* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Lab #8

Multi-state modeling of biomolecules wikipedia , lookup

Point mutation wikipedia , lookup

Citric acid cycle wikipedia , lookup

Peptide synthesis wikipedia , lookup

Photosynthetic reaction centre wikipedia , lookup

Metalloprotein wikipedia , lookup

Proteolysis wikipedia , lookup

Protein structure prediction wikipedia , lookup

Genetic code wikipedia , lookup

Amino acid synthesis wikipedia , lookup

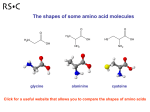

FSTC 313 FOOD CHEMISTRY LABORATORY Non-enzymatic browning 1. Introduction Under many food processing conditions, reducing sugars produce brown colors that are desirable and important in some foods. Other brown colors obtained upon heating or during longterm storage of foods are undesirable. Common browning of foods on heating or on storage is usually due to a chemical reaction between reducing sugars and a free amino acid or a free amino group of an amino acid that is part of a protein chain. This reaction is called the Maillard reaction. It is also called non-enzymatic browning to differentiate it from the often rapid, enzyme-catalyzed browning commonly observed in freshly cut fruits and vegetables, such as apples and potatoes. When aldoses or ketoses are heated in solution with amines, a variety of reactions follow, producing numerous compounds, such as flavors, aromas, and dark-colored polymeric materials. The flavors, aromas, and colors may be either desirable or undesirable. They may be produced by frying, roasting, baking, or storage. First, the reducing sugar reacts reversibly with the amine to produce a glycosylamine. This undergoes a reaction called the Amadori rearrangement, and it continues, especially at pH 5 or lower, to give an intermediate that dehydrates. Eventually a furan derivative is formed; that from a hexose is 5-hydroxymethyl-2-furaldehyde (HMF). Under less acidic conditions, the reactive cyclic compounds (HMF and others) polymerize to a dark-colored, insoluble material. Figure 1. Conversion of the Amadori product into HMF. Maillard browning products, including soluble and insoluble polymers, are found where reducing sugars and amino acids, proteins and other nitrogen-containing compounds are heated together, such as in soy sauce and bread crusts. Maillard reaction products are important contributors to the flavor of milk chocolate. The Maillard reaction is also important in the production of caramels, toffees, and fudges, during which reducing sugars also react with milk proteins. D-Glucose undergoes the browning reaction faster than does D-fructose. Application of heat is generally required for nonenzymatic browning. While Maillard reactions are useful, they also have a negative side. Reaction of reducing sugars with amino acids destroys the amino acid. This is of particular importance with lysine, an essential amino acid whose amino group can react when the amino a cid is part of a protein molecule. 2. Objectives a. To gain a better understanding of non-enzymatic browning reactions and their role in food products. b. To investigate the influence of substrate type on the rate of the Maillard reaction and establish the effect of pH on Maillard browning reaction rates. 3. Materials Beakers Spectrophotometer Water bath Screw-cap test tubes with caps Phosphate buffers, pH 4.5 and 8.5. Glucose and Fructose Solutions (0.5M each) Amino Acids (AA): Glycine and Glutamine Solutions (0.5M each) 4. Methods 1. Add 2 mL of glucose, fructose, sucrose, or mixtures into test tubes (see below). 2. Add 2 mL of glycine, glutamine, or mixture into the same tubes. 3. Bring to a known volume (~10 mL) with pH 4.5 buffer in one set. 4. Bring to a known volume (~10 mL) with pH 8.5 buffer in the second set. 5. Keep all final volumes the same. 6. Prepare a blank of pH 4.5 buffer for the spectrophotometer, no heating. 7. Label your test tubes, cap them tightly, and place them in a boiling water bath for 5, 10, and 20 min. 8. Pull one tube for each pH at each time. 9. Cool your tubes in cool water. 10. Add 200 µL to a microplate and read absorbance at 420 nm. Maillard Options. Use any and all sugar/AA combinations at each pH and time. Sugars Amino Acids pH Times Glucose Glycine 4.5 5 Fructose Glutamine 8.5 10 Glucose + Fructose 20 Sucrose 5. Results and Discussion: Plot absorbance as a function of time for each sugar-amino acid solution for each pH. How does each factor influence browning and the rate of browning and why? o Type of sugar o Type of AA o Mixtures o pH o Time 6. Organoleptic Observations: To be discussed in class. Discussion Question/Application Example: Kraft was so pleased with your resume that they offered you a job and assigned you to a food product development position. Your first project was to improve the color and flavor of their frozen, microwavable meat entrees. These products need a nice golden-brown surface color and a meaty-flavored brown gravy that can only be derived from the Maillard reaction. How can this be accomplished?