* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download AN2787

Stepper motor wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Power engineering wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electrical substation wikipedia , lookup

Power inverter wikipedia , lookup

Electrical ballast wikipedia , lookup

Stray voltage wikipedia , lookup

Surge protector wikipedia , lookup

Three-phase electric power wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Schmitt trigger wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Two-port network wikipedia , lookup

Current source wikipedia , lookup

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power MOSFET wikipedia , lookup

Mains electricity wikipedia , lookup

Voltage regulator wikipedia , lookup

Switched-mode power supply wikipedia , lookup

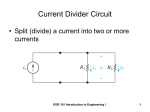

Current mirror wikipedia , lookup

AN2787 Application note Monolithic VR demonstration board for chipset and DDR2/3 supply for ultramobile PC (UMPC) applications Introduction PM6641 demonstration board order code: STEVAL-ISA050V1 (previously coded as PM6641EVAL). The PM6641 demonstration board is a monolithic voltage regulator (VR) module with internal power MOSFETs, specifically designed to supply DDR2/3 memory and chipset in ultramobile PC and real estate constrained portable systems. It integrates three independent, adjustable, constant frequency buck converters, a ±2 Apk low dropout (LDO) linear regulator, and a ±15 mA low-noise buffered reference. Each regulator is provided with basic undervoltage (UV) and overvoltage (OV) protections, programmable soft-start and current limit, active soft-end, and pulse skipping at light loads. This document describes all features of the PM6641 demonstration board. Figure 1. September 2008 PM6641 demonstration board Rev 1 1/37 www.st.com www.BDTIC.com/ST Contents AN2787 Contents 1 Main features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2 Demonstration kit schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 3 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 4 Component assembly and layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 5 I/O interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 6 Recommended equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 7 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 7.1 JP1 VDDQ output discharge (DSCG pin) . . . . . . . . . . . . . . . . . . . . . . . . . 15 7.2 JP3 switching regulator phase control (SET_PH1 pin) . . . . . . . . . . . . . . 15 7.3 JP4 1.8 V (VDDQ) external/internal divider (VFB_1S8 pin) . . . . . . . . . . . 16 7.4 JP5 1.5 V external/internal divider (VFB_1S5 pin) . . . . . . . . . . . . . . . . . . 17 7.5 JP6 1.05 V external/internal divider (VFB_1S05 pin) . . . . . . . . . . . . . . . . 17 7.6 JP7 current limit (CSNS pin) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 8 Test setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 9 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 10 STEVAL-ISA050V1 evaluation tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 10.1 SW regulators turn-on (soft-start) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 10.2 SW regulator - working mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 10.3 Load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 10.4 Load transient responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 10.5 Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 10.6 Phase management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 10.7 Fault management (OVP, UVP, UVLO, thermal) . . . . . . . . . . . . . . . . . . . 30 10.8 SW regulators current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 10.9 Soft-end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 2/37 www.BDTIC.com/ST AN2787 Contents 10.10 Thermal behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 11 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 3/37 www.BDTIC.com/ST List of figures AN2787 List of figures Figure 1. Figure 2. Figure 3. Figure 4. Figure 5. Figure 6. Figure 7. Figure 8. Figure 9. Figure 10. Figure 11. Figure 12. Figure 13. Figure 14. Figure 15. Figure 16. Figure 17. Figure 18. Figure 19. Figure 20. Figure 21. Figure 22. Figure 23. Figure 24. Figure 25. Figure 26. Figure 27. Figure 28. Figure 29. Figure 30. Figure 31. Figure 32. Figure 33. Figure 34. Figure 35. Figure 36. Figure 37. Figure 38. PM6641 demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 PM6641 demonstration board schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Top side component placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Top view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Layer 2 view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Layer 3 view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Bottom view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Bottom side component placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 JP1 DSCG pin setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 JP3 phase control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 JP4 1.8 V divider selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 JP5 1.5 V divider selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 JP6 1.05 V divider selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 PM6641 demonstration board programmed current limit vs. CSNS resistor . . . . . . . . . . . 18 JP8 setting switching frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 PM6641 demonstration board test setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 VDDQ turn-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 VDDQ, VTT and VTTREF turn-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 PWM mode: VDDQ output voltage, phase voltage and inductor current, current load = 2.3 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Pulse skip mode: VDDQ output voltage, phase voltage and inductor current, current load = 0 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Forced PWM mode (soft OV): VDDQ output voltage, phase voltage, inductor current and Power Good signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 VDDQ (1.8 V) load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 1.5 V load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 1.05 V load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 VTT load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 VTTREF load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 VDDQ, VTT and VTTREF, VDDQ load transient response, IVDDQ = 0 to 2.3 A at 2.5 A/µs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 1.5 V output voltage and inductor current, 1.5 V rail load transient response, 1.5 V = 0 to 1.25 A at 2.5 A/µs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 1.05 V output voltage and inductor current, 1.05 V rail load transient response. I1.05 V = 0 to 1.75 A at 2.5 A/µs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 VDDQ, VTTREF, VTT and VTT output current, VTT rail load transient response, IVTT = –1 A to +1 A at 2.5 A/µs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 SW regulators efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 SW regulators phases, 120 deg phase shift. SETPH1 pin tied to AGND . . . . . . . . . . . . . . 29 SW regulators phases, no phase shift - synchronous clock, SETPH1 pin tied to AVCC . . 30 VDDQ, VTT, VTTREF output voltage, VDDQ temporarily shorted to 3.3 V, output overvoltage protection triggered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 VDDQ, VTT, VTTREF output voltage and VDDQ inductor current, VDDQ feedback pin temporarily shorted to GND, output undervoltage protection triggered . . . . . . . . . . . . . . . 31 VDDQ (1.8 V), 1.5 V, 1.05 V output voltage and AVCC input power supply, input undervoltage lockout triggered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 VDDQ (1.8 V), 1.5 V, 1.05 V and VTT rails output voltage, thermal shutdown triggered . . 32 1.5 V rail output voltage, 1.5 V inductor current and output current, peak current limit 4/37 www.BDTIC.com/ST AN2787 Figure 39. Figure 40. Figure 41. List of figures reached . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 VDDQ(1.8 V), VTT and VTTREF rail output voltage, EN_1S8 and EN_VTT tied to AGND - soft off with tracking discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 VDDQ(1.8 V), VTT and VTTREF rail output voltage. EN_1S8 and EN_VTT tied to AGND - soft off without tracking discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 PM6641 demonstration board surface temperature when loaded with typical currents, Tamb = 23 °C, VIN = 3.3 V, FSW = 660 kHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 5/37 www.BDTIC.com/ST Main features 1 AN2787 Main features Switching section ● 0.8 V ±1% voltage reference ● 2.7 V to 5.5 V input voltage range ● Fast response, constant frequency, current mode control ● Three independent, adjustable, SMPS for DDR2/3 (VDDQ) and chipset supply ● S3-S5 states compliant with DDR2/3 section ● Active soft-end for all outputs ● Selectable tracking discharge for VDDQ ● Separate Power Good signals ● Pulse skipping at light load ● Programmable current limit and soft-start for all outputs ● Latched OVP, UVP protection ● Thermal protection Reference and termination voltages (VTTREF and VTT) ● ±2 Apk LDO for DDR2/3 termination (VTT) with foldback ● Remote VTT output sensing ● High-Z VTT output in S3 ● ±15 mA low-noise DDR2/3 buffered reference (VTTREF) 6/37 www.BDTIC.com/ST 2 3 1 JP4 STRIP 3 1 0603-1u C1 0603-100p C29 + C5 EL SMD C-10u R6 0603-120k R5 0603-150k TP8 GND TP9 VOUT_1S8 VCC 1 R3 0603-100k VIN C22 0603-330p R11 0603-100k 0603-22n C19 0603-15p C32 C2 0805-10u 1 C15 B Case - 220u C6 B Case - 220u 2839-1u C21 2 3 1 2 JP6 STRIP 3 C24 0603-330p C17 C12 0805-10u 0603-33n C18 R10 0603-180k U1 PM6641_QFPN 1 AVCC TP16 AGND C11 1206-22u 36 35 34 33 32 31 30 29 28 27 26 25 C9 B Case - 220u EN_VTT EN_1S5 EN_1S05 VIN_1S5 VSW_1S5_2 VSW_1S5_1 SGND_1S5_2 SGND_1S5_1 VFB_1S5 COMP_1S5 SS_1S5 PG_1S5 L3 2839-1u VOUT_1S05 1 TP12 0603-100p C31 THERMAL R9 0603-56k R2 0603-4R3 0603-100n AGND_1 SET_SWF VOUT_1S8 CSNS SGND_1S8_1 SGND_1S8_2 VSW_1S8_1 VSW_1S8_2 VIN_1S8_1 VIN_1S8_2 VFB_1S8 COMP_1S8 0603-15p C33 49 1 2 3 4 5 6 7 8 9 10 11 12 R33 0603-join 1 TP14 VTT 1 TP1 VTTREF 1 AVCC R13 0603-68k 0603-join R32 R4 0603-68k JP1 STRIP 3 2 0603-22n L1 2 1 STRIP 2 JP8 2 1 1 STRIP 2 JP7 0603-100n AVCC R1 0603-4R3 C16 1 1 AVCC 1 2 AVCC C4 0805-10u VIN GND 1 TP13 R31 0603-join 1 2 VCC GND TP17 EL SMD C-10u 1 2 2839-1u5 VIN 0603-100p C25 R34 0603-join 1 VIN TP7 TP18 AUX 0603-100p C26 R17 0603-68k AUX R18 0603-68k AUX R22 0603-68k R19 0603-68k 1 2 3 4 TP2 PG_1S8 TP3 PG_1S5 8 7 6 5 TP4 PG_1S05 R8 0603-120k R7 0603-100k SW DIP-4 SW1 JP5 STRIP 3 0603-100p C28 R23 0603-68k 2 + C8 EL SMD C-10u 0603-100p C27 R21 0603-68k AUX R20 0603-68k 0603-100p C30 C7 B Case - 220u C3 0805-10u R30 0603-join C23 0603-470p L2 C34 0603-15p 1 C20 0603-22n R12 0603-47k JP3 STRIP 3 + C13 C10 EL SMD C-10u B Case - 220u C14 2 AVCC 3 1 TP15 LDOIN 2 1 1 TP6 AGND 3 2 48 47 46 45 44 43 42 41 40 39 38 37 VCC VTT_FB DSCG VTTREF LDO_IN VTT VTT_GND AVCC AGND_2 SET_PH1 AGND_3 EN_1S8 SS_1S8 SS_1S05 COMP_1S05 VFB_1S05 SGND_1S05_1 SGND_1S05_2 VSW_1S05_1 VSW_1S05_2 VIN_1S05_1 VIN_1S05_2 PG_1S05 PG_1S8 13 14 15 16 17 18 19 20 21 22 23 24 1 2 TP5 VCC + 1 1 2 3 1 1 www.BDTIC.com/ST 1 TP10 VOUT_1S5 TP11 GND 1 Figure 2. 1 2 1 AN2787 Demonstration kit schematic Demonstration kit schematic PM6641 demonstration board schematic 7/37 Bill of material AN2787 3 Bill of material Table 1. PM6641 demonstration board list of components Qty Component Description Package Part number MFR Value Standard 1µ Murata 10 µ Note 1 C1 Ceramic, 10 V, X5R, 20% SMD 0603 4 C2, C3, C4, C12 Ceramic, 10 V, X5R, 20% SMD 0805 4 C5, C8, C13, C14 5 C6, C7, C9, C10, C15 Ceramic, 4 V, X5R, 20% SMD 1206 AMK316BJ107ML Taiyo Yuden 100 µ 1 C11 Ceramic, 6.3 V, X5R, 10% SMD 1206 GRM31CR60J226KE19 Murata 22 µ 2 C16, C17 Ceramic, 16 V, X7R, 10% SMD 0603 Standard 100 n 1 C18 Ceramic, 25 V, X7R, 10% SMD 0603 Murata 33 n 3 C19, C20, C21 Ceramic, 16 V, X7R, 10% SMD 0603 Standard 22 n 2 C22, C24 Ceramic, 50 V, C0G, 5% SMD 0603 Standard 330 pF 1 C23 Ceramic, 50 V, C0G, 5% SMD 0603 Standard 470 pF 4 C25, C26, C27, C28 Ceramic, 50 V, C0G, 5% SMD 0603 Standard 100 pF 3 C29, C30, C31 Ceramic, 50 V, C0G, 5% SMD 0603 n.m. 3 C32, C33, C34 Ceramic, 50 V, C0G, 5% SMD 0603 n.m. 2 R1, R2 Chip resistor, 0.1 W, 1% SMD 0603 Standard 3R3 1 R3 Chip resistor, 0.1 W, 1% SMD 0603 Standard 100 kΩ 9 R4, R13 R17, R18, R19, R20, R21, R22, R23 Chip resistor, 0.1 W, 1% SMD 0603 Standard 68 kΩ 1 R16 Chip resistor, 0.1 W, 1% SMD 0603 1 R5 Chip resistor, 0.1 W, 1% SMD 0603 GRM21BR61A106KE19 SMD C case n.m. GRM188R71E333KA01 n.m. Standard 8/37 www.BDTIC.com/ST 150 kΩ AN2787 Bill of material Table 1. PM6641 demonstration board list of components (continued) Qty Component Description Package Part number MFR Value 2 R6, R8 Chip resistor, 0.1 W, 1% SMD 0603 Standard 120 kΩ 1 R7 Chip resistor, 0.1 W, 1% SMD 0603 Standard 100 kΩ 1 R9 Chip resistor, 0.1 W, 1% SMD 0603 Standard 56 kΩ 1 R10 Chip resistor, 0.1 W, 1% SMD 0603 Standard 180 kΩ 1 R11 Chip resistor, 0.1 W, 1% SMD 0603 Standard 100 kΩ 1 R12 Chip resistor, 0.1 W, 1% SMD 0603 Standard 47 kΩ 3 R32, R33, R34 Chip resistor, 0.1 W, 1% SMD 0603 Standard 0Ω 2 R30, R31 Chip resistor, 0.1 W, 1% SMD 0603 2 L1, L3 SMT 11Arms, 9.5 mΩ SMD 2827 744312100 /LF Würth 1.0 µH 1 L2 SMT 9 Arms, 10.5 mΩ SMD 2827 744312150 /LF Würth 1.5 µH 1 U1 IC VR - 48-pin VFQFPN 7x7 PM6641 STMicroelectronics 5 JP1, JP3, JP4, JP5, JP6 Header, 3-pin SIP3 2 JP7, JP8 Header, 2-pin SIP2 5 TP1, TP2, TP3, TP4, TP18 Header, single pin 13 TP5, TP6, TP7, TP8, TP9, TP10, TP11, TP12, TP13, TP14, TP15, TP16, TP17 Test point 1 SW1 Switch 4-SPST DIP-8 Note short n.m. Standard 9/37 www.BDTIC.com/ST Component assembly and layout 4 Component assembly and layout Figure 3. Top side component placement Figure 4. Top view 10/37 www.BDTIC.com/ST AN2787 AN2787 Component assembly and layout Figure 5. Layer 2 view Figure 6. Layer 3 view 11/37 www.BDTIC.com/ST Component assembly and layout Figure 7. Bottom view Figure 8. Bottom side component placement 12/37 www.BDTIC.com/ST AN2787 AN2787 5 I/O interface I/O interface The PM6641 demonstration board has the following test points given in Table 2. Table 2. PM6641 demonstration board input/output interface Test point Description VCC (TP5) +5 V IC supply, positive terminal LDOIN (TP15) LDO (VTT) linear regulator input power supply AUX (TP18) Auxiliary 3.3 V for pull-up (not required) AGND (TP6, TP16) VCC, LDO, VTT and VTTREF common return VIN (TP7) Power supply input voltage positive terminal GND (TP8, TP11, TP13, TP17) Power supply and switching regulator outputs common return V1S8 (TP9) 1.8 V (VDDQ) switching regulator output V1S5 (TP10) 1.5 V switching regulator output V1S05 (TP12) 1.05 V switching regulator output VTT (TP14) LDO (VTT) linear regulator output VTTREF (TP1) Voltage reference (VTTREF) buffer output PG1S8 (TP2) 1.8 V (VDDQ) switching regulator Power Good signal PG1S5 (TP3) 1.5 V switching regulator Power Good signal PG1S05 (TP4) 1.05 V switching regulator Power Good signal 13/37 www.BDTIC.com/ST Recommended equipment 6 Recommended equipment ● 5 V power supply ● 3.3 V, 20 W power supply ● Active loads ● Digital multimeters ● 500 MHz four-trace oscilloscope 14/37 www.BDTIC.com/ST AN2787 AN2787 7 Configuration Configuration The PM6641 demonstration board allows the user to test all the main features of the VR PM6641, acting on 7 different jumpers and 4 switches. SW1 (4 SPST switches) lets the user enable the switching regulators and the VTT linear regulator. In the following sections each jumper is analyzed. 7.1 JP1 VDDQ output discharge (DSCG pin) The JP1 jumper is used to choose between the tracking discharge or nontracking discharge of the 1.8 V rail (VDDQ) output. When the 1.8 V rail is deactivated (EN_1S8 goes low) and the DSCG is set high, tracking discharge takes place: ● The 1.8 V rail regulator is discharged by the internal MOSFETs ● The 0.9 V LDO and VTTREF work tracking with half of the 1.8 V rail When the 0.9 V LDO and VTTREF reach a voltage threshold of about 300 mV, the nontracking discharge mode is performed by closing the internal discharge MOSFETs. If the nontracking discharge mode is chosen, when EN_1S8 goes low, the 1.8 V and 0.9 V rails and the VTTREF buffer are independently discharged by internal MOSFETs. Figure 9. JP1 DSCG pin setting Tracking Discharge Non Tracking Discharge 7.2 JP3 switching regulator phase control (SET_PH1 pin) The JP3 jumper allows selecting two different oscillator settings in order to change the delay between the pulses that start the control cycle. The inner clock is divided in order to obtain three slower clocks with a fixed delay of 120 deg. By setting JP3 as depicted in Figure 10, it is possible to synchronize the 1.8 V, 1.5 V and 1.05 V switching regulator clocks or to select 120 deg delay in order to decrease the total RMS input current. 15/37 www.BDTIC.com/ST Configuration AN2787 Figure 10. JP3 phase control JP3 120deg Phase Shifting Synchronous The 120 deg phase shifting is the default configuration in which the inner clock is divided and three pulses delayed by 120 deg are obtained to trigger the switching regulator loops. The synchronous clocking allows all the regulators to start at the same pulse, avoiding the jitter due to simultaneous turn-on and off of different sections, but increasing the overall RMS input current. 7.3 JP4 1.8 V (VDDQ) external/internal divider (VFB_1S8 pin) The JP4 jumper allows selecting the internal divider or the external divider for the 1.8 V switching regulator. When the VFB_1S8 pin is connected directly to the output capacitor, the internal divider is enabled and this section provides 1.8 V output voltage. When the multifunction pin VFB_1S8 is tied to the central tap of an external divider, the switching regulator becomes adjustable, with the following output voltage: Equation 1 ⎛R ⎞ Vout = ⎜⎜ 5 + 1⎟⎟ ⋅ 0.8 V ⎝ R6 ⎠ Figure 11. JP4 1.8 V divider selection External Divider Enabled Internal Divider Enabled 16/37 www.BDTIC.com/ST AN2787 7.4 Configuration JP5 1.5 V external/internal divider (VFB_1S5 pin) The JP5 jumper allows selecting the internal divider or the external divider for the 1.5 V switching regulator. When the VFB_1S5 pin is connected directly to the output capacitor, the internal divider is enabled and this section provides 1.5 V output voltage. When the multifunction pin VFB_1S5 is tied to the central tap of an external divider, the switching regulator becomes adjustable, with the following output voltage: Equation 2 ⎛R ⎞ Vout = ⎜⎜ 7 + 1⎟⎟ ⋅ 0.8 V R ⎝ 8 ⎠ Figure 12. JP5 1.5 V divider selection Internal Divider Enabled External Divider Enabled 7.5 JP6 1.05 V external/internal divider (VFB_1S05 pin) The JP6 jumper allows selecting the internal divider or the external divider for the 1.05 V switching regulator. When the VFB_1S05 pin is connected directly to the output capacitor, the internal divider is enabled and this section provides 1.05 V output voltage. When the multifunction pin VFB_1S5 is tied to the central tap of an external divider, the switching regulator becomes adjustable, with the following output voltage: Equation 3 ⎛R ⎞ Vout = ⎜⎜ 9 + 1⎟⎟ ⋅ 0.8 V R ⎝ 10 ⎠ Figure 13. JP6 1.05 V divider selection External Divider Enabled Internal Divider Enabled 17/37 www.BDTIC.com/ST Configuration 7.6 AN2787 JP7 current limit (CSNS pin) Each switching regulator current limit is set by inserting a resistor between the CSNS pin and AGND. By changing this resistor value, all the current limits change, as shown in Figure 14. Figure 14. PM6641 demonstration board programmed current limit vs. CSNS resistor Peak Current Limit 7,00 6,00 Current Limit [A] 5,00 CL_1V8 4,00 CL_1V5 3,00 CL_1V05 2,00 1,00 0,00 50 70 90 110 130 150 170 Rcsns [kOhm ] If the CSNS pin is tied to AVCC, the current limit is set through the inner reference resistor (equal to 50 kΩ). Figure 15. JP8 setting switching frequency Default Switching Frequency Adjusted Switching Frequency 18/37 www.BDTIC.com/ST AN2787 8 Test setup Test setup Figure 16 shows the suggested setup connections between the PM6641 demonstration board, the loads, and the external supply. Figure 16. PM6641 demonstration board test setup 19/37 www.BDTIC.com/ST Getting started 9 AN2787 Getting started The following step-by-step power-up and power-down sequences are provided in order to correctly evaluate the PM6641 demonstration board performance. Power-up sequence ● Connect power supplies as shown in the PM6641 demonstration board test setup (Figure 16) and insert the meters in order to perform the desired performance evaluation. Connect the scope-probes as desired ● Set the JP1 through JP8 jumpers in order to properly configure the PM6641 demonstration board. Set the SW1 switches (EN_1S8, EN_VTT, EN_1S5, EN_1S05) to the ON position. Do not change jumper settings when the board is powered ● Set the VCC supply to 5 V ±5% and the current limit to 100 mA ● Set the VIN supply to a voltage in the range 2.7 V to 3.6 V ● Set all active loads to 0 A ● Turn-on the VIN supply ● Turn-on the VCC supply ● Vary the 1.8 V (VDDQ) load from 0 A to 4 A ● Vary the 1.5 V load from 0A to 2.5 A ● Vary the 1.05 V load from 0A to 3.5 A ● Vary the 0.9 V (VTT) load from 0 A to 2 A to test source capability. To test sink capability use the alternative VTT load connection shown in Figure 16 ● Vary VTTREF load to test source capabilty. Power-down sequence ● Decrease VTTREF and VTT loads to 0 A ● Turn-off the 1.8 V (VDDQ), 1.5 V, 1.05 V loads ● Decrease VCC supply from 5 V to 3.8 V in order to test the input undervoltage lockout (UVLO) ● Increase VCC supply from 3.8 V to 5 V to restart the device ● Use the EN_1S8 and En_VTT switches to enter/exit the S0-S3-S5 states ● Turn-off the VCC supply ● Turn-off the VIN supply. 20/37 www.BDTIC.com/ST AN2787 STEVAL-ISA050V1 evaluation tests 10 STEVAL-ISA050V1 evaluation tests 10.1 SW regulators turn-on (soft-start) When the EN_xx pin is toggled high, the correspondent SW regulator performs the soft-start as programmed through the external soft-start capacitor. Figure 17 depicts VDDQ (1.8 V) turn-on with CSS = 22 nF. Figure 17. VDDQ turn-on 21/37 www.BDTIC.com/ST STEVAL-ISA050V1 evaluation tests AN2787 Figure 18. VDDQ, VTT and VTTREF turn-on 10.2 SW regulator - working mode Each switching regulator changes working mode with the appropriate load. When the load is heavy, the SW enters PWM mode, but when the load is light, pulse skip mode is entered. Each SW regulator is also able to sink current from the output (forced PWM mode when a soft overvoltage occurs). 22/37 www.BDTIC.com/ST AN2787 STEVAL-ISA050V1 evaluation tests Figure 19. PWM mode: VDDQ output voltage, phase voltage and inductor current, current load = 2.3 A 23/37 www.BDTIC.com/ST STEVAL-ISA050V1 evaluation tests AN2787 Figure 20. Pulse skip mode: VDDQ output voltage, phase voltage and inductor current, current load = 0 A Figure 21. Forced PWM mode (soft OV): VDDQ output voltage, phase voltage, inductor current and Power Good signal 24/37 www.BDTIC.com/ST AN2787 10.3 STEVAL-ISA050V1 evaluation tests Load regulation Figure 22. VDDQ (1.8 V) load regulation Figure 23. 1.5 V load regulation 25/37 www.BDTIC.com/ST STEVAL-ISA050V1 evaluation tests Figure 24. 1.05 V load regulation Figure 25. VTT load regulation Figure 26. VTTREF load regulation 26/37 www.BDTIC.com/ST AN2787 AN2787 10.4 STEVAL-ISA050V1 evaluation tests Load transient responses Figure 27. VDDQ, VTT and VTTREF, VDDQ load transient response, IVDDQ = 0 to 2.3 A at 2.5 A/µs Figure 28. 1.5 V output voltage and inductor current, 1.5 V rail load transient response, 1.5 V = 0 to 1.25 A at 2.5 A/µs 27/37 www.BDTIC.com/ST STEVAL-ISA050V1 evaluation tests AN2787 Figure 29. 1.05 V output voltage and inductor current, 1.05 V rail load transient response. I1.05 V = 0 to 1.75 A at 2.5 A/µs Figure 30. VDDQ, VTTREF, VTT and VTT output current, VTT rail load transient response, IVTT = –1 A to +1 A at 2.5 A/µs 28/37 www.BDTIC.com/ST AN2787 10.5 STEVAL-ISA050V1 evaluation tests Efficiency Figure 31. SW regulators efficiency 10.6 Phase management Figure 32 and 33 show the SW regulators loaded with 1.3 A (VDDQ rail), 1.25 A (1.5 V rail) and 1.75 A (1.05 V rail). By connecting the SETPH1 pin to AGND or to AVCC the following two different phase shifts are allowed. Figure 32. SW regulators phases, 120 deg phase shift. SETPH1 pin tied to AGND 29/37 www.BDTIC.com/ST STEVAL-ISA050V1 evaluation tests AN2787 Figure 33. SW regulators phases, no phase shift - synchronous clock, SETPH1 pin tied to AVCC 10.7 Fault management (OVP, UVP, UVLO, thermal) Each switching regulator is able to detect the output overvoltage and undervoltage. When the OV is detected the high-side MOSFET is turned off and the low-side MOSFET is turned on. When the UV is detected, the power MOSFETs are both turned off and the discharge MOSFET is turned on (soft-end). The soft-end is also performed when the junction temperature is higher than 150 °C. Figure 34. VDDQ, VTT, VTTREF output voltage, VDDQ temporarily shorted to 3.3 V, output overvoltage protection triggered 30/37 www.BDTIC.com/ST AN2787 STEVAL-ISA050V1 evaluation tests Figure 35. VDDQ, VTT, VTTREF output voltage and VDDQ inductor current, VDDQ feedback pin temporarily shorted to GND, output undervoltage protection triggered When the input undervoltage is detected, the VDDQ (1.8 V) rail performs the output voltage soft-end. The 1.5 V and 1.05 V rails turn-off the high-side power MOSFET and turn-on the low-side one. 31/37 www.BDTIC.com/ST STEVAL-ISA050V1 evaluation tests AN2787 Figure 36. VDDQ (1.8 V), 1.5 V, 1.05 V output voltage and AVCC input power supply, input undervoltage lockout triggered Figure 37. VDDQ (1.8 V), 1.5 V, 1.05 V and VTT rails output voltage, thermal shutdown triggered 32/37 www.BDTIC.com/ST AN2787 10.8 STEVAL-ISA050V1 evaluation tests SW regulators current limit Cycle-by-cycle the high-side MOSFET current is monitored and if it's higher than the programmed current limit, the high-side MOSFET is immediately turned off. Figure 38. 1.5 V rail output voltage, 1.5 V inductor current and output current, peak current limit reached 10.9 Soft-end Each SW regulator, when turned off, performs the output voltage soft-end by turning off the power MOSFET and turning on the discharge MOSFET. When the output voltage is lower than about 300 mV, the low-side power MOSFET is turned on. VTTREF and VTT can track half of VDDQ also during the soft off. These rails are allowed two different modes of discharge: tracking and nontracking discharge. 33/37 www.BDTIC.com/ST STEVAL-ISA050V1 evaluation tests AN2787 Figure 39. VDDQ(1.8 V), VTT and VTTREF rail output voltage, EN_1S8 and EN_VTT tied to AGND - soft off with tracking discharge Figure 40. VDDQ(1.8 V), VTT and VTTREF rail output voltage. EN_1S8 and EN_VTT tied to AGND - soft off without tracking discharge 34/37 www.BDTIC.com/ST AN2787 10.10 STEVAL-ISA050V1 evaluation tests Thermal behavior The device temperature is mainly influenced by LDO VTT current. The typical working currents are shown in Table 3. Table 3. Average working currents for each rail Rail Current [A] VDDQ (1.8 V) 1.35 1.5 V 1.25 1.05 V 1.75 VTT (0.9 V) 0.3 VTT is supplied by VDDQ and the device (average) temperature is 54.5 °C. Figure 41. PM6641 demonstration board surface temperature when loaded with typical currents, Tamb = 23 °C, VIN = 3.3 V, FSW = 660 kHz 35/37 www.BDTIC.com/ST Revision history 11 AN2787 Revision history Table 4. Document revision history Date Revision 05-Sep-2008 1 Changes Initial release 36/37 www.BDTIC.com/ST AN2787 Please Read Carefully: Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any time, without notice. All ST products are sold pursuant to ST’s terms and conditions of sale. Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no liability whatsoever relating to the choice, selection or use of the ST products and services described herein. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such third party products or services or any intellectual property contained therein. UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK. Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any liability of ST. ST and the ST logo are trademarks or registered trademarks of ST in various countries. Information in this document supersedes and replaces all information previously supplied. The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners. © 2008 STMicroelectronics - All rights reserved STMicroelectronics group of companies Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America www.st.com 37/37 www.BDTIC.com/ST