* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Metal foams as compact high performance heat

Underfloor heating wikipedia , lookup

Vapor-compression refrigeration wikipedia , lookup

Insulated glazing wikipedia , lookup

Passive solar building design wikipedia , lookup

Thermal comfort wikipedia , lookup

Thermoregulation wikipedia , lookup

Space Shuttle thermal protection system wikipedia , lookup

Radiator (engine cooling) wikipedia , lookup

Dynamic insulation wikipedia , lookup

Cutting fluid wikipedia , lookup

Thermal conductivity wikipedia , lookup

Solar water heating wikipedia , lookup

Solar air conditioning wikipedia , lookup

Heat equation wikipedia , lookup

Intercooler wikipedia , lookup

Cogeneration wikipedia , lookup

Building insulation materials wikipedia , lookup

Heat exchanger wikipedia , lookup

Thermal conduction wikipedia , lookup

R-value (insulation) wikipedia , lookup

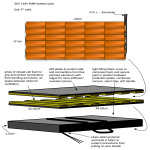

ARTICLE IN PRESS Mechanics of Materials 35 (2003) 1161–1176 www.elsevier.com/locate/mechmat Metal foams as compact high performance heat exchangers K. Boomsma a, D. Poulikakos a a,* , F. Zwick b Laboratory of Thermodynamics in Emerging Technologies, Institute of Energy Technology, Swiss Federal Institute of Technology, ETH Center, ML J 36, 8092 Zurich, Switzerland b ABB Corporate Research Ltd., Segelhof, 5405 Baden-D€attwil, Switzerland Received 1 June 2002; received in revised form 30 January 2003 Abstract Open-cell metal foams with an average cell diameter of 2.3 mm were manufactured from 6101-T6 aluminum alloy and were compressed and fashioned into compact heat exchangers measuring 40.0 mm · 40.0 mm · 2.0 mm high, possessing a surface area to volume ratio on the order of 10,000 m2 /m3 . They were placed into a forced convection arrangement using water as the coolant. Heat fluxes measured from the heater-foam interface ranged up to 688 kW m2 , which corresponded to Nusselt numbers up to 134 when calculated based on the heater-foam interface area of 1600 mm2 and a Darcian coolant flow velocity of approximately 1.4 m/s. These experiments performed with water were scaled to estimate the heat exchangersÕ performance when used with a 50% water–ethylene glycol solution, and were then compared to the performance of commercially available heat exchangers which were designed for the same heat transfer application. The heat exchangers were compared on the basis of required pumping power versus thermal resistance. The compressed open-cell aluminum foam heat exchangers generated thermal resistances that were two to three times lower than the best commercially available heat exchanger tested, while requiring the same pumping power. 2003 Elsevier Ltd. All rights reserved. Keywords: Metal foam; Porous media; Heat transfer; Open-cell aluminum foam 1. Introduction Flow through porous media has been studied in detail ever since DarcyÕs publication in 1856 (Darcy, 1856). His work described the fluid flow pressure drop across a porous medium as a linear function of the flow velocity and material permeability. Since then, a series of improvements have * Corresponding author. Tel.: +41-1-632-2738; fax: +41-1632-1176. E-mail address: [email protected] (D. Poulikakos). been made to describe the pressure drop behavior in better detail, one of which was accounting for temperature variations in the fluid by Hazen (1893). These temperature variations were later linked to the viscosity of the fluid by Kr€ uger (1918). The addition of a quadratic term in the linear Darcy Law was first proposed by Dupuit (1863), although many mistakenly credit Forchheimer with the addition of the quadratic term as a result of his extensive review of other porous media studies (Forchheimer, 1901). A thorough review of the history of the study of fluid dynamics through porous media can be found in a review by 0167-6636/$ - see front matter 2003 Elsevier Ltd. All rights reserved. doi:10.1016/j.mechmat.2003.02.001 ARTICLE IN PRESS 1162 K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 Nomenclature A C CTE D FS K L M Nu P Q R Re T V W_ c f h j k area [m2 ] form coefficient [m1 ] coefficient of thermal expansion [m m1 K1 ] diameter [m] Full scale permeability [m2 ] length [m] compression factor [–] Nusselt number (defined in Eq. (12)) [–] pressure [bar] volumetric flow rate [m3 s1 ] thermal resistance (defined in Eq. (12)) [K W1 ] Reynolds number (defined in Eq. (4)) [– ] temperature [C, K] velocity [m s1 ] pumping power [W] specific heat [kJ kg1 K1 ] friction factor [–] convection coefficient [W m2 K1 ] Colburn factor (defined in Eq. (10)) [–] thermal conductivity [W m1 K1 ] Lage (1998). An end result of the nearly 150 yearold work in porous media is the widely accepted equation (Eq. (1)) which governs the pressure drop of a fluid passing through a porous medium. DP l ¼ V þ qCV 2 L K ð1Þ The term DP is the pressure drop across the medium, L is the length of the medium in the flow direction, l is the dynamic viscosity of the fluid, K is the permeability of the medium, V is the clearchannel (Darcian) velocity of the fluid, q is the density of the fluid, and C is the form coefficient of the medium. The extension of the fluid dynamic work in porous media in a channel to include simultaneous convective heat transfer can be traced back as far as Koh and Colony (1974); Koh and Stevens m_ q w mass flow rate [kg s1 ] heat rate [W] absolute error [–] Greek symbols D difference [–] a thermal diffusivity [m2 s1 ] e porosity fraction (range 100 P e > 0) [%] l dynamic viscosity [kg m1 s1 ] m kinematic viscosity [m2 s1 ] q density [kg m3 ] Subscripts c coolant con convection cs cross-sectional eff effective f fluid hyd hydraulic inlet inlet outlet outlet p perimeter pl plate s solid th thermal (1975). Their analysis considered a simple slug flow velocity profile through the porous medium, but the cooling effects generated by the presence of a porous medium were shown. In the course of developing better analytical models for channel convection, Kaviany (1985) presented an analytical solution of the transport equations based on the quadratic-extended Darcy flow model (Eq. (1)). Advancements continued in numerical work on forced convection through packed beds of spheres which included the notable numerical work performed by Poulikakos and Renken (1987) and the corresponding experimental investigation (Renken and Poulikakos, 1988). Many other models have been proposed to account for other variables, such as wall effects (Kaviany, 1985; Mehta and Hawley, 1969), variable porosity (Amiri and Vafai, 1994; Nield et al., 1999), and ARTICLE IN PRESS K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 1163 even non-Newtonian fluids (Chen and Hadim, 1998, 1999). The great majority of these studies that are covered by Kaviany (1995) consider spherical media, which possess porosities in the range e 0:3–0:6. This configuration is known as a bed of packed spheres, which models fluid flow through sediment and other granular systems. The question arises how far these concepts based on spherical media can be taken to include other types of porous media. One type of a nonspherical porous medium is open-cell metal foam. The structure of open-cell metal foams (Fig. 1) opens itself to a wide variety of possible applications which include, but are not limited to, light weight high strength structural applications, mechanical energy absorbers, filters, pneumatic silencers, containment matrices and burn rate enhancers for solid propellants, flow straighteners, catalytic reactors, and more recently, heat exchangers. The open-cell metal foam structure has the desirable qualities of a well designed heat exchanger, i.e. a high specific solid–fluid interface surface area, good thermally conducting solid phase, and a tortuous coolant flow path to promote mixing. Depending on the particular opencell metal foam configuration, its specific surface area varies between approximately 500 to over 10,000 m2 /m3 in compressed form (ERG, 1999). The metal matrix can be manufactured from a high thermally conducting solid such as aluminum (ks 200 W m1 K1 ) or copper (ks 400 W m1 K1 ), which, merely by its presence in a static fluid, dramatically increases the overall effective thermal conductivity of the fluid-system (Calmidi and Mahajan, 1999). The overall effective thermal conductivity of the solid–fluid system (keff ) can be most generally described by the porosity (e) and the conductivities of the fluid and solid phases by kf and ks , respectively (Kaviany, 1995). improved analytical heat conduction model based on the idealized 3-D unit cell of an open-cell metal foam. There currently exist analytical (du Plessis et al., 1994; Diedericks and du Plessis, 1997; Smit and du Plessis, 1999; Lu et al., 1998) and numerical models (Calmidi and Mahajan, 2000; Lage et al., 1996) for the fluid flow and heat transfer in packed beds of spheres and extensive databanks of fluid flow and heat transfer experiments used as verification of these models (Antohe et al., 1997; Lage et al., 1997; Lage and Antohe, 2000; Boomsma and Poulikakos, 2002). However, in the case of open-cell metal foams, the numerical models have had limited success, and the experimentation to verify these models is restricted, particularly to the coolant, which is typically air. In cooling electronics which generate a large amount of excess heat, a liquid coolant is generally preferred over air because of the greater thermal conductivity and specific heat capacitance. In view of these requirements, experiments using a forced liquid coolant are needed not only to investigate the feasibility of using open-cell metal foams as heat exchangers, but also to provide a basis against which numerical models can be compared. The goal of this investigation is to provide an experimental study of the performance of open-cell aluminum foam heat exchangers in a forced convection flow arrangement using a liquid coolant, which is deionized, degassed water. Comparisons with existing heat exchanger systems for the application of cooling of electronics are also provided. keff ¼ ekf þ ð1 eÞks The goal of the experiment was to measure the hydraulic and thermal performance of the opencell aluminum foams when used as heat exchangers in a forced convection flow arrangement. The concept was to direct the coolant flow through a rectangular channel in which the aluminum foam heat exchanger is placed, occupying the entire cross-section of the channel. A heater was attached to the aluminum foam via the heat spreader plate, ð2Þ This increase in overall effective thermal conductivity of the solid–fluid system to a level above that predicted by Eq. (2) was shown in the 2-D conduction model by Calmidi and Mahajan (1999). Noting the influence of the structure on the thermal conductivity of the metal foam matrix, Boomsma and Poulikakos (2001) developed an 2. Experiment 2.1. Apparatus ARTICLE IN PRESS 1164 K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 Fig. 1. (a) Open-cell aluminum foam (T-6106 alloy) in its as-manufactured state with a porosity of e ¼ 92% and approximately 6 mm diameter pores (ks 200 W m1 K1 ). (b) Close-up view on an individual cell of the aluminum foam depicted in (a). (c) Open-cell metal foam similar to that shown in (a), but after compression by a factor of four. (d) Close-up view of the compressed foam depicted in (c). Note the altered form of the individual cells that had originally resembled the cell in (b). ARTICLE IN PRESS K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 through which the heat was conducted and eventually convected into the coolant stream. The characterization of the open-cell metal foam heat exchangers included measuring the temperature of the heater block, the temperature of the heat spreader plate, the coolant temperature at several locations in the coolant flow, the power delivered to the heating device, and the pressure drop across the heat exchangers for various coolant flow rates. A general overview of the experimental apparatus is shown in Fig. 2. The channel assembly is shown in detail in two separate views in Fig. 3. Eight pressure taps measuring 0.2 mm in diameter were bored into the housing at various locations to measure the static pressure, as seen in Fig. 3(b). The outermost ports were used for the pressure drop calculations to avoid the static pressure variations generated by the acceleration and deceleration of the fluid as it enters and leaves the metal foam. The other six ports were used as a Power Supply 1165 symmetry check of the flow. During the experiments, the pressure variation between the left and right ports did not fluctuate more than 3% and was therefore neglected. The metal foam heat exchanger housing was manufactured from Ryton R4, which has a low thermal conductivity (0.3 W m1 K1 ) and a reasonable CTE (22 · 106 m/m C). The static pressure drop of the coolant across the metal foam heat exchanger was measured by two different differential pressure transducers corresponding to their individual pressure ranges. A Huba differential pressure transducer was used for measuring the pressure in the lower pressure range, from 0 to 0.20 bar, with an accuracy of 0.5% FS (±0.001 bar). For the pressure range from 0.20 to 3.45 bar, an Omega (PX81DO-050DT) differential pressure transducer was employed with an accuracy of 0.25% FS (±0.009 bar). E-type thermocouples (chromel/constantan) of 0.15 mm diameter Oscilloscope Data Acquisition PC Metal Foam Heater Assembly Foam Housing Rotameter Pressure Transducer Pressure Regulating Valve Thermocouples 20.0 Valve Array USB Data Acquisition Device Coolant Chiller/ Recirculator Coolant Flow Direction Fig. 2. Schematic view of the experimental setup used to measure the thermal and hydraulic characteristics of the compressed aluminum foam heat exchangers. ARTICLE IN PRESS 1166 K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 HEATER ASSEMBLY METAL FOAM PRESSURE PORTS FLOW INLET FLOW OUTLET (a) FLOW INLET 4cm 7cm FLOW OUTLET (b) Fig. 3. (a) Cross-sectional view of the foam test housing which shows the location of the aluminum foam heat exchanger, the heater assembly, and the path of the coolant flow. (b) Top view of the foam test housing depicted in (a) with the lid removed to show the placement of the foam component of the assembled compressed foam heat exchanger. measured the temperatures at various locations of the experimental apparatus. The thermocouples were calibrated in a thermal bath to within 0.5 C and were inserted through the 0.2 mm diameter pressure taps that were located in the bottom of the channel to measure the temperature of the coolant flow (Fig. 3(b)). The pressure drop measurements were performed both with and without the thermocouples inserted through the pressure taps to determine if their presence altered the pressure readings. No effects were observed. The data from the thermocouples and the pressure transducers were measured by a USB data acquisition device manufactured by IOTech. This device enabled the real-time measurement, recording, and display of the temperature and pressure drop data on the attached personal computer. The coolant was pumped through the experimental apparatus by a Neslab chiller. It provided a maximum coolant flow rate of approximately 10 l/min, could dissipate a total of 1600 W, and regulated the coolant inlet temperature to within 0.3 C. The coolant flow rate was measured using two different rotameters. The lower flow rate range varied from 0 to 1.0 l/min, which corresponded to a flow velocity of 0–0.21 m/s for a channel crosssection of 40.0 mm · 2.0 mm. For this lower range, a V€ ogtlin rotameter with 1% FS (±0.01 l/min) accuracy was utilized. The higher flow rate range tested varied from 1.00 to 5.00 l/min, corresponding to a flow velocity range of 0.21–1.04 m/s for a channel cross-section of 40.0 mm · 2.0 mm. In the higher flow rate range, a Wisag 2000 rotameter was employed with an accuracy of 1% FS (±0.11 l/min). The heating system consisted of a block machined from oxygen-free copper (ks 400 W m1 K1 ) measuring 40.0 mm · 44.0 mm · 20.0 mm high. Five holes measuring 6.35 mm in diameter were bored through the block to hold five 220 W cartridge heaters in place. The voltage and current delivered to the five cartridge heaters were monitored by an oscilloscope. The maximum power delivered to the heater block was 1100 W. Smaller holes measuring 0.2 mm in diameter were drilled into the top and base of the copper heater block, perpendicular to the coolant flow direction. This allowed the insertion of small diameter thermocouples to measure the temperature difference across the heater block. 2.2. Aluminum foam heat exchangers One of the desirable qualities of the open-cell metal foam in a heat exchanger application is the large specific surface area, which ranges from approximately 500 to over 3000 m2 /m3 . Compressing the foam further increases this already large surface area to volume ratio. To generate an array of open-cell metal foam heat exchangers, 6101-T6 aluminum alloy (ks ¼ 218 W m1 K1 ) was cast into foam form at two different porosities of e ¼ 92% and 95% with an average cell diameter of 2.3 mm. This foam is listed as 40 PPI by the ARTICLE IN PRESS K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 1167 Table 1 Compressed foam physical data (Panel A), uncompressed foam physical data (Panel B) Foam Panel A 5% 8% Compression Name Expected porosity [%] Measured porosity [%] 2 4 6 8 95-02 95-04 95-06 95-08 90.0 80.0 70.0 60.0 88.2 80.5 68.9 60.8 2 3 6 92-02 92-03 92-06 84.0 76.0 52.0 87.4 82.5 66.9 Panel B Foam Pore diameter [mm] Specific surface area [m2 /m3 ] Measured porosity [%] 40 PPI 2.3 2700 92.8 manufacturer (ERG, 1999). The PPI acronym designates pores per linear inch, but due to the ambiguity of this label, the pore diameters of the uncompressed 40 PPI foam were visually measured by hand using a microscope and a scale calibrated to one-tenth of a millimeter and were tabulated in Table 1. The specific surface area of these foams was further increased by compressing them by a factor of M, which signifies the ratio of the pre-compression to post-compression height of the foam block. In the one-dimensional compression process, the lateral sides of the metal foam are not restrained. This is done to prevent any mass accumulation in the foam caused by lateral material movements during the compression process. However, any material which ‘‘flows’’ to the outside of the compression device is lost in the machining of the foam to its final overall dimensions, thus the resulting porosity of the foam may be higher than what would be predicted by Eq. (3). ecompressed ¼ 1 Mð1 euncompressed Þ ð3Þ The porosities of the aluminum foams were calculated by weighing them and comparing the density to that of solid 6101-T6 aluminum alloy. The corresponding expected porosities were also calculated by Eq. (3), using the manufacturerÕs stated initial, uncompressed porosity of euncompressed and the given nominal compression factor, M. Table 1 lists both the measured and expected po- 100 Expected Porosity (95%) Effective Porosity (95%) Expected Porosity (92%) Effective Porosity (92%) 90 80 ε [%] 70 60 50 0 2 4 6 8 10 M Fig. 4. Plot of the porosity of the raw foam material which was used in the aluminum foam heat exchangers. The lines denote the porosity predicted by the manufacturerÕs stated initial porosity (e) and compression factor (M) based on Eq. (3), while the individual points are the measured values for the raw foam material. rosities, and Fig. 4 shows their relationship graphically. The various configurations of aluminum foams are named using two pairs of digits. The first pair is pre-compression porosity; the number 92 designates euncompressed ¼ 92%. The second pair of digits designates the compression factor, M. The foam 92-04, for example, was 92% porous in its uncompressed state and then compressed by a factor of four. In Fig. 4, the porosities of the 95% pre-compression foam samples that ARTICLE IN PRESS 1168 K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 were measured closely follow the relationship as predicted by Eq. (3). However, the porosities of the 92% pre-compression foam remained higher than those predicted by Eq. (3) and the manufacturerÕs given data. By the consistency of the error of the porosity data points from the predicted line for the 92% initial porosity foam, it can be assumed that this discrepancy is due to an inaccurate estimate of the initial porosity given by the foam manufacturer. The open-cell aluminum foams measured 40.0 mm · 40.0 mm · 2.0 mm after the final machining process. To make them functional heat exchangers, each foam piece was brazed in a central position to an adjoining heat spreader plate which enabled a copper heating block to be mounted on the opposing side. Each heat spreader plate consisted of 6092 aluminum alloy with 18% SiC particles to increase the thermal conductivity to approximately 250 W m1 K1 and measured 58.0 mm · 58.0 mm · 1.9 mm thick. 2.3. Experimental procedure Each open-cell aluminum foam heat exchanger was tested three times following the identical procedure. The heat exchanger was mounted into the test housing. The coolant was then pumped through the foam at the maximum attainable flow rate, which varied according to the overall flow resistance of the individual heat exchanger. The inlet temperature of the coolant was held at 22±0.3 C. After the 20 min stabilization period, full power to the heater cartridges was turned on, and the entire experimental apparatus was allowed to reach steady-state. Starting from the maximum flow rate, the temperatures at various locations were measured and recorded in real-time via the USB data acquisition device and PC, which also recorded the pressure drop reading from the pressure transducer. The maximum coolant temperature allowed during operation was 100 C, at which the coolant began to vaporize. The flow rate was read from the rotameter. After the data were taken, the flow rate was reduced, and the apparatus was given 5 min to reach steady-state for the next data point measurement. As noted in the work by Boomsma and Poulikakos (2002) and Antohe et al. (1997), the direction in which the flow rate is adjusted does not have an effect on the calculated permeability and form coefficient needed to describe the flow resistance of a porous medium. 3. Results and discussion 3.1. Pressure drop The amount of work required to pump the coolant through a heat exchanger is a critical heat exchanger design parameter. In the work by Boomsma and Poulikakos (2002), the open-cell metal foams which comprised the in-flow component of the heat exchangers in this study were tested for their hydraulic characteristics. The parameters used to describe the pressure drop characteristics of the foam heat exchangers are the permeability (K) and the form coefficient (C) which are defined in Eq. (1). The metal foam configurations used in this heat transfer study were produced under conditions identical to those used for the foams in the hydraulic characterization study of open-cell metal foams conducted by Boomsma and Poulikakos (2002). However, in assembling the heat exchangers, some of the aluminum brazing material which attaches the foam to the heat spreader plate partially filled the pores at the interface which reduced the effective flow cross-sectional area of the heat exchanger and increased the flow resistance of the metal foam heat exchangers when compared to the results of the similar, unbrazed foams in Boomsma and Poulikakos (2002). The assembled heat exchangers were tested anew for their hydraulic characteristics and the results of the pressure drop tests were plotted graphically in Fig. 5. The left-hand ordinate is given in length normalized units of [bar m1 ] based on the 40.0 mm length of the heat exchangers, and the right-hand ordinate is the actual pressure drop measured in the experiments, and is given in the units of [bar]. As expected, those foams which possess the highest solid fraction (lowest e) as seen in Table 1 generated the largest pressure drop. These were led by the two most compressed foams, ARTICLE IN PRESS K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 3.2 80 95-02 95-04 95-06 95-08 92-02 92-03 92-06 70 60 50 ∆P/L 40 [bar·m-1] 2.8 2.4 2.0 1.6 30 1.2 20 0.8 10 0.4 0 0.0 0.5 1.0 V 1.5 ∆P [bar] 0.0 2.0 [m·s-1] Fig. 5. Pressure-drop curves for the metal foam heat exchangers plotted on a length-normalized (DPL1 ) and actual pressure scale (DP ) against the Darcian flow velocity (V ). 95-06 and 95-08, with foam 92-06 generating nearly the same pressure drop. The foam which produced the lowest pressure drop was foam 9502, which was also the most porous of the samples. The hydraulic characteristics of the brazed foams were calculated by using a least squares curve fitting approach as described in Antohe et al. (1997) and Boomsma and Poulikakos (2002) to solve for the K and C in Eq. (1). These permeability and form coefficient values were compared to the values obtained in Boomsma and Poulikakos (2002), which used the same aluminum foam configurations, but without any brazing material. Table 2 compares the permeability and form coefficients between the assembled heat exchangers and the unbrazed foam blocks, along with the corresponding uncertainty percentages. Almost every assembled heat exchanger showed an increase in the flow resistance compared to its un- 1169 brazed counterpart due to the presence of the brazing material in the pores of the open-cell metal foam at the brazing interface. Foams 95-08 and 92-06 showed a slight decrease in the flow resistance when compared to their unbrazed counterparts. This change in behavior by the two most highly compressed brazed foams can be attributed to warpage and distortion in the foam from the brazing process, thereby allowing flow bypass. With the remaining five aluminum foam heat exchangers, the amount of the increase of the flow resistance was not consistent. The change in the flow restriction depends upon the non-standard individual production process of each heat exchanger. For a more general base of comparison, the hydraulic characteristics of the heat exchangers can be viewed using non-dimensional flow factors. One of which is the Reynolds number (Re) as defined for porous media in Kaviany (1995). For a degree of uniformity in the field of porous media, the characteristic length used in the Re is replaced by the square root of the permeability (K) as shown in Eq. (4), where q is the density of the fluid, V is the Darcian flow velocity, and l is the dynamic viscosity of the fluid. pffiffiffiffi qV K Re ¼ ð4Þ l The other commonly used non-dimensional flow describing factor is the Fanning friction factor (f ) which is given in Eq. (5). This provides information concerning the required pressure drop (DP ) across a heat exchanger and comes into use Table 2 Flow resistance comparison Foam 95-02 95-04 95-06 95-08 92-02 92-03 92-06 a Unbrazeda Brazed heat exchanger K [1010 m2 ] C [m1 ] K [1010 m2 ] rk [%] C [m1 ] rC [%] 44.4 19.7 5.25 2.46 36.7 23.0 3.88 1168 2707 4728 8701 1142 1785 5518 34.4 6.87 3.16 2.52 30.8 8.26 3.95 13.4 7.0 8.7 7.4 10.2 9.1 6.7 1276 2957 5066 4731 1472 2820 3399 2.9 3.2 9.8 5.6 5.0 3.9 5.4 Results reported in Boomsma and Poulikakos (2002). ARTICLE IN PRESS 1170 K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 100 Nu ¼ 95-02 95-04 95-06 95-08 92-02 92-03 92-06 f 10 1 0 20 40 60 80 100 120 140 Re Fig. 6. The calculated friction factor (f ) of the aluminum foam heat exchangers based on Eq. (5) plotted against the Re as defined in Eq. (4). when the heat transfer performance-to-cost ratio is considered. DP 2 f ¼ qV L 4 Dhyd 2 ð5Þ In Eq. (5), the hydraulic diameter (Dhyd ) is described by Eq. (6) Dhyd ¼ 4Acs Lp ð6Þ with Acs being the cross-sectional area of the flow channel (80.0 mm2 ), and Lp being the wetted perimeter of the flow channel (84.0 mm). Fig. 6 plots the friction factor (f ) of Eq. (5) against the Re, as calculated in Eq. (4). The plot of the friction factor levels off after a permeability based Re of approximately 20. In this range, the pressure drop over the foam is dominated by the form coefficient of Eq. (1). This is in agreement with the published results on the pressure drop of the flow through both uncompressed and compressed metal foams in Boomsma and Poulikakos (2002). 3.2. Heat exchanger performance A practical measure of the performance of a heat exchanging device is the dimensionless Nusselt number (Nu) (Bejan, 1995) as given in Eq. (7). hDhyd q Dhyd ¼ Acon DT kc kc ð7Þ The coefficient h is the convection heat transfer coefficient which characterizes the heat transfer between a solid and a fluid. The thermal conductivity of the coolant is given as kc , and the flow of heat driven by a temperature difference of DT is represented as q. Dhyd is the hydraulic diameter as given in Eq. (6). For uniformity in comparing these results to the those from other investigations, the convection surface area, Acon , was considered to be the interface area between the open-cell aluminum foam and the heat spreader plate (1600 mm2 ). The temperature reference in Eq. (7) is an arbitrary variable, because the location of the reference temperature positions is subjective. It was not possible to reliably measure the temperature of the aluminum foam directly, so two small holes were drilled 1 mm deep into the top surface of the 1.9 mm thick heat spreader plate on opposing sides of the copper heating block at central location, giving a temperature reference (Tpl ) that was independent of the quality of the soldering between the heating element and the heat exchanger. It gave a good measure of the average plate temperature when compared to the temperature difference across the copper heater block, which experienced a maximum temperature difference from approximately 18 C at the lower coolant flow speed range to less than 1 C at the upper end of the coolant flow speed range (V > 1:0 m/s). The other reference temperature (Tc;inlet ) was the temperature of the coolant at the channel entrance. It was set to 295 K and did not vary more than ±0.3 K during the experimentation. The following is the final relation for DT used in Eq. (7) DT ¼ Tpl Tc;inlet ð8Þ where Tpl is the temperature of the AlSiC heat spreader plate and Tc;inlet is the temperature of the coolant at the inlet of the metal foam heat exchanger. The heat transfer rate to the coolant (q) is defined by the following energy balance q ¼ m_ cðTc;outlet Tc;inlet Þ ð9Þ ARTICLE IN PRESS K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 where m_ is the mass flow rate of the coolant passing through the heat exchanger, c is the specific heat of the incompressible coolant, and Tc;outlet is the coolant temperature at the metal heat exchanger outlet. The inlet and outlet coolant temperatures ðTc;inlet ; Tc;outlet Þ were measured at 1.5 cm before and after the heat exchanger at the middle of the 2 mm channel height to accurately measure the mean temperature of the stream. The heat transfer rate which was evaluated with Eq. (9) was then back checked against the measurement of the power deliver to the heater cartridges to ensure that the mean temperature of the coolant stream was being measured. With the substitution of Eqs. (8) and (9) into Eq. (7), the Nu was calculated by the following expression from the experimental data. Nu ¼ ¼ q Dhyd Acon ðTpl Tc;inlet Þ kc m_ cðTc;outlet Tc;inlet Þ Dhyd Acon ðTpl Tc;inlet Þ kc ð10Þ The Nusselt numbers for the open-cell aluminum foam heat exchangers were calculated at various coolant flow rates and plotted against the coolant flow speed in Fig. 7. The bare AlSiC heat spreader plate is also included in this comparison, and is labeled as ‘‘plate.’’ All Nusselt numbers began at zero for a zero coolant flow velocity and increased monotonically 140 120 100 80 95-02 95-04 95-06 95-08 92-02 92-03 92-06 plate Nu [-] 60 40 20 0 0.0 0.5 1.0 1.5 2.0 V [m/s] Fig. 7. The heat convection quantifying Nu as calculated in Eq. (7) plotted against the Darcian flow velocity (V ). 1171 with increasing coolant velocity. In the lower coolant flow velocity range, up to 0.729 m/s, the aluminum foam heat exchanger 92-06 achieved the largest Nu values. At the coolant flow velocity value of 0.729 m/s, the Nu of foam 95-04 surpassed that of foam 92-06, and then continued for a maximum Nu of 134.6 at a coolant flow velocity of 1.33 m/s. The foams with the lowest Nu values were the two most porous foams, 92-02 and 95-02, as seen by the comparison between Fig. 7 and Table 1, in which the porosities of the raw metal foam used for the heat exchangers are given. The Nu values of the remaining three aluminum foam heat exchangers, 92-03, 95-06, and 95-08, were nearly identical, except in the coolant velocity range under 0.50 m/s, where foam 95-08 had consistently a lower Nu value than the other two foams, 92-03 and 95-06. Heat exchangers are commonly characterized by the Colburn j factor, which gives a heat transfer performance estimate comparing the convection coefficient to the required flow rate of a heat exchanger. This relationship is closely related to the friction factor in Fig. 6. The Colburn j factor is based on the measured convection coefficient (h), the necessary velocity of the coolant in order to achieve the corresponding convection coefficient (V ), and the fluidÕs mechanical and thermal properties, as described by the density (q), specific heat (c), kinematic viscosity (m ¼ l q1 ), and the fluid thermal diffusivity (a ¼ k q1 c1 ). The Colburn j factor is given in Eq. (11). h v 2=3 j¼ ð11Þ qcV a Fig. 8 plots the Colburn j factor against the Re, as defined in Eq. (4) and done in the work by Kays and London (1984), which has become one of the standard methods for reporting the performance of heat exchanging devices. Note that the bare plate is not included on this graph because the Re in a clear channel is calculated in a completely different manner from the metal foam experiments. The characteristic length in the Re of a clear channel is based on the hydraulic diameter (Dhyd ), while in a porous medium, the characteristic length is derived from the permeability (K). ARTICLE IN PRESS 1172 K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 0.25 100 95-02 95-04 95-06 95-08 92-02 92-03 92-06 0.20 0.15 95-02 95-04 95-06 95-08 92-02 92-03 92-06 plate 10 W [W] j 1 0.10 0.1 0.05 0.01 0.00 0.001 (a) 0 20 40 60 80 100 120 0 140 50 Re Fig. 8. The commonly used heat exchanger characterization parameter, the Colburn j factor of Eq. (11) plotted against the Re as defined in Eq. (4). W_ ¼ DPQ ð12Þ In Eq. (12), W_ is the pumping power, DP is the pressure drop across the aluminum foam heat exchanger, and Q is the volumetric flow rate of the coolant passing through the heat exchanger. In addition to the Nu and the Colburn j factor, a common means to measure the heat convection effectiveness is the thermal resistance. Lower thermal resistance facilitates the heat flow through the heat exchanger. Eq. (13) gives the common definition (Rth ) for the thermal resistance in a heat convection arrangement. Rth ¼ DT Tpl Tc;inlet ¼ q m_ cðTc;outlet Tc;inlet Þ ð13Þ The measured value of the power delivered to the heating cartridges via the oscilloscope was used as a back check for reasonable figures obtained by measuring the temperature difference of the cool- 200 10 15 20 95-02 95-04 95-06 95-08 92-02 92-03 92-06 3 In any heat exchanger design, the heat convection performance of the heat exchanger must be weighed against the energy required to operate the system, which is the pumping power in this configuration. The required pumping power was calculated for the aluminum foam heat exchangers at various coolant flow velocities according to Eq. (12). 150 5 4 3.3. Pumping power considerations 100 Rth [K . kW –1] W [W] 2 1 (b) 0 0 5 Rth [K . kW –1] Fig. 9. (a) Plot of the required pumping power (W_ ) defined in Eq. (12) against the corresponding thermal resistances (Rth ) as calculated in Eq. (13). (b) Close-up view of the pumping power versus thermal resistance plot of (a) showing foam 92-06 best approaching the ideal zero-approaching value for both the pumping power and thermal resistance. ant across the heat exchanger. During the experiments, the power losses to the environment did not exceed 10%. The thermal resistances were calculated for the aluminum foam heat exchangers and the bare plate at various coolant flow velocities and were plotted in Fig. 9 against the required pumping power as defined in Eq. (12). Fig. 9(a) is a convenient log plot of the data for a general overview. In the corresponding plot of the same data in Fig. 9(b) on a linear scale, the optimal design is that which minimizes the distance from the point to the origin of the plot. This point was obtained by foam 92-06, with a thermal resistance of 8.00 ARTICLE IN PRESS K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 K kW1 and a required pumping power of 1.29 W at a coolant flow velocity of 0.356 m/s. The two other foams which also rated well in this performance to efficiency comparison were foams 95-04 and 92-03. The worst performance by a metal foam heat exchanger was generated by 95-08, which did not even fit into the scale of Fig. 9(b). Its relatively poor performance can be attributed to the brazing process which also caused the unusually low flow resistance for such a compressed foam (Fig. 5). The bare plate had the overall highest average thermal resistance. Comparing the bare plate against two foams at a relatively high thermal resistance of 50 K kW1 , namely foams 95-02 and 92-02, the plate required a pumping power which was 10 times greater than that required by the two aforementioned foams. 3.4. Heat exchanger comparison To evaluate their practicality as heat exchangers in industrial applications, the results of the heat transfer experiments performed on the aluminum foam heat exchangers were compared to test results from an internal investigation performed by Asea Brown Boveri (Tute, 1998) on various heat exchangers. This evaluation was carried out by comparing the required coolant pumping power against the thermal resistance. However, since these readily available heat exchanger configurations were tested with a 50% water–ethylene glycol solution, the aluminum foam heat exchanger experiments had to be scaled to account for the higher viscosity and lower thermal capacitance of the 50% water–ethylene glycol solution. The relevant physical properties of water (Incropera and De Witt, 1990) and the 50% ethylene glycol–water coolant (Tute, 1998) are listed in Table 3. The experiments reported in Tute (1998) were conducted on a cooling system which consisted of 1173 eight individual heat exchangers. Therefore, the pumping power and thermal resistance results reported in Fig. 9 had to be further adjusted to estimate the performance of a heat exchanger array consisting of eight individual metal foam heat exchangers. To make these coolant and configuration adjustments, an approach based on the following assumptions was used to scale the performance of aluminum foam heat exchangers as if they were tested with a 50% water–ethylene glycol solution in an array of eight individual heat exchangers. 1. The heat rate (q) for all varying flow conditions remained unchanged from the water experiments to the 50% water–ethylene glycol experiments. 2. The operating temperatures measured in the water experiments remained unchanged. 3. The volumetric flow rate of 50% water–ethylene glycol solution was adjusted in proportion to its lower heat capacitance value and its higher density to maintain the same heat transfer rate achieved in the experiments conducted with water. This adjustment required a 31% greater volumetric flow rate of the 50% water–ethylene glycol mixture to achieve the same cooling capacity under the first assumption. 4. To estimate the pressure drop across the aluminum foam heat exchangers using the 50% water–ethylene glycol solution, the permeability (K) and form coefficient (C) obtained from the pressure drop experimentation were used in Eq. (1). 5. The required pumping power for a cooling unit of eight heat exchangers is obtained by multiplying the required pumping power of an individual heat exchanger by a factor of eight. 6. The thermal resistance of a cooling unit consisting of eight individual metal foam heat exchangers Table 3 Coolant properties at 300 K Property coolant Density q [kg m3 ] Thermal conductivity k 103 [W m1 K1 ] Dynamic viscosity l 103 [N s m2 ] Specific heat c [J kg1 K1 ] Water 50% water–ethylene glycol 997 1034 613 420 0.86 3.19 4179 3302 ARTICLE IN PRESS 1174 K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 1000 95-02 95-04 95-06 95-08 92-02 92-03 92-06 plate 100 10 W [W] 1 0.2 mm Gap 0.1 Heat exch. with protrusions Brand name heat exch. 0.01 0 2 4 6 Rth [ K . kW –1] 8 10 12 Fig. 10. Plot of the predicted pumping power (W_ ) versus thermal resistance (Rth ) for the compressed aluminum foam heat exchangers when using a 50% water–ethylene glycol coolant. These results are compared to the results of test on three commercially available heat exchanger configurations as reported in Tute (1998). was estimated by dividing the thermal resistance of a single 1600 mm2 metal foam heat exchanger by a factor of eight. Fig. 10 plots the required pumping power (Eq. (12)) against the thermal resistance defined in Eq. (13) for various compressed aluminum foam heat exchangers and the bare AlSiC plate as they would perform in an array of eight individual heat exchangers using a 50% water–ethylene glycol solution. These results are overlayed onto the test results by ABB (Tute, 1998), in which three different heat exchanger configurations were considered. These tested heat exchangers consisted of a brand name heat exchanger, a generic flat plate heat exchanger with small protrusions to act as turbulence enhancers, and a simple flat plate with a 0.2 mm channel height. In the experiments done by ABB (Tute, 1998), each individual heat exchanger had a convection surface area in contact with the coolant measuring 34 mm in the length of the flow stream and 45 mm across, which provided an overall convective area of 1530 mm2 . This is compared to the configuration for the experiments completed on the compressed aluminum foam heat exchangers, which was 1600 mm2 , or 4.6% larger. The thermal resistances of the commercially available heat exchanger configurations in Tute (1998) were calculated in a manner identical to Eq. (13). Several observations can be made by scaling the water experiments to using the 50% water–ethylene glycol solution. Comparing the compressed aluminum foam heat exchangers in Fig. 10, it is clear that they generated an Rth that was lower than the best heat exchanger tested by ABB (Tute, 1998) by a factor of nearly two. Another relevant observation is the preservation of the order of the pumping power curves of the various compressed aluminum foam heat exchangers. This means that the relative performance of the heat exchangers with the 50% water–ethylene glycol solution can be well evaluated by using water. The only exception was the flat AlSiC plate. Due to its high permeability (K) and correspondingly low form coefficient (C), the pumping power requirement for the AlSiC plate increased by a disproportionately smaller factor than the compressed aluminum foam heat exchangers, and in Fig. 10, the performance of the AlSiC plate surpassed that of the worst performing compressed aluminum foam heat exchanger, 95-08, due to its relatively high thermal resistance. Table 4 Average uncertainty of coefficients (%) Foam q Nu ReK f j W_ 95-02 95-04 95-06 95-08 92-02 92-03 92-06 17.9 13.1 14.5 13.6 16.3 13.7 12.6 19.3 14.5 25.8 14.3 16.9 14.7 15.1 11.8 9.6 11.9 11.5 13.2 10.3 10.3 16.5 16.5 20.6 20.6 13.5 16.5 18.3 21.6 17.3 28.6 18.0 19.1 17.5 18.2 17.1 8.8 7.8 8.5 15.7 9.9 7.9 ARTICLE IN PRESS K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 1175 3.5. Uncertainty analysis References The coefficients plotted in Figs. 5–10 were analyzed for their associated uncertainties following the standard procedure outlined in Taylor (1997). An example to find the absolute uncertainty value of f , labeled as wf , which is a function of V and P is as follows: sffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi 2 2ffi of of wV wP ð14Þ wf ¼ þ oV oP Amiri, A., Vafai, K., 1994. Analysis of dispersion effects and nonthermal equilibrium, non-darcian, variable porosity incompressible-flow through porous-media. International Journal of Heat and Mass Transfer 37, 939–954. Antohe, B.V., Lage, J.L., Price, D.C., Weber, R.M., 1997. Experimental determination of permeability and inertia coefficients of mechanically compressed aluminum porous matrices. Journal of Fluids Engineering––Transactions of the ASME 119, 404–412. Bejan, A., 1995. Convection Heat Transfer. John Wiley & Sons, Inc., New York. Boomsma, K., Poulikakos, D., 2001. On the effective thermal conductivity of a three-dimensionally structured fluid-saturated metal foam. International Journal of Heat and Mass Transfer 44, 827–836. Boomsma, K., Poulikakos, D., 2002. The effects of compression and pore size variations on the liquid flow characteristics of metal foam. Journal of Fluids Engineering––Transactions of the ASME 124, 263–272. Calmidi, V.V., Mahajan, R.L., 1999. The effective thermal conductivity of high porosity fibrous metal foams. Journal of Heat Transfer––Transactions of the ASME 121, 466– 471. Calmidi, V.V., Mahajan, R.L., 2000. Forced convection in high porosity metal foams. Journal of Heat Transfer––Transactions of the ASME 122, 557–565. Chen, G., Hadim, H.A., 1998. Forced convection of a powerlaw fluid in a porous channel––numerical solutions. Heat and Mass Transfer 34, 221–228. Chen, G., Hadim, H.A., 1999. Forced convection of a powerlaw fluid in a porous channel––integral solutions. Journal of Porous Media 2, 59–69. Darcy, H., 1856. Les Fontaines Publiques de la ville de Dijon. Dalmont, Paris. Diedericks, G.P.J., du Plessis, J.P., 1997. Modelling of flow through homogeneous foams. Mathematical Engineering in Industry 6, 133–154. du Plessis, P., Montillet, A., Comiti, J., Legrand, J., 1994. Pressure-drop prediction for flow-through high-porosity metallic foams. Chemical Engineering Science 49, 3545– 3553. Dupuit, J., 1863. Etudes Theoriques et Pratiques sur le Mouvement des Eaux. Dunod, Paris. ERG, 1999. Duocel Aluminum Foam Data Sheet. ERG Material and Aerospace, Oakland. Forchheimer, P., 1901. Wasserbewegung durch Boden. Z. Ver. Deutsch. Ing. 45, 1736–1741, pp. 1781–1788. Hazen, A., 1893. Some physical properties of sand and gravels with special reference to their use in filtration. Massachusetts State Board of Health, Twenty-fourth Annual Report. Incropera, F.P., De Witt, D.P., 1990. Introduction to Heat Transfer, second ed. John Wiley & Sons, New York. Kaviany, M., 1985. Laminar-flow through a porous channel bounded by isothermal parallel plates. International Journal of Heat and Mass Transfer 28, 851–858. The average percentage values of these coefficients are tabulated in Table 4. 4. Conclusion Open-cell aluminum foams were compressed by various factors and then fashioned into heat exchangers intended for electronic cooling applications which dissipate large amounts of heat. Various common heat exchanger evaluation methods were applied to the data assembled from the extensive heat transfer experiments, which included the hydraulic characterization, the heat transfer performance, and an efficiency study to determine the most efficient metal foam heat exchanger configuration for a particular heat transfer configuration. It was seen that the compressed aluminum foams performed well not only in the heat transfer enhancement, but they also made a significant improvement in the efficiency over several commercially available heat exchangers which operate under nearly identical conditions. The metal foam heat exchangers decreased the thermal resistance by nearly half when compared to currently used heat exchangers designed for the same application. Acknowledgements It is gratefully acknowledged that this research was supported jointly by the Swiss Commission for Technology and Innovation (CTI) through project no. 4150.2 and by the ABB Corporate Research Center, Baden-D€ attwil, Switzerland. ARTICLE IN PRESS 1176 K. Boomsma et al. / Mechanics of Materials 35 (2003) 1161–1176 Kaviany, M., 1995. Principles of Heat Transfer in Porous Media, second ed. Springer-Verlag, New York. Kays, W.M., London, A.L., 1984. Compact Heat Exchangers, third ed. McGraw-Hill, New York. Koh, J.C.Y., Colony, R., 1974. Analysis of cooling effectiveness for porous material in a coolant passage. Journal of Heat Transfer––Transactions of the ASME 96, 324–330. Koh, J.C.Y., Stevens, R.L., 1975. Enhancement of cooling effectiveness by porous materials in coolant passages. Journal of Heat Transfer––Transactions of the ASME 97, 309–311. Kr€ uger, E., 1918. Die Grundwasserbewegung. Internationale Mitteilungen f€ ur Bodenkunde 8, 105. Lage, J.L., 1998. The fundamental theory of flow through permeable media from darcy to turbulence. In: Ingham, D.B., Pop, I. (Eds.), Transport Phenomena in Porous Media. Elsevier Science, Ltd., Oxford, pp. 1–30. Lage, J.L., Antohe, B.V., 2000. DarcyÕs experiments and the deviation to nonlinear flow regime. Journal of Fluids Engineering––Transactions of the ASME 122, 619–625. Lage, J.L., Weinert, A.K., Price, D.C., Weber, R.M., 1996. Numerical study of a low permeability microporous heat sink for cooling phased-array radar systems. International Journal of Heat and Mass Transfer 39, 3633–3647. Lage, J.L., Antohe, B.V., Nield, D.A., 1997. Two types of nonlinear pressure-drop versus flow-rate relation observed for saturated porous media. Journal of Fluids Engineering––Transactions of the ASME 119, 700–706. Lu, T.J., Stone, H.A., Ashby, M.F., 1998. Heat transfer in open-cell metal foams. Acta Materialia 46, 3619–3635. Mehta, D., Hawley, M.C., 1969. Wall effect in packed columns. I & EC Process Design and Development 8, 280–282. Nield, D.A., Porneala, D.C., Lage, J.L., 1999. A theoretical study, with experimental verification, of the temperaturedependent viscosity effect on the forced convection through a porous medium channel. Journal of Heat Transfer–– Transactions of the ASME 121, 500–503. Poulikakos, D., Renken, K., 1987. Forced-convection in a channel filled with porous-medium, including the effects of flow inertia, variable porosity, and brinkman friction. Journal of Heat Transfer––Transactions of the ASME 109, 880–888. Renken, K.J., Poulikakos, D., 1988. Experiment and analysis of forced convective heat-transport in a packed-bed of spheres. International Journal of Heat and Mass Transfer 31, 1399– 1408. Smit, G.J.F., du Plessis, J.P., 1999. Modelling of non-Newtonian purely viscous flow through isotropic high porosity synthetic foams. Chemical Engineering Science 54, 645– 654. Taylor, J.R., 1997. An Introduction to Error Analysis, second ed. University Science Books, Sausalito. Tute, A., 1998. Versuchsbericht f€ ur die thermischen Messungen an K€ uhlk€ orpern ohne oberfl€achenvergr€ ossende Massnahmen. Asea Brown Boveri, VB8033.doc.