poor contact in the sensor’s and/or PCM’s connector or was repaired and PCM memory was not cleared. Thoroughly check connectors for looseness, poor connection,bending, corrosion, contamination, deterioration, or damage. Repair or replace as necessary and go to "Verification vehicle Repair" procedure TERMINAL AND CONNECTOR INSPECTION 1. Many malfunctions in the electrical system are caused by poor harness and terminals. Faults can also be caused by interference from other electrical systems, and mechanical or chemical damage. 2. Thoroughly check connectors for looseness, poor connection, bending, corrosion, contamination,deterioration, or damage. 3. Has a problem been found? ? Repair as necessary and go to "Verification of vehicle Repair" procedure. 8/8/2006 ? Go to "Power circuit insepction" procedure. POWER CIRCUIT INSPECTION 1. Ignition "OFF" 2. Disconnect DM-TL connector. 3. Ignition "ON" AND Engine "OFF" 4. Measure voltage between terminal 4 of DM-TL harness connector and chassis ground. Specification : Approx. B+ 5. Is measure voltage within Specification? ? Go to "Control circuit insepction" procedure. ? Check for open or short circuit between Main relay and terminal 3 of DM-TL? Especially check "10A ECU" fuse is blown or not installed Repair as necessary and go to "Verification Vehicle Repair" procedure. CONTROL CIRCUIT INSPECTION 1. Ignition "OFF" 2. Disconnect DM-TL connector. 3. Ignition "ON" AND Engine "OFF" 8/8/2006 4. Measure voltage between terminal 2 of DM-TL harness connector and chassis ground. Specification : approximately 3.7V 5. Is measure voltage within Specification? ? Go to "Component Inspection" procedure. ? Check for Open or short in Solenoid Control harness.? Repair as necessary and then go to "Verification of Vehicle Repair" procedure. COMPONENT INSPECTION 1. Check Solenoid A. Ignition "OFF" B. Disconnect DM-TL connector. C. Measure resistance between terminal 2 and 4 of DM-TL harness connector.(To sender side) Specification : 20?(68?F) : approximately 31? 8/8/2006 D. Is measure resistance within Specification? ? Go to "Check Pump" as below. ? Substitute with a known-good Pump motor and check for proper operation. If the problem is corrected, replace Pump motor and then go to "Verification of Vehicle Repair" procedure. 2. Check Pump A. Ignition "OFF" B. Disconnect DM-TL connector. C. Measure resistance between terminal 1 and 4 of DM-TL harness connector.(To sender side) Specification : 20?(68?F) : approximately 118? D. Is measure resistance within Specification? ? Substitute with a known-good PCM and check for proper operation. If the problem is corrected, replace PCM and then go to "Verification of Vehicle Repair" procedure. ? Substitute with a known-good DM-TL and check for proper operation. If the problem is corrected, replace DM-TL and then go to "Verification of Vehicle Repair" procedure. VERIFICATION OF VEHICLE REPAIR After a repair, it is essential to verify that the fault has been corrected. 8/8/2006 1. Monitor and record the Freeze Frame Data for the Diagnostic Trouble Code (DTC) which has been diagnosed. 2. Using a Scantool, Clear the DTCs. 3. Operate the vehicle within conditions noted in the freeze frame data or enable conditions. 4. Monitor that all rediness test have been verified as "Complete" 5. Are any DTCs present ? ? Go to the applicable troubleshooting procedure. ? System is performing to specification at this time. This was found at http://www.hmaservice.com/index.jsp?SSOSESSIONID=AyExJlh29thYVtq%2F6jwhR1 S1 . 8/8/2006