* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Microbiology Of Fermented Foods and Beverages by momina

Citric acid cycle wikipedia , lookup

Genetic code wikipedia , lookup

Fatty acid synthesis wikipedia , lookup

Amino acid synthesis wikipedia , lookup

Biosynthesis wikipedia , lookup

Microbial metabolism wikipedia , lookup

15-Hydroxyeicosatetraenoic acid wikipedia , lookup

Biochemistry wikipedia , lookup

Specialized pro-resolving mediators wikipedia , lookup

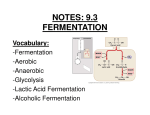

MICROBIOLOGY OF FERMENTED FOODS AND BEVERAGES BY: MOMINA MASUD CONTENTS Introduction. Properties of fermented foods and beverages. Microorganisms and metabolisms. Role of bacteria in the production. Lactic acid bacteria. The main genera of lactic acid bacteria. Role of molds and yeast in the production. Cultured dairy products. Cheese Beer fermentation INTRODUCTION Fermented foods and beverages are one of the first foods used by human beings. Tastes better and well conserved. It is important to regulate the growth and activity of microorganisms. Microorganisms need to be standardized. Activity constantly fluctuates due to encounter with different inhibitory chemicals. Fermented food and beverages industry must meet demands of: 1. Steadiness 2. Superiority and 3. Protection PROPERTIES OF FERMENTED FOODS AND BEVERAGES 1. 2. 3. 4. 5. 6. Preservation. Nutrition. Functionality. Organoleptic. Uniqueness. Economic value. MICROORGANISMS AND METABOLISMS Ethanol producing yeasts and bacteria producing lactic acid are the most frequently used. Some organisms play involuntary role. For example the production of tempeh, Manufactured after the inoculation of soybeans with rhizopus oligosporus Contamination may occur due to presence of vitamin B12 synthesizing bacteria. Makes tempeh a fine source of vitamin B12 ROLE OF BACTERIA IN THE PRODUCTION OF FERMENTED FOOD AND BEVERAGES The bacteria are divided into three main phyla: 1. Firmicutes. a) gram positive bacteria-lactic acid bacteria b) bacillus and brevibacterium-less common 2. Proteobacteria. a) gram negative bacteria-vinegar fermentation and wine spoilage. 3. Actinobacteria. a) staphylococcus-used in meats for flavoring. b) bifidobacterium-added to enhance nutritional worth. c) micrococcus. THE LACTIC ACID BACTERIA Gram positive rods and cocci, non spore forming. Aero tolerant, acid tolerant and facultative anaerobes. Heterotrophic chemoorganotrophs, due to their carbon and energy needs. Consist of species which are adaptable to less nutrient rich environments. Inhabit habitats like: meat, low pH foods, ethanolic environments, milk etc. Capable of breaking down sugars to produce lactic acid and other products. Make them very important in fermentations. Two Fermentative pathways Homo fermentative Pathway: almost 90% conversion of sugar substrate just to Lactic acid. Hetero fermentative pathway: 50% conversion to lactic acid rest is converted to CO2, acetic acid and ethanol. RESPIRATION IN LACTIC ACID BACTERIA Lactococcus lactis contains an integral respiratory pathway consisting of: 1. cytochromes 2. dehydrogenases 3. menoquinones 4. Gene cydAB-encodes for cytochrome oxidase, supplies the terminal oxidase. note: heme is missing in this pathway and needs to be added, as it is essential for the activity of catalase enzyme and cytochrome proteins. After a fermentative period, respiratory growth period follows. Lactococci were provided respiring conditions (aerobic and presence of heme)-cell growth was much better. Growth of cells extended over longer period of time. Cell densities higher as compared to cells not undergoing respiration. Viability of respiring cells extended over a longer period since pH around 6.0, fermentation produced little lactic acid. Aim is maximum cell biomass while maintaining cell viability. Lactococci lack citric acid cycle, therefore NADH should be generated through other pathways. MAIN GENERA OF LACTIC ACID BACTERIA AND THEIR ROLE IN FERMENTATION 1. Lactococcus: Non motile, home fermentative and facultative anaerobes. Optimum growth temperature 30o C L.lactis plays an important role in the dairy industry. Two different species: a) L.lactis subsp lactis-most strains of this grow at 40o C, greater tolerance to salt up to 4%. b) L.lactis subsp cremoris-most strains of this grow at a temperature of above 38o C, lesser tolerance to salt. The latter sub specie is measured to be less tolerant during dairy fermentation due to its encounter with environmental pressures Despite of this it is known to make better quality cheese, conditions need to be optimized. 2. Streptococcus: Varied species, extensive range of locales. Non motile, homo fermentative and facultative anaerobe. Most important specie, Streptococcus thermophilusimportant role in fermentation. It is well adapted to milk environments. Produces lactic acid after the fermentation of lactose. High optimum temperature of 40o C to 42o C. Needs amino acids as it is fairly proteolytic. Salt tolerant, limited metabolic diversity and bile sensitive. 3. Lactobacillus: Comprises of 80 or more species. Live in diverse habitats-plant and vegetable material, juice, dairy and meat environments, fermented beverages. Presence in gastrointestinal tracts, act as probiotics. Play a role in spoilage of fermented as well as non-fermented foods. Optimum temperature for growth varies from 30oC to 45oC. High tolerance to salt, low water activity and osmotic pressure. Many strains grow in acidic environments. Some show tolerance against ethanol and bile. Require nutrient rich environment-fatty acids, peptides and amino acids. Some require nucleotides and vitamins. Lactobacilli can ferment a wide range of sugars provided they have a fermentable source of carbohydrates. Ferment common sugars like: lactose, glucose, fructose. Ferment plant derived carbohydrates: trehalose, cellobiose, amygdalin. May act directly or indirectly. Act directly by being added in starter cultures. Act indirectly by their presence in equipment and raw materials. Two main species used in dairy starter cultures: a) lactobacillus helveticus b) lactobacillus delbrueckii ROLE OF MOLDS AND YEASTS IN THE PRODUCTION OF FERMENTED FOODS AND BEVERAGES . Molds: filamentous and multi cellular, produce sexual and asexual spores. Most commonly used mold in fermentation are: penicillin and aspergillus. Yeast: non filamentous and uni cellular, non sporulating and produce only sexual spores. Most important are sacchromyces. Sacchromyces are needed in the production of fermented products like wine, beer, bread products. Wine fermentations may be natural or spontaneous and different yeasts might be involved. Two common styles of beer production through fermentation include: Ales: requires yeast S.cerevisiae. Referred as top fermenting yeasts as they flocculate at the top of the vessel. Lagers: requires yeast S.pastorianus. referred bottom fermenting yeasts as they settle at the bottom of the vessel. Penicillium: a) Penicillium roquefort: famous species n fermentation. Gives blue-veined cheese its typical color. Vital for characteristics of cheeses like flavor and aroma. b) Penicillium camemberti: white mold species. Vital because it takes part in the fermentation of Brie and camembert cheeses. Aspergillus: a) Aspergillus oryzae b) Aspergillus sojae Used in the manufacture of soy pastes, soya sauces and rice wines. CULTURED DAIRY PRODUCTS Milk has a carbohydrate rich, nutrient dense composition, suitable as a fermentation substrate. Fresh milk has characteristics in which microorganism can grow easily. Lactic acid bacteria can take part in fermentation and conveniently grow in milk Make a hostile environment for pathogenic bacteria by producing lactic acid from lactose. Common dairy products include yogurt, buttermilk, cream. These products have increased nutritional worth. Yogurt starter culture includes: a) Streptococcus thermophilus. b) Lactobacillus delbrueckii subspbulgaricus These also act as probiotics. Lactobacillus acidophilus and bifidobacterium are indirectly involved in yogurt fermentation. Lactic acid fermentation should cause the pH to decrease and isoelectric point of casein should be reached. At the isoelectric point, the pH of the protein is such that the net electrical charge is zero and protein is at a point where it has lowest solubility. There are acidic and basic amino acids present which become protonated by the decrease in pH. The amino acids become more positive and at a point positive and negative charges are equal. Isoelectric point of casein is 4.6 After isoelectric point is reached, a coagulum forms. Ethanol, acetaldehyde and acetic acid are also produced by cultures. Contribute to flavor and texture. CHEESE Also a product of fermentation. Raw materials simple, end product unbelievable. Solid part is concentrated, water eliminated. Concentration processes decrease microbial and enzymatic activity-longer shelf life. Concentration process comprises of concentration of protein and fat, elimination of water. High temperature and low pH improves elimination of water. A very high temperature not useful, inactivates microbes, poor quality cheese. Coagulation is the process by which liquid milk converted to solid cheese. Coagulum not left attached, cut into curds. Cooking and washing steps. BEER FERMENTATION Fermented beverage. Well preserved. Processes are not easy to control and optimize. Filtering of beer to enhance clearness might have adverse affects, might eliminate the pleasing taste. Two main phases of beer making: a) First phase-mashing b) Second phase-fermentation phase First phase-mashing (enzymatic nature) Starch Sugars fermented by yeast Alteration of barley, the cereal grain Malt Mash Wort, growth medium which is nutrient rich Second phase-fermentation (microbiological nature) Growth of yeasts in wort Yeast grows in anaerobic conditions-fermentation Sugars converted to ethanol and CO2 Beer in misty form-unstable. Steps to eliminate extra microbes and yeast Carbonation