* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download How to Test the Voltage Drop Between the Battery

Immunity-aware programming wikipedia , lookup

Stepper motor wikipedia , lookup

Electrical ballast wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electrical substation wikipedia , lookup

Electromagnetic compatibility wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Three-phase electric power wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power electronics wikipedia , lookup

Power MOSFET wikipedia , lookup

Rechargeable battery wikipedia , lookup

Automatic test equipment wikipedia , lookup

Current source wikipedia , lookup

Schmitt trigger wikipedia , lookup

Portable appliance testing wikipedia , lookup

Opto-isolator wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Distribution management system wikipedia , lookup

Voltage regulator wikipedia , lookup

Surge protector wikipedia , lookup

Buck converter wikipedia , lookup

Alternating current wikipedia , lookup

Stray voltage wikipedia , lookup

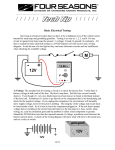

Technician’s Version Vehicle “How To” Test Guide Demo Left click the mouse to advance. About the material on this CD The power point and word documents contained on this CD are provided without expressed or implied warranty. The entire risk as to the quality and use of this information is totally the responsibility of the end user. Should any information contained in this CD prove to be defective, the end user assumes the entire cost of any and all incidental and consequential damages. Vested LLC does not warrant that the test setup and techniques shown will meet the end uses requirements. Vested LLC does not warrant that the test procedures are error free. All tests presented have been performed by a Vested LLC representative with vehicle responding results. Vested LLC, its officers, agents, or representatives will in no way be liable for any damages, including loss of profits, loss of savings, or other consequential or incidental damages arising out of the use of the test procedures contained in this CD. The tests procedures presented on the CD have been performed with the results shown. Vested LLC does not intend or imply that the test procedures replace vehicle manufacturer's authorized or recommended test procedures. Always check the information given against that recommended by the manufacturer of the vehicle you are working on. Left click the mouse to advance. How To Use The Test Guide Never use the enter key on the computer. If you inadvertently hit the enter key or the left mouse button on any part of a screen other than a blue button, simply right click in open space, and left click on “previous” to take you back. Use only the left and right mouse buttons as explained below. When you see (Notes) on a slide, right click the mouse, then left click on “Speaker Notes” for additional information. You may have to use the sliding bar on the right side of speaker notes to get to the beginning of the notes. Now: Lets go through an example of how to use the guide. You will advance to a slide with further instructions, and come back here. Left click the mouse on the blue button to access information on “Meters”. X Meters. When finished with the example, left click your mouse to advance to the Master Index. Vehicle “How to” Master Index X Meters. X Battery Testing. X Computer/Module Testing. X Continuity Testing and Ohmmeter Usage. X Current Path, Connections, and Switch Contact Testing. X Fuse, Fusible Link, and Circuit Breaker Testing. X Generator Testing. X Relay Testing. X Starter Testing. X Shared Current Path and Voltage Drop Testing. X Other Tests and Information. (X buttons are active) When finished, right click your mouse and left click on “End Show”. Meters. X How Accurate is Your Test Meter? (X buttons are active) Understanding What a Voltmeter is Reading. How to Set the DVOM Meter for Reading: Open Circuit Voltage, Charging Voltage, or Source Voltage. How to Set the DVOM Meter, Leads, and Probes for Reading: The voltage drop between: the battery positive (+) terminal and the input pin to any load on the vehicle. How to Set the DVOM Meter, Leads, and Probes for Reading: The voltage drop between: the battery negative (-) terminal and the output pin or case ground from any load on the vehicle. How to Set the DVOM Meter, Leads, and Probes for Reading: The amount of source voltage available to any load on the vehicle. How to Calibrate an Inductive Pick Up That Plugs into a Voltmeter. How to Read a 100 millivolts per amp Inductive Pick up. How to Make and Use a 10X Inductive Multiplier. How to Extend Meter Leads When Testing a Long Distance From the Battery. Back How Accurate is Your Test Meter? Accuracy of: Plus or minus 0.5% (.005%) is Acceptable Plus or minus 0.1% (.001%) is Best Check the owner’s manual for your meter under DC accuracy. Lets compare meter readings of Best (0.1% accuracy) to Poor (1% accuracy) If the actual charging voltage was 14.30V and your meter had: and another meter had: Plus or minus 0.1% Accuracy (Best) Plus or minus 1% Accuracy (Poor) This meter could read: This meter could read” @ + .1% ------- 14.31V @ + 1% -------- 14.44V @ - .1% ------- 14.29V @ - 1% -------- 14.15V and be off actual by .014V and be off actual by .143V If the actual battery open circuit voltage was 12.66V and your meter had: and another meter had: + / - 0.1% Accuracy (Best) + / - 1% Accuracy (Poor) This meter could read: This meter could read: @ + .1% ------- 12.67V @ + 1% -------- 12.78V @ - .1% ------- 12.65V @ - 1% -------- 12.53V and be off actual by .013V and be off actual by .126V Less than .050V (50mV) is a common acceptable voltage drop on a sensor or computer ground. If your meter is off by 140mV, you will never find the problem. Notes – Right click mouse, left click on speaker notes. Back Battery Testing X How to Test the Voltage Drop Between the Battery (+) Post and Clamp. How To Test For Voltage Drop Between The Battery (-) Post and Clamp. How to Test the Open Circuit Voltage of the Battery. How to Charge the Battery. How to Do a Battery Load Test Using a VAT 40 or 45. How To Do a Battery Load Test Without a Load Tester. How to Find the Parasitic Drain on any Battery Using an Auxiliary Battery. How to do a 3 - Minute Charge Test on a Battery. How to Test the Voltage Drop Between the Battery (+) Terminal and the Starter Motor Armature Lead. How To Test the Voltage Drop Between: The Battery Positive (+) Terminal and Fuses. How To Test The Voltage Drop of a Battery Positive + Pigtail Wire . How To Test Connectors and Connections of Positive Pigtail Wires. How to test the voltage drop between the wire and the clamp material in a battery positive (+) pigtail. How to Test the Voltage Drop Between the Battery Negative (-) Terminal and Where the Negative (-) Cable Attaches to the Frame or the Block. How to Test the Voltage Drop Between: the Battery Negative Cable Conductor and its Connector. How to Test the Voltage Drop Across a Suspect Negative Pigtail Back Cable or Wire Connector. How to Test the Voltage Drop Between the Battery (+) Post and Clamp Voltmeter set to read millivolts DC. Set voltmeter to read millivolts. Post and clamp can be tested for voltage drop as shown. This important test cannot be done on a side mount battery. Always remove, clean, replace, and retighten both (+) and (-) side mount cables as a starting point to base system testing and good troubleshooting. Post Top & Side Mount Battery Side mount battery does not allow for a voltage drop test between the battery mating surface and the cable connector. Electrolysis waiting to happen! Copper cable connectors Engine EngineCranking running Reverse voltmeter lead positions for testing the negative post Alloy coated bolts Lead battery surface Notes Back Computer/Module Testing. X How to Test the Voltage Drop of Computer Voltage Feed Wires That Can Be Back-probed. How to Test the Voltage Drop of Computer Ground Wires That Can Be Back-probed. How to Load Test Computer Voltage Feed Wires. How to Load Test Computer Ground Wires. Back How to Test the Voltage Drop of Computer Voltage Feed Wires That Can Be Back-probed Voltmeter set to read millivolts .500V (500mV) Maximum Notes Back Continuity Testing and Ohmmeter Usage X How to Test for Continuity with an Ohmmeter. Cautions When Using an Ohmmeter. How To Tell if Solid State Components are Affecting Ohmmeter Resistance Readings. Back How to Test for Continuity with an Ohmmeter 1. Black lead to common (ground) input. 2. Red lead to volt / ohm input. 3. Set DVOM to Ohms. 4. Auto ranging meters are now set, non-auto ranging meters - set to lowest ohms scale. 5. With meter set, and on, leads separated, note what your meter reads (this could be “1" or “OL” or something else). 6. Touch the leads together, note what your meter reads (this could be 000.2, 000.4, or something else. 7. When the leads are touched together, this tells you that there is a continuous path from the meter’s battery, through the leads, back to the meter’s battery. There is “continuity”, or a “completed” circuit. This type of “continuity” testing is useful to find and “open”, and a “short to ground” in a piece of wire. If you touched one meter lead to each end of a piece of wire that you thought was continuous, and your meter read what you saw in step 5 above, you have found an “open”, and must replace the wire in order for the circuit to be complete. Notes – Right click mouse, left click on speaker notes. Back Current Path, Connections, and Switch Contact Testing. X How to Test the Voltage Drop of Any Length of Wire. How to Test for Available Voltage to a “Hot at All Times” Connection How To Test For Available Voltage to a “Hot In Start Or Run” Connection How to Load Test a “Hot at all Times Connection. How to Load Test a “Hot in Start or Run” Connection. How to Test Any Mechanical Switch Using an Ohmmeter. How to do a Voltage Drop Test on Any Mechanical Switch. How to Test the Voltage Drop of a “Suspect Wire Connector”. Back How to Test the Voltage Drop of Any Length of Wire The wire to be tested must be in the circuit carrying current either to or from the circuit load. 1. Set the voltmeter to read millivolts or on the lowest volt scale. 2. Put the voltmeter positive (+) probe on the end of the wire closest to the battery. 3. Put the voltmeter negative lead on the other end of the wire. 4. Operate the circuit. 5. If the voltage drop is more than .100V (100mV), the wire, or connections are bad. 6. If excessive, remove the wire at both ends and clean the connections, retest. 7. If still excessive, replace the wire. Notes – Right click mouse, left click on speaker notes. Back Fuse, Fusible Link, and Circuit Breaker Testing. X How to Test the Voltage Drop Across a Fuse Connection. How to use a Blown Fuse to Direct Your Troubleshooting. How to Find a Short to Ground (that resulted in a blown fuse), Using a Light Bulb Load. How To Test Fusible Link Wire. How To Quickly Test a Suspect Circuit Breaker. Back How to Test the Voltage Drop Across a Fuse Connection Excess space between a fuse tang and its female connector can cause a voltage drop high enough to affect the operation of the circuit load. “Wiggle” the fuse during the test. 100mV Maximum .100V Maximum All circuits the fuse protects should be ON during this test if possible. The higher the current flow, the greater the voltage drop. If a mechanical fuse connection is loose enough, it can cause an intermittent. Notes Back Generator Testing. X How to Test the Generator Charging Voltage. How to Test the Voltage Drop Between: the Generator Output and the Battery Positive (+) Terminal. How to Test the Voltage Drop Between: the Battery Negative (-) Terminal and the Generator Housing. How to Test the Voltage Drop Between: the Generator Housing and the Block. How to Test for Generator AC Riding on DC How to Check For Bad Diodes in the Generator using the “Diode Test Mode” of the DVOM. How to Test for Shorted Diodes in the Generator Using the “Micro Amp Range” of the DVOM. How to Verify a Good Generator. How to Test the Battery as a Possible Cause of Multiple Generator Replacements. Back How to Test the Generator Charging Voltage Set voltmeter to read volts DC. Put voltmeter positive (+) probe on battery (+) terminal. Put voltmeter negative (-) probe on battery (-) terminal. Run the engine at 1500 RPM, and turn on every load that can be turned on – AC compressor, blower motor, rear window defogger, head lights, etc. Let engine run for more than 1 minute after all loads are on. Source voltage will be between 13.5 and 14.9 on most vehicles. If above 15volts, this could be caused by a faulty generator regulator. (Notes) © Back Relay Testing How to Deal With a “Suspect Relay”. How to Troubleshoot a Relay Controlled Circuit. Back Starter Testing X How to Test the Cranking Voltage Available to the Starter Motor How to Test the Voltage Drop Between: the Battery (+) Terminal and the Starter Motor Armature Lead. How to Test the Voltage Drop of a Starter Mounted or Remote Mounted Solenoid. How To Test the Voltage Drop Between: Battery Negative (-) Terminal and the Starter Motor Housing. How to Test the Voltage Drop Between: the Starter Housing and the Block. How to do a Starter Motor Amp Draw Test with a VAT 40 or 45. How to do a Starter Motor Amperage Draw Test With a Load Tester That Has a Voltmeter & Amp Meter, but No Inductive Pick Up. How to do a Starter Motor Amperage Draw Test With an Inductive Pick Up Plugged Into a Digital Voltmeter. Back How to Test the Cranking Voltage Available to the Starter Motor Voltmeter negative (-) to a clean post top or side mount negative (-) bolt, NOT on cable, or clamp. Engine CRANKING Should be within 2 ½ Volts of Source Voltage Voltmeter positive (+) to a clean spot on the starter motor armature lead, NOT on solenoid nut, washer, or stud. The voltmeter is set to read volts DC. This voltmeter will show the value of voltage that is available to the starter motor while cranking. It does not show the actual voltage drop that is Notes occurring during cranking. Back Shared Current Path and Voltage Drop Testing. X How To Find Open Circuit, Charging, Or Source Voltage. How To Find The Amount Of Source Voltage Available To Any Load. How To Find The Voltage Drop Between: The Battery Positive Terminal And The Input Pin To Any Load. How To Find The Voltage Drop Between: The Ground Side Of Any Load And The Battery Negative Terminal. How To Find The Voltage Drop Between: Truck Bed And Cab Sheet Metal. How To Find The Voltage Drop Between: The Battery Negative (-) Terminal And The Bulkhead Ground Strap. How To Find The Voltage Drop Between: The Bulkhead And The Block. How To Find The Voltage Drop Between: The Battery Negative (-) Terminal And A Battery Negative (-) Pigtail Attached To Sheet Or Frame Metal. Back How To Find Open Circuit, Charging, Or Source Voltage This meter probe set up shows the value of the battery’s open circuit voltage, some times referred to as “source voltage” when the engine is off. It also shows the value of the battery’s charging voltage, sometimes also referred to as “source voltage” when the engine is running. Back Other Tests and Information. X How to Stop Electrical Switch Pop “Noise” in a Radio. How a Voltage Drop Can Cause Ring Gear Damage. How To Find the Percent of Alcohol in Gasoline. How to Check for Water in Brake Fluid Using a Voltage Drop Test. How to Check Acid Content In Coolant With a Voltage Drop Test. How to Test a Rear Window Defogger Using a Test Light. How to Test a Rear Window Defogger using a Voltmeter. How to Test Thermistor Temperature Sensors. Battery Drain Times When Components are Left On. Wire Sizes, Diameter, Ohms/1000Ft. and Rated Continuous Amperage Observed wire sizes used on a 2007 C/K GMC. How DC “Motor Drag” Can Affect Voltage Drop. How DC Motor In-Rush Current Can Affect Voltage Drop. Precautions to Observe Whenever a Vehicle Component is Unplugged. When the Voltage Drop Is Still Excessive after Repair, Then What? Back How to Stop Electrical Switch Pop “Noise” in a Radio Switches and motors can cause electrical “noise” in a radio. 1 1’st capacitor: Wire to voltage feed side of the switch. Case to load side. Electrons jumping air gaps when switch or relay contacts open can sometimes cause a “popping” noise in a radio. The drawings show three progressive steps for placing capacitors to eliminate this problem. There is space between a motor brush and its’ contact surface that allows an air gap. If the brush “bounces” the air gap is increases. When ever an electron travels in “open air” its will emit radio frequency interference waves. This we hear as static in our radio. 2 2’nd capacitor: Wire to same location. Case to ground. 3 3’rd capacitor: Wires to load side. Case to ground. Condensers (capacitors) can also be located “across” or in parallel with generator brushes to slip rings and brushes to armature in motors. If a condenser is placed in parallel across the brush / slip ring, or brush / armature , the electron will take a path of lease resistance and go into the capacitor rather than leap the air gap. Doing this, it will emit less radio frequency interference. Radio Shack part #272-126 or #272-131 capacitors. Notes Next This is the end of the program. To go back to the beginning, push this button: or, to end the program, right click the mouse, then left click on “End Show”.