* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Analysis of Honey Samples - Research Commons@Waikato

Monoclonal antibody wikipedia , lookup

Community fingerprinting wikipedia , lookup

Metalloprotein wikipedia , lookup

Butyric acid wikipedia , lookup

Citric acid cycle wikipedia , lookup

Nucleic acid analogue wikipedia , lookup

Proteolysis wikipedia , lookup

Point mutation wikipedia , lookup

Fatty acid metabolism wikipedia , lookup

Fatty acid synthesis wikipedia , lookup

Peptide synthesis wikipedia , lookup

Protein structure prediction wikipedia , lookup

Genetic code wikipedia , lookup

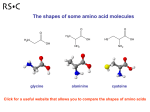

Amino acid synthesis wikipedia , lookup