* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Aerosols

Compounding wikipedia , lookup

Neuropharmacology wikipedia , lookup

Psychopharmacology wikipedia , lookup

Pharmacokinetics wikipedia , lookup

Drug discovery wikipedia , lookup

Neuropsychopharmacology wikipedia , lookup

Pharmaceutical industry wikipedia , lookup

Prescription costs wikipedia , lookup

Tablet (pharmacy) wikipedia , lookup

Prescription drug prices in the United States wikipedia , lookup

Drug interaction wikipedia , lookup

Psychedelic therapy wikipedia , lookup

Pharmacogenomics wikipedia , lookup

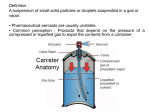

Dr. Bridg’ette Israel Spring 2011 Aerosols Definition: The term aerosol is used to denote various systems ranging from those of a colloidal nature to systems consisting of pressurized packages. Aerosols have been defined as colloidal systems consisting of very finely subdivided liquid or solid particles dispersed in and surrounded by a gas. Inhalation Therapy Has been used for many years Many scientists have revisited this route of administration The number of new drug entities delivered by the inhalation route has increased over the past 5 to 10 years. This type of therapy also has been applied to delivery of drugs through the nasal mucosa, as well as through the oral cavity for buccal absorption. Inhalation Therapy Originally, this type of therapy was used primarily to administer drugs directly to the respiratory system (treatment of asthma) Inhalation therapy is now delivering drugs to the bloodstream and their desired site of action. Proteins (insulins), steroids, cardiac agents, immunizing agents, etc, are being developed for delivery in this manner. Inhalation Therapy Drugs administered via the respiratory system (inhalation therapy) can be delivered either orally or nasally. These products can be developed as a: nebulizer/atomizer dry powder inhaler nasal inhaler metered dose aerosol inhaler Inhalation Therapy Drugs delivered via a nebulizer/atomizer are generally formulated as aqueous solutions (or suspensions) They are inhaled by the patient through an atomizer, nebulizer, or other similar devices. Background Information Dry powders have been used for inhalation therapy for over 75 years. The active ingredients were packaged in capsules, representing a single dose of drug. The capsule was punctured and a small amount of powder fell into a chamber while the patient inhaled. The procedure was repeated until all of the powder was inhaled. While these dry powders were somewhat popular during the early 1940s–1950s, they fell into disuse with the introduction of the aerosol metered dose inhaler (MDI), which became available around 1955. Background Information This first generation MDI was formulated with chlorofluorocarbons (CFC), was compact, and contained epinephrine hydrochloride or albuterol as the active ingredient. MDIs became very popular for the treatment of asthmatics. CFC’s began phasing out in 1996 Dry powders ~60 doses of active ingredient were developed and became commercially available from 2000 to 2003. Several dry powder inhalers currently available include salmeterol, fluticasone, and budesonide. Mometasone dry powder inhaler is available in Europe while insulin dry powder inhaler is presently in the final stages of development and submitted to the Food and Drug Administration for review. These dry powder inhalers do not contain a propellant. They consist of active, very potent drugs that are dispensed from a specially designed package. An accurate amount of drug as a dry powder is released while the patient inhales deeply. Nasal Metering Device Produces an aqueous spray consisting of active ingredient and excipients. The drugs used can act locally within the nasal mucosa or systemically by passing through the nasal mucosa and enter the general circulation system. This occurs via numerous capillary vessels present in the mucosa. These nasal sprays can also be formulated similar to MDIs using propellants and a nasal adapter. Metered-Dosed Inhaler Developed in the mid 1950’s & became a possible convenient dosage form for the delivery of medication to the respiratory system. Atomizers and nebulizers, in many instances did not offer convenience of use, so that administration of drugs by atomizers/nebulizers was generally left to hospital or at-home use. While many improvements were made to these nebulizers and atomizers, they lacked the convenience of use especially as to their portability and use outside of a hospital and/or home setting. Metered Dose Inhaler consists of a pressurized container filled with active ingredient, excipients and propellant, and a metered-dose valve. The pressurized container is placed within an oral adapter (mouthpiece), and when the unit is dispensed, an exact amount of drug is expelled in the proper particle size distribution to achieve maximum deposition of drug into the lungs. The aerosol dosage form (MDI) has become the dosage form of choice for delivery of drugs to the lungs. Metered dose inhalers are formulated as solutions or suspensions of active drug in a mixture of solvents, dispersing agents, and liquefied gas propellants. Topical Pharmaceutical Aerosols Can be formulated: spray, foam, and semisolid used to deliver therapeutic agents topically to the skin surface, rectally, and vaginally They consist of a liquid, emulsion, or semisolid concentrate and liquefied gas or compressed gas propellant. Many therapeutically active ingredients have been administered or applied to the body by means of the aerosol dosage form. This dosage form has been used orally to dispense a variety of agents such as budesonide, salmeterol xinafoate, fluticasone propionate, fenoterol, epinephrine hydrochloride, albuterol, albuterol sulfate, metaproterenol sulfate, cromolyn sodium, flunisolide hemihydrate, ipratropium bromide, beclomethasone dipropionate, and triamcinolone acetonide. These MDIs were formulated using a CFC propellant and are currently in widespread use in the United States even though the use of CFCs has been phased out throughout the world. Some exemptions have been granted to Third World Countries and “essential use” exemption has been granted to MDIs, which were commercially available prior to the year 2000. Oral aerosols have been used mainly for the symptomatic treatment of asthma as well as for the treatment of several other ailments. These aerosols have been readily accepted by both physician and patient. Advantages of Aerosol Use Rapid onset of action Circumvention of the first-pass effect and avoidance of degradation in the GI tract Lower dosage that will minimize adverse reactions, especially in the case of steroid therapy where most of the steroid reaches the respiratory tract and less is swallowed Advantages of Aerosol Use Dose titration to individual needs and ideal for prn medication Alternate route when therapeutic agent may interact chemically or physically with other medicinals needed concurrently Viable alternative when the drug entity exhibits erratic pharmacokinetics upon oral or parenteral administration Container and valve closure are tamperproof Components of Aerosol Package Propellant Container Valve and actuator Product concentrate Propellant Responsible for developing pressure. Expel the product when the valve is opened. Aids in atomization or foam production of product Types of Propellants 1. Liquefied gases : Fluorinated hydrocarbons Cholofluorocarbons (CFC) Hydro fluorocarbons Hydrochlorofluorocarbon Hydrocarbons Hydrocarbon ethers 2. Compressed gases Chlorofluorocarbon Chemically inert Flammable Non-toxic. Expensive when compared with hydrocarbons (HC). Deplete ozone layer. Hydrocarbon (HC) Chemically stable No hydrolysis Inflammable Low order of toxicity Less expensive Environmentally acceptable Compressed Gas Low expansion power and has no chilling effect. Foams produced by them are less stable when compare with liquefied gas foams Widely used in dispensing food and non-food products in original form i.e., semisolid. Used as propellants in dental creams, hair preparations, ointments, antiseptics, germicide aerosols Containers 1. 2. 3. Metal Tinplate steel Aluminum Stainless steel a. b. Glass Uncoated Plastic-coated glass Tin-Plate Steel Materials used for the manufacture of aerosol container must withstand pressure as 140 to 180 psig at 1300 F. These containers consist of a steel plate that has been electroplated on both sides with tin. The thickness of tin is described in weight. Size of container is measure of diameter and height. Recent development: welded side-seam which eliminates soldering operation, saves manufacturing time and decreases the possibility of product/container interaction. Aluminum Containers Used to manufacture extruded (seamless) containers. Less danger of incompatibility due to its seamless nature and greater resistance to corrosion. Inside aluminum containers are coated with organic materials like epoxy, vinyl, phenolic or polyamide resins to provide additional resistance. Aluminum containers get corroded by pure water and ethanol. Stainless Steel Containers • Limited to small size due to production problems and cost. They are extremely strong and resistant to most materials. In most cases no internal coating is used. Glass Containers Limited to those products having lower pressure and lower percentage of propellant. Stronger than metallic container Use of glass allows greater degree of freedom in design of container. Two types: a. Plastic coated glass: these containers are protected by plastic coating that prevents the glass from shattering in the event of breakage. b. Uncoated glass: low cost and provide clarity by which all the contents of the container can be viewed. Coating Epoxy or vinyl coating are generally used. Vinyl resin forms tough coating but is poorly resistant to steam about 2000 C. Epoxy coatings has greater degree or heat stability hence mixture of above two coating are used. Quality control of aerosols 1. 2. 3. 4. 5. 6. Propellant : tested for vapor pressure, identity, purity and acceptability. Valves, actuators and dip tubes : valve acceptance, delivery rate. Containers : dimensions, defects in lining, weight of container. Weight checking Leak checking : checking of crimp dimension, leaked tank testing. Spray testing : to check valve and spray pattern.