* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Passive components in MMIC technology

Multidimensional empirical mode decomposition wikipedia , lookup

Buck converter wikipedia , lookup

Integrated circuit wikipedia , lookup

Scattering parameters wikipedia , lookup

Zobel network wikipedia , lookup

Audio crossover wikipedia , lookup

Fault tolerance wikipedia , lookup

Printed circuit board wikipedia , lookup

Two-port network wikipedia , lookup

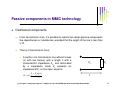

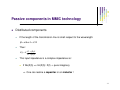

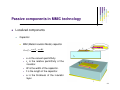

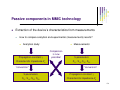

Passive components in MMIC technology Evangéline BENEVENT Università Mediterranea di Reggio Calabria DIMET 1 Passive components in MMIC technology Introduction Passive components in MMIC technology Design cycle of passive components in MMIC technology Distributed components Inductor, capacitor Localized components Resistor, capacitor, inductor Microwave characterization of passive devices S-parameters Extraction of device’s characteristics from measurements De-embedding and calibration 2 Passive components in MMIC technology Introduction Passive components in MMIC technology Design cycle of passive components in MMIC technology Distributed components Inductor, capacitor Localized components Resistor, capacitor, inductor Microwave characterization of passive devices S-parameters Extraction of device’s characteristics from measurements De-embedding and calibration 3 Passive components in MMIC technology Introduction Maxwell’s equations All electromagnetic behaviors can ultimately be explained by Maxwell’s four basic equations: ∂B ∂D ∇.D = ρ ∇.B = 0 ∇×E = − ∂t ∇×H = j + ∂t However, it isn’t always possible or convenient to use these equations directly. Solving them can be quite difficult. Efficient design requires the use of approximations such as lumped and distributed models. Why are models needed? Models help us predict the behavior of components, circuits and systems. Lumped models are useful at lower frequencies, where some physical effects can be ignored. Distributed models are needed at higher frequencies to account for the increased behavioral impact of those physical effects. 4 Passive components in MMIC technology Introduction Two ports models Two-port, three-port, and n-port models simplify the input/output response of active and passive devices and circuits into “black boxes” described by a set of four linear parameters. Lumped models use representations such as admittances (Y) and resistances (R). Distributed models use S-parameters (transmission and reflection coefficients). Limitations of lumped models At low frequencies most circuits behave in a predictable manner and can be described by a group of replaceable, lumped-equivalent black boxes. 5 Passive components in MMIC technology Introduction Limitations of lumped models At microwave frequencies, as circuit element size approaches the wavelengths of operating frequencies, such a simplified type of model becomes inaccurate. The physical arrangements of the circuit components can no longer be treated as black boxes. We have to use a distributed circuit element model and S-parameters. S-parameters S-parameters and distributed models provide a means of measuring, describing, and characterizing circuits elements. They are used for the design of many high-frequency products. 6 Passive components in MMIC technology Introduction Passive components in MMIC technology Design cycle of passive components in MMIC technology Distributed components Inductor, capacitor Localized components Resistor, capacitor, inductor Microwave characterization of passive devices S-parameters Extraction of device’s characteristics from measurements De-embedding and calibration 7 Passive components in MMIC technology Design cycle of passive components in MMIC technology Choice (or no choice!) of the substrate respect to the application or the specifications Choice of additional key materials such as dielectric and magnetic materials Analytical models ⇒ approximated size and performance of passive components EM simulation (numerical modeling) ⇒ performance of passive components Performance = specifications? NO YES Fabrication of a prototype, Characterization, Test Performance = specifications? DESIGN COST ! NO YES GOOD JOB ! 8 Passive components in MMIC technology Introduction Passive components in MMIC technology Design cycle of passive components in MMIC technology Distributed components Inductor, capacitor Localized components Resistor, capacitor, inductor Microwave characterization of passive devices S-parameters Extraction of device’s characteristics from measurements De-embedding and calibration 9 Passive components in MMIC technology Distributed components From transmission lines, it is possible to realize low values passive components like capacitances or inductances, provided that the length of the line is less than λ/10. Theory of transmission lines: A section of a transmission line without losses (or with low losses), with a length ℓ, with a characteristic impedance Zc, and terminated by a impedance (load) ZL presents an impedance Z(ℓ), on the input, equal to: Z (l ) = Z c Z L + jZ c tg ( βl ) Z c + jZ L tg ( βl ) Zc ZL ℓ [1] C. Algani, “Composants passifs”, Support de cours du CNAM, Spécialité Electronique-Automatique. 10 Passive components in MMIC technology Distributed components If the length of the transmission line is small respect to the wavelength: βℓ < π/6 or ℓ < λ/12 Then: Z (l ) = Z c Z L + jZ c βl Z c + jZ L βl This input impedance is a complex impedance so: If Re(Z(ℓ)) << Im(Z(ℓ)): Z(ℓ) → pure imaginary ⇒ One can realize a capacitor or an inductor ! 11 Passive components in MMIC technology Distributed components Inductor: If ZL = 0 or ZL << Zctg(βℓ): By identification: The synthesized inductance L (H) has a value equal to: This inductance can be realized by a short-circuited line or by a line with a characteristic impedance Zc high respect to the impedance of the load. Z ( l ) ≈ jZ c tg ( β l ) Z = jLω L≈ Zc ω tg ( βl ) 12 Passive components in MMIC technology Distributed components Real realization of distributed inductor: Series inductance: ℓ Z01 Z02 Z0 >> Z01, Z02 Z0 Z01 Shunt inductance: Z0 ℓ Short-circuit 13 Passive components in MMIC technology Distributed components Capacitor: Zc jtg ( β l) If ZL = ∞ or ZL >> Zctg(βℓ): By identification: The synthesized capacitance C(F) has a value equal to: This capacitance can be realized by a open-circuit line or by a line with a characteristic impedance Zc low respect to the impedance of the load. Z= Z (l) ≈ 1 jCω C= tg ( β l ) ωZ c 14 Passive components in MMIC technology Distributed components Real realization of distributed capacitor: Series capacitance: Z0 Shunt capacitance: Z0 << Z01, Z02 Z0 g ℓ Z01 Z02 Z0 15 Passive components in MMIC technology Introduction Passive components in MMIC technology Design cycle of passive components in MMIC technology Distributed components Inductor, capacitor Localized components Resistor, capacitor, inductor Microwave characterization of passive devices S-parameters Extraction of device’s characteristics from measurements De-embedding and calibration 16 Passive components in MMIC technology Localized components The localized components have higher values than the distributed components. However, due to parasitic elements at high frequency, the dimensions of localized components must be small compared to the wavelength (ℓ < λ/30). In this way, the variations of phase are negligible. Localized components can be described by analytical models which take into account the frequency-dependent parasitic effects and different kinds of losses by adding other localized components. 17 Passive components in MMIC technology Localized components Resistor Structure: resistor metallization substrate ground plane The resistance R (Ω) of a conductor strip is defined by the following equation: R= 1 l σ W ⋅t where σ is the conductivity of the conductor, ℓ the length, W the width, and t the thickness of the conductor strip. If the conductor strip is square, the resistance does not depend on the dimensions of the strip and the “square resistance” (Ω/square) is equal to: Rs = 11 σ t 18 Passive components in MMIC technology Localized components Resistor At high frequency, the current circulates only in a thin thickness of the resistive layer called “skin depth” and not in the total thickness t. The skin depth δ (m) depends on the frequency: δ= 2 ωµ 0 µ c σ where ω=2πf is the pulsation (rad/s), µ0 and µc are the conductivities of the vacuum and conductor respectively, σ is the conductivity. The square resistance becomes: Rs = 11 σδ Typical values: 20 to 500 Ω/square. 19 Passive components in MMIC technology Localized components C3 Resistor R (f) Resistor model: L C1 C2 R is the resistance, depending on the skin-effect, The distributed nature of the resistor is taken into account with the series inductance L, C1, C2 are the parasitic shunt capacitances to ground of the resistor and its contact pads, C3 is the end-to-end feedback capacitance. [2] Frank Ellinger, “RF Integrated Circuits and Technologies”, Springer, 2007. 20 Passive components in MMIC technology Localized components Capacitor Interdigital capacitor The capacitance increases with the number of fingers. Port 1 Port 2 21 Passive components in MMIC technology Localized components Capacitor Interdigital capacitor Equivalent circuit: C C1 R L C2 C is the interdigital capacitance. R corresponds to the resistive losses. L is the parasitic inductance of the fingers. C1, C2 are the parasitic capacitances to the ground. 22 Passive components in MMIC technology Localized components Capacitor Interdigital capacitor Advantages: Only one metallization plane, Easy to manufacture. Drawback: Too small capacitance: typically C = 0.5 to 2 pF/mm². 23 Passive components in MMIC technology Localized components Capacitor MIM (Metal-Insulator-Metal) capacitor C MIM (F ) = ε 0ε r S e = ε 0 ε r Wl e ε0 is the vacuum permittivity. εr is the relative permittivity of the insulator. W is the width of the capacitor. ℓ is the length of the capacitor. e is the thickness of the insulator layer. 24 Passive components in MMIC technology Localized components Capacitor MIM (Metal-Insulator-Metal) capacitor MIM capacitor model: L1 C C1 R L2 C2 C is the MIM capacitance, R corresponds to the losses of the capacitor, C1, C2 are the parasitic capacitances to ground from bottom, top plate, L1, L2 are the parasitic inductances of bottom, top plate. 25 Passive components in MMIC technology Localized components Capacitor MIM (Metal-Insulator-Metal) capacitor Choice of the dielectric material: The higher the relative permittivity of the material is, the higher the value of the capacitance is (C = εdielectric.C0). So one can choose a high permittivity material. But in a MMIC circuit, the capacitors must support various DC polarization voltages. So one have to also consider the breakdown voltage (or breakdown electric field). [3] C. Rumelhard, “MMIC Composants”, Techniques de l’Ingénieur. 26 Passive components in MMIC technology Localized components Capacitor MIM (Metal-Insulator-Metal) capacitor For example, in order to the titanium dioxide (TiO2) supports the same voltage than the tantalum pentoxide (Ta2O5), it is necessary to multiple the thickness by five, so to reduce the capacitance by five. Dielectric material Relative permittivity Breakdown electric field (V/µm) Capacitance density for Vmax = 50 V (pF/mm²) 5 300 265 Si3N4 (silicon nitride) 6.5 250 290 Al2O3 (alumina) 8.8 250 390 Ta2O5 (tantalum pentoxide) 25 200 885 TiO2 (titanium dioxide) 55 50 490 SiO2 (silica) 27 Passive components in MMIC technology Localized components Capacitor MIM (Metal-Insulator-Metal) capacitor This is summarized in the third column with the capacitance density for a maximum voltage. Regarding this parameter, the best dielectric material is now the tantalum pentoxide instead of the titanium dioxide. Dielectric material Relative permittivity Breakdown electric field (V/µm) Capacitance density for Vmax = 50 V (pF/mm²) 5 300 265 Si3N4 (silicon nitride) 6.5 250 290 Al2O3 (alumina) 8.8 250 390 Ta2O5 (tantalum pentoxide) 25 200 885 TiO2 (titanium dioxide) 55 50 490 SiO2 (silica) 28 Passive components in MMIC technology Localized components Capacitor MIM (Metal-Insulator-Metal) capacitor Because of the leakage area, in real topology, it is necessary to add an air bridge. Air bridge (deck) Air bridge (pillar) 2nd thick metal First metal 2nd thick metal Silicon nitride Si3N4 Silicon nitride Si3N4 Leakage area First metal Substrate Substrate 29 Passive components in MMIC technology Localized components Inductor Rectangular plate inductor 2l W +t L = 2 µ 0 l ln + 0.5 + 3l W + t ℓ t W In order to reduce the area occupied by the inductor, one can: Fold down the conductor, Make loops. 30 Passive components in MMIC technology Localized components Inductor Loop inductor l L = 2.10 −9.l ln − 1.76 W + t W is the width of the conductor, t is the thickness of the conductor, ℓ is the circumference of the loop equal to: l = 2πR 31 Passive components in MMIC technology Localized components Inductor Meander inductor l W + t L = 2.10 −9.l ln + 0.22 + 1.19 l W + t W is the width of the conductor, t is the thickness of the conductor, ℓ is the length of the meander. Typical values: 0.4 to 4 nH. 32 Passive components in MMIC technology Localized components Inductor Circular spiral inductor L = 10 −9. 394a ²n ² K 8a + 11c K = 0.57 − 0.145ln W h W > 0.05 h a= Do + Di 4 c= Do − Di 2 n is the number of turns, W is the width of the conductor, h is the height of the substrate, Do is the outer diameter, Di is the inner diameter. Typical values: 0.2 to 15 nH. 33 Passive components in MMIC technology Localized components Inductor Square spiral inductor There are many ways to layout a planar spiral inductor. The optimal structure is the circular spiral. This structure places the largest amount of conductors in the smallest possible area, reducing the series resistance of the spiral. This structure, however, is often not used because it is not supported by many mask generation systems. Many of these systems are able to only generate Manhattan geometries (and possibly 45° angles as well). Manhattan-style layouts only contain structures with 90°angles. [4] R.L. Bunch, D.I. Sanderson, S. Raman, Application Note, “Quality factor and inductance in differential IC implementations”, IEEE Microwave Magazine, June 2002. 34 Passive components in MMIC technology Localized components Inductor Square spiral inductor So a simple solution is to approximate a circle by a polygon. An octagonal spiral as a Q that is slightly lower than the circular structure but is much easier to lay out. Octagonal inductor The square spiral structure does not have the best performance, but it is one of the easiest structure to lay out and simulate. 35 Passive components in MMIC technology Localized components Inductor Square spiral inductor L= 2 µ 0 n ²d avg 2.067 + 0.178 ρ + 0.125 ρ ² ln π ρ n is the number of turns, davg represents the average diameter of the spiral, ρ represents the percentage of the inductor area that is filled by metal traces. 36 Passive components in MMIC technology Localized components Inductor with magnetic material When a high permeability material is placed near a conductor carrying electrical current, the inductance of the conductor is know to increase. Ideally, if a conductor is enclosed in an infinite magnetic medium, the inductance is increased by a factor of µr, the relative permeability of the medium. If µr is purely real (no magnetic loss) and large, then the inductance as well as the quality factor Q of the structure are significantly enhanced. It also means that, for the same inductance value, a much smaller substrate area would be needed. Furthermore, since the magnetic flux is confined within the magnetic material, cross-talk between the inductors on the same chip would be reduced. [5] V. Korenivski, R.B. van Dover, “Magnetic film inductors for radio frequency applications”, J. Appl. Phys. 82 (10), Nov. 1997, pp. 5247-5254. 37 Passive components in MMIC technology Localized components Inductor with magnetic material Thin film solenoid with a magnetic core What’s a solenoid? 38 Passive components in MMIC technology Localized components Inductor with magnetic material Thin film solenoid with a magnetic core Cross section of thin film rectangular solenoid W conductor/coil magnetic core µr insulator µ0 ts tm ti tc 39 Passive components in MMIC technology Localized components Inductor with magnetic material Thin film solenoid with a magnetic core Top view of thin film rectangular solenoid 1 2 3 Wc … N turns W ℓ 40 Passive components in MMIC technology Localized components Inductor with magnetic material Thin film solenoid with a magnetic core Inductance: L= NΦ µ 0 µ r N ²W .t m = I l where N is the number of turns, Φ the magnetic flux, µ0 the vacuum permeability, µr the relative permeability of the magnetic material, tm its thickness, W the width of the solenoid, ℓ its length. Quality factor: Q= ωL R = ωµ 0 µ r Nt mW c t c 2lρ where Wc is the width of the conductor strip, tc its thickness, ρ its resistivity.. 41 Passive components in MMIC technology Localized components Inductor with magnetic material Thin film solenoid with a magnetic core Parasitic capacitance: C ≈ 2Nε W cW ti where ε = ε0.εr is the permittivity of the insulator, ti its thickness. Resonance frequency: 8π ² µ 0 µ r εN 3W ²t mWc fr = = ti l 2π LC 1 −1/ 2 42 Passive components in MMIC technology Localized components Inductor with magnetic material Magnetically sandwiched stripe inductor L = µ0 µr l tm 2W Magnetic layer µr Conductor strip µ0 2K W 1 − tanh 2K W K= tm tc= g gt m µ r 2 Where µ0 is the vacuum permeability, µr the relative permeability of the magnetic material, ℓ the length of the strip, tm the thickness of the magnetic, W the width of the structure, g the gap between the two magnetic layers. 43 Passive components in MMIC technology Localized components Inductor with magnetic material Magnetically wrapped stripe inductor L = µ0 µr l Magnetic layer µr Conductor strip µ0 tm tc= g The magnetically wrapped stripe inductor is an improved version of the magnetically sandwiched stripe inductor as the factor: 1− tm 2W 2K W tanh W 2K was removed. This is due to the enclosure of the magnetic flux in the wrapped version. 44 Passive components in MMIC technology Introduction Passive components in MMIC technology Design cycle of passive components in MMIC technology Distributed components Inductor, capacitor Localized components Resistor, capacitor, inductor Microwave characterization of passive devices S-parameters Extraction of device’s characteristics from measurements De-embedding and calibration 45 Passive components in MMIC technology S-parameters Two-port model Any device can be described by a set of four variables associated with a two-port model. Two of these variables represent the excitation (independent variables), and the remaining two represent the response of the device to the excitation (dependent variables). If the device is excited by voltage sources V1 and V2, the currents I1 and I2 will be related by the following equations: I1 = y 11V1 + y 12V2 I 2 = y 21V1 + y 22V2 I1 Port 1 V1 I2 Two-port device V2 Port 2 [6] Test & Measurement Application Note 95-1, Hewlett Packard, “S-parameters techniques for faster, More accurate network design”, 1997. 46 Passive components in MMIC technology S-parameters Two-port model In this case, with port voltages selected as independent variables and port currents taken as dependent variables, the relating parameters are called short-circuit admittance parameters, or y-parameters. Four measurements are required to determine the four parameters y11, y12, y21, y22. Each measurement is made with one port excited by a voltage source, while the other port is short-circuited. For example: y 21 = I2 V1 V 2 =0 At high frequencies, lead inductance and capacitance make short and open circuits difficult to obtain. So the characterization of microwave devices by S-parameters is more convenient. 47 Passive components in MMIC technology S-parameters Using S-parameters “Scattering parameters” which are commonly referred as S-parameters, are a parameter set that relates to the traveling waves that are scattered or reflected when an n-port network is inserted into a transmission line. S-parameters are usually measured with the device imbedded between a 50 Ω load and source. ZS VS ∼ a1 a2 Two-port device b1 b2 ZL 48 Passive components in MMIC technology S-parameters Incident and reflected waves The independent variables a1 and a2 are normalized incident voltages: a1 = a2 = 2 Z0 V2 + I 2 Z 0 2 Z0 voltage wave incident on port 1 = Z0 = = voltage wave incident on port 2 Z0 Vi 1 Z0 Vi 2 = Z0 The dependent variables b1 and b2 are normalized reflected voltages: b1 = b2 = V1 + I1Z 0 V1 − I1Z 0 2 Z0 V2 − I 2 Z 0 2 Z0 = voltage wave reflected from port 1 = Z0 = voltage wave reflected from port 2 Z0 Vr 1 Z0 = Vr 2 Z0 The parameters are referenced to Z0 (supposed real and positive) generally equal to 50 Ω 49 Passive components in MMIC technology S-parameters Definition of S-parameters S21 a1 b1 S11 a2 S22 S12 b2 The linear equations describing the two-port device are then: b1 = S11a1 + S12 a2 b2 = S21a1 + S22a2 Under the matrix form: b1 S11 S12 a1 b = S 2 21 S22 a2 50 Passive components in MMIC technology S-parameters Definition of S-parameters S11 is the input reflection coefficient with the output port terminated by a matched load (ZL = Z0 sets a2 = 0): b1 S11 = a2 a1 = 0 S21 is the forward transmission coefficient with the output port terminated by a matched load (ZL = Z0 sets a2 = 0): b2 S 21 = a2 =0 S22 is the output reflection coefficient with the input port terminated by a matched load (ZS = Z0 sets VS = 0): b2 S 22 = a1 a1 a 2 =0 S12 is the reverse transmission coefficient with the input port terminated by a matched load (ZS = Z0 sets VS = 0): S12 = b1 a2 a1 = 0 51 Passive components in MMIC technology S-parameters Cascade of several two-port devices The ABCD matrix: a1 b1 b1 A B a2 a = C D b 2 1 Two-port device 1 Two-port device 2 Two-port device 3 [A1B1C1D1] [A2B2C2D2] [A3B3C3D3] Equivalent two-port device 2 [ABCD] a2 a1 b1 b1 A B a2 A1 B1 A2 a = C D b = C D C 2 1 1 2 1 a2 b2 b2 B2 A3 D2 C3 B3 a2 D3 b2 52 Passive components in MMIC technology S-parameters Two other matrix are widely used: Y-matrix (admittance matrix) I1 V1 Y11 Y12 V1 I = [Y ].V = Y 2 2 21 Y22 V2 Z-matrix (impedance matrix) V1 I1 Z11 Z12 I1 V = [Z ].I = Z 2 2 21 Z 22 I 2 I1 Port 1 V1 I2 Two-port device V2 Port 2 53 Passive components in MMIC technology S-parameters Relations between the matrix of a two-port device 54 Passive components in MMIC technology S-parameters Relations between the matrix of a two-port device 55 Passive components in MMIC technology S-parameters ABCD matrix and S-parameters matrix of useful two-port devices Z Y Z1 Z2 Z3 56 Passive components in MMIC technology S-parameters ABCD matrix and S-parameters matrix of useful two-port devices Y3 Y1 Y2 α Zc, γ ℓ 57 Passive components in MMIC technology Introduction Passive components in MMIC technology Design cycle of passive components in MMIC technology Distributed components Inductor, capacitor Localized components Resistor, capacitor, inductor Microwave characterization of passive devices S-parameters Extraction of device’s characteristics from measurements De-embedding and calibration 58 Passive components in MMIC technology Extraction of the device’s characteristics from measurements How to compare analytical and experimental (measurements) results? Analytical study: Propagation constant γ Characteristic impedance Zc “conversion” Comparison is now possible! Measurements: S-parameters S11, S12, S21, S22 “conversion” S-parameters Propagation constant γ S11, S12, S21, S22 Characteristic impedance Zc 59 Passive components in MMIC technology Extraction of the device’s characteristics from measurements Experimental results: During measurements, the device is placed between two 50 Ω ports. 50 Ω port Two-port device 1-Γ Γ 50 Ω port T -Γ Γ Γ 1+Γ Γ 50 Ω port 1+Γ Γ -Γ Γ T Γ 50 Ω port 1-Γ Γ Graph of fluency 60 Passive components in MMIC technology Extraction of the device’s characteristics from measurements Extraction of the characteristic impedance and the propagation constant from the S-parameters (for a reciprocal device): Transmission coefficient: T= S 21 1 − S11Γ Propagation constant: 1 l γ = − ln(T ) Reflection coefficient: Γ = K ± K² + 1 K= S11 ² − S 21 ² + 1 2S11 Γ ≤1 Characteristic impedance: Zc = Z0 1+ Γ 1− Γ 61 Passive components in MMIC technology Extraction of the device’s characteristics from measurements Calculation of S-parameters from analytical evaluation of the propagation constant and the characteristic impedance (for a reciprocal device): Transmission coefficient: T = exp( −γl ) Reflection coefficient: Γ= Zc − Z0 Zc + Z0 S-parameters: S11 = S 22 = Γ(1 − T ²) 1 − T ²Γ ² S12 = S 21 = T (1 − Γ ²) 1 − T ²Γ ² 62 Passive components in MMIC technology Introduction Passive components in MMIC technology Design cycle of passive components in MMIC technology Distributed components Inductor, capacitor Localized components Resistor, capacitor, inductor Microwave characterization of passive devices S-parameters Extraction of device’s characteristics from measurements De-embedding and calibration 63 Passive components in MMIC technology De-embedding and calibration Vector network analyzer (VNA) Vector Network Analyzer are commonly used to measure S-parameters of a DUT (Device Under Test). VNA are available for measurements from 45 MHz up to 220 GHz. The DUT is excited on one port by a sinusoidal signal of constant magnitude and a frequency range defined by the user. The transmitted and reflected signals are measured by the VNA. The operation is repeated for each port, and then the scattering matrix (S-parameters) can be evaluated for each point of frequency. [7] B. Bayard, “Contribution au développement de composants magnétiques pour l’électronique hyperfréquence”, Thèse de Doctorat, 2000. 64 Passive components in MMIC technology De-embedding and calibration Vector network analyzer (VNA) In case of a two-port device, the VNA automatically excites first the port 1 of the DUT and measures the parameters S11 and S21, and second excites the port 2 and measures the parameters S22 and S12. In this way, it is not necessary to reverse the DUT. When one of the two port is excited, the VNA divides the signal in two parts. The first one will be the excitation source of the DUT, the second one will be needed as a reference. The reflected and transmitted signals should be compared to this reference. The DUT is linked to the VNA by coaxial cables. The bandwidth of the cables and the VNA must be greater than the frequency range study of the DUT. 65 Passive components in MMIC technology De-embedding and calibration Thin frequency sweeping Vector network analyzer (VNA) Digit keypad Screen display Port 1 Port 2 Command buttons 66 Passive components in MMIC technology De-embedding and calibration Measurement benchmark VNA Port 1 Coaxial cable Port 2 DUT GSG coplanar probes Substrate Ground Signal 67 Passive components in MMIC technology De-embedding and calibration Calibration permits to suppress the parasitic effects of the cables, the probes and the VNA. VNA Port 1 Coaxial cable Port 2 DUT GSG coplanar probes Substrate CALIBRATION 68 Passive components in MMIC technology De-embedding and calibration Calibration: Two categories of errors: Random errors: Can not be corrected, Supposed negligible respect to the systematic errors, Example: noise, temperature drift, user manipulation … To use the maximal power source without saturate the DUT to optimize the SNR (Signal/Noise Ratio). Systematic errors: Reproducible errors, Must be corrected by the calibration. 69 Passive components in MMIC technology De-embedding and calibration Calibration Systematic errors: Directivity error: error due to the imperfect separation of reflected and transmitted signals. Impedance mismatching of the generator output: a part of the signal reflected by the DUT is reflected by the generator. Impedance mismatching of the load: a part of the signal transmitted by the DUT to the load is reflected by the load. Tracking error: this error is due to the path difference between the measured (external) signals and the reference (internal) signals. Error due to the dissymmetry of the switch that orients the signals from the generator to the ports 1 or 2. Insulation error: this is due to the coupling between the two ports. 70 Passive components in MMIC technology De-embedding and calibration Calibration The goal of the calibration is to obtain a perfect measurement system by removing the errors introduced by the experimental benchmark. The calibration consists on the measurement of special components called “standards” in order to obtain data to evaluate the elements of the error model. The standards take place in a “calibration kit” or a calibration substrate. Three models exist: The model with 12 error elements, The model with 10 error elements, The model with 8 error elements. Complexity Accuracy 71 Passive components in MMIC technology De-embedding and calibration Calibration The model with 12 error elements: Forward (F) model ⇒ 6 elements EIF Sij: intrinsic S-parameters of the DUT EIF: insulation error Transmission measurement Incident wave 1 EGF: generator impedance mismatching ELF: load impedance mismatching EDF EDF: directivity error ERF: reflection error Reflected wave S21 EGF ERF S11 ETF S22 ELF S12 ETF: transmission error 72 Passive components in MMIC technology De-embedding and calibration Calibration The model with 12 error elements: Reverse (R) model ⇒ 6 elements Reflected wave Sij: intrinsic S-parameters of the DUT S21 EIR: insulation error EGR: generator impedance mismatching ELR ELR: load impedance mismatching ETR: transmission error S22 S12 EDR: directivity error ERR: reflection error S11 Transmission measurement ETR ERR EGR EDR 1 Incident wave EIR 73 Passive components in MMIC technology De-embedding and calibration OSTL calibration (open-short-thru-load calibration) Commonly used calibration based on the model with 12 error elements. 4 standards are required: open, short, thru, and load. Large bandwidth calibration. OST (open-short-thru) or OSL (open-short-line) calibration Based on the model with 8 error elements. ⇒ 3 standards are needed instead of 4. The standard “load” is eliminated, this is the hardiest to manufacture. 74 Passive components in MMIC technology De-embedding and calibration TRL calibration (thru-reflect-line) High accuracy calibration. Initially based on the model with 8 error elements. Standard “thru”: the two ports are directly linked together. The standard “thru” must be perfect. Standard “reflect”: each port is connected to a unknown device with a high reflection level. Standard “line”: the two ports are linked by a transmission line. The length of the line could be unknown. LRL calibration (line-reflect-line) Identical to the TRL calibration, but it could be convenient for the calibration of planar lines since they can not be directly linked together (the standard “thru” is not feasible). 75 Passive components in MMIC technology De-embedding and calibration Schematic of a calibration substrate Probes positioned on a calibration substrate Transition from probes to coaxial cable GSG probes positioning on the contact pads of an inductor 2 probes on the same support Probes positioning on the contact pads of an IC 76 Passive components in MMIC technology De-embedding and calibration Manual probe system 77 Passive components in MMIC technology De-embedding and calibration De-embedding permits to suppress the parasitic effects of the transition between the probes and the DUT, and the access of the DUT. VNA Port 1 Coaxial cable Port 2 DUT GSG coplanar probes Substrate DE-EMBEDDING 78 Passive components in MMIC technology De-embedding and calibration De-embedding techniques fall into two broad categories: Modeling based approach, Measurement based approach. The de-embedding approach starts with the knowledge (by measurements or simulation) of the S-parameters of a structure containing the discontinuity to be studied and other auxiliary part such as traces, adapters, etc. The S parameters of these parts are evaluated by means of simulation or measurements. The S matrix of the discontinuity is extracted from the S matrix of the complete structure by means of the information on the auxiliary parts. More exactly, the ABCD matrix is used for the calculation. [8] S. Agili, A. Morales, “De-embedding techniques in signal integrity: a comparison study”, 2005 Conference on Information Sciences and Systems. 79 Passive components in MMIC technology De-embedding and calibration De-embedding step-by-step: Measurement of the S-parameters of the complete structure and conversion in ABCD matrix. Evaluation by measurement or simulation of the S-parameters of the auxiliary parts and conversion in ABCD matrix. Evaluation of the ABCD matrix of the DUT, and conversion in Sparameters: ADUT C DUT B DUT A1 = D DUT C1 −1 B1 Atotal . D1 C total B total A2 . D total C 2 B2 D 2 Substrate DUT [A1B1C1D1] −1 [ADUT BDUT CDUT DDUT] [A2B2C2D2] [AtotalBtoitalCtotalDtotal] 80 Passive components in MMIC technology De-embedding and calibration De-embedding Example with a planar spiral inductor: [9] S. Couderc, “Etude de matériaux ferromagnétiques doux à forte aimantation et à résistivité élevée pour les radio-fréquences, applications aux inductances spirales planaires sur silicium pour réduire la surface occupée”, Thèse de Doctorat, 2006. 81 Passive components in MMIC technology De-embedding and calibration On-wafer de-embedding: Short-open de-embedding The open-short de-embedding method is a two-step de-embedding method and is considered as the industry standard. Shunt and series parasitic elements are removed by using open and short dummy structures, respectively. Consequently, a short and an open circuits are added on the wafer for each device to be measured. [10] M. Drakaki, A.A. Hatzopoulos, S. Siskos, “De-embedding method fro on-wafer RF CMOS inductor measurements”, Microelectronics Journal 40 (2009) 958-965. [11] T.E. Kolding, “On-wafer calibration techniques for GHz CMOS measurements”, Proc. IEEE 1999 Int. Conf. on Microelectronic Test Structures, Vol. 12, March 1999, pp. 105-110. 82 Passive components in MMIC technology De-embedding and calibration On-wafer de-embedding: Short-open de-embedding From the measurement of the short-circuit, the open circuit, and the twoport device, it is possible to extract the intrinsic characteristics of the DUT: ( −1 YDUT = Ytotal − Z short ) −1 ( −1 − Yopen − Z short ) −1 Zshort Zshort DUT Yopen Yopen 83 Passive components in MMIC technology De-embedding and calibration On-wafer de-embedding: Short-open de-embedding Example of a coplanar transmission line: De-embedding reference planes Open circuit Short circuit 84 Passive components in MMIC technology De-embedding and calibration On-wafer de-embedding: Short-open de-embedding Example of a planar spiral inductor: 85 Passive components in MMIC technology Evangéline BENEVENT Università Mediterranea di Reggio Calabria DIMET Thank you for your attention! 86