* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Oral Extended Release Drug Delivery System: A Promising Approach

Polysubstance dependence wikipedia , lookup

Plateau principle wikipedia , lookup

Orphan drug wikipedia , lookup

Psychopharmacology wikipedia , lookup

Compounding wikipedia , lookup

Neuropharmacology wikipedia , lookup

Pharmacognosy wikipedia , lookup

Pharmacogenomics wikipedia , lookup

Theralizumab wikipedia , lookup

Nicholas A. Peppas wikipedia , lookup

Pharmaceutical industry wikipedia , lookup

Prescription costs wikipedia , lookup

Drug design wikipedia , lookup

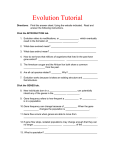

Drug interaction wikipedia , lookup

[AJPTech.] Asian J. Pharm. Tech. 2012; Vol. 2: Issue 2, Pg 38-43 ISSN- 2231–5705 (Print) www.asianpharmaonline.org ISSN- 2231–5713 (Online) 0974-3618 REVIEW ARTICLE Oral Extended Release Drug Delivery System: A Promising Approach Sunil Kumar1, Anil Kumar1, Vaibhav Gupta1, Kuldeep Malodia1 and Pankaj Rakha2 1 Lord Shiva College of Pharmacy, Sirsa, Haryana( India). Shri Baba Mastnath Institute of Pharmaceutical Sciences and Research, Asthal Bohr, Rohtak, Haryana (India). *Corresponding Author E-mail: [email protected] 2 ABSTRACT: Oral drug delivery is the most preferred route for the various drug molecules among all other routes of drug delivery, because ease of administration which lead to better patient compliance. So, oral extended release drug delivery system becomes a very promising approach for those drugs that are given orally but having the shorter half-life and high dosing frequency. Extended release drug delivery system which reduce the dosing frequency of certain drugs by releasing the drug slowly over an extended period of time. There are various physiochemical and biological properties which affect the extended release drug delivery system. This article providing the recent literature regarding development and design of extended release tablets. KEY WORDS: Extended Release, Extended Release Drug Delivery System, Half Life. INTRODUCTION: Oral route is the most oldest and convenient route for the administration of therapeutic agents because of low cost of therapy and ease of administration leads to higher level of patient compliance.1 Approximately 50% of the drug delivery systems available in the market are oral drug delivery systems and historically too, oral drug administration has been the predominant route for drug delivery.2,3 It does not pose the sterility problem and minimal risk of damage at the site of administration.4 The sustained release, sustained action, prolonged action, controlled release, extended action, timed release, depot and respiratory dosage forms are terms used to identify drug delivery system that are designed to achieve a prolonged therapeutic effect by continuously releasing medication over an extended period of time after administration of a single dose Extended release formulation is an important program for new drug research and development to meet several unmet clinical needs. There are several reasons for attractiveness of these dosage forms viz. provides increase bioavailability of drug product, reduction in the frequency of administration to prolong duration of effective blood levels, Reduces the fluctuation of peak trough concentration and side effects and possibly improves the specific distribution of the drug.9 During the past three decades, numerous oral delivery systems have been developed to act as drug reservoirs from which the active substance can be released over a defined period of time at a predetermined and controlled rate.5 The oral controlled release formulation have been developed for those drug that are easily absorbed from the gastrointestinal tract (GIT) and have a short half-life are eliminated quickly from the blood circulation.6 As these will release the drug slowly into the GIT and maintain a constant drug Extended release drug delivery system achieves a slow release of the drug over an extended period of time or the concentration in the plasma for a longer period of time.7 drug is absorbed over a longer period of time. Extended release dosage form initially releases an adequate amount of drug to bring about the necessary blood concentration (loading dose, DL) for the desired therapeutic response and therefore, further amount of drug is released at a controlled rate (maintenance dose, DM) to maintain the said blood levels for some desirable period of time.10,11 Received on 11.05.2012 Accepted on 24.05.2012 © Asian Pharma Press All Right Reserved Asian J. Pharm. Tech. 2(2): April-June 2012; Page 38-43 38 [AJPTech.] Asian J. Pharm. Tech. 2012; Vol. 2: Issue 2, Pg 38-43 time of undissolved drug and limited solubility at absorption site. So these types of drug are undesirable to be formulated as extended release drug delivery system. Drug having extreme aqueous solubility are undesirable for extended release because, it is too difficult to control release Suitable Drug Candidate for Extended Release Drug of drug from the dosage form. Delivery System: The drugs that have to be formulated as a ERDDS should Partition Co-efficient: meet following parameters. As biological membrane is lipophilic in nature through • It should be orally effective and stable in GIT medium. which the drug has to pass, so partition co-efficient of drug • Drugs that have short half-life, ideally a drug with half influence the bioavailability of drug very much. Drug life in the range of 2 – 4 hrs makes a good candidate for having lower partition co-efficient values less than the formulation into ER dosage forms eg. Captopril, optimum activity are undesirable for oral ER drug delivery system, as it will have very less lipid solubility and the drug Salbutamol sulphate. • The dose of the drug should be less than 0.5g as the will be localized at the first aqueous phase it come in oral route is suitable for drugs given in dose as high as 1.0g contact. Drug having higher partition co-efficient value greater than the optimum activity are undesirable for oral eg. Metronidazole. • Therapeutic range of the drug must be high. A drug for ER drug delivery system because more lipid soluble drug ERDDS should have therapeutic range wide enough such will not partition out of the lipid membrane once it gets in that variations in the release do not result in concentration the membrane. beyond the minimum toxic levels14 Protein Binding: The Pharmacological response of drug depends on unbound Merits of Extended Release Drug Delivery System: • The extended release formulations may maintain drug concentration rather than total concentration and all drugs bound to some extent to plasma and/or tissue therapeutic concentrations over prolonged periods. • The use of extended release formulations avoids the proteins. Proteins binding of drug play a significant role in its therapeutic effect regardless the type of dosage form as high blood concentration. extensive binding to plasma, increase biological half life • Reduce the toxicity by slowing drug absorption. and thus, such type of drug will release upto extended • Minimize the local and systemic side effects. period of time then there is no need to develop extended • Improvement in treatment efficacy. release drug delivery for this type of drug. • Minimize drug accumulation with chronic dosing. • Improvement of the ability to provide special effects. • Enhancement of activity duration for short half life Drug Stability: As most of ER Drug delivery system is designing to release drugs. drug over the length of the GIT, hence drug should be stable in GI environment. So drug, which is unstable, can’t Demerits Extended Release Drug Delivery System: Despite of several merits, extended release dosage forms be formulated as oral ER drug delivery system, because of bioavailability problem. are not devoid of certain demerits explained following: • In case of acute toxicity, prompt termination of therapy Mechanism and Site of Absorption: is not possible. • Less flexibility in adjusting doses and dosage Drug absorption by carrier mediated transport and those absorbed through a window are poor candidate for oral ER regimens. • Risk of dose dumping upon fast release of contained drug delivery system. Drugs absorbed by passive diffusion, pore transport and through over the entire length of GIT are drug. suitable candidates for oral ER drug delivery system. • High cost of preparation. • The release rates are affected by various factors such Dose Size: as, food and the rate transit through the gut. • The larger size of extended release products may cause If a product has dose size >0.5g it is a poor candidate for ER drug delivery system, because increase in bulk of the difficulties in ingestion or transit through gut.15,16,17 drug, thus increases the volume of the product. Thus dose Factors Affecting the Extended Release Drug Delivery of drug should small to make a good drug candidate for extended release drug delivery system. System: Objectives of Extended Release Drug Delivery System: Every noval drug delivery system had a rationale for developing the dosage form likewise, ERDDS also having some objectives that are discussed below: : Physiochemical Properties: Aqueous Solubility: Certain drug substance having low solubility is reported to be 0.1 mg/mL. As the drug must be in solution form before absorption, drug having low aqueous solubility usually suffers oral bioavailability problem due to limited GI transit Biological Properties: Absorption: The absorption behaviour of a drug can affect its suitability as an extended release product. The aim of formulating an extended release product is to place a control on the 39 [AJPTech.] Asian J. Pharm. Tech. 2012; Vol. 2: Issue 2, Pg 38-43 delivery system. It is essential that the rate of release is much slower than the rate of absorption. If we assume the transit time of most drugs and devices in the absorptive areas of GI tract is about 8-12 hours, the maximum half-life for absorption should be approximately 3-4 hours. Otherwise the device will pass out of absorptive regions before drug release is complete. Therefore the compounds with lower absorption rate constants are poor candidates for extended release systems. Some possible reasons for a low extent of absorption are poor water solubility, small partition co-efficient, acid hydrolysis, and metabolism or its site of absorption. dispersed in an insoluble matrix of rigid non swellable hydrophobic matrials is called as matrix system. Materials used for rigid matrix are insoluble plastics such as PVC and fatty materials like stearic acid, beewax etc. With plastic materials the drug is generally kneaded with the solution of PVC in an organic solvent and granulated. It is a hollow system containing an inner drug core surrounded in water insoluble membrane is called as reservoir devices. Polymer can be applied by coating or microencapsulation. The rate controlling mechanism partitioning into membrane with subsequent release into surrounding fluid by diffusion and commonly used polymers are HPC, EC and PVA. Distribution: The distribution of drugs in tissues can be important factor in the overall drug elimination kinetics. Since it not only lowers the concentration of circulating drug but it also can be rate limiting in its equilibrium with blood and extra vascular tissue, consequently apparent volume of distribution assumes different values depending on time course of drug disposition. Drugs with high apparent volume of distribution, which influence the rate of elimination of the drug, are poor candidate for oral ER drug delivery system e.g. Chloroquine. For design of extended release products, one must have information on disposition of the drug. Dissolution Controlled Drug Release: In these products, the rate dissolution of the drug (and thereby availability for absorption) is controlled by slowly soluble polymer or by microencapsulation. Once the coating is dissolved, the drug becomes available for dissolution. By varying the thicknesses of the coat and its composition, the release rate of drug can be controlled. These systems are easiest to design. With inherently slow dissolution rate. Such drugs act as a natural prolonged release products. That produces slow dissolving forms when it comes in contact with GI fluids and having high aqueous solubility and dissolution rate. Metabolism: Drug, which extensively metabolized is not suitable for ER drug delivery system. A drug capable of inducing metabolism, inhibiting metabolism, metabolized at the site of absorption or first-pass effect is poor candidate for ER delivery, since it could be difficult to maintain constant blood level e.g. levodopa, nitroglycerine. Drugs that are metabolised before absorption, either in lumen or the tissues of the intestine, can show decreased bioavailability from the extended releasing systems. Most intestinal walls are saturated with enzymes. As drug is released at a slow rate to these regions, lesser drug is available in the enzyme system. Hence the systems should be devised so that the drug remains in that environment to allow more complete conversion of the drug to its metabolite. Osmotically Controlled Drug Release: The rate of release of drug in these products is determined by the constant in flow of water across a semi permeable membrane into a reservoir which contains an osmotic agent called as osmogens. The rate of release is constant and can be controlled within tight limits yielding relatively constant blood concentration. The advantage of this type of product is that the constant release is unaltered by the environment of the gastrointestinal tract and relies simply on the passage of water into the dosage form. The rate of release can be modified by altering the osmotic agent and the size of the hole. Half-life of Drug: A drug having biological half-life between 2 to 8 hours is best suited for oral ER drug delivery system. As if biological half-life < 2hrs the system will require unacceptably large rate and large dose and biological halflife > 8hrs formulation of such drug into ER drug delivery system is unnecessary.16,18-20 Swelling Controlled Drug Release System: It is useful for sustaining the release of highly soluble drug. The materials for such matrices are hydrophilic gums and natural origin (guar gum, tragacanth), semi-synthetic (HPMC, CMC, Xanthan gum) or synthetic (Polyacrylamides). The drug and gum are granulated together with solvent such as alcohol and compressed into tablets. The release of drug from initially dehydrated hydro gels involves adsorption of water and desorption of drug from a swelling controlled diffusion system. As the gum swell and the drug diffuses out of it. Mechanistic Aspects of Oral Extended Release System Continuous Releases: Diffusion Controlled Drug Release: In this system the rate controlling step is not the dissolution rate but the diffusion of dissolved drug through a polymeric barrier. The two types of diffusion controlled system are – Matrix System and Reservoir Devices. The drug is Chemically Controlled Drug Release: In this system the drug is chemically bound to a matrix (which is not necessarily biodegradable), coated solid dosage forms from which drug release occurs only upon crack formation within the surrounding membrane, and microchip-based drug delivery systems. If the drug is covalently bound to an insoluble matrix former via 40 [AJPTech.] Asian J. Pharm. Tech. 2012; Vol. 2: Issue 2, Pg 38-43 hydrolysable bondings, the latter are more or less rapidly drug particles use of mucoadhesive polymer and altering the size of the dosage form. cleaved upon water penetration into the device. Dissolution and Diffusion Controlled Release System: In this system the drug core is encased in a partially soluble membrane. Pores are thus created due to dissolution of parts of membrane which permits entry of aqueous medium into the drug core and hence drug dissolution allows diffusion of dissolved drug out of the system. An example of obtaining such a coating is using a mixture of ethyl cellulose with PVP or methyl cellulose; the latter dissolves in water and creates pores in the insoluble ethyl cellulose membrane. Mucoadhesive System: A bioadhesive polymer such as cross-linked polyacrylic acid, when incorporated in a tablet, allows it to adhere to the gastric mucosa or epithelium. Such a system continuously releases a fraction of drug into the intestine over prolonged periods of time. Size-Based System: Gastric emptying of a dosage form can be delayed in the fed state if its size is greater than 2 mm. Dosage form of size 2.5 cm or larger is often required to delay emptying long Hydrodynamic Pressure Controlled Release System: A hydrodynamic pressure-activated drug delivery system enough to allow once daily dosing. Such forms are however can be fabricated by enclosing a collapsible, impermeable to swallow. container, which contains a liquid drug formulation to form a dug reservoir compartment, inside rigid shape retaining Delayed Release System: housing. A composite laminate of an absorbent layer and Intestinal Release System: swellable, hydrophilic polymer layer is sandwiched A drug may be enteric coated for intestinal release for between the drug reservoir compartment and the housing. In several known reasons such as to prevent gastric irritation, the GI tract the laminate absorb the gastrointestinal fluid prevent destabilization in gastric pH, etc. Certain drugs are through the annular opening at the lower end of the housing delivered to the distal end of small intestine for absorption and become increasingly swollen, which generates via peyer’s patches or lymphatic system. Peyer’s patches hydrodynamic pressure in the system. The hydrodynamic are mucosal lymphoid tissues that are known to absorb pressure thus created forces the drug reservoir compartment macromolecules like proteins and peptides and antigens by to reduce in volume and causes the liquid drug formulation endocytosis. Selective release of such agents to peyer’s to release through the delivery orifice at the specific rate21. patch region prevents them from getting destroyed/digested by the intestinal enzymes. Such a site can be utilized for Such systems are also called as push-pull osmotic pumps. oral delivery of insulin. pH-Independent Formulation: Such system are designed to eliminate the influence of Colonic Release System: changing the gastrointestinal pH on dissolution and Drugs are poorly absorbed through colon but may be absorption of drugs by formulating them with sufficient delivered to such a site for two reasons – Local actions as in amount of buffering agents (salts of phosphoric, citric or the treatment of ulcerative colitis with mesalamine and tartaric acids) that adjust the pH to the desired value as the systemic absorption of protein and peptide drugs like dosage form passes along the GIT and permit drug insulin and vasopressin. The advantage is taken of the fact pH sensitive bioerodible polymers like dissolution and release at a constant rate independent of that gastrointestinal pH. The dosage form containing drug and polymethacrylates release the medicament only at the buffer is coated with a permeable substance that allows alkaline pH of colon or use of divinylbenzene cross-linked entry of aqueous medium but prevents dispersion of tablets. polymer that can be cleaved only by the azoreductase of colonic bacteria to release free drug for local effect or systemic absorption.21,22 Delayed Transit and Continuous Release System: These systems are designed to prolong their residence in the GIT along with their release. Often, the dosage form is Polymers Used in Preparations of CRDDS fabricated to detain in the stomach and hence the drug Hydrogels: present therein should be stable to gastric pH. Systems • Polyhydroxyethylmethylacrylate (PHEMA) included in this category are as follows: • Cross-linked polyvinyl alcohol (PVA) • Cross-linked polyvinylpyrrolidone (PVP) Altered Density System: • Polyethyleneoxide (PEO) The transit time of GI contents is usually less than 24 hours. • Polyacrylamide (PA) This is the major limiting factor in the design of oral controlled release formulation which can reduce the Soluble Polymers: frequency of dosing to a time period little more than the • Polyethyleneglycol (PEG) residence time of drug. If the residence time of drug in the • Polyvinyl alcohol (PVA) stomach or intestine is prolonged in some way the • Polyvinylpyrrolidone (PVP) frequency of dosing can be reduced. There are 3 ways by • Hydroxypropylmethylcellulose (HPMC) which this can be achieved such as altering the density of 41 [AJPTech.] Asian J. Pharm. Tech. 2012; Vol. 2: Issue 2, Pg 38-43 Table 1: Extended Release Tablets Available in National and International Market Brand Name Active Ingredient(s) Metapure-XL Tab Metoprolol Succinate Etomax – ER Tab Etodolac Betacap –TR Cap Propranolol HCl Metaride Tab Glimipiride and Metformin HCl Augmentin – XR Tab Amixicillin and Potassium Clavulanate Wellbutrin - XL Tab Buproprion HCl Revelol – XL Tab Metoprolol Succinate Dayo – OD Tab Divolproex Sodium Sentosa – ER Tab Venlafaxine Zanocin – OD Tab Ofloxacin Glizid – MR Tab Gliclazide Metzok Tab Metoprolol Succinate Tegritol - CR Tab Carbemezapine Glimestar PM Tab Glimipride,Pioglitazone and metformin Supermet – XL Tab Metoprolol Succinate Gabaneuron – SR Tab Gabapentin and Methylcobalamin Cefoclox – XL Tab Cefpodoxime Dicloxacillin and Lactic acid bacillus Zen Retard Tab Carbemezapine Tolol AM Tab Metoprolol Succinate Exermet GM 502 Tab Glimepiride and Metformin HCl Mahacef – XL Tab Cefpodoxime Dicloxacillin and Lactic acid bacillus Gluconorm PG Tab Glimepiride, Pioglitazone and Metformin HCl Minipress –XL Tab Parazocin HCl Pomed – EX Tab Pantaprozol and domperidone Riomet – Trio 2 Tab Metformin HCl Divaa – OD Tab Divalproex Sodium Metocontin Tab Metoclopramide HCl Fecontin – F Tab Ferrous Glycine Sulphate and Folic acid Diucontin – K 20/250 Tab Frusemide Unicontin – E Tab Theophyllin Licab – XL Tab Lithium Carbonate Embeta – XR Tab Metoprolol Succinate Glycomet – 1 GM Tab Metformin HCl Venlor – XR Tab Venlafexine HCl Altiva – D Tab Fexofenadine HCl and Pseudoephidrine sulphate Sporidex – AF Tab Cefalaxin Vasovin- XL Tab Nitroglycerin Lithosun SR Tab Lithium Carbonate Etura Tab Etodolac Intalith CR Lithium Carbonate Pari – SR Tab Proxitine HCl Reolol – AM 25/5 Tab Metoprolol Succinate Valprol – CR Tab Metoprolol Succinate and Amlodipine Perinorm – CD Cap Sodium Valproate and Valproic Acid Gluconorm G Tab Metformin HCl Zetpol CR Tab Carbemezapine Epsolin ER Cap Phenytoin Sodium Gluconorm – SR Tab Metformin HCl Carvidon – MR Tab Trimetazidine HCl Biodegradeble Polymers: • Polylactic acid (PLA) • Polyglycolic acid (PGA) • Polycaprolactone (PLA) • Polyanhydrides • Polyorthoesters Manufacturer Emcure, Mumbai Ipca, Mumbai Sun Pharma, J and K Unichem, Mumbai Glaxosmithkline, Mumbai Glaxosmithkline, Mumbai Ipca, Mumbai Lupin, Baddi(HP) Nicholas Piramal, Baddi(HP) Ranbaxy, Ponta Sahib. Panacea Biotech, Lalru(CHD). USV, Mumbai Novartis, Goa Discovery Mankind, Ponta Sahib Piramal Healthcare, Baddi(HP) Aristo, Baddi(HP) Khandelwal Intas, Ahemdabad Unichem, Mumbai Cipla, Baddi(HP) Discovery Mankind, Ponta Sahib Lupin, Baddi (HP) Pfizer, Goa Panjon Ranbaxy, Ponta Sahib Intas, Ahemdabad Modi-Mundi Pharma, Meerut Modi-Mundi Pharma, Meerut Modi-Mundi Pharma, Meerut Modi-Mundi Pharma, Meerut Torrent, Ahemdabad Intas, Ahemdabad USV, Mumbai Cipla Protec, Baddi(HP) Sidmak Ranbaxy, Ponta Sahib Torrent, Ahemdabad Sun Pharma, J and K Dr’ Reddy, Hydrabad Intas, Ahmadabad Ipca, Mumbai Ipca, Mumbai Intas, Ahmadabad Ipca, Mumbai Lupin, Baddi(HP) Sun Pharma, J and K Zydus, Ahmadabad Lupin, Baddi(HP) Microlab, Banglore Non Biodegradeble Polymers: • Polyethylene vinyl acetate (PVA) • Polydimethylsiloxane (PDS) • Polyetherurethane (PEU) • Polyvinyl chloride (PVC) • Cellulose acetate (CA) 42 [AJPTech.] Asian J. Pharm. Tech. 2012; Vol. 2: Issue 2, Pg 38-43 Mucoadhesive Polymers : • Polycarbophil • Sodium carboxymethyl cellulose • Polyacrilic acid • Tragacanth • Methyl cellulose • Pectin • Natural gums • Xanthan gum • Guar gum • Karaya gum23 9. 10. 11. 12. Extended Release Tablets Available in National and International Markets: 13. There are so many ER Tablets of different drug molecule by different manufacturers are available in the market. Some of 14. their name is depicted in table 1. CONCLUSION: 15. We concluded from the above discussion that extended release formulations are very much helpful in increasing the effectiveness of the drugs with short half life and also improve patient compliance by decreasing the dosing frequency. Now, a wide range of drugs are formulated in a variety of different oral extended release dosage forms. However, only those which result in a significant reduction in dose frequency and a reduction in toxicity resulting from high concentration in the blood or gastrointestinal tract are likely to improve therapeutic outcomes. To be a successful extended release product, the drug must be released from the dosage form at a predetermined rate, dissolve in the gastrointestinal fluids, maintain sufficient gastrointestinal residence time, and may be absorbed at a rate and will replace the amount of drug being metabolized and excreted. 16. 17. 18. 19. 20. 21. 22. REFERENCES: 1. 2. 3. 4. 5. 6. 7. 8. Aher K B, Bhavar G B, Joshi H P, Chaudhari S R, Recent advances in compression-coated tablets as a controlled drug delivery system, Saudi pharmaceutical journal, 2011, 01. Shivakumar H G, Gowda D V, Kumar T M P, Floating controlled drug delivery systems for prolonged gastric residence: a review, Ind. J. Pharm., 2004, 38(45), 172-78. Sharma A, Sharma S, Jha K K, The study of salbutamol matrix tablets using different polymers as release retarding agent, The pharma research, 2009, 01, 15-22. Sharma P P, Sharma S, Khokra S L, Sahu R K, Jangde R, Singh J, Formulation, development and evaluation of sustained release matrix tablets containing salbutamol sulphate, Pharmacologyonline2, 2011, 1197-1203. Chein Y W, Oral drug delivery and delivery systems, Marcel dekker,inc.,New York, 1992, 01, 139-96. Ahsan M Q, Rahman M M, Jha M K, Ahmed I, Moghal M M R, Rahman M H, Development and in-vitro evaluation of sustained release matrix tablets of salbutamol sulphate using methocel K100M CR polymer, International journal of pharmaceutical sciences and research, 2011, 02(03), 567-76. Modi S A, Gaikwad P D, Bankar V H, Pawar S P, Sustained release drug delivery system: A review, International journal of pharma. Research and development, 2011, 02(12), 147-59. Murthy P N V N, Shafiullah D, Datta M, Formulation, development and evaluation of controlled release matrix tablets 23. 43 of guaiphenesin and salbutamol sulphate, Der pharmacia letter, 2011, 3(4), 325-334. El-halim S M A, Amin M M, Gazayerly O N E, Gawad N A A E, Salbutamol sulphate controlled release hydrophllic matrix tablets, RGUHS journal of pharmaceutical sciences, 2011, 01(03), 194200. Khan M G, Controlled release oral dosage forms: Some recent advances in matrix type drug delivery systems, The sciences, 2001, 1(5), 350-354. Ghosh A, Gupta K S, Formulation, development and in-vitro evaluation of sustained release matrix tablets of salbutamol sulphate, JPRHC, 2003, 02(03),222-27. Srivastav M, Prabhakar, Omray A, Extended release tablet technologies-matrix, melt granulation and multiparticulates: An overview, International journal of universal pharmacy and life sciences, 2011, 01(02), 331-54. Ratial D A, Gaikwad P D, Bankar V H, Pawar S P, A review on: Sustained released technology, International journal of research in ayurveda and pharmacy, 2011, 02(06), 1701-08. Jayanthi B, Manna P M, Madhusudhan S, Mohanta G P, Manavalan R, Per oral extended release products- A overview, Journal of applied pharmaceutical science, 2011, 01(02), 50-55. Pogula M, Nazeer S, Extended release formulation, International journal of pharmacy and technology, 2010, 02(04), 625-84. Jain N K, Controlled and novel drug delivery system, In progress in controlled and novel drug delivery system, C B S publishers and distributors, New delhi, 2004, 01. 419-35. Dandagi P M, Masthiholimath V S, Patil M B, Manvi F V, Gadad A P, Sharma R, Development and evaluation of theophylline and salbutamol sulphate sustained release matrix tablets, Indian journal of pharm. Sci.,2005, 76(05), 598-602. Brahmankar D M, Jaiswal S B, A treatise of biopharmaceutics and pharmacokinetics, Vallabh Prakashan, 1995, 01, 335-55. Maderuelo C, Zarzuelo A, Lanao, Critical factors in the release of drugs from sustained release hydrophilic matrices, journal of controlled release, 2011, 154, 2-19. Banker S G, Rhodes C T, Modern pharmaceutics, Sustained and controlled release drug delivery systems, 2005, 01, 501-13. Robinson J R, Lee V H L, Controlled drug delivery “Fundamentals and application”, Informa Healthcare, 2009, 20, 373-421. Verma R K, Krishna D M, Garg S, Formulation aspects in the development of osmotically controlled oral drug delivery systems, Journal of Controlled Release, 2002, 79, 7-27. Raizada A, Bandari A, Kumar B, Polymers in drug delivery: A review, International Journal of Pharma. Research and Development, 2010, 02(08), 9-20.