* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Optimal placement of shunt connected facts device in a series long

Standby power wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Opto-isolator wikipedia , lookup

Utility frequency wikipedia , lookup

Power factor wikipedia , lookup

Wireless power transfer wikipedia , lookup

Audio power wikipedia , lookup

Power over Ethernet wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Power inverter wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Electrification wikipedia , lookup

Stray voltage wikipedia , lookup

Surge protector wikipedia , lookup

Power MOSFET wikipedia , lookup

Electric power system wikipedia , lookup

Electric power transmission wikipedia , lookup

Buck converter wikipedia , lookup

Three-phase electric power wikipedia , lookup

Electrical substation wikipedia , lookup

Voltage optimisation wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Power engineering wikipedia , lookup

Mains electricity wikipedia , lookup

OPTIMAL PLACEMENT OF SHUNT CONNECTED FACTS

DEVICE IN A SERIES LONG TRANSMISSION LINE

ABSTRACT

This paper deals with the optimal location and parameters of

Unified Power Flow Controllers (UPFCs) in electrical power systems. The UPFC is one of

the most promising FACTS devices in terms of its ability to control power system

quantities. Shunt FACTS devices are used for controlling transmission voltage, power

flow, reducing reactive losses, and damping of power system oscillations for high power

transfer levels. In this paper the optimal location of a shunt FACT device is investigated for

an actual line model of a transmission line having series compensation at the center.

As one of the most promising FACTS devices in terms of its ability to

control power system quantities, UPFC Effect of change in degree of series compensation on

the optimal placement of the shunt FACTS device to get the highest possible benefit is

studied. The results obtained shown that optimal placement of the shunt FACTS device

varies with the change in the level of series compensation.

Key Words:

Optimal placement

Shunt FACTS,

Series compensation

Unified power flow controller (UPFC)

OPTIMAL PLACEMENT OF SHUNT CONNECTED FACTS

DEVICE IN A SERIES LONG TRANSMISSION LINE

CONTENTS

PAGE NO.

CHAPTER-1

INTRODUCTION

1

1.1General

2

1.2 Basics of Power Transmission Network

3

1.3 Control of Power Flow in AC Transmission Line

8

CHAPATER-2

2. Flexible AC Transmission System Controllers

13

2.1 General Description

13

2.2 The FACTS controllers can be classified as

15

2.2.1 Depending on the power electronic devices used in the control,

The FACTS controllers

2.2.2 The variable impedance type controllers

15

15

2.2.3 The VSC based FACTS controllers

15

2.2.4 Some of the special purpose FACTS controllers

16

2.3 Voltage Source Converter Based Controllers

17

2.4 A General Equivalent Circuit for FACTS Controllers

24

2.5 Benefits with the Application of FACTS Controllers

26

2.6 Application of FACTS Controllers in Distribution Systems

28

CHAPATER-3

3.1Comparison between Series and Shunt Capacitor

3.2 Static Var Compensator

30

32

3.2.1 Analysis of SVC

33

3.2.2 Expression for Voltage and Power

36

3.2.3 Configuration of SVC

37

3.3 Thyristor Switched Capacitor (TSC)

42

3.4 SVC Controller

42

3.5 STATCOM

45

3.5.1 THREE PHASE STATCOM’S EQUIVALENT CIRCUIT

AND STEADY STATE EQCATION

3.6Shunt compensation is of two types

52

3.6.1 Shunt capacitive compensation

52

3.6.2 Shunt inductive compensation

52

3.7 TRANSMISSION LINE MODEL

48

54

3.8 SERIES COMPENSATED TRANSMISSION LINE WITH

SHUNT FACTS DEVICES

56

CHAPATER-4

SIMULINK FILES AND RESULTS

58

4.1 CIRCUIT DIAGRAM

58

4.2 PROGRAM

61

4.3 OUT PUT WAVE FORM

62

CHAPTER-5

CONCULSION

67

CHAPTER-6

REFERENCES

68

LIST OF FIGURES

PAGE NO.

CHAPTER-1

Fig 1.1 A line transmitting power form a generating station

4

Fig 1.2 A line supplying power to load

5

Fig 1.2.1 Two generating station supplying load

7

Fig 1.2.2 two areas connected by a tie line

8

Fig 1.3 power Transfer Capacity as a function of line length

9

Fig 1.4 A Lossless line with an ideal PST

11

Figure 1.5: Transmission line compensated by controllable

12

Reactive power source

CHAPTER-2

Fig 2.1 Shunt connected STATCOM

17

Fig 2.2 series connected SSSC

18

Fig 2.3 unified power flow control

18

Fig 2.4 A Three phase, six pulse VSC

20

Fig 2.5 A Single phase half wave converter

21

Fig2.6 waveform of Van and the fundamental component

23

Fig2.7 An equivalent circuit for UPFC

25

CHAPTER-3

Fig 3.1 series capacitor

31

Fig 3.2 Shunt capacitor

31

Fig 3.3 Analysis of SVC

34

Fig 3.4 characteristic of SVC

35

Fig 3.5 control characteristic of SVC

36

Fig 3.6 A Typical SVC (TSC-TCR) Configuration Thyristor

38

Controlled Reactor

Fig 3.7 A TCR circuit

39

Fig 3.8 waveforms of v and I

40

Fig 3.9 waveforms of vL and vT

40

Fig 3.10 SVC controller

43

Fig 3.11 STAT COM’s schematic representation

45

Fig. 3.12 equivalent one-phase circuit of the ST

46

Figure 3.13 Lagging currents

47

Figure 3.14 leading currents

47

Fig. 3.15. Three-phase STATCOM´s equivalent circuit.

49

Fig 3.16 series compensation

52

Fig 3.17shunt compensation

53

Fig 3.18 2-port,4-terminal model of a transmission line

54

Fig 3.19 series compensated transmission line with a shunt Fact device

56

Idel of a transmission line

Fig 3.20 schematic diagram of a SVC

57

Fig 3.21Examples of FACTS for shunt compensation

57

CHAPTER-4

Fig 4.1 SIMULINK diagram

58

Fig 4.2 STATCOM Designing circuit

Fig 4.3 SVC Designing circuit

60

Fig 4.4 Variation in maximum SE power for diff. value of %S.

63

Fig 4.5 Variation in maximum RE power for diff. value of %S

64

Fig 4.6 Variation in transmission angle at the max. SE power for diff. % S

65

Fig 4.7 Variation in the maximum RE power of section-1 and

66

SE power of section-2 against k for diff. value of %S.

.

59

CHPATER- 1

INTRODUCTION

The flexible AC transmission system (FACTS) has received much

attention in the last 2 decades. It uses high current power electronic devices to control the

voltage, power flow, stability, etc. of a transmission system. FACTS technologies can

essentially be defined as highly engineered power-electronics-based systems, integrating the

control and operation of advanced power semiconductor based converters (or valves) with

software based information and control systems, which produce a compensated response to the

transmission network that is interconnected via conventional switchgear and transformation

equipment. FACTS devices can be connected to a transmission line in various ways, such as in

series with the power system (series compensation), in shunt with the power system (shunt

compensation), or both in series and shunt. For example, the static VAR compensator (SVC)

and static synchronous compensator (STATCOM) are connected in shunt; static synchronous

series compensator (SSSC) and thyristor controlled series capacitor (TCSC) are connected in

series; thyristor controlled phase shifting transformer (TCPST) and unified power flow

controller (UPFC) are connected in a series and shunt combination. In series compensation, the

FACTS is connected in series with the power system. It works as a controllable voltage source.

Series inductance occurs in long transmission lines, and when a large current flow causes a

large voltage drop. To compensate, series capacitors are connected. In shunt compensation,

power system is connected in shunt with the FACTS.

It works as a controllable current source. The term and definition of

various FACTS devices are described in references [1]-[5]. The pressure associated with

economical and environmental constraints has forced the power utilities to meet the future

demand by fully utilizing the existing resources of transmission facilities without building

new lines. FACTS devices are very effective and capable of increasing the power transfer

capability of a line, as thermal limits permit, while maintaining the same degree of stability

[3]-[9]. Numerous recent applications of FACTS have proven to be cost-effective, longterm solutions. With the improvements in current and voltage handling capabilities of the

power electronic devices that have allowed for the development of Flexible AC

Transmission System (FACTS), The possibility has arisen in using different types of

controllers for efficient shunt and series compensation. Applying FACTS on a broad-scale

basis for both local and. Shunt FACTS devices are used for controlling transmission

voltage, power flow, reducing reactive losses, and damping of power system oscillations for

high power transfer levels [5]-[8]-[9].With the wide spread and active consideration of the

installation of FACTS controllers for better controllability.

1.1 General:

Modern power systems are designed to operate efficiently to supply power on demand to

various load centers with high reliability. The generating stations are often located at distant

locations for economic, environmental and safety reasons. For example, it may be cheaper to

locate a thermal power station at pithead instead of transporting coal to load centers.

Hydropower is generally available in remote areas. A nuclear plant may be located at a place

away from urban areas.

Thus, a grid of transmission lines operating at high or extra high voltages is required to

transmit power from the generating stations to the load centers.

In addition to transmission lines that carry power from the sources to loads, modern power

systems are also highly interconnected for economic reasons. The interconnected systems

benefit by

(a) Exploiting load diversity

(b) Sharing of generation reserves and

(c) Economy gained from the use of large efficient units without sacrificing reliability.

However, there is also a downside to ac system interconnection { the security can be

adversely affected as the disturbances initiated in a particular area can spread and propagate

over the entire system resulting in major blackouts caused by cascading outages.

1.2 Basics of Power Transmission Networks:

A large majority of power transmission lines are AC lines operating at different

voltages (10 kV to 800 kV). The distribution networks generally operate below 100 kV while

the bulk power is transmitted at higher voltages. The lines operating at different voltages are

connected through transformers which operate at high efficiency. Traditionally, AC lines have

no provision for the control of power flow. The mechanically operated circuit breakers (CB)

are meant for protection against faults (caused by flashovers due to overvoltages on the lines or

reduced clearances to ground). A CB is rated for a limited number of open and close operations

at a time and cannot be used for power flow control. (Unlike a high power electronic switch

such as thyristor, GTO, IGBT, IGCT, etc.).

Fortunately, ac lines have inherent power flow control as the power flow is determined

by the power at the sending end or receiving end. For example, consider a transmission line

connecting a generating station to a load centre in Fig.1.1. Assuming the line to be lossless and

ignoring the line charging, the power flow (P) is given by

Where X is the series line reactance. Assuming V 1 and V2 to be held constants (through voltage

regulators at the two ends),

the power injected by the power station determines the flow of power in the

line. The difference in the bus angles is automatically adjusted to enable P = P G (Note that

usually there could be more than one line transmitting power from a generating station to a

load centre). If one or more lines trip, the output of the power station may have to be reduced

by tripping generators, so as to avoid overloading the remaining lines in operation .

Fig 1.1 A line transmitting power form a generating station

Fig 1.2 A line supplying power to load

Fig. 1.2 shows another situation where a line supplies power to a load located at bus (2). Here

also the eq. applies but the power flow in the line is determined by the load supplied. The

essential difference between the two situations is that in

Fig. 1.1 the load centre is modeled

as an infinite bus which can absorb (theoretically) any amount of power supplied to it from the

generating station. This model of the load centre assumes that the generation available at the

load centre is much higher than the power supplied from the remote power station (obviously,

the total load supplied at the load centre is equal to the next generation available at that bus).

The reliability of the power supply at a load bus can be improved by arranging two (or more)

sources of power as shown in Fig. 1.2.1 Here, P 1 is the output of G1 while P2 is the output of G2

(Note that we are neglecting losses as before). However, the tripping of any one line will

reduce the availability of power at the load bus. This problem can be overcome by providing a

line to interconnect the two power stations. Note that this results in the creation of a mesh in

the transmission network.This improves the system reliability, as tripping of any one line does

not result in curtailment of the load. However, in steady state, P 1 can be higher or lower than

PG1 (the output of G1).The actual power flows in the 3 lines forming a mesh are determined by

Kirchhoff's Voltage Law (KVL).

In general, the addition of an (interconnecting) line can result in increase of power flow in a

line (while decreasing the power flow in some other line). This is an interesting feature of AC

transmission lines and not usually well understood (in the context of restructuring). In

general, it can be stated that in an uncontrolled AC transmission network with loops (to

improve system reliability), the power flows in individual lines are determined by KVL and

do not follow the requirements of the contracts (between energy producers and customers).

In other words, it is almost impossible to ensure that the power flow between two nodes

follows a predetermined path. This is only feasible in radial networks (with no loops), but the

reliability is adversely affected as even a single outage can result in load curtailment.

Consider two power systems, each with a single power station meeting its own local load,

interconnected by a tie line as shown in Fig. 1.2.1.In this case, the power flow in the tie line

(P) in steady state is determined by the mismatch between the generation and load in the

individual areas. Under dynamic conditions, this power flow is determined from the

equivalent circuit shown in Fig. 1.2.2.If the capacity of the tie is small compared to the size

(generation) of the two areas, the angles ±1 and ±2 are not affected much by the tie line

power flow.

Thus, power flow in AC tie is generally uncontrolled and it becomes essential to trip the tie

during a disturbance, either to protect the tie line or preserve system security. In comparison

with a AC transmission line, the power flow in a HVDC line in controlled and regulated.

However, HVDC converter stations are expensive and HVDC option is used primarily for (a)

long distance bulk power transmission (b) interconnection of asynchronous systems and (c)

underwater (submarine) transmission. The application of HVDC transmission (using thyristor

converters) is also constrained by the problem of commutation failures affecting operation of

multiterminal or multi-feed HVDC systems. This implies that HVDC links are primarily used

for point-to-point transmission of power and asynchronous interconnection (using Back to

Back (BTB) links).

Fig 1.2.1 Two generating station supplying load

Fig 1.2.2 two areas connected by a tie line

1.3 Control of Power Flow in AC Transmission Line:

We may like to control the power flow in a AC transmission line to (a) enhance power

transfer capacity and or (b) to change power flow under dynamic conditions (subjected to

disturbances such as sudden increase in load, line trip or generator outage) to ensure system

stability and security. The stability can be affected by growing low frequency, power

oscillations (due to generator rotor swings), loss of synchronism and voltage collapse caused

by major disturbances.

Where δmax (300_ 400) is selected depending on the stability margins and the stiffness of the

terminal buses to which the line is connected. For line lengths exceeding a limit, P max is less

than the thermal limit on the power transfer determined by the current carrying capacity of the

conductors (Note this is also a function of the ambient temperature). As the line length

increases, X increases in a linear fashion and P max reduces as shown in Fig. 1.3

Fig 1.3 power Transfer Capacity as a function of line length

The series compensation using series connected capacitors increases P max as the compensated

value of the series reactance (Xc) is given by

Where kse is the degree of series compensation. The maximum value of k se that can be used

depends on several factors including the resistance of the conductors. Typically k se does not

exceed 0.7. Fixed series capacitors have been used since a long time for increasing power

transfer in long lines. They are also most economical solutions for this purpose.

However, the control of series compensation using thyristor switches has been introduced only

10{15 years ago for fast power flow control. The use of Thyristor Controlled Reactors (TCR)

in parallel with fixed capacitors for the control of X c, also helps in overcoming a major

problem of Sub synchronous Resonance (SSR) that causes instability of torsional modes when

series compensated lines are used to transmit power from turbo generators in steam power

stations. In tie lines of short lengths, the power flow can be controlled by introducing Phase

Shifting Transformer (PST) which has a complex turn’s ratio with magnitude of unity.

The power flow in a lossless transmission line with an ideal PST (see Fig. 1.4) is given

Fig 1.4 A Lossless line with an ideal PST

Again, manually controlled PST is not fast enough under dynamic conditions. Thyristor

switches can ensure fast control over discrete (or continuous) values of §, depending on the

configuration of PST used. P max can also be increased by controlling (regulating) the receiving

end voltage of the AC line. When a generator supplies a unity power factor load (see Fig. 1.2,

the maximum power occurs when the load resistance is equal to the line reactance). It is to be

noted that V2 varies with the load and can be expressed as

By providing dynamic reactive power support at bus (2) as shown in Fig. (1.5), it is possible to

regulate the bus voltage magnitude.

Figure 1.5: Transmission line compensated by controllable reactive power source.

At receiving end power (QC) that has to be injected is given by

Comparing eq. (1.6) with (1.1), it can be seen that the maximum power transfer can be doubled

just by providing dynamic reactive power support at the receiving end of the transmission line.

This is in addition to the voltage support at the sending end. It is to be noted that while steady

state voltage support can be provided by mechanically switched capacitors, the dynamic

voltage support requires synchronous condenser or a power electronic controller such as Static

Var Compensator (SVC) or Static synchronous Compensator (STATCOM).

CHAPATER-2

Flexible AC Transmission System Controllers

2.1 General Description:

The large interconnected transmission networks (made up of predominantly overhead

transmission lines) are susceptible to faults caused by lightning discharges and decrease in

insulation clearances by undergrowth. The power flow in a transmission line is determined by

Kirchhoff's laws for specified power injections (both active and reactive) at various nodes.

While the loads in a power system vary by the time of the day in general, they are also subject

to variations caused by the weather (ambient temperature) and other unpredictable factors. The

generation pattern in a deregulated environment also tends to be variable (and hence less

predictable). Thus, the power flow in a transmission line can vary even under normal, steady

state conditions. The occurrence of a contingency (due to the tripping of a line, generator) can

result in a sudden increase/decrease in the power flow. This can result in overloading of some

lines and consequent threat to system security.

A major disturbance can also result in the swinging of generator rotors which

contribute to power swings in transmission line It is possible that the system is subjected to

transient instability and cascading outages as individual components (lines and generators) trip

due to the action of protective relays. If the system is operating close to the boundary of the

small signal stability region, even a small disturbance can lead to large power swings and

blackouts. The increase in the loading of the transmission lines sometimes can lead to voltage

collapse due to the shortage of reactive power delivered at the load centers.

This is due to the increased consumption of the reactive power in the transmission

network and the characteristics of the load (such as induction motors supplying constant

torque). The factors mentioned in the previous paragraphs point to the problems faced in

maintaining economic and secure operation of large interconnected systems. The problems are

eased if sufficient margins (in power transfer) can be maintained. This is not feasible due to the

difficulties in the expansion of the transmission network caused by economic and

environmental reasons. The required safe operating margin can be substantially reduced by t he

introduction of Fast dynamic control over reactive and active power by high power electronic

controllers.

This can make the AC transmission network flexible' to adapt to the changing

conditions caused by contingencies and load variations. Flexible AC Transmission System

(FACTS) is defined as `Alternating current transmission systems incorporating power

electronic-based and other static controllers to enhance controllability and increase power

transfer capability' [1,2]. The FACTS controller is defined as “a power electronic based system

and other static equipment that provide control of one or more AC transmission system

parameters”.

2.2 The FACTS controllers can be classiffied as

1. Shunt connected controllers

2. Series connected controllers

3. Combined series-series controllers

4. Combined shunt-series controllers

2.2.1 Depending on the power electronic devices used in the control, the

FACTS controllers can be classified as:

(i) Variable impedance type

(ii) Voltage Source Converter (VSC)

2.2.2 The variable impedance type controllers include

(i) Static Var Compensator (SVC), (shunt connected)

(ii) Thyristor Controlled Series Capacitor or compensator (TCSC), (series connected)

(iii) Thyristor Controlled Phase Shifting Transformer (TCPST) of Static PST (combined

shunt and series)

2.2.3 The VSC based FACTS controllers are:

(i) Static synchronous Compensator (STATCOM) (shunt connected)

(ii) Static Synchronous Series Compensator (SSSC) (series connected)

(iii) Interline Power Flow Controller (IPFC) (combined series-series)

(iv) Unified Power Flow Controller (UPFC) (combined shunt-series)

2.2.4 Some of the special purpose FACTS controllers are:

(i) Thyristor Controller Braking Resistor (TCBR)

(ii) Thyristor Controlled Voltage Limiter (TCVL)

(iii) Thyristor Controlled Voltage Regulator (TCVR)

(iiii) Inter phase Power Controller (IPC)

(v) NGH-SSR damping

The FACTS controllers based on VSC have several advantages over the variable

impedance type. For example, a STATCOM is much more compact than a SVC for similar

rating and is technically superior. It can supply required reactive current even at low values of

the bus voltage and can be designed to have in built short term overload capability. Also, a

STATCOM can supply active power if it has an energy source or large energy storage at its DC

terminals. The only drawback with VSC based controllers is the requirement of using self

commutating power semiconductor devices such as Gate Turn-off (GTO) thyristors, Insulated

Gate Bipolar Transistors (IGBT), Integrated Gate Commutated Thyristors (IGCT).

Thyristors do not have this capability and cannot be used although they are available in

higher voltage ratings and tend to be cheaper with reduced losses. However, the technical

advantages with VSC based controllers coupled will emerging power semiconductor devices

using silicon carbide technology are expected to lead to the wide spread use of VSC based

controllers in future.

It is interesting to note that while SVC was the first FACTS controllers (which utilized

the thyristor valves developed in connection with HVDC line commutated convertors) several

new FACTS controller based on VSC have been developed. This has led to the introduction of

VSC in HVDC transmission for ratings up to 300 MW.

2.3 Voltage Source Converter Based Controllers:

Introduction:

This section is aimed at giving a brief introduction to the VSC based controller. The

individual controllers are discussed in detail in the following chapters (6-8). The schematic

diagram of a STATCOM is shown in Fig.2.1 while that of a SSSC is shown in Fig.2.2. The

diagram of a UPFC is shown in Fig.2.3.

2.1 Shunt connected STATCOM

Fig 2.2 series connected SSSC

Fig 2.3 unified power flow contro

A six pulse Voltage Source Converter (VSC) is shown in Fig. 2.4.By suitable control, the phase

and the magnitude of the AC voltage injected by the VSC can be controlled .The Phase Lock

Loop (PLL) ensures that the sinusoidal component of the injected voltage is synchronized

(matching in frequency and required phase angle) with the voltage of the AC bus to which VSC

is connected through an inductor.

Often, the leakage impedance of the interconnecting transformer serves as the inductive

impedance that has to separate the sinusoidal bus voltage and the voltage injected by the VSC

(which contains harmonics).The injection of harmonic voltages can be minimized by

multipulse (12, 24 or 48), and/or multilevel convertors. At low power levels, it is feasible to

provide pulse width modulation (PWM) to control the magnitude of the fundamental

component of the injected voltage. The high voltage IGBT devices can be switched up to 2 kHz

and high frequency of sinusoidal modulation enables the use of simple L-C (low pass) filters to

reduce harmonic components.

Fig 2.4 A Three phase, six pulse VSC

The operation of a VSC can be explained with reference to a single phase (half-wave)

convertor shown in Fig. 2.5. This can represent one leg of the 3 phase VSC.

Fig 2.5 A Single phase half wave converter

TA+ and TA- are controllable switches which can be switched on or off at controllable instants in

a cycle. The diodes ensure that the current can flow in both directions in the DC capacitor. The

switches TA+ and TA- work in complementary fashion only one of them is on while the other is

off. If the switch is turned on only once during a cycle, this is called as the square-wave

switching scheme with each switch conducting for 180 0 in a cycle. The peak value of the

fundamental component (VAN1) is given by

The waveform contains odd harmonics with the magnitudes

It is to be noted that in the square wave switching scheme, only the phase angle of the voltage

injected by the VSC can be controlled (and not the magnitude). It will be shown in chapter 6

that in a three phase converter with 3 legs the triple harmonics will disappear such that the nonzero harmonic order (h) is given by

Increasing the pulse number from six to twelve has the effect of eliminating the harmonics

corresponding to odd values of n.The introduction of PWM has the effect of controlling the

magnitude of the fundamental component of the injected voltage by the VSC. For this case, the

waveform of the voltage VAN is shown in Fig2.6 Using sinusoidal modulation (with triangular

carrier wave), the peak value of the injected sinusoidal voltage can be expressed as

Where m is called the modulation index.

The maximum modulation index can be achieved with space vector modulation and is given by

[10]

It is to be noted that the modulation index (m) and the phase angle (α) are controlled to regulate

the injected current by the shunt connected VSC. Neglecting losses, a STATCOM can only

inject reactive current in steady state.

Fig2.6 waveform of Van and the fundamental component

The reactive current reference can be controlled to regulate the bus voltage. In a similar fashion

the reactive voltage injected by a lossless SSSC can be controlled to regulate the power flow in

a line within limits.

The combination of a STATCOM and a SSSC, in which the STATCOM feeds (or absorbs)

power on the DC side to SSSC, can be used to regulate both active and reactive power flow in a

line (subject to the constraints imposed by the ratings of the converters in addition to th e limits

on bus voltages).

2.4 A General Equivalent Circuit for FACTS Controllers:

The UPFC is the most versatile FACTS controller with 3 control variables (the

magnitude and phase angle of the series injected voltage in addition to the reactive current

drawn by the shunt connected VSC). The equivalent circuit of a UPFC on a single phase basis

is shown in Fig2.7. The current i is drawn by the shunt connected VSC while the voltage e is

injected by the series connected VSC. Neglecting harmonics, both the quantities can be

represented by phasors I and E. Neglecting power losses in the UPFC, the following constraint

equation applies.

Fig2.7 An equivalent circuit for UPFC

Where Ip and Ir are `real' and `reactive' components of the current drawn by the shunt connected

VSC. Similarly Vp and Vr and the `real' and `reactive' voltages injected by the series connected

VSC. Positive Ip and Vp indicate positive `real' (active) power flowing into the shunt connected

VSC and flowing out of the series connected VSC. The positive values of Ir and Vr indicate

reactive power drawn by the shunt convertor and supplied by the series converter. These

conventions will be used throughout this book.

The remaining shunt and series connected FACTS controllers can be viewed as special cases of

a UPFC. For example in a SVC,

There are 3 constraint equations and one control variable (B SV C) in a SVC.In a STATCOM, Ir

is the control variable. Table 1.1 gives the constraint equations and control variables for all the

FACTS controllers. Note that in a STATCOM or SSSC with an energy source at the DC

terminals, there are 2 control variables as Ip or Vp is non-zero.

2.5 Benefits with the Application of FACTS Controllers :

Primarily, the FACTS controllers provide voltage support at critical buses in the system

(with shunt connected controllers) and regulate power flow in critical lines (with series

connected controllers). Both voltage and power flow are controlled by the combined series and

shunt controller (UPFC). The power electronic control is quite fast and this enables regulation

both.

Under steady state and dynamic conditions (when the system is subjected to disturbances).

The benefits due to FACTS controllers are listed below.

1. They contribute to optimal system operation by reducing power lossesand improving voltage

profile.

2. The power °ow in critical lines can be enhanced as the operating margins can be reduced due

to fast controllability. In general, the power carrying capacity of lines can be increased to

values upto the thermal limits (imposed by current carrying capacity of the conductors).

3. The transient stability limit is increased thereby improving dynamic security of the system

and reducing the incidence of blackouts caused by cascading outages.

4. The steady state or small signal stability region can be increased by providing auxiliary

stabilizing controllers to damp low frequency oscillations.

5. FACTS controllers such as TCSC can counter the problem of Sub synchronous Resonance

(SSR) experienced with fixed series capacitors connected in lines evacuating power from

thermal power stations (with turbo generators).

6. The problem of voltage fluctuations and in particular, dynamic over voltages can be

overcome by FACTS controllers.

The capital investment and the operating costs (essentially the cost of power losses and

maintenance) are off set against the benefits provided by the FACTS controllers and the

`payback period' is generally used as an index in the planning.

The major issues in the deployment of FACTS controllers are

(a) The location

(b) Ratings (continuous and short term) and

(c) Control strategies required for the optimal utilization.

Here, both steady-state and dynamic operating conditions have to be considered. Several

systems studies involving power flow, stability, short circuit analysis are required to prepare

the specifications. The design and testing of the control and protection equipment is based on

Real Time Digital Simulator (RTDS) or physical simulator.It is to be noted that a series

connected FACTscontroller (such as TCSC) can control power flow not only in the line in

which it is connected, but also in the parallel paths (depending on the control strategies). This

will be explained in chapter 4.

2.6 Application of FACTS Controllers in Distribution Systems:

Although the concept of FACTS was developed originally for transmission network;

this has been extended since last 10 years for improvement of Power Quality (PQ) in

distribution systems operating at low or medium voltages. In the early days, the power quality

referred primarily to the continuity of power supply at acceptable voltage and frequency.

However, the prolific increase in the use of computers, microprocessors and power electronic

systems has resulted in power quality issues involving transient disturbances in voltage

magnitude, waveform and frequency. The nonlinear loads not only cause PQ problems but are

also very sensitive to the voltage deviations.In the modern context, PQ problem is defined as

\Any problem manifested in voltage, current or frequency deviations that result in failure or

misoperation of customer equipment" [5]. The PQ problems are categorized as follows

1. Transients

(a) Impulsive

(b) Oscillatory

2. Short-duration and Long-duration variations

(a) Interruptions

(b) Sag (dip)

(c) Swell

3. Voltage unbalance

4. Waveform distortion

(a) DC offset

(b) Harmonics

(c) Inter harmonics

(d) Notching

(e) Noise

5. Voltage Flicker

6. Power frequency variations

CHAPTER-3

3.1Comparison between Series and Shunt Capacitor:

The maximum power flow in the line is given by substituting + in the expression for the

power flow (P) is chosen from considerations of the steady state margin that will not result in

the power flow exceeding limits during a contingency. For the same amount of maximum

power transfer, we obtain the following relation

While transferring maximum power, the reactive power (Qse) supplied by the series capacitor

(for a symmetric line with VS = VR = V ) is given by

The reactive power (Qsh) supplied by the shunt capacitor (Bc) at P = Pmax is obtained as

The above relation shows that the series capacitor is much more effective than the shunt

capacitor in increasing power transfer.

Fig 3.1 series capacitor

Fig 3.2 Shunt capacitor

Another factor in the comparison of the series and shunt (capacitor) compensation is the

electrical resonance frequency. The comparison can be made from the Fig.3.1&3.2

The electrical resonance frequency (f seer ) for the series capacitor compensation

The resonance frequency for the shunt capacitor compensation is obtained as

Where f0 is the operating system frequency (50 or 60 Hz).Note that in deriving these

expression, the equation, XL2 = Zn tan µ 2 is used.

It is shown in reference [3] that oscillations of the generator rotor corresponding to a sub

synchronous frequency torsional mode (of frequency, fm) causes amplitude modulation of the

generator voltage. This causes two side bands of frequency (f0 - fm) and (f0 + fm) of the

injected voltage, which result in a sub synchronous frequency and a super synchronous

frequency current components °owing in the generator armature. While the sub synchronous

frequency current component results in a negative damping torque, the super synchronous

frequency current results in a positive damping torque. The electrical resonance at frequency,

f0 - fm, increases the negative damping torque while resonance at f0+fm, results in increase in

the positive damping torque.

This implies that there is no danger of Sub synchronous Resonance (SSR) with shunt

capacitor, while it exists with the series capacitor. On the other hand, the rating of the shunt

capacitor required is high unless the lines are substantially long resulting in large operating

values of ±max. The cost of a series capacitor is higher (typically by a factor of 2) as it has to

be designed to withstand overvoltages during fault transients.

3.2 Static Var Compensator :

It is a variable impedance device where the current through a reactor is controlled using

back to back connected thyristor valves. The application of thyristor valve technology to SVC

is an overshoot of the developments in HVDC technology. The major difference is that

thyristor valves used in SVC are rated for lower voltages as the SVC is connected to an EHV

line through a step down transformer or connected to the tertiary winding of a power

transformer. The application of SVC was initially for load compensation of fast changing loads

such as steel mills and arc furnaces.

Here the objective is to provide dynamic power factor improvement and also balance the

currents on the source side whenever required. The application for transmission line

compensators commenced in the late seventies. Here the objectives are:

1. Increase power transfer in long lines

2. Improve stability with fast acting voltage regulation

3. Damp low frequency oscillations due to swing (rotor) modes

4. Damp sub synchronous frequency oscillations due to torsional modes

5. Control dynamic overvoltages

A SVC has no inertia compared to synchronous condensers and can be extremely fast in

response (2-3 cycles). This enables the fast control of Reactive power in the control range.

3.2.1 Analysis of SVC:

The location of SVC is important in determining its effectiveness. Ideally, it should be located

at the electrical centre of the system or midpoint of a transmission line. For example, consider a

symmetric lossless transmission line with SVC connected at the midpoint (see Fig. 3.3).

Without SVC, the voltage at the midpoint is given by,

where µ = 1 is the electrical length of the line, l is the length of the line and is the phase

constant given by

Where l and c are positive sequence inductance and capacitance of the line per unit length, f is

the operating frequency.

Fig 3.3 Analysis of SVC

It can be shown that the voltage variation in the line (due to variation in ±) is maximum at the

midpoint. SVC helps to limit the variation by suitable control. The steady state control

characteristics of SVC is shown in Fig. 3.4 where ADB is the control range. OA represents the

characteristic where the SVC hits the capacitor limit, BC represents the SVC at its inductor limit.

Note that SVC current is considered positive when SVC susceptance is inductive. Thus

The slope of OA is BC (susceptance of the capacitor) and the slope of OBC is BL

(susceptance of the reactor). A positive slope (in the range of 1-5%) is given in the control range

to (a) enable parallel operation of more than one SVC connected at the same or neighboring

buses and (b) prevent SVC hitting the limits frequently.

Fig 3.4 characteristic of SVC

Control characteristic of SVC The steady state value of the SVC bus voltage is determined from

the intersection of the system characteristic and the control characteristic (see Fig. 3.5). The

system characteristic is a straight line with negative slope and is defined by

where VTh and XTh are the Thevenin voltage and reactance viewed from the SVC bus. For the

system shown in Fig. 3.1, we have

Where Zn is the surge impedance defined by

3.2.2 Expression for Voltage and Power

(a) Control Range: The SVC control range is described by

Fig 3.5 control characteristic of SVC

Determination of operating point of SVC where Xs is the slope of the control characteristic. Vref

is the SVC voltage (corresponding to point D) when ISV C = 0.

The expression for power °ow in the line is given by

With Vref = V , it can be shown that P is given by,

3.2.3 Configuration of SVC:

There are two types of SVC:

1. Fixed Capacitor-Thyristor Controlled Reactor (FC-TCR)

2. Thyristor Switched Capacitor - Thyristor Controlled Reactor (TSC-TCR).

The second type is more flexible than the first one and requires smaller rating of the reactor and

consequently generates less harmonics. The schematic diagram of a TSC-TCR type SVC is

shown in Fig. This shows that the TCR and TSC are connected on the secondary side of a stepdown transformer. Tuned and high pass filters are also connected in parallel which provide

capacitive reactive power at fundamental frequency.

The voltage signal is taken from the high voltage SVC bus using a potential transformer. The

TSC is switched in using two thyristor switches (connected back to back) at the instant in a cycle

when the voltage across valve is minimum and positive. This results in minimum switching

transients. In steady state, TSC does not generate any harmonics. To switch o® a TSC, the gate

pulses are blocked and the thyristors turns off when the current through them fall below the

holding currents. It is to be noted that several pairs of thyristors are connected in series as the

voltage rating of a thyristor is not adequate for the voltage level required. However the voltage

ratings of valves for a SVC are much less than the voltage ratings of a HVDC valve as a step

down transformer is used in the case of SVC. To limit di/dt in a TSC it is necessary to provide a

small reactor in series with the capacitor.

Fig 3.6 A Typical SVC (TSC-TCR) Configuration Thyristor Controlled Reactor

A Typical SVC (TSC-TCR) Configuration Thyristor Controlled Reactor. The current in a TCR

can be continuously varied from zero (corresponding to zero conduction angle) to maximum

(corresponding to conduction angle of 180±) by phase control in which the ¯ring angle ® (with

respect to the zero crossing of the voltage) is varied from 180± to 90±. The instantaneous current

iTCR over half a cycle is given by

Where V is the rms voltage applied, XL is the fundamental frequency reactance of the reactor.

The current waveform in a single phase TCR is shown in Fig. 3.7. The current is non-sinusoidal

and contains odd harmonics which are functions of the conduction angle. The fundamental

component of the TCR current, I1 is given by

Fig 3.7 A TCR circuit

Fig 3.8 waveforms of v and i

Fig 3.9 waveforms of vL and vT

The conduction angle is related to ® by

The TCR current contains odd harmonics. The rms value of the nth harmonic is given by

Another way of reducing the harmonics generated by TCR is to segment the TCR into two or

more parallel connected branches and operate all except one of the branches as Thyristor

Switched Reactors (TSR) which do not contribute any harmonics. The controllability is provided

by varying the (phase control) of one of the TCR branches.

The advantages of TSC-TCR type SVC over FC-TCR type are

(i).The reduction in the reactor size and consequently the harmonics generated

(ii).Greater flexibility in control and

(iii). Better performance under system fault conditions.

The power losses in the quiescent operating condition (with SVC output current close to zero)

also tend to be less with TSC-TCR type SVC. For a FC-TCR type SVC, the rating of TCR covers

the entire control range (AB) in the control characteristics of SVC shown in Fig.3.4. On the other

hand, the rating of the TCR required for a TCS-TCR type SVC is DB.

Although FC-TCR type SVC can generate higher harmonic currents, existing (¯xed)

capacitor bank can be designed as a later. This is not feasible in the case of TSC-TCR type

SVC. The speeds of response for both types of SVC are similar. Fast switching of capacitor

can be used to reduce overvoltages and for better control response under faulted conditions.

3.3 Thyristor Switched Capacitor (TSC):

When a capacitor is switched into a sinusoidal voltage source, a large current surge flows

through the capacitor if the initial voltage across the capacitor is different than the supply voltage

at the instant of switching. The current through the capacitor will be finite (corresponding to the

steady state value) if the initial capacitor voltage is equal to the supply voltage at the instant of

switching. However the rate of change of current di/dt will be very high, beyond the rating of the

thyristor devices (acting as switches). To limit the di/dt , it is necessary to insert a reactor in

series with the capacitor,

3.4 SVC Controller

The block diagram of basic SVC Controller incorporating voltage regulator is shown in Fig.3.11.

This shows that both voltage (VSV C) and current (ISV C) signals are obtained from potential

and current transformers and then rectified. The AC filter is basically a notch filter to eliminate

the signal component of frequency corresponding to the parallel resonance in the system viewed

from the SVC bus. The line capacitance (in parallel with SVC capacitance) can result in parallel

resonance with the line inductance. The SVC voltage regulator has a tendency to destabilize this

resonant mode of oscillation and the notch later is aimed at overcoming this problem. As a matter

of fact, any parallel resonance mode (of frequency below second harmonic) can have adverse

interaction with SVC voltage regulator.

If series capacitors are used along with SVC, then they can cause parallel resonance with a

neighboring shunt reactor. If the second (parallel resonance) mode has a lower frequency (say

below 20 Hz), a high pass filter in addition to the notch filter has been suggested

Fig 3.10 SVC controller

The rectified signal is filtered. The DC side filters include both a low pass filter (to remove the

ripple content) and notch filters tuned to the fundamental and second harmonic components.

The notch filters are provided to avoid the adverse interactions of SVC caused by second

harmonic positive sequence and fundamental frequency negative sequence voltages on the SVC

bus. For example, second harmonic positive sequence voltages at the SVC bus cause a

fundamental frequency component in the recited signal that results in the modulation of SVC

susceptance at the same frequency. This in turn (due to amplitude modulation) results in two

components at side band frequencies (0,2f) in the SVC current.

The dc component can result in unsymmetrical saturation of the SVC transformer and

consequent increase in the magnetization current containing even harmonics. It has been

observed that this adverse harmonic interaction between the SVC and the network can result in

large distortion of the SVC bus voltage and impaired operation of SVC (termed as second

harmonic instability). The auxiliary signals mentioned in Fig.3.10 are outputs from the

Susceptance (or reactive power) Regulator (SR) and Supplementary Modulation Controller

(SMC). The Susceptance Regulator is aimed at regulating the output of SVC in steady state

such that the full dynamic range is available during transient disturbances.

The output of Susceptance Regulator modifies the voltage reference Vref in steady state.

However its operation is deliberately made slow such that it does not affect the voltage

regulator function during transients. In contrast to the Susceptance Regulator, the

Supplementary Modulation Controller (SMC) is designed to improve the performance of SVC

during transient conditions and not affect the steady state. SMC has control input using

appropriate signal obtained from local measurements and provide a limited output at either the

summing junction before the voltage regulator or after it. Thus, it modulates directly either the

SVC bus voltage or susceptance in order to damp oscillations and improve stability.

3.5 STATCOM

A schematic representation of the one-phase STATCOM is shown in Figure 3.11. It is

composed by a voltage source converter (VSC), and its associated shunt connected transformer

[6]. The transformer is used as a link between the VSC and the system.

Fig 3.11 STAT COM’s schematic representation

To explain the basic STATCOM’s operation principles, it is considered that the coupling

transformer is lossless; this way, its equivalent one-phase circuit is depicted in Figure 2, where

EvR represents the voltage in the STATCOM’s terminals and Ek is the voltage in the power

system bus.

Fig. 3.12 equivalent one-phase circuit of the STATCOM

The basics of the STATCOM’s operation is that the amplitude and phase angle of the voltage

drop ΔEx, Figure 3.12, can be controlled, defining the amount and direction of active and

reactive power flows through the reactance [6]. If we take θk = 0 as the reference to simplify the

formulation, the following equations (1)-(3), are the voltage and power equations applied to the

circuit.

Under normal operation conditions, a small amount of active power must flows into the

VSC to compensate for the power losses that exist in its interior, and in reference to Figure 2,

δvR is kept slightly different that θk.. In Figure 3.13 are drawn the space vector representation of

the STATCOM.

Figure 3.13 Lagging currents

Figure 3.14 leading currents.

Figure 3.13. represents a operation condition where VvR > Vk, with a lagging power factor, in

such circumstances, the STATCOM is absorbing active power from the system and giving

reactive power to the same one. On the other hand, Figure 3.14. represents a operation condition

where (VvR < Vk), with leading power factor; now, the STATCOM absorbs active and reactive

power from the system.

In summary, in reference to the equations (1)-(3) and observing Figure 3, if Vk is assumed

constant, we take the conclusion that through the variation of VvR, it can be achieved that the

STATCOM absorbs or delivers reactive power to the system with compensation purposes.

Therefore, a more flexible model of the STATCOM is represented as a variable voltage source

EvR, for which the magnitude and phase angle can be adjusted with the object of satisfying a

specific voltage magnitude at the point of connection. The voltage magnitude VvR is conditioned

by some maximum and minimum limits, which are a function of the STATCOM’s capacitor

rating. In this paper, the simulations include the limits on STATCOM’s voltage magnitude within

(0.9–1.1) p.u. However, the phase angle δvR can vary between 0 and 2π radian

3.5.1 THREE PHASE STATCOM’S EQUIVALENT CIRCUIT AND

STEADY STATE EQUATION

With the help of the previous one-phase STATCOM formulation, it is easy to deduce the

three-phase model. The shunt voltage source of the three-phase STATCOM may be represented

by:

where ρ indicates phase quantities, a, b and c.

The equivalent circuit of the three-phase STATCOM is shown in Figure 3.15 in a wye

configuration. This model is used to derive the steady state equations included into the threephase power flow formulation.

Fig. 3.15. Three-phase STATCOM´s equivalent circuit.

Based in the equivalent circuit of Figure 3.15, the following equation can be written

The equations that represent active and reactive power injection at the terminal system can be

written as

In the same way, the expressions at the STATCOM´s terminal become

To integrate the variables of the STATCOM into the three-phase power flow formulation, two

variables are unknown by phase, Vρ vR y δρ vR, therefore, six additional equations are required.

For the first equation, we will take account that the STATCOM can consume active power from

the system or can be loss-less too, that is, it doesn't consume neither it generates active power. So

the equation that models the active power in the STATCOM is given by the equation (12).

The second equation can be the k-th voltage magnitude. As the voltage magnitude in this node is

specified, then Vρ vR substitutes Vρ k as state variable. Therefore, based on the equivalent

circuit of Figure 4 and the equations (5) - (13), the following linearized equation can be obtained

Thus, the three-phase STATCOM model is integrated into the steady state formulation. In the

simulations, the STATCOM´s node where is connected, is represented as a PV type node. This

node can change to PQ type when, during the process, one of the limits in the device’s voltage

magnitude is violated.

3.6Shunt compensation is of two types:

3.6.1 Shunt capacitive compensation:

This method is used to improve the power factor. Whenever an inductive load is connected to the

transmission line, power factor lags because of lagging load current. To compensate, a shunt

capacitor is connected which draws current leading the source voltage. The net result is

improvement in power factor.

3.6.2 Shunt inductive compensation:

This method is used either when charging the transmission line, or, when there is very low load

at the receiving end. Due to very low, or no load, very low current flows through the transmission

line. Shunt capacitance in the transmission line causes voltage amplification (Ferranti Effect).

The receiving end voltage may become double the sending end voltage (generally in case of very

long transmission lines). To compensate, In the case of a no-loss line, voltage magnitude at

receiving end is the same as voltage magnitude at sending end: VS = VR=V. Transmission

results in a phase lag δ that depends on line reactance X. shunt inductors are connected across the

transmission lines.

Fig 3.16 series compensation

Fig 3.17shunt compensation

In power systems, appropriate placement of these devices is becoming important. Improperly

placed FACTS controllers fail to give the optimum performance and can even be

counterproductive. Therefore, proper placement of these devices must be examined. This paper

investigates the optimal location of shunt FACTS device in a series compensated transmission

line to get the maximum possible benefit of maximum power transfer and system stability. The

rating of a shunt FACT device is selected in such a way so as to control the voltage equal to

sending end voltage at the bus of the shunt FACT device. It is observed that the optimal location

of a shunt FACT device deviates from the center of the line towards the generator side with the

increase in the degree of series Compensation.

A series capacitor is placed at the center to get the maximum power transfer capability and

compensation efficiency for the selected rating of the shunt FACTS device. The shunt FACTS

device is operated at that rating that is able to control the bus voltage of shunt FACTS device

equal to sending end voltage so as to get the maximum possible benefit of maximum power

transfer and stability under steady state conditions.

3.7 TRANSMISSION LINE MODEL:

In this study, it is considered that the transmission line parameters are uniformly

distributed and the line can be modeled by a 2-port, 4-terminal networks as shown in Figure 3.16.

This figure represents the actual line model. The relationship between sending end (SE) and

receiving

end

(RE)

quantities

of

the

line

Fig 3.18 2-port,4-terminal model of a transmission line

can

be

written

as:

It is clear from Eq. (6) that the RE power reaches the maximum value when the angle δ becomes

β. However, the SE power PS of Eq. (4) becomes maximum at δ = (Π− β). In this study, a 345

kV single circuit transmission line (450 km in length), is considered. It is assumed that each

phase of line has a bundle of 2 conductors of size one million cmils each and conductors are fully

transposed. The series impedance and shunt admittance of the line are found to be Z = (0.02986 +

j0.2849) Ω/km and y = j3.989 × 106 S/km, respectively, at 50 Hz. The parameters are obtained

using the PSCAD/EMTDC software package. The results of the line are presented in p.u. on a

100 MVA, 345 kV base [3].

3.8 SERIES COMPENSATED TRANSMISSION LINE WITH SHUNT

FACTS DEVICES

Consider that the line is transferring power from a large generating station to an infinite

bus and equipped with series capacitor at center and a shunt FACT device at point ‘m’ as shown

in Figure 2. Parameter k is used to show the fraction of the line length at which the FACTS

device is placed. The shunt FACTS device may be a SVC or STATCOM and is usually

connected to the line through a step-down transformer as shown in Figures 3.19 and 3.20. The

transmission line is divided into 2 sections (1 & 2), and section 2 is further divided in subsections

of length [(0.5-k) & half-line length]. Each section is represented by a separate 2-port, 4-terminal

network (similar to Figure 2) with its own ABCD constants considering the actual line model

Fig 3.19 series compensated transmission line with a shunt Fact device

Fig 3.20 schematic diagram of a SVC

Fig 3.21Examples of FACTS for shunt compensation

It is supposed that the rating of the shunt FACTS device is large enough to supply the reactive

power required to maintain a constant voltage magnitude at bus m and the device does not absorb

or supply any active power.

CHAPTER-4

SIMULINK FILES AND RESULTS

4.1 CIRCUIT DIAGRAM:

Discrete,

Ts = 5e-005 s.

Machine initialized for

P=1500 MW

Vt=13.8kV

Open this block

to visualize

recorded signals

A

Data Acquisition

C

a2

b2

c2

a3

b3

c3

B

A

B

C

Three -Phase Series Compensated Network

300 MVA

735/230 kV

Pm

250 MW

m

aA

A

a

aA

A

a

aA

A

b

bB

B

b

bB

B

b

bB

B

C

c

cC

C

c

cC

C

c

cC

C

Series

Comp. 1

B2

Series

Comp. 2

B3

30,000 MVA

735 kV

6*350MVA

13.8 kV

6*350 MVA B1

13.8/735 kV

100 MW

Line 1

(300 km)

330 Mvar

shunt devices

Line 2

(300 km)

A

B

C

C

B

a

B

A

A

C

E

E

A

SSM B

A

B

C

-C-

Pm

A

B

C

-C-

330 Mvar

Fig 4.1 Simulink diagram

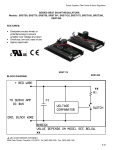

A three-phase, 60 Hz, 735 kV power system transmitting power from a power plant consisting of

six 350 MVA generators to an equivalent network through a 600 km transmission line.

The transmission line is split in two 300 km lines connected between buses B1,B2, and B3. In

order to increase the transmission capacity, each line is series compensated by capacitors

representing 40% of the line reactance. Both lines are also shunt compensated by a 330 Mvar

shunt reactance. The shunt and series compensation equipments are located at the B2 substation

where a 300 MVA 735/230 kV transformer with a 25 kV tertiary winding feeds a 230 kV, 250

MW load. The series compensation subsystems are identical for the two lines. For each line, each

phase of the series compensation module contains the series capacitor , a metal oxide varistor

(MOV) protecting the capacitor, and a parallel gap protecting the MOV.

When the energy dissipated in the MOV exceeds a threshold level of 30 MJ, the gap simulated by

a circuit breaker is fired. CB1 and CB2 are the two line circuit breakers.

STATCOM DESIGNING Circuit

Fig 4.2 STATCOM DESIGNING CIRCUIT

SVC DESIGNING CIRCUIT

Fig 4.3 SVC DESIGNING CIRCUIT

4.2 PROGRAM:

j=0;

for c=0.45:-0.15:0

j=j+1;

n(j)=c

i=0;

for k=0.1:0.05:0.5

i=i+1;

m(i)=k

sim('seriescomp');

x(i,j)=max(re.signals.values)

y(i,j)=max(se.signals.values)

z(i,j)=max(angle.signals.values)

zz(i,j)=max(se2.signals.values)

end

end

figure(1);

plot(x(1:9,1:4), 'DisplayName', 'x(1:9,1:4)', 'YDataSource', 'x(1:9,1:4)'); figure(gcf)

figure(2);

plot(y(1:9,1:4), 'DisplayName', 'y(1:9,1:4)', 'YDataSource', 'y(1:9,1:4)'); figure(gcf)

figure(3);

plot(z(1:9,1:4), 'DisplayName', 'z(1:9,1:4)', 'YDataSource', 'z(1:9,1:4)'); figure(gcf)

figure(4);

plot(zz(1:9,1:4), 'DisplayName', 'zz(1:9,1:4)', 'YDataSource', 'zz(1:9,1:4)'); figure(gcf)

4.3 OUT PUT WAVEFORMS:

For a simplified model, when there is no FACTS device connected to the line, maximum

power transfer through the line is given by [3]:

Many researchers established that the optimal location of shunt FACTS device for a simplified

model is at K= 0.5 when there is no series compensation in the line. For such cases maximum

power transmission capability (Pm) and maximum transmission angle (δ m) become double.

However, for an actual line model power flow is given by Eqs. (4) and (6) instead of Eq. (9) and

the above results may not be considered accurate. One of the objectives of this paper is to find

the maximum power and corresponding location of shunt FACTS device for different series

compensation levels (%S) located at the center of the line.

A sophisticated computer program was developed to determine the various characteristics of the

system using an actual model of the line sections. The constant of the same RE power of section

(1) and SE power of section (2) (P r1 = P s2) is incorporated into the problem. In all cases, V s =

Vr = Vm = 1.0 p.u. unless specified. The maximum power Pm and corresponding angle δm are

prior determined for various values of location (K). Figures 4.4-4.7 show the variation in

maximum RE power(pmr), maximum sending end power, and transmission angle (δm) at the

maximum sending end power, respectively, against (K) for different series compensation levels

(%S)

It can be noticed from Figures 4.5and 4.6 that pms> p mr for any series compensation

level (%S) because of the loss in the line. From Figure 5 it can be noted that when %S = 0 the

value of

P ms increases as the value of (K) is increased from zero and reaches the maximum

value of 18.5 p.u. at K = 0.45 (but not at K = 0.5). Slope of the p m s curve suddenly changes

at K= 0.45 and the value of Pms decreases when K > 0.45.

A similar pattern for Pm rbe observed from Figure 6 when (%S = 0). When series compensation

in the line is taken into account, we observe that the optimal location of the shunt FACTS device

will change and shifts towards the generator side. As seen from Figure 5, when %S = 15 then

Pms increases from 12.5 p.u. (at K = 0) to its maximum value 22 p.u. (at K = 0.375).When K is

further increased then Pms decreases. It means that, for maximum power transfer capability, the

optimal location of the shunt device will change when series compensation level changes. When

%S = 30, the optimal location further shifts to the generator side and Pms increases from 15.2 p.u.

(at K = 0) to its maximum value 26.8 p.u. (at K = 0.3).

Fig 4.4 Variation in maximum SE power for diff. value of %S.

Fig 4.5 Variation in maximum RE power for diff. value of %S.

Similarly, when %S = 45, we obtain the optimal location of the shunt device at

K = 0.225. A similar pattern for P

m

rcan

be observed from Figure 6 for different series

compensation levels. In Figure 7, it can be observed that in the absence of series compensation

(%S = 0) the angle at the maximum SE power increases from 95.8o at K = 0 to its maximum

value 171.1o at K = 0.45. When %S = 15 then ð mwhen K is increased and reaches its maximum

value 180.5o at K = 0.375. When %S = 30 then δ m increases when K is increased and reaches its

maximum value 185o at K = 0.3 and for %S= 45 it is 188o for K = 0.225. As the degree of series

compensation level (%S) increases, the stability of the system increases and the optimal location

of the shunt FACTS device changes.

Fig 4.6 Variation in transmission angle at the max. SE power for diff. % S.

Figure 8 shows the variation of the maximum RE power of section 1 (PR1m) and maximum SE

power of section 2 (PS2m) against the value of K for different series compensation levels (%S).

It can be seen in Figure 8 that for an uncompensated line then maximum power curves cross at K

= 0.45 and the crossing point is the transition point.

Thus, to get the highest benefit in terms of maximum power transfer capability and system

stability, the shunt FACTS device must be placed at K = 0.45, which is slightly off- center. When

the series compensation level is taken into account then for %S = 15 the maximum power curves

cross at K = 0.375 and maximum power transfer capability increases. It means that when series

compensation level (%S) is increased then the optimal location of the shunt device shifts towards

the generator side. Similarly when %S = 30 then the optimal location is at K = 0.3 and for %S =

45it is at K = 0.25.

Fig 4.7 Variation in the maximum RE power of section-1 and SE power of section-2

for diff. value of %S.

against k

CHAPTER-5

CONCULSION

This paper investigates the effect of series compensation on the optimal location of a shunt

FACTS device to get the highest possible benefit of maximum power transfer and system

stability. Various results were found for an actual line model of a series compensated 345 kV,

450 km line. It has been found that the optimal location of the shunt FACTS device is not fixed

as reported by many researchers in the case of uncompensated lines but it changes with the

change in degree of series compensation. The deviation in the optimal location of the shunt

FACT device from the center point of line depends upon the degree of series compensation and it

increases almost linearly from the center point of the transmission line towards the generator side

as the degree of series compensation (%S) is increased. Both the power transfer capability and

stability of the system can be improved much more if the shunt FACTS device is placed at the

new optimal location instead of at the mid-point of the line.

The effect of SVC and STATCOM controllers in enhancing power system stability has been

examined. Though both the devices can provide extra damping to the system, it has been

demonstrated that STATCOM is very effective in enhancing system performance in situations

where system voltages are very much depressed. Also, because of its fast response time,

STATCOM control is superior to that of SVC

CHAPTER-6

REFERENCES

[1] Nemat-Talebi et al, SoutheastCon, 2004. Proceedings. IEEE “An efficient Power injection

modeling and sequential power flow Algorithm for FACTS Devices”, page(s): 97104.[DOI10.1109/SECON.2004.1287904

[2] Gyugyi, L. 1995, ”Unified power flow controller concept for flexible AC Transmission

system”, IEEE Proceedings- Volume 10, Issue 2, Apr 1995 Page(s):1085 - 1097. [DOI

10.1109/61.400878]

[3]Proceedings on Generation Transmission & Distribution, Vol. 147, No. 4, pp. 218-22, 2000.

[DO I 10.1049/ip-gtd: 20000412]

[4] Narain G. Hingorani, Laszlo Gyugyi, 1999, Understanding FACTS: Concepts and

Technology of Flexible AC Transmission Systems, Wiley-IEEE Press, December 1999. ISBN

978-0-7803-3455

[5] N.G. Hingorani, L. Gyugyi, Understanding FACTS, Concept and Technology of Flexible AC

Transmission Systems, New York, Wiley, 2000.

[6] Xiao-Ping Zhang, Christian Rehtanz, Bikash Pal, 2006, Flexible AC Transmission Systems:

Modelling and Control, Springer, March 2006.ISBN 978-3-540-30606-1

http://www.springer.com/3-540-30606 4

7] A. Edris, R. Adapa, M.H. Baker, L. Bohmann, K. Clark, K. Habashi, L. Gyugyi, J. Lemay, A.

Mehraban, A.K. Myers, J. Reeve, F. Sener, D.R. Torgerson, R.R. Wood, Proposed Terms and

Definitions for Flexible AC Transmission System(FACTS), IEEE Transactions on Power

Delivery, Vol. 12, No. 4, October

[8] Giuseppe, Fusco / Mario, Russo, 2006, AdaptiveVoltage Control in Power Systems:

Modelling, Design and Applications (Advances in Industrial Control)? Springer | ISBN

184628564X | November 13, 2006 |

[9] P. Kundur, 1994, Power system stability and control, EPRI Power System Engineering Series,

New York, McGraw-Hill Inc., 1994.

[10] Tate J.E and Thomas J.Overbye, 2005, “A Comparison of the Optimal Multiplier in Polar

and Rectangular Coordinates” IEEE Transactions on Power systems, Vol.20,No 4,

[DOI 10.1109/TPWRS.2005.857388]

[11] Tate J.E and Thomas J.Overbye, 2005, “A Comparison of the Optimal Multiplier in Polar

and Rectangular Coordinates” IEEE Transactions on Power systems, Vol.20,No 4.

[12]M. Saravanan, S. M. R. Slochanal, P. Venkatesh, J. P. S. Abraham, 2007, “Application of

particles warm optimization technique for optimal location of FACTS devices considering cost of

installation and system load ability”, Electric Power Syst. Research, vol. 77, pp. 276-283.

Proceedings of the World Congress on Engineering 2009 Vol.1WCE 2009, July 1 - 3, 2009,

London, U.K. ISBN: 978-988-17012-5-1 WCE 2009