* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

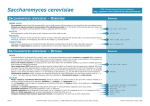

Download Exploring Yeast as a Cell Factory for the Production of Carboxylic

Pharmacometabolomics wikipedia , lookup

Biochemical cascade wikipedia , lookup

Butyric acid wikipedia , lookup

Microbial metabolism wikipedia , lookup

Biosynthesis wikipedia , lookup

Fatty acid metabolism wikipedia , lookup

Amino acid synthesis wikipedia , lookup

Fatty acid synthesis wikipedia , lookup

Metabolic network modelling wikipedia , lookup

Basal metabolic rate wikipedia , lookup

Citric acid cycle wikipedia , lookup