* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Smart Dust: Communicating with a Cubic

Survey

Document related concepts

Transcript

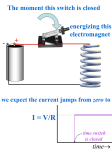

Smart Dust: Communicating with a Cubic-Millimeter Computer Presentation by Hörður Mar Tómasson 13. October 2006 The Smart Dust project • Went on at UC Berkeley 1998-2001 • Primary investigator: Kristofer S.J. Pister The goal • • • • • 1 mm³ motes with onboard sensors, CPUs and wireless communications facilities forming the basis of a sensor network Fundamental goal • To explore the limitations of microfabrication technology Ideas for uses for smart dust • • • • • Surveillance networks for defense Monitoring environmental conditions Human-computer interfaces Inventory and product quality control Tracking movements of animals Power considerations • Batteries: 1 J/mm³ storage • Capacitors: 10 mJ/mm³ usable storage • Solar cells: 1 J/(mm² · day) in sunlight or 1-10 mJ/(mm² · day) indoors • Optical receiver: 0.1 nJ/bit • Optical transmitter: 1 nJ/bit • A/D converter: 1 nJ/sample • Computation: 1 pJ/instruction Power considerations • 1000 8-bit operations per sample will not make a big difference in power used. • 1 mJ per day from a solar cell indoors will be sufficient for making a measurement every second, processing the result and transmitting it. Low-energy computation • Smaller transistors with less parasitic capacitance consume less dynamic power. • Reduced supply voltage also means less dynamic power. • Leakage currents can be decreased by reverse biasing the channel-to-source junction. • Clock rates of 1-100 kHz are sufficient for working with some important types of physical signals. Wireless communication • Radio communication currently requires several mW of power and preferably antennas longer than a millimeter. • Semiconductor lasers and diode receivers can use less power and are more directional. • The Smart Dust project explored optical communication. Passive reflective systems • A MEMS corner cube reflector (CCR) with a side that can be tilted • Less than 1 nJ used per transition • The mote can use the CCR to communicate with a base station equipped with a light source. Active steered laser systems • Semiconductor laser • Collimating lens • MEMS steerable micromirror Optical receiver • An imaging receiver has several benefits. • Only one pixel receives the signal but the ambient light is divided between the pixels. • Several signals can be received in parallel. • The authors did an experiment with a laser and a video camera. • A smart pixel has an integrated receiver. Ad hoc mote networks • If the motes can communicate directly with each other, they can form ad hoc multihop networks to carry the data around. • This is an interesting problem for network algorithm design. An Ultra-Low Energy Microcontroller for Smart Dust Wireless Sensor Networks Presentation by Hörður Mar Tómasson 13. October 2006 Creators of the microcontroller • Brett A. Warneke • Kristofer S.J. Pister Application • The microcontroller was developed for this prototype smart dust mote. Architectural features • • • • • • • Highly independent subsystems Component-level clock gating in decoder Processor halt mode Guarded ALU inputs Multiple busses Harvard architecture Load-store RISC Main oscillator • • • • • • Runs continuously at a few kHz Operates real time clock and five timers One timer for each sensor sampling period One timer for invoking the transmitter One timer for invoking the receiver One timer for waking up the datapath Other oscillators • 100 kHz for driving the sensor ADC • 8 MHz for sampling a 1 Mb/s optical signal ADC automation • The ADC is configurable to different levels of automation. • At the minimum level, the sensor and sample and hold are activated. • At the maximum level, the voltage is compared to a threshold and, if the threshold is exceeded, converted and stored in the SRAM along with a time stamp. Transmitter • The processor core uses two registers to specify what memory blocks contain data to be transmitted. • The transmitter formats the data into packets and transmits them asynchronously to the CCR. Four types of received packets • Short sync packets trigger the transmitter. • Immidiate packets contain an instruction that is immediately executed. • Program packets are streamed to the program memory. • Data packets are streamed to the data memory. Trimmable oscillator Specifications RF Telemetry System for an Implantable Bio-MEMS Sensor Presentation by Hörður Mar Tómasson 13. October 2006 The long range goal • NASA wants to develop implantable sensors to monitor physiological parameters of humans during space flights. • It would be of great benefit to have contactless powering and data readout for the implants. Advantages of contactless powering and telemetry • The inductor/antenna is small in size. • There is no need to implant batteries. • The circuit only operates when interrogated, avoiding heating of the surrounding tissue and extending the life span of the sensor. • Feed-through wires not needed, enhancing mobility and reducing risk of infection. This paper • A system for contactless powering and RF telemetry from an implantable bio-MEMS sensor. • A square spiral inductor/antenna • A MEMS capacitive pressure sensor • A pick-up antenna Spiral inductor/antenna MEMS pressure sensor Pick-up system • • • • A printed circuit with mounted components Spiral inductor/antenna, printed MMIC low noise amplifier, mounted on Antenna matching network, mounted discrete components, Π-network • Output connector Operating principle • The idea is to send pulses down into the implant and detect the decaying sine response. Parameters • Desired frequency range: 200 - 700 MHz • Expected capacitance of pressure sensor: 0.3 - 4 pF • Expected required parameters for square inductor: 150 nH and Q=10 • Several inductors with different geometries were tried. Fabrication of the inductor • • • • High resistance silicon wafer Spin-on glass coating Chrome/gold metallization The goal is to have high Q. The next step • Exploring coupling between the inductor and the pick-up antenna through stratified media